Concrete pipeline raw material pouring device

A concrete and pipeline technology, applied in the direction of supply equipment, manufacturing tools, etc., can solve the problems of low efficiency, high labor costs, low production efficiency of concrete pipelines, etc., to improve pouring efficiency, liberate labor costs, and save manual transportation effect of material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

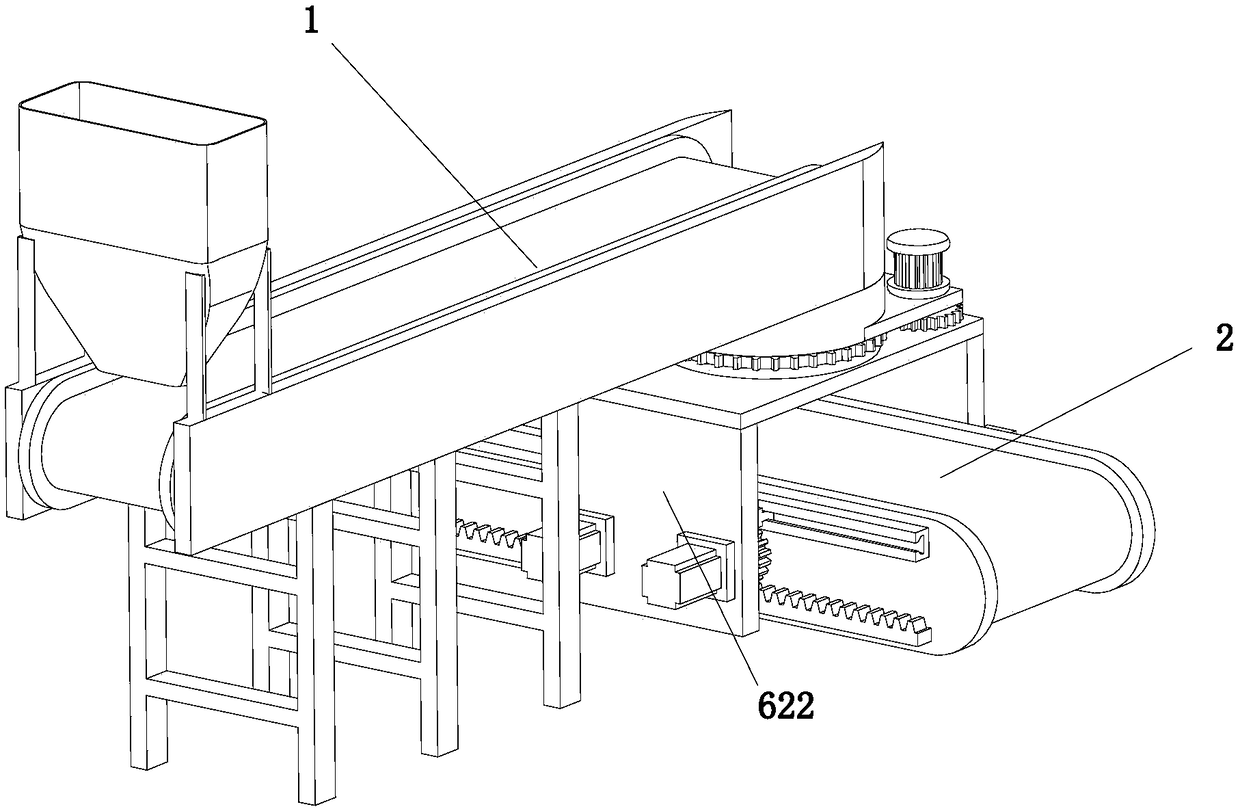

