Disc turning-over device, and cleaning system and method

A technology of turning over the plate and the plate body, applied in the field of cleaning, can solve the problems of low operation efficiency, time-consuming and labor-intensive, labor-intensive labor, etc., and achieve the effects of high cleaning efficiency, good cleaning effect and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

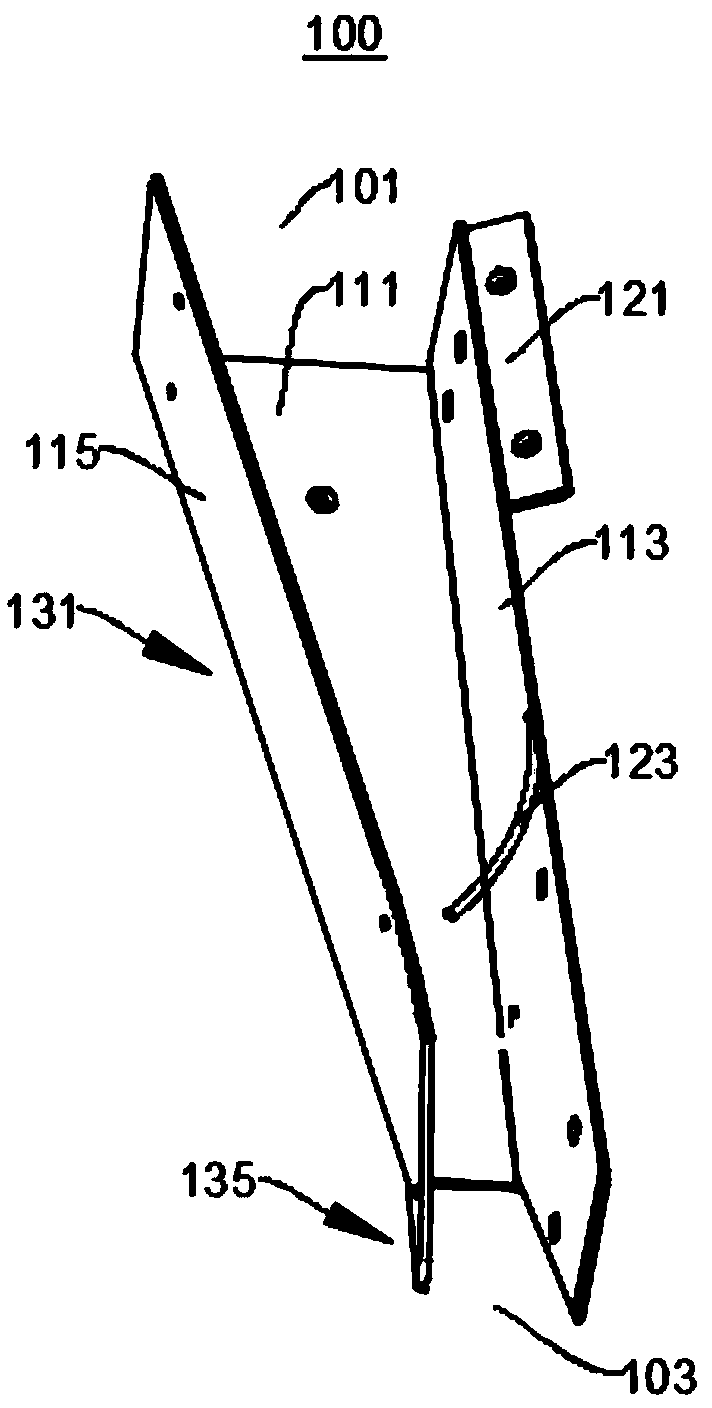

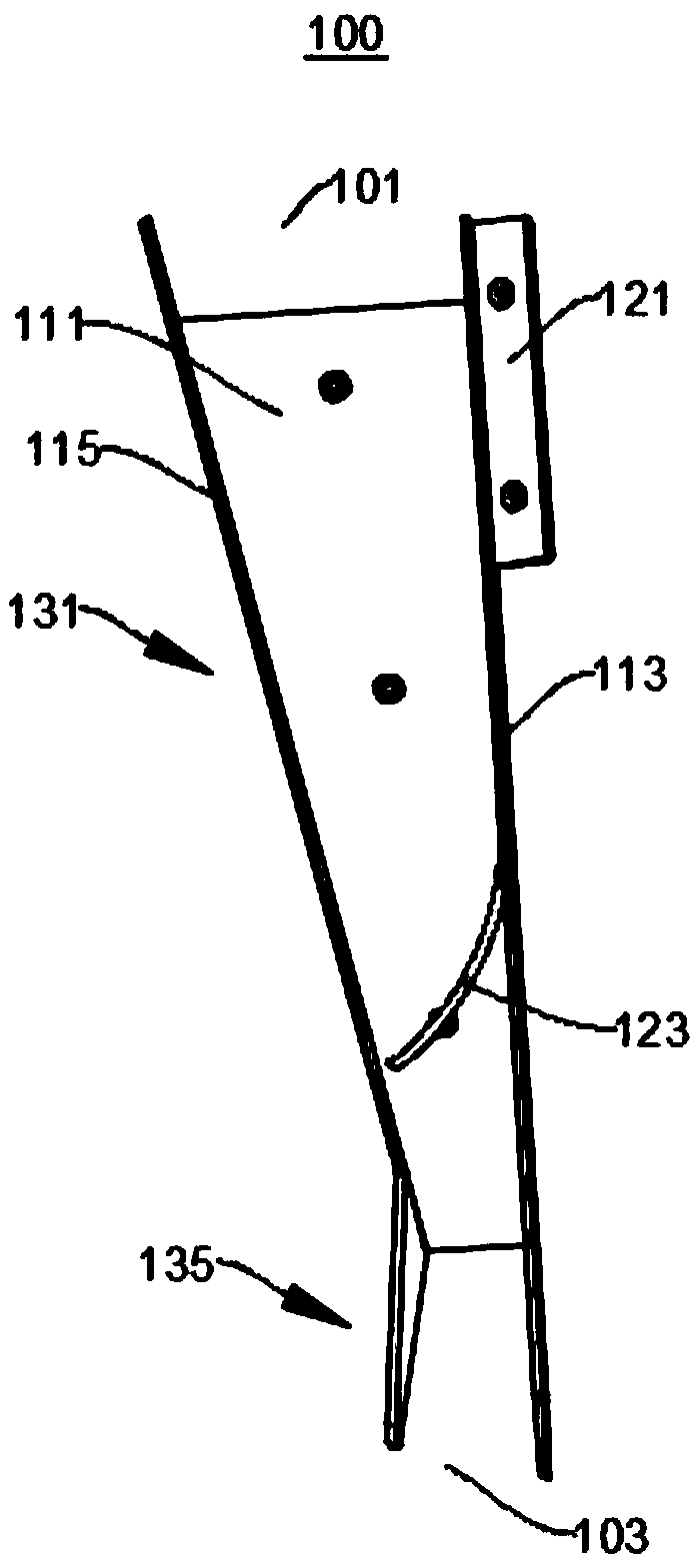

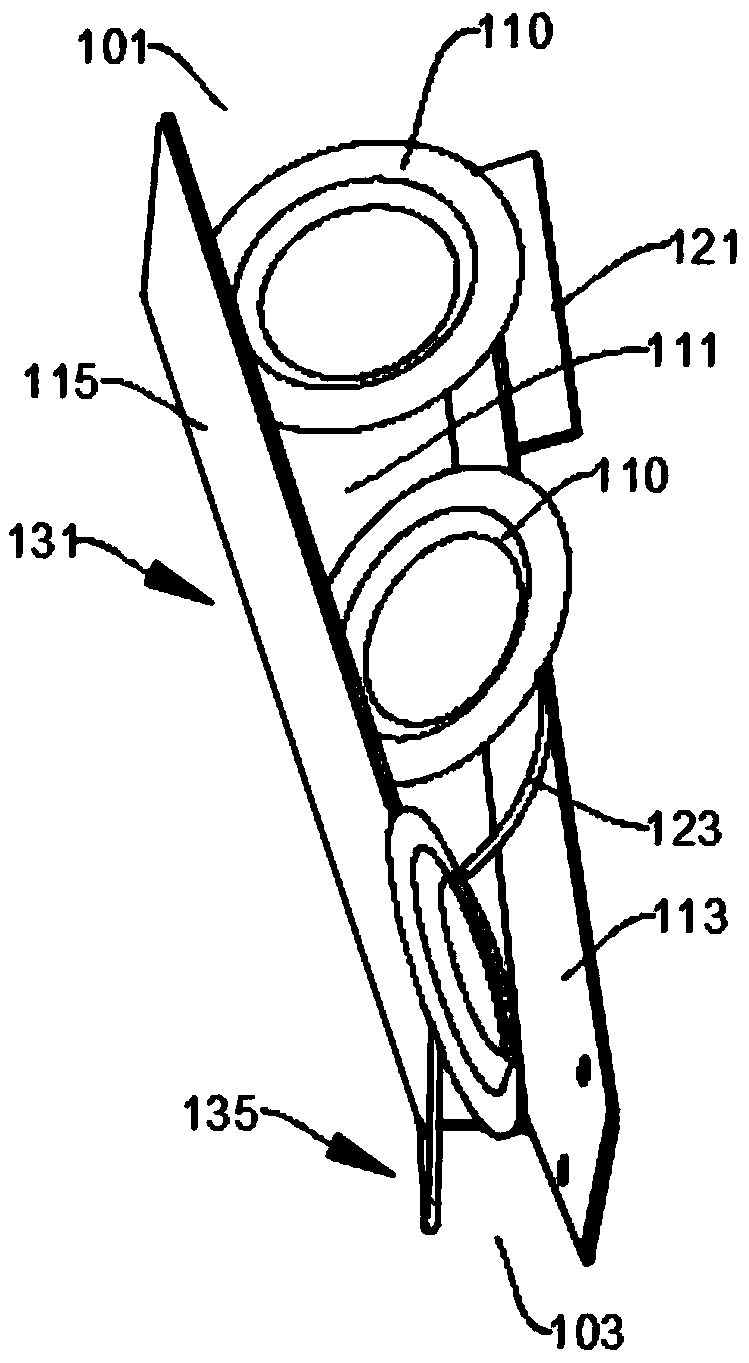

[0055] figure 1 A structural schematic diagram of the first viewing angle of the disk turning device 100 provided for a specific embodiment of the present invention, figure 2 For the structural schematic diagram of the second viewing angle of the turning device 100 provided by the specific embodiment of the present invention, please refer to figure 1 and figure 2 .

[0056] The turning device 100 provided in this embodiment is provided with a turning chute, and the turning chute includes a first inlet 101 and a first outlet 103 that communicate with each other, and the position of the first inlet 101 is higher than that of the first outlet 103, so that the turning The body 110 naturally slides down by its own gravity. The plate body 110 refers to a dinner plate or a plate-shaped item, especially a dinner plate.

