Recycling mechanism and deep-fried dough stick preparation machine

A technology of recycling and recycling mechanism, which is applied in oil/fat baking, baking, food science, etc., and can solve the problems of personnel scalding, large fuel consumption, time-consuming and labor-intensive problems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

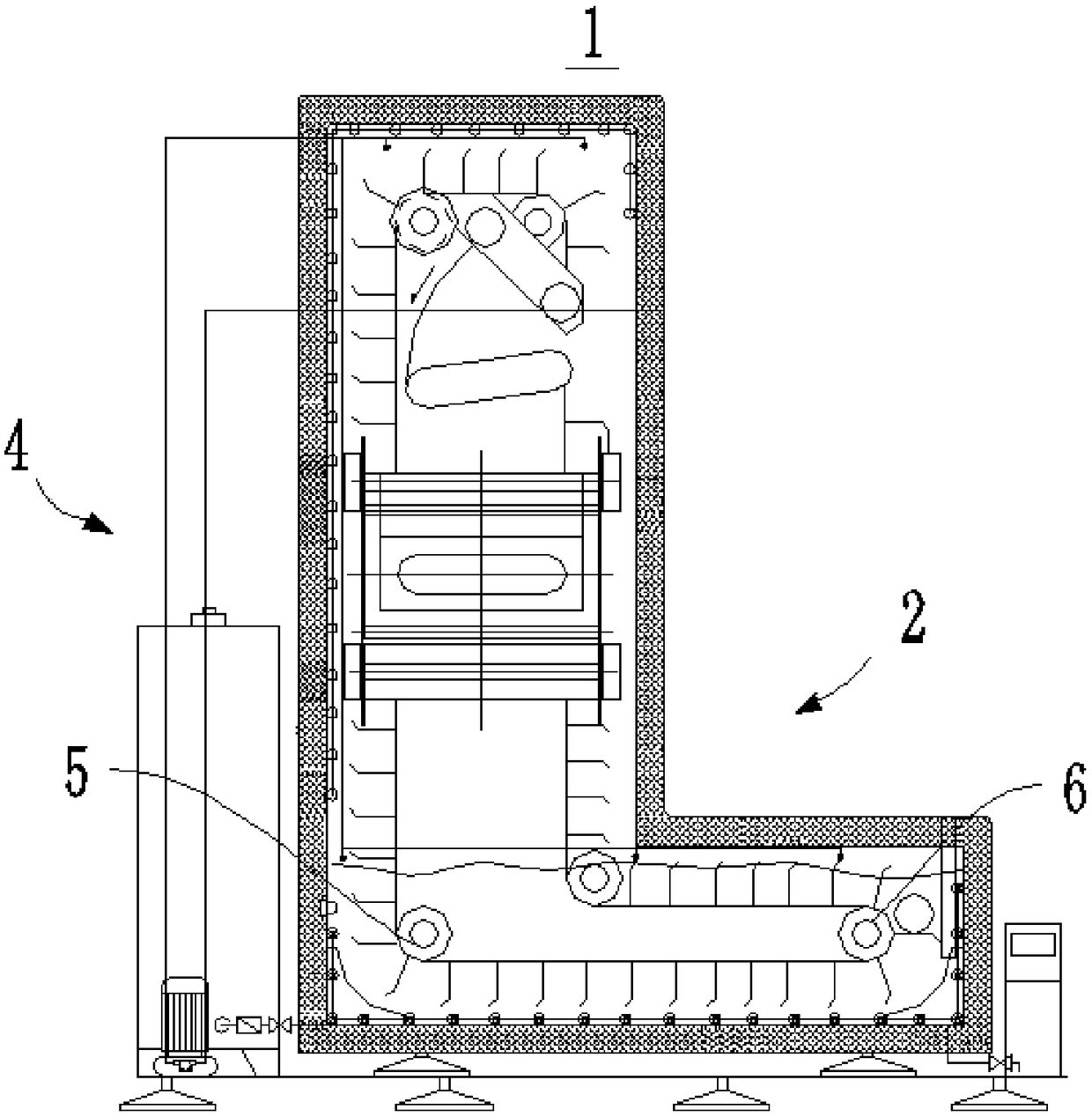

[0035] This embodiment provides a frying machine for deep-fried dough sticks, which includes a recycling machine, which mainly realizes fully automatic frying of deep-fried dough sticks and recycling of remaining oil, thereby achieving the effect of saving manpower and material resources.

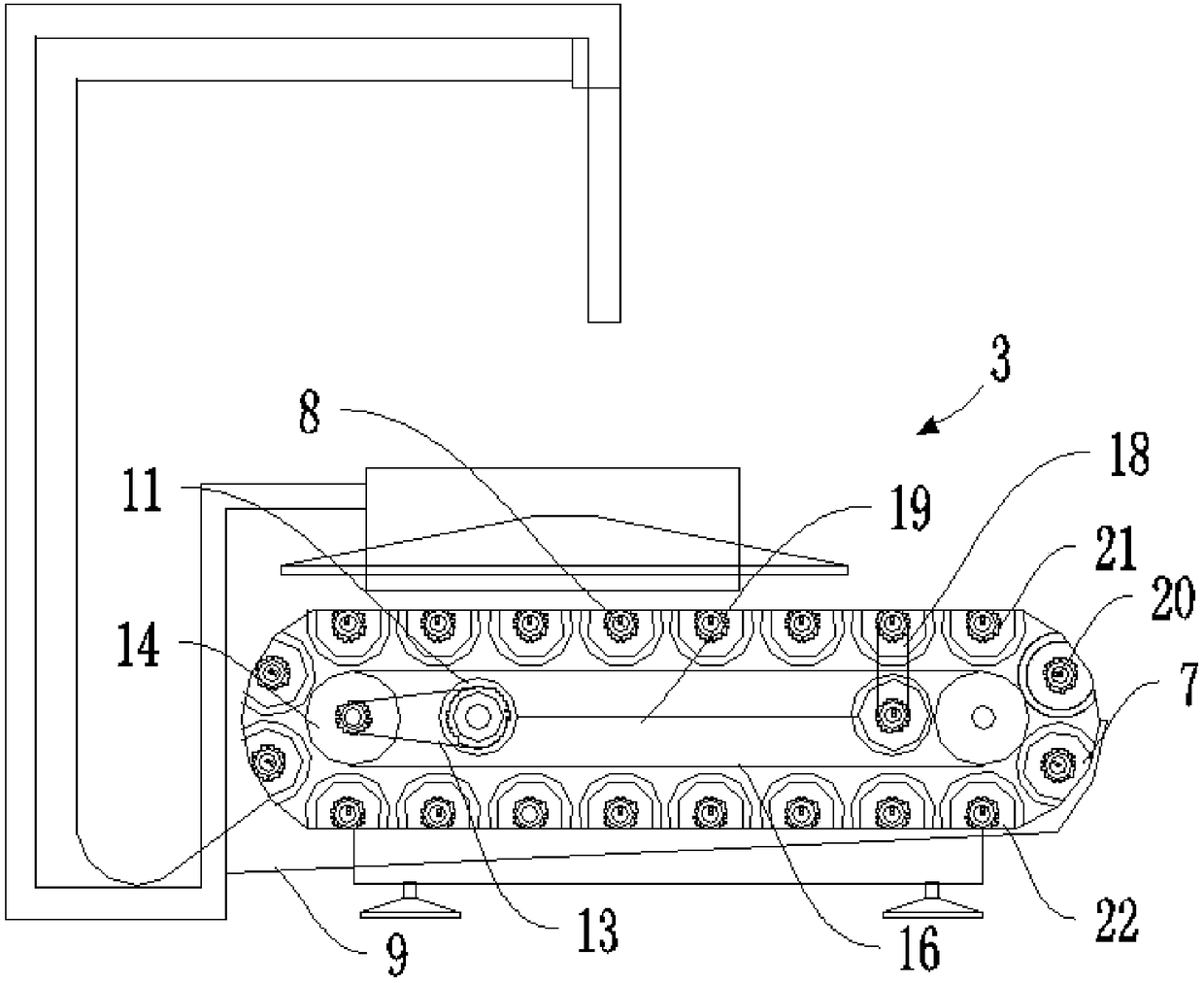

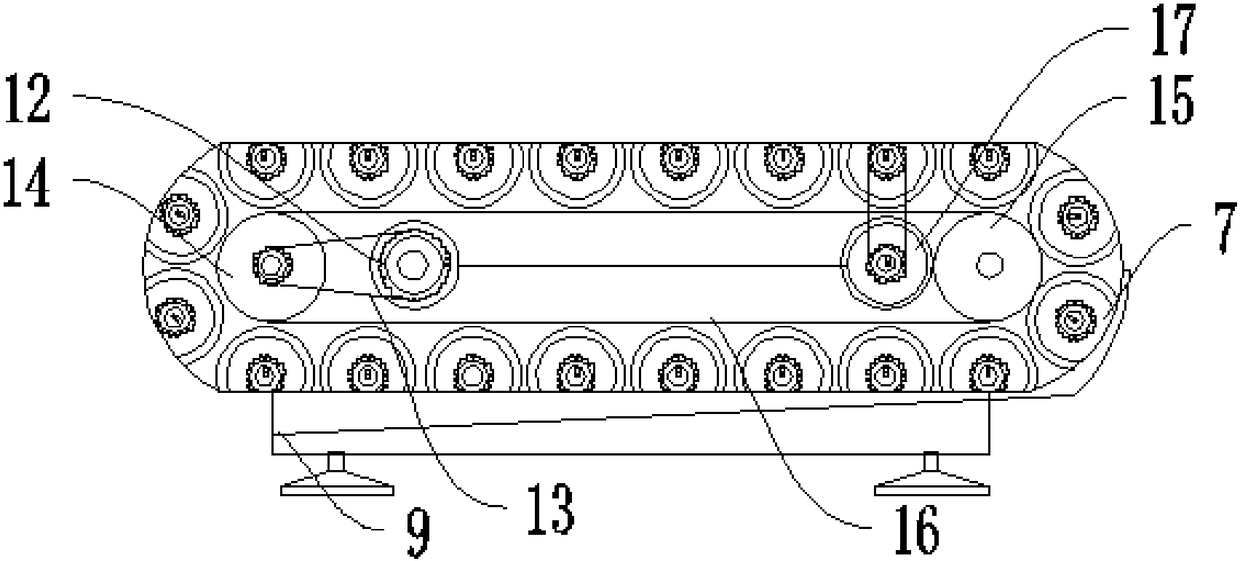

[0036] see Figure 1 to Figure 4 , the recycling recovery mechanism 1 includes a drive mechanism 2, a fried dough stick mechanism 3 and a residual oil recovery mechanism 4, the drive mechanism 2 includes a main transmission assembly 5 and a slave transmission assembly 6, and the fried dough stick mechanism 3 includes a plurality of fried oil sticks 7 and a plurality of fried dough sticks Overturn the assembly 8, a plurality of oil frying tanks 7 have multiple oil outlets, and the remaining oil recovery mechanism 4 includes an oil guide plate 9 and a recovery oil tank 10; the main transmission assembly 5 is connected to the slave transmission assembly 6; the circumferential direction of the mul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com