Zero-discharge double-cylinder rotary carbonization furnace for preparing active carbon

A technology of activated carbon preparation and carbonization furnace, which is applied in the direction of rotary carbonization furnace, coke oven, chemical industry, etc. It can solve the problems of combustible organic matter, short carbon powder raw material travel, waste of resources, etc., to save energy and reduce environmental pollution , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

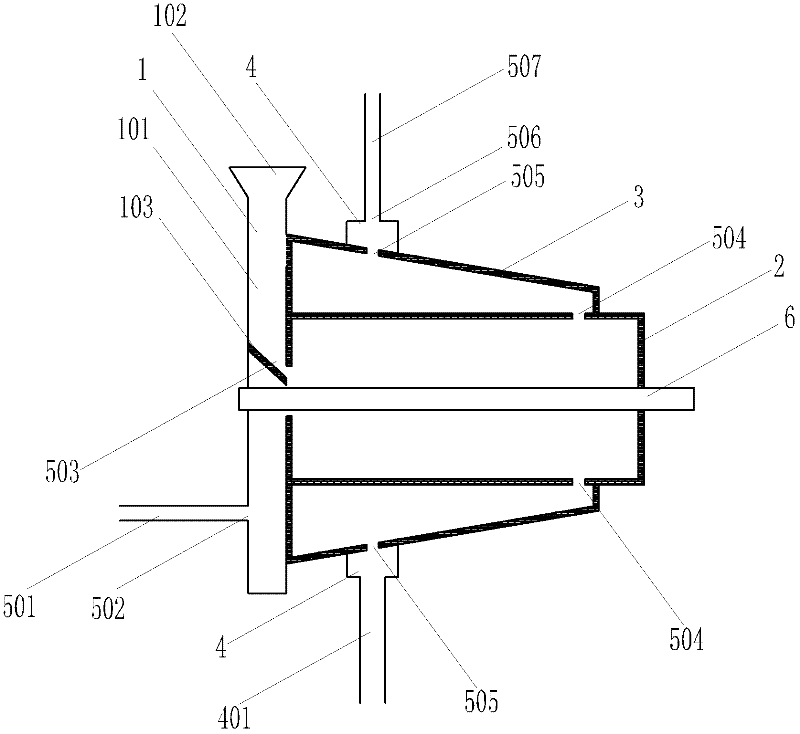

[0038] Such as figure 1 As shown, embodiment 1 of the carbonization furnace of the present invention includes a feeding device 1, a rotatable inner cylinder 2, a rotatable outer cylinder 3, a collecting device 4, a gas-flue gas circuit structure, a heating device 6, and a driving inner cylinder And the driving device (not shown in the figure) that outer cylinder rotates.

[0039] Wherein, the inner cylinder 2 is a closed cylinder with a horizontal axis, and a plurality of lifting plates (not shown in the figure) are arranged on its inner wall; a first opening 503 is provided on the end surface of the head of the inner cylinder 2; A plurality of second openings 504 are provided, all of which are located on the same longitudinal section at the same distance from the rear end of the inner cylinder 2 .

[0040] Feed device 1 is the feed pipe 101 that is communicated with the first opening 503; The bottom end of feed pipe 101 is closed, and the top is provided with feed port 102; ...