[0057] Specifically, the turning chute includes a first bottom surface 111 , and a first side wall 113 and a second side wall 115 are provided on both sides of ...

no. 2 example

[0070] Figure 4 A structural schematic diagram of a viewing angle of the stand device 300 provided for a specific embodiment of the present invention, Figure 5 For a structural schematic diagram of an application scenario of the stand device 300 provided in a specific embodiment of the present invention, please refer to Figure 4 and Figure 5 .

[0071] A cleaning system provided in this embodiment includes a vertical disk device 300 , a cleaning tunnel 40 and the above-mentioned turning device 100 . Optionally, the vertical disk device 300 is arranged at the end of the first conveying section 10, and the first conveying section 10 conveys the disc body 110 with different positive and negative sides into the vertical disk device 300, between the vertical disk device 300 and the turning device 100 A second conveying section 20 is provided, and the second conveying section 20 is used for conveying the disk body 110 passing through the upright disk device 300 to the disk turn...

no. 3 example

[0095] A cleaning method provided in this embodiment includes:

[0096] Standing tray, conveying the tray body 110 into the tray device 300, so that the tray body 110 is output in an upright state, and after entering the second conveying section 20, the tray body 110 is tilted to one side under the action of gravity to be in an upright state.

[0097] To turn over the disk, the disk body 110 in the upright state is transported to the disk turning device 100, and the disk body 110 is output in an upside-down state.

[0098] For cleaning, the disk bodies 110 in an inverted state are transported to the cleaning tunnel 40 to clean each disk body 110 . In this cleaning method, the disk bodies 110 with different fronts and backs are sorted first, that is, the disk bodies 110 with different fronts and backs are placed upright, and then all the disk bodies 110 placed upright are reversed, and finally all the disk bodies 110 are cleaned with Entering the cleaning tunnel 40 in an inver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com