Automatic leakage detection system and method for plate-type heat exchanger

A plate heat exchanger, automatic inspection technology, applied in the testing of instruments, machines/structural components, and detecting the appearance of fluid at the leakage point, etc., can solve the problems of heavy labor, manual destruction, and low leak detection efficiency, etc. problem, to achieve the effect of increasing utilization value, high degree of automation, and fast operation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

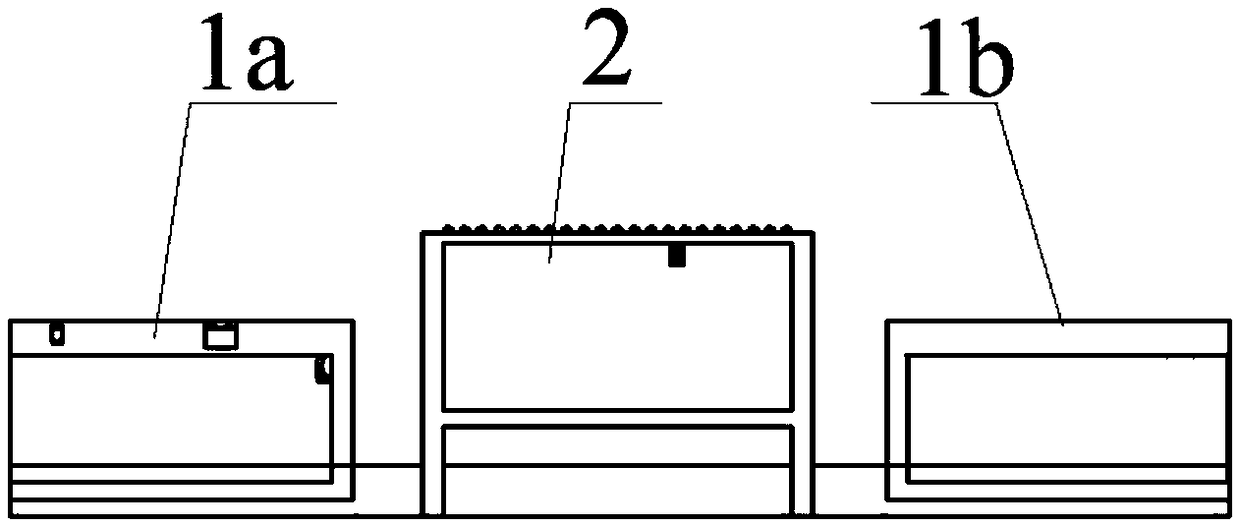

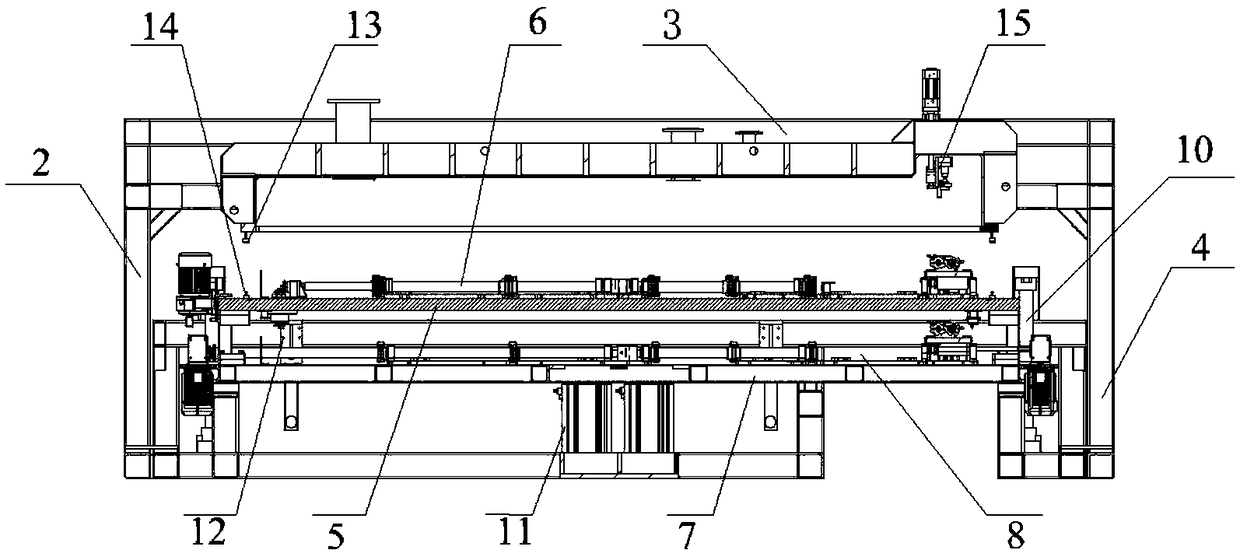

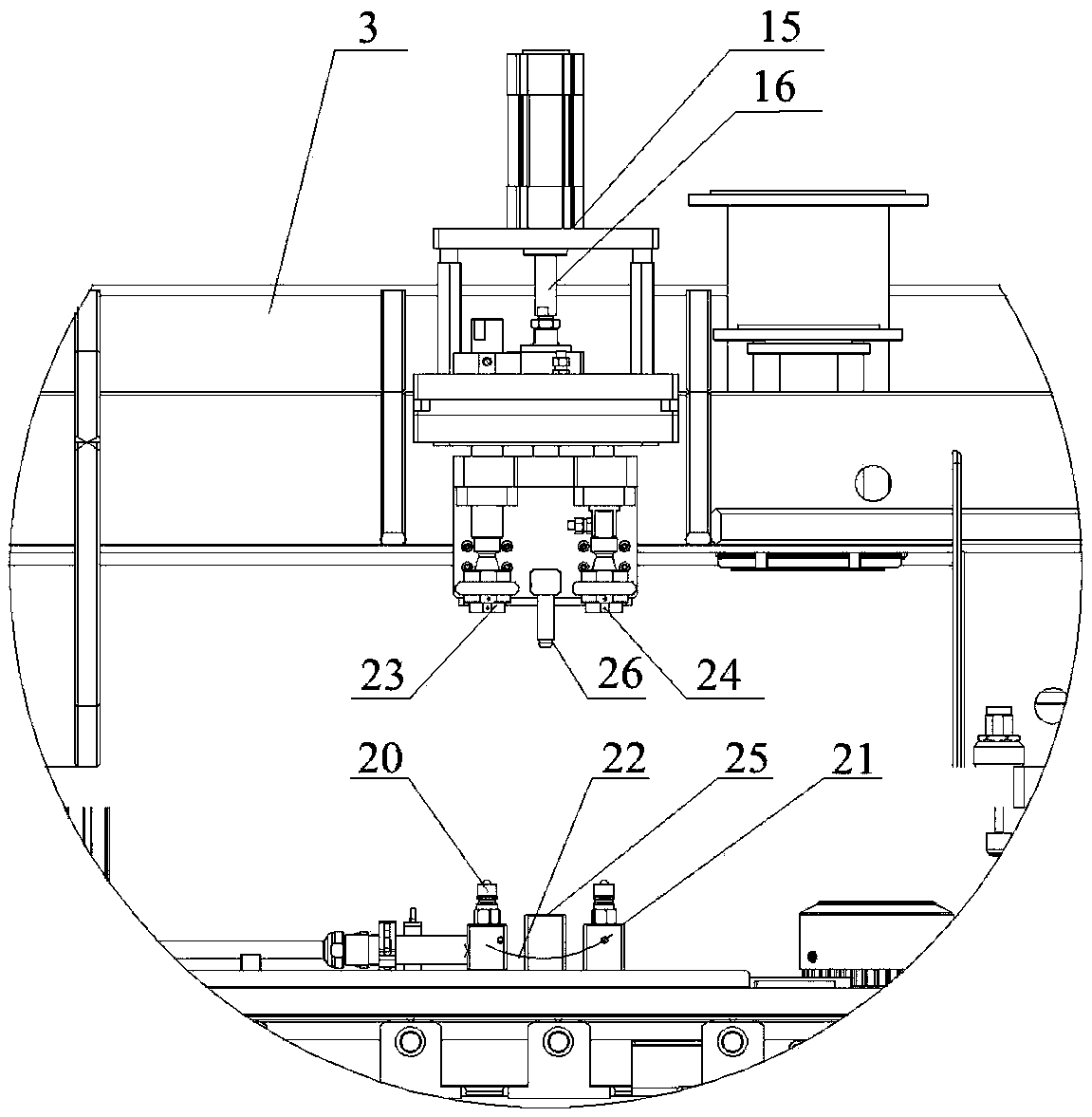

[0024] Such as figure 1 , 2 As shown, this embodiment provides an automatic leak detection system for plate heat exchangers, including an input conveying device 1a, a vacuum helium leak detection packing 2 and an output conveying device 1b, which are sequentially arranged to form an automatic leak detection assembly line. The helium leak detection box 2 includes a vacuum box 3, the bottom of which is open and fixed on a support 4, and a horizontal vacuum box door 5 corresponding to the bottom opening of the vacuum box 3 is arranged on the support 4, The upper horizontal power mechanism 6 is set on the vacuum box door plate 5, the support plate 7 with a fixed vertical distance from the vacuum box door plate 5 is set under the vacuum box door plate 5, and the lower horizontal power mechanism 8 is set on the support plate 7, The vacuum box door panel 5 and the support plate 7 are slidably connected with the support 4 through a vertical sliding mechanism; Lift the cylinder 11, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com