Embodiment 2

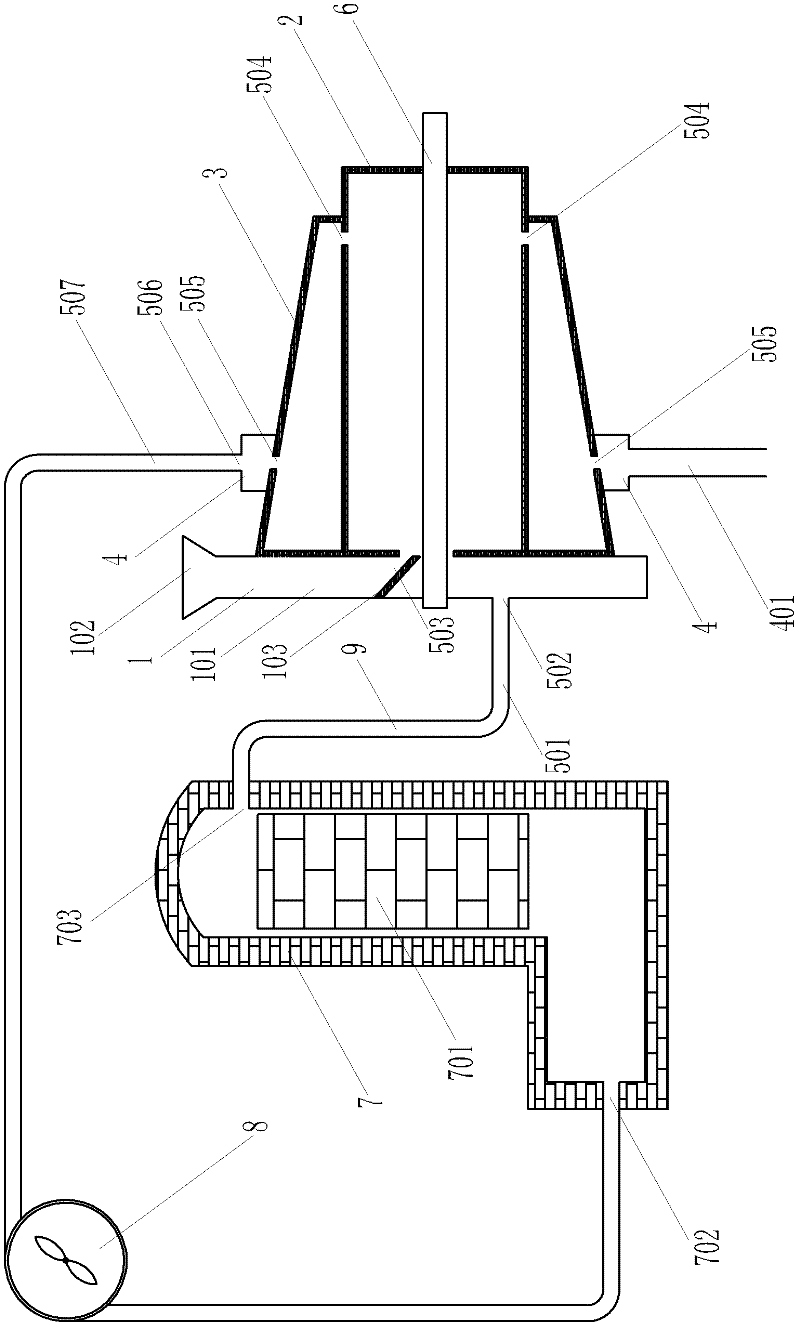

[0051] image 3 Shown is the system composed of Embodiment 2 of the carbonization furnace of the present invention and the combustion furnace. The difference between this embodiment 2 and embodiment 1 is: the gas-flue gas and the carbon powder raw material are in countercurrent contact, that is, the combustible gas generated by the carbon powder raw material in the inner cylinder 2 under the action of heat is against the flow direction of the carbon powder raw material Enter the combustion device through the first opening 503, the fifth opening 502, and the first gas pipe 501, and generate high-temperature flue gas after burning in the combustion device. The high-temperature flue gas enters the outer cylinder 3 through the second gas pipe 507 , the fourth opening 506 , and the third opening 505 , and enters the inner cylinder 2 through the second opening 504 .

Embodiment 3

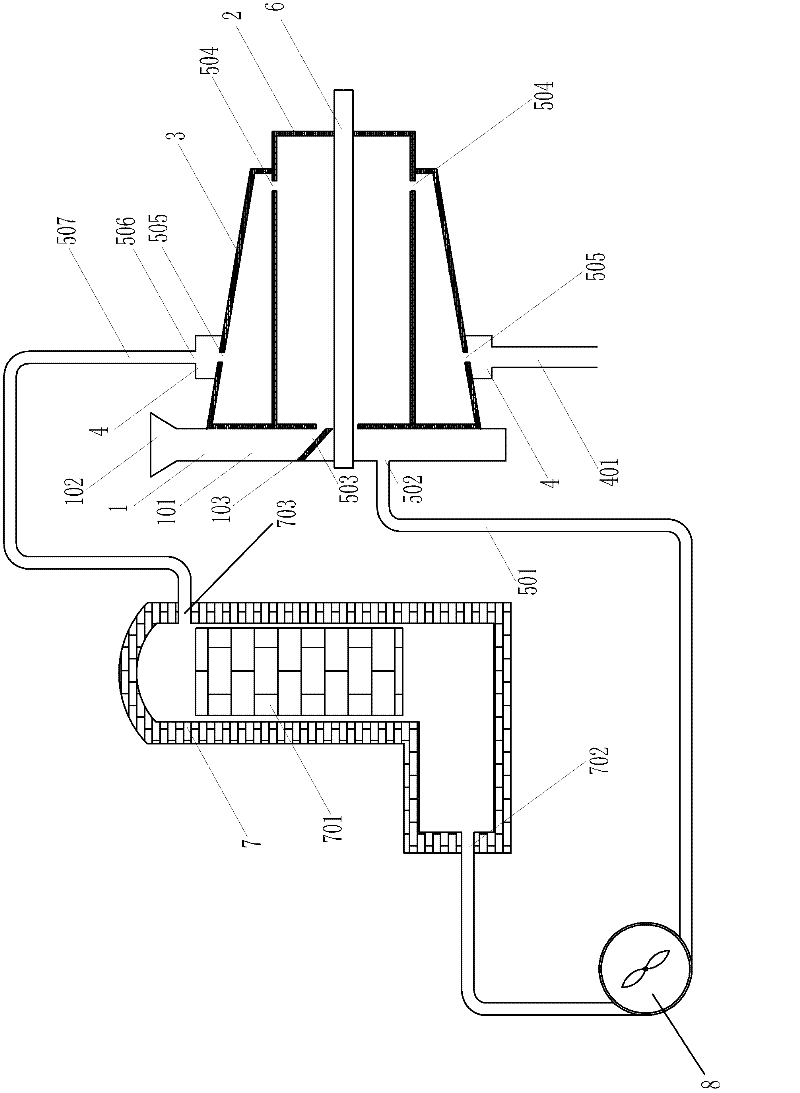

[0053] As another solution of the present invention, other parts are similar to Embodiment 1, the difference is that both the inner cylinder and the outer cylinder are in the shape of a truncated cone, the thicker tail of the outer cylinder is adjacent to the thinner head of the inner cylinder, and the outer cylinder is thinner. The head is adjacent to the thicker tail of the inner cylinder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com