Integral die cutting machine of plastic packing box

A packaging box and integrated technology, which is applied in the field of integrated die-cutting machines for plastic packaging boxes, can solve the problems of increased processing cost, large waste edge area, and increased processing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

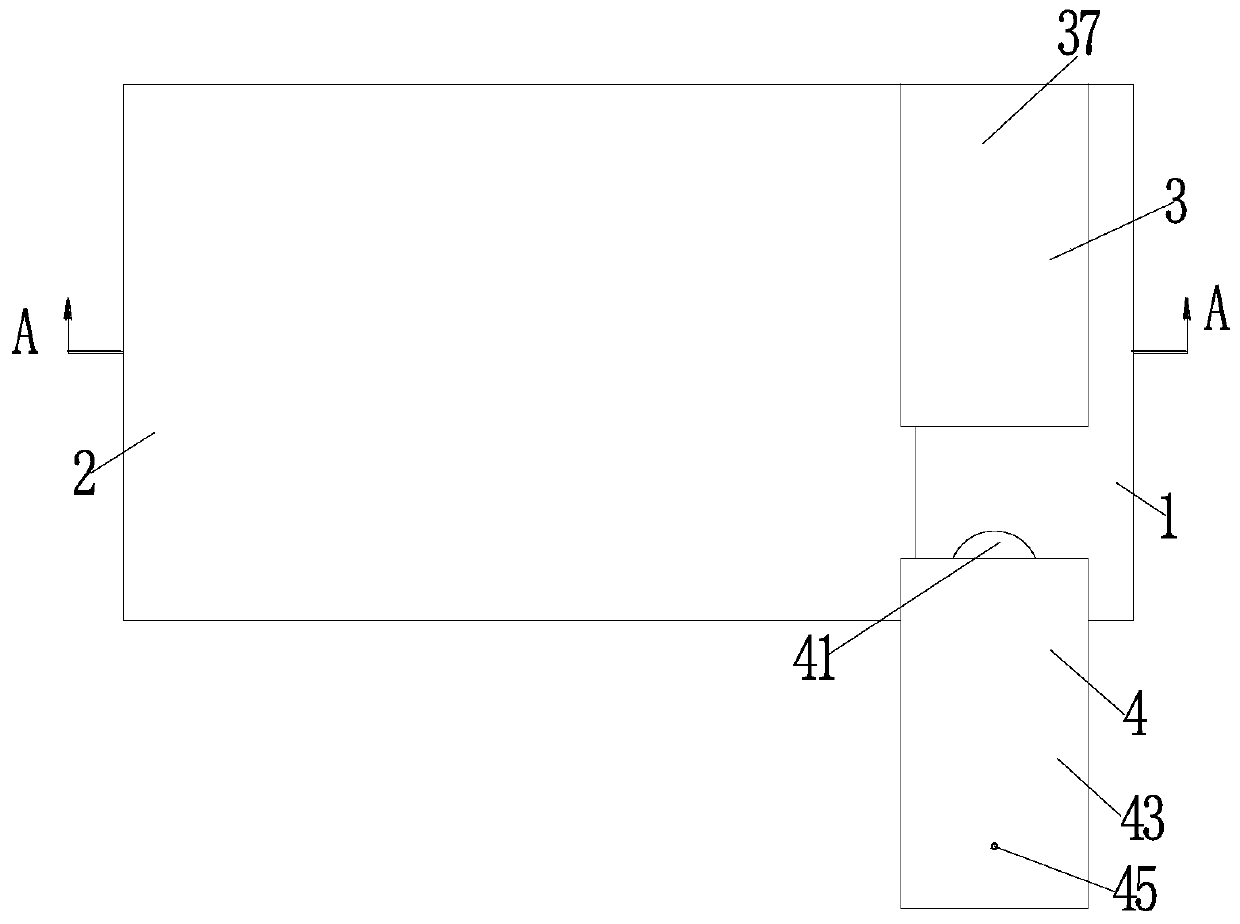

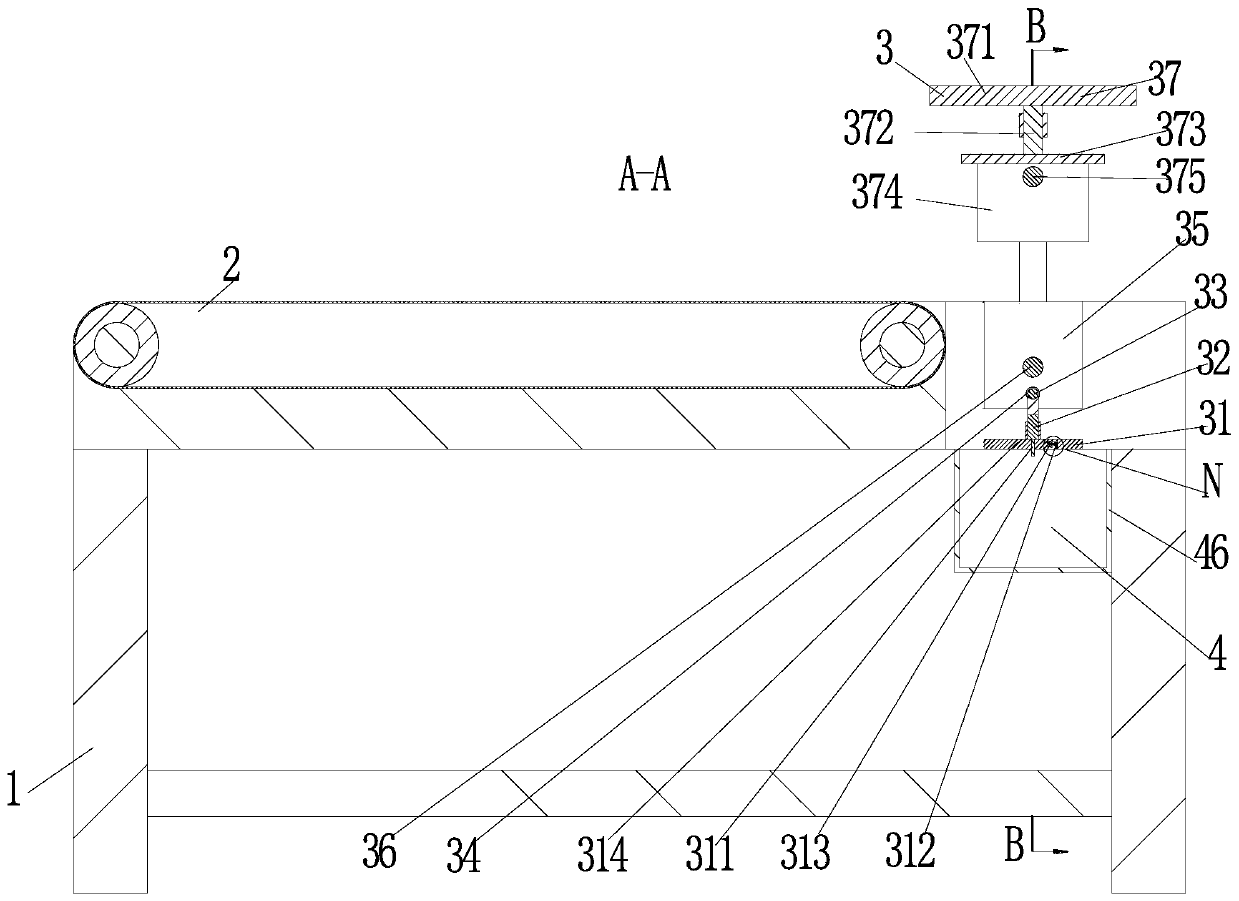

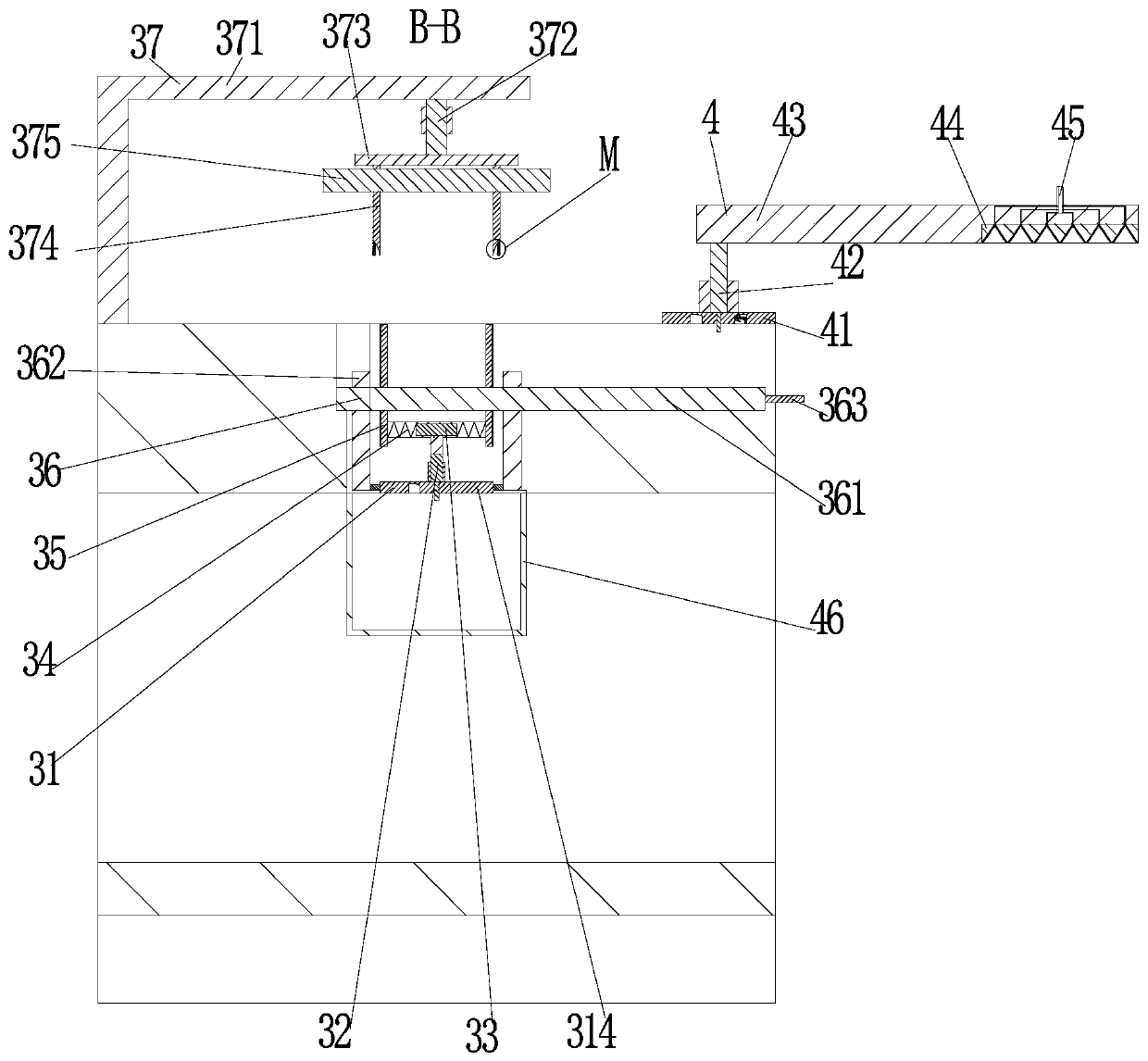

[0032] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, the following combination Figure 1 to Figure 7 , to further elaborate the present invention.

[0033] An integral die-cutting machine for plastic packaging boxes, comprising a workbench 1, a belt conveyor 2, a die cutting device 3 and a collection device 4, a belt conveyor 2 is installed on the upper left side of the workbench 1, and the belt conveyer Die-cutting device 3 is installed at the right end of machine 2, and collecting device 4 is installed at the lower end of die-cutting device 3; Wherein:

[0034] Described die-cutting device 3 comprises swivel frame 31, telescopic support 32, T-shaped post 33, large spring 34, positioning plate 35, thread frame 36 and cutting frame 37, and workbench 1 right side upper end is equipped with swivel frame 1. 31, a telescopic support 32 is fixedly installed on the swivel frame, a T-shaped post 33 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com