Door flip device

A technology for turning over devices and door panels, which is applied to devices and coatings that apply liquid to surfaces, and can solve problems such as low work efficiency and damage to door panels.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

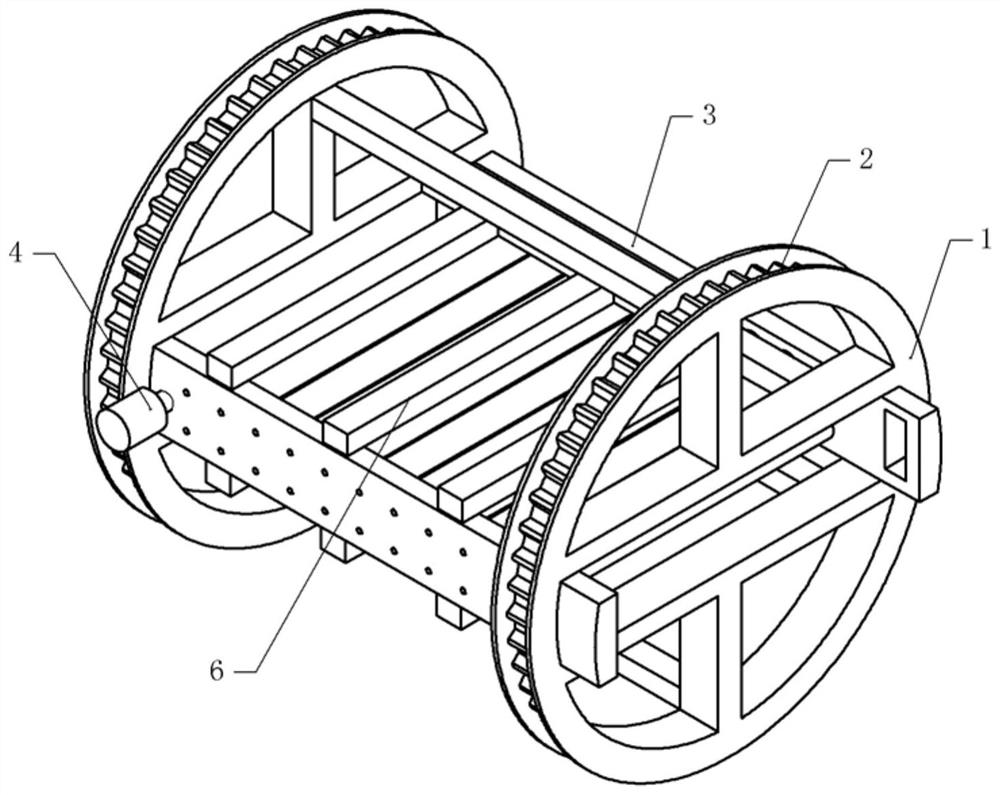

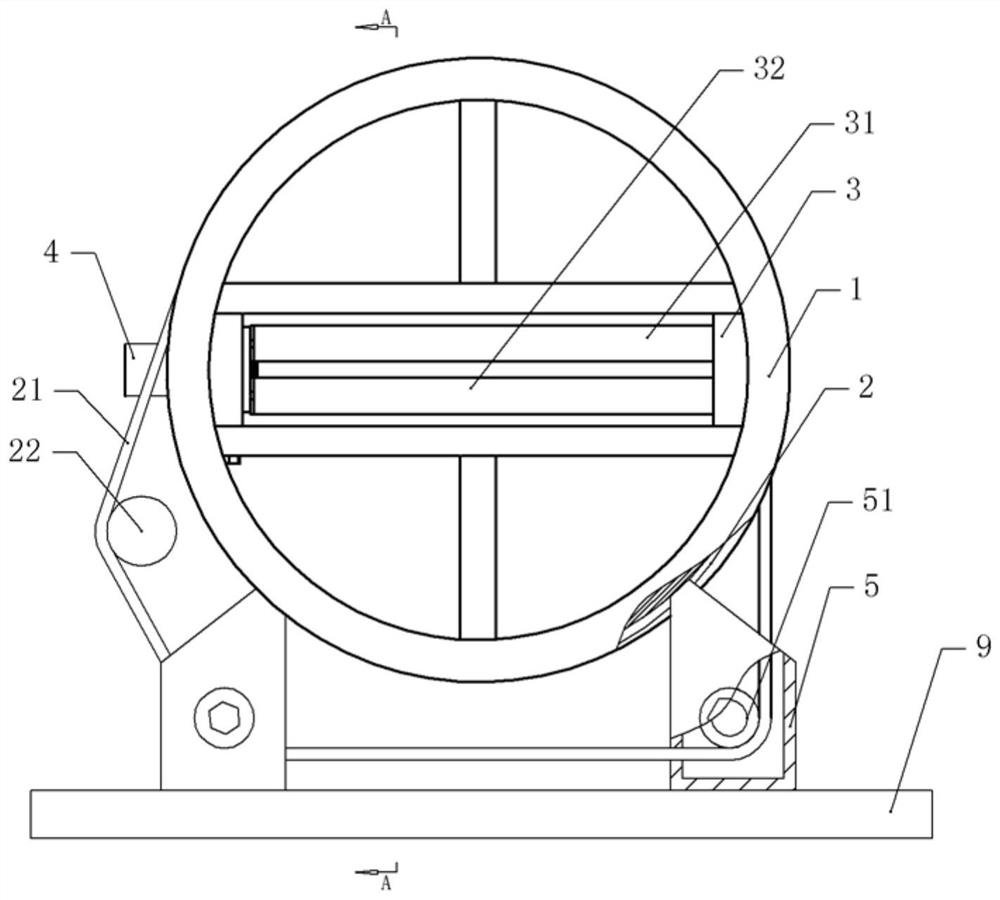

[0046] A door panel turning device, basically as attached figure 1 And attached figure 2 As shown, the runner 1 is included, the upper and lower parts of the runner 1 are welded with brackets, and an opening is formed between the two brackets.

