Split frame type electric cake overturning machine

A frame-type, turning machine technology, applied in the field of cake-shaped material turning mechanism, can solve the problems of unsuitable spoke cake material, large turning range, low turning frequency, etc., and achieve the effect of simple structure, fast turning speed and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with drawings and embodiments.

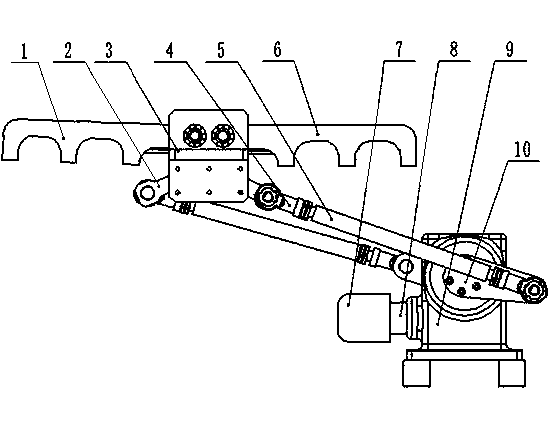

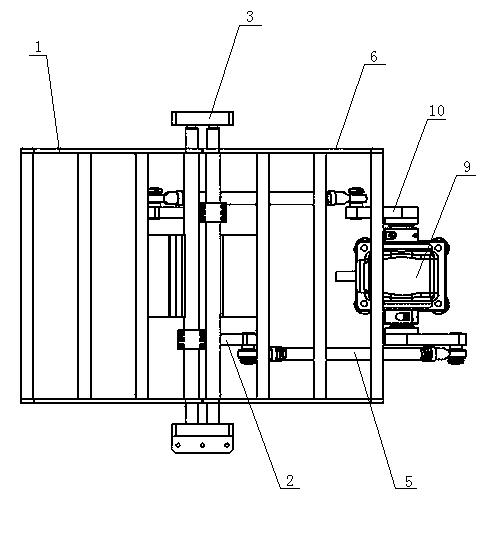

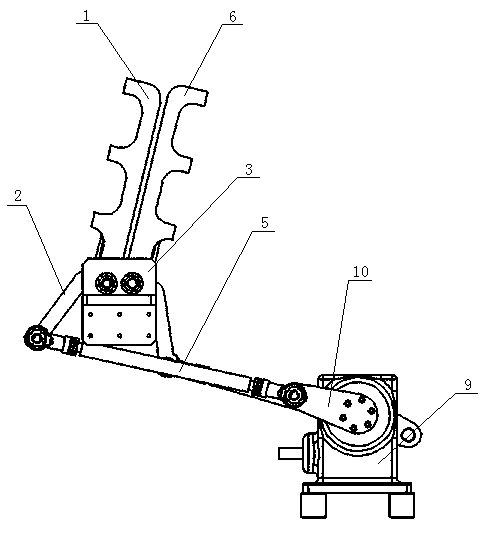

[0013] Such as figure 1 , 2 , 3, the present embodiment provides a split frame type electric cake material turning machine, including a servo motor 7, a reducer 9, a crank 10, a connecting rod 5, a driving connecting rod 2, a turning body, and the turning body consists of two It consists of independent flaps 1 and 6. The flaps 1 and 6 are installed on the side panels 3 through the rotating shaft, and the side panels 3 can be fixed on the roller table. The input shaft of the reducer 9 is connected with the servo motor 7 through the coupling 8. The output shafts on both sides of the reducer 9 are respectively connected to two cranks 10, one end of the connecting rod 5 is connected to the crank 10 through the joint bearing 4, and the other end of the connecting rod 5 is connected to the drive connecting rod 2 through the joint bearing 4, and the drive connection Rod 2 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com