Heating furnace portable type slag removal conveying device

A technology of conveying device and heating furnace, which is applied in descaling device, heat treatment furnace, lighting and heating equipment, etc., to achieve the effect of reducing manual transportation, speeding up cleaning efficiency and facilitating movement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

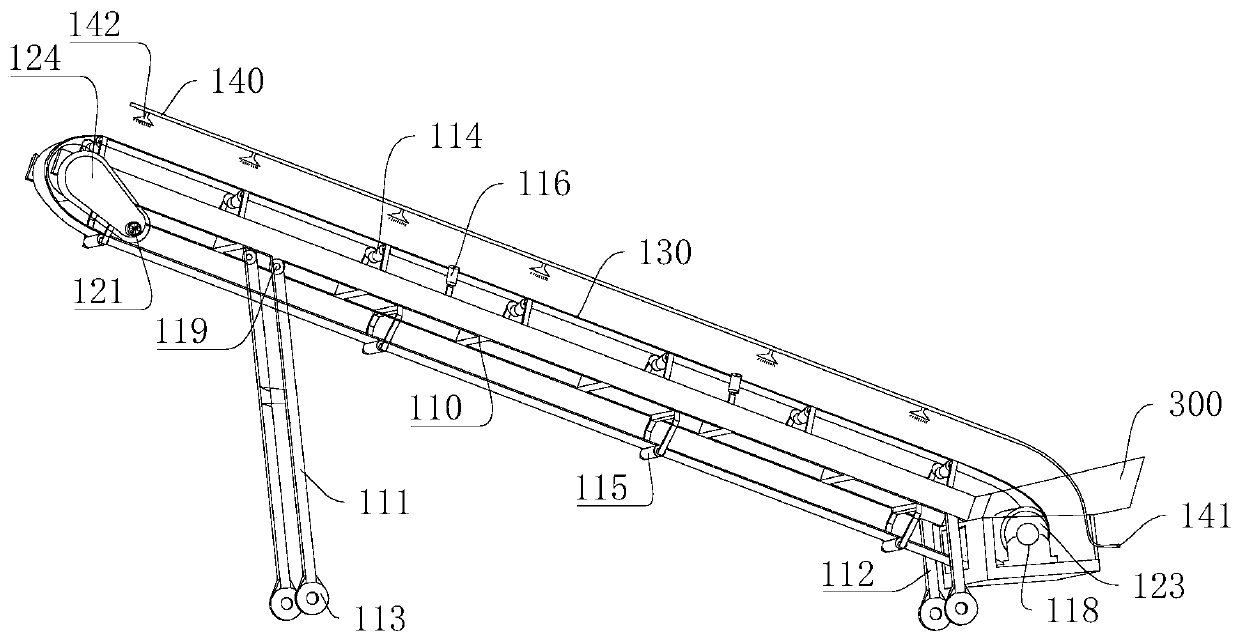

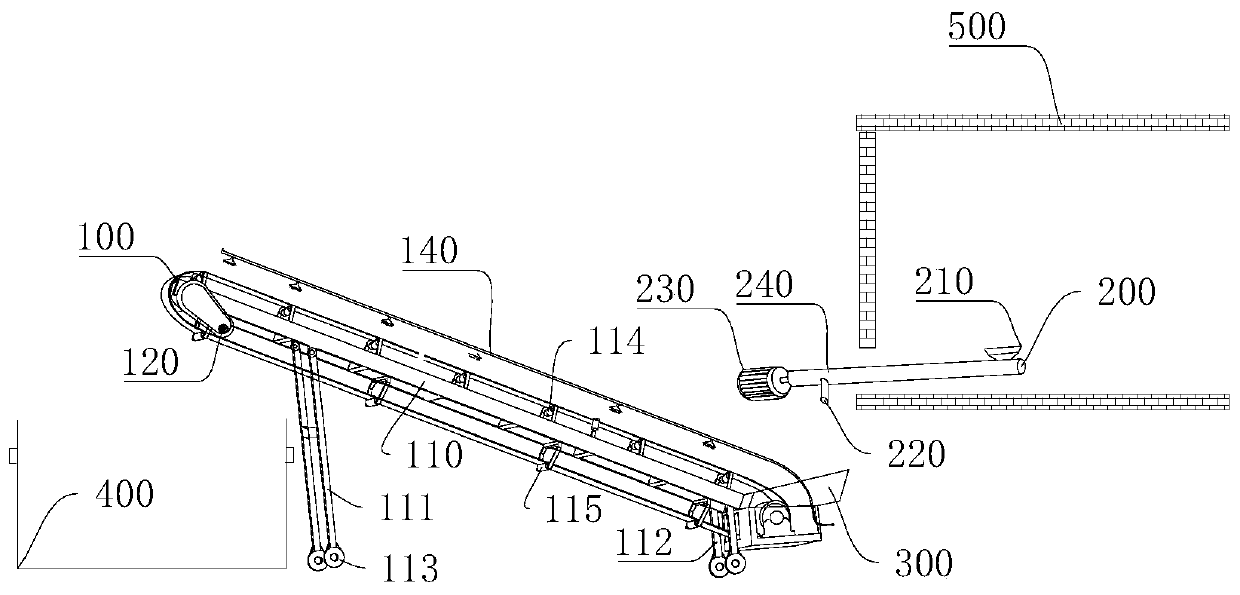

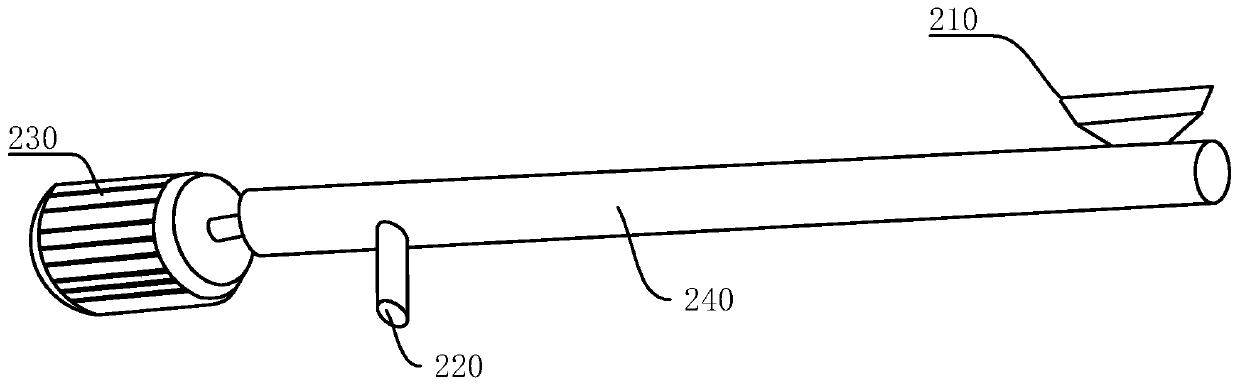

[0034] Such as Figure 1-3 Shown, a kind of belt transmission device is characterized in that, comprises:

[0035] Bracket 110 , the bracket 110 is a support frame from the entire belt transmission device 100 .

[0036] The driving device 120, the driving device 120 is arranged at both ends of the bracket 110, the driving device 120 provides power for the belt transmission device 100, and changes the direction of movement.

[0037] Conveyor belt 130, the conveyor belt 130 is arranged on the outside of the bracket 110, the two ends of the conveyor belt 130 are connected with the driving device 120, the conveyor belt 130 is the carrier of the main conveying object, and the driving device 120 provides power to drive the conveyor belt 130 around the bracket 110 rotates, and the object is transported from this end of support 110 to the other end of support 110.

[0038] The support 110 below is provided with the first moving leg 111 and the second moving leg 112, and the first mo...

Embodiment 2

[0053] Such as figure 1 and Figure 4 Shown, a kind of belt transmission device 100 is characterized in that, comprises:

[0054] Bracket 110 , the bracket 110 is a support frame from the entire belt transmission device 100 .

[0055] The driving device 120, the driving device 120 is arranged at both ends of the bracket 110, the driving device 120 provides power for the belt transmission device 100, and changes the direction of movement.

[0056] Conveyor belt 130, the conveyor belt 130 is arranged on the outside of the bracket 110, the two ends of the conveyor belt 130 are connected with the driving device 120, the conveyor belt 130 is the carrier of the main conveying object, and the driving device 120 provides power to drive the conveyor belt 130 around the bracket 110 rotates, and the object is transported from this end of support 110 to the other end of support 110.

[0057] The support 110 below is provided with the first moving leg 111 and the second moving leg 112, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com