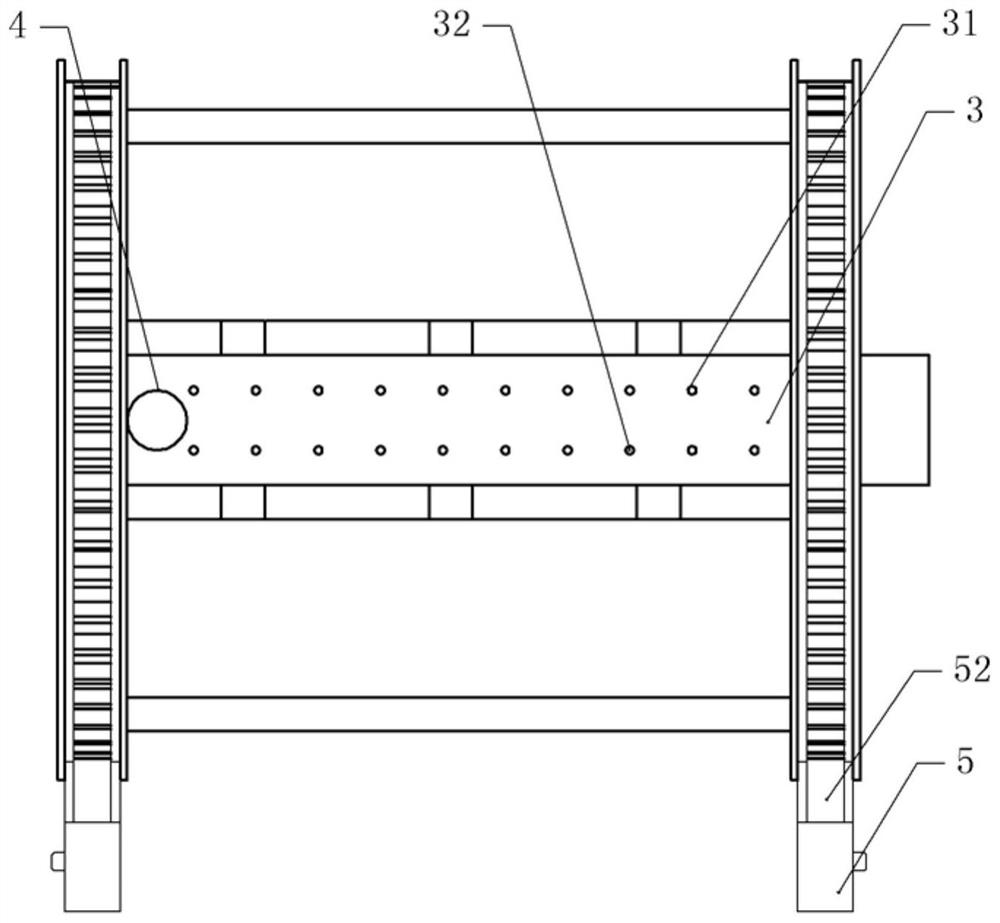

[0047] In this embodiment, there are two runners 1 , and the two runners 1 are arranged coaxially. Both sides of the two runners 1 are welded with connecting plates 3 , and the connecting plates 3 are arranged along the axial direction of the runners 1 . Between the two connecting plates 3 are rotatably connected a plurality of pairs of roller groups uniformly distributed along the length direction of the connecting plates 3 . The top and bottom of connecting plate 3 are all fixed with stabilizing plate 6 by fastening bolts, and the two ends of stabilizing plate 6 are respectively fixed two on connecting plate 3, and stabilizing plate 6 strengthens the stability of connecting plate 3.

[0048] There is a groove on the runner 1, the ...

Embodiment 2

[0057] The difference between embodiment two and embodiment one is that, as attached Figure 6 And attached Figure 7 As shown, one side of the inner side wall of any runner 1 is provided with a driving gear 11, the driving gear 11 is coaxial with the runner 1 and the driving gear 11 is fixed on the mounting base 9 through a connecting rod, and the right side of the driving gear 11 meshes There is a driven gear 7, the driven gear 7 and the driving gear 11 have a certain gear ratio, for example: 1:3, the driven gear 7 is coaxially fixed with a crankshaft 71, and the two ends of the crankshaft 71 are respectively connected to two runners in rotation. 1 The plate from which the inner side wall extends.

[0058] combined with Figure 6 As shown, the connecting plate 3 on the right side is horizontally slidably connected with a clamping tube 8 , which is sleeved on the outer periphery of the lower roller 32 , and the right side of the clamping tube 8 can abut against the bump of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com