Seed metering and fertilizer feeding device of seeder

A fertilizer discharge device and seeder technology, which is applied in the direction of fertilization device, seeder parts, interval quantitative sowing machinery, etc., can solve the problems of fertilizer tailing, unclear boundary, seed and fertilizer contact, etc. ditch resistance, avoid contact with seed fertilizer, and reduce water loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

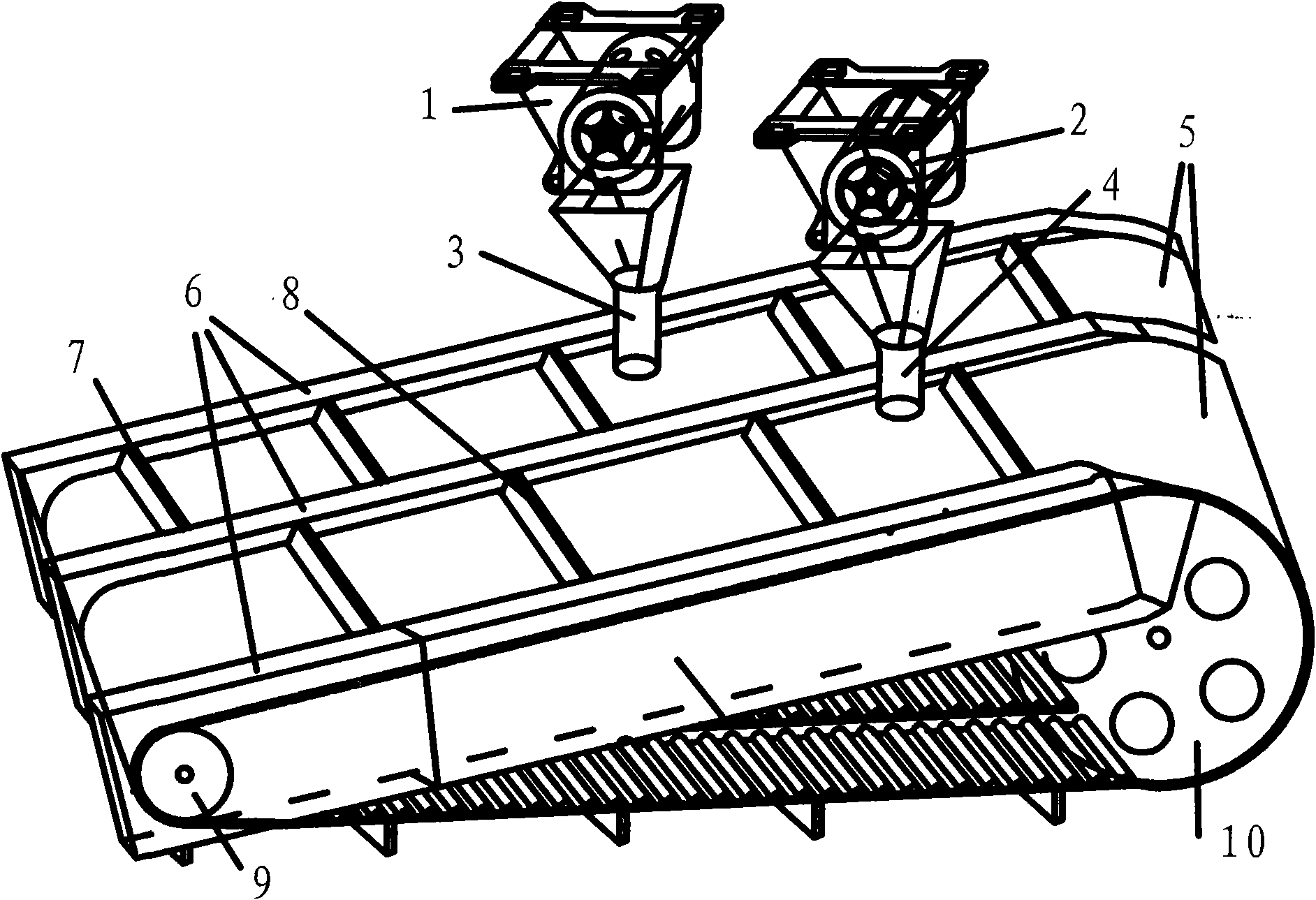

