Roll-over stand for welding girder of crane

A technology of flipping frame and crane, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of affecting welding quality, affecting welding efficiency, not easy to turn over, etc., to achieve the improvement of welding efficiency and welding quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

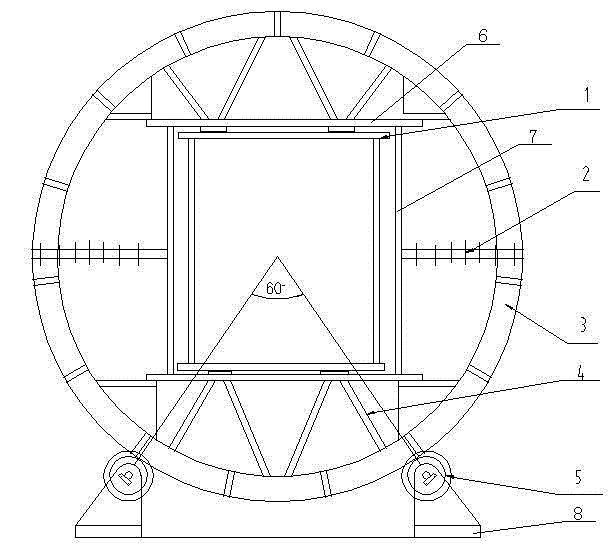

[0014] Such as figure 1 As shown in the figure, an overturn frame for welding the main girder of a crane includes a longitudinal support plate 6 and a transverse support plate 7 for fixing the main girder 1, and the longitudinal support plate 6 is fixed by a “V”-shaped rib plate 4 and the turning circle 3 Above, the transverse supporting plate 7 is fixed on the turning ring 3 by the bolt 2, the turning ring 3 is rollingly matched with the two turning frame support wheels 5, and the two turning frame supporting wheels 5 are respectively connected to the corresponding turning bracket 8 in rotation.

[0015] "V" font ribs 4 are four groups, and every two groups of "V" font ribs 4 fix one side longitudinal supporting plate 7 on the turning circle 3.

[0016] The direction of the supporting force of the two overturning brackets 8 forms an angle of 50°-70°.

[0017] The overturn frame supporting wheel 5 is a cylinder, and the side surface of the cylinder has a groove, and the groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com