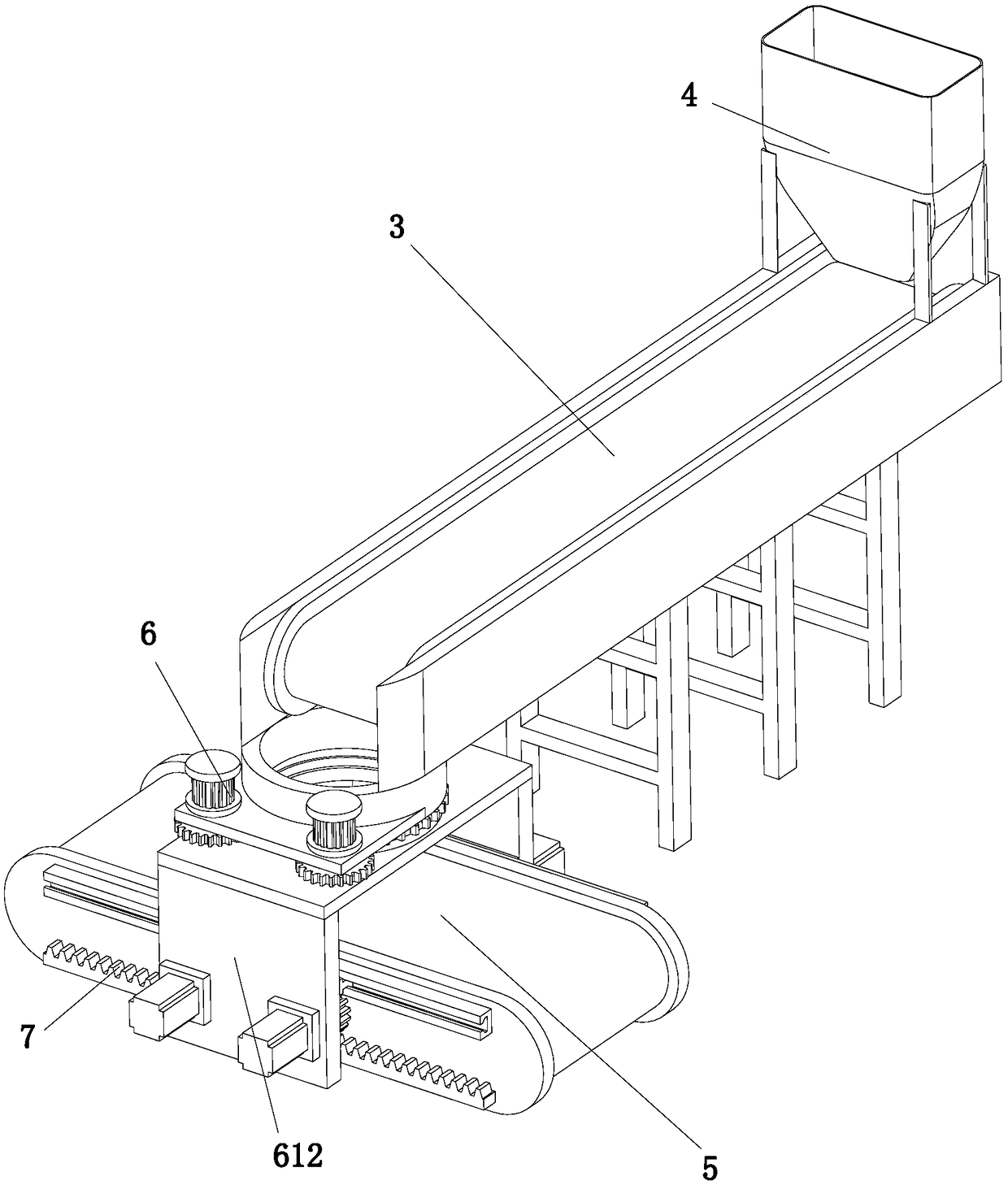

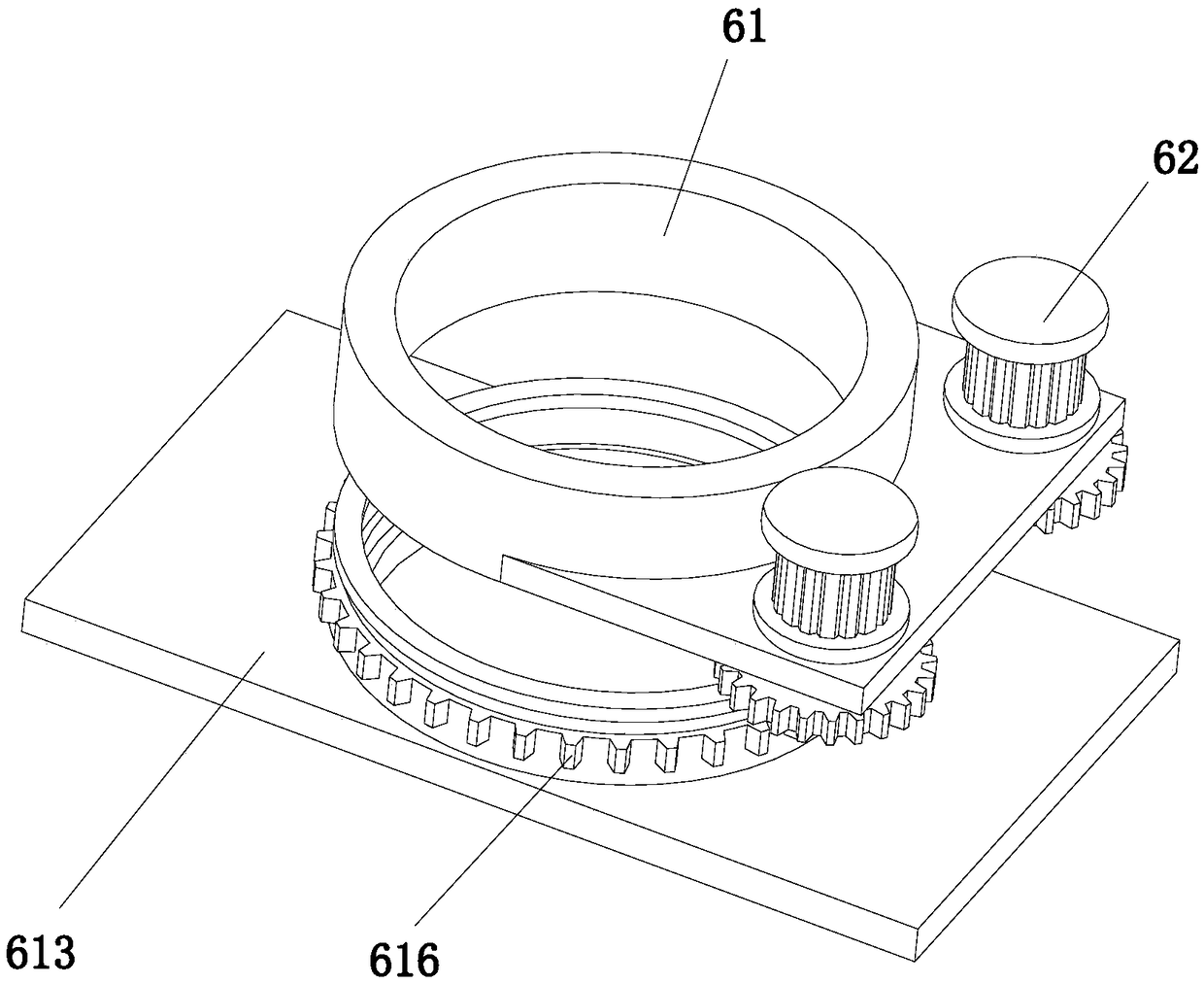

[0021] refer to Figure 1 to Figure 6 The shown concrete pipeline raw material pouring device includes a conveying device 1 for conveying materials, a rotary conveying device 2 for transitionally conveying materials and a control device, and the conveying device 1 includes a first conveyor belt for conveying materials 3 and a feed hopper 4 arranged directly above the input end of the first conveyor belt 3, the rotary conveyor 2 includes a second conveyor belt 5 for conveying materials, a rotary mechanism 6 for driving the second conveyor belt 5 to rotate horizontally, and In order to drive the translation mechanism 7 that the second conveyor belt 5 moves along its own conveying direction, the rotation mechanism 6 is fixedly installed on the bottom of the output end of the first conveyor belt 3, and the rotation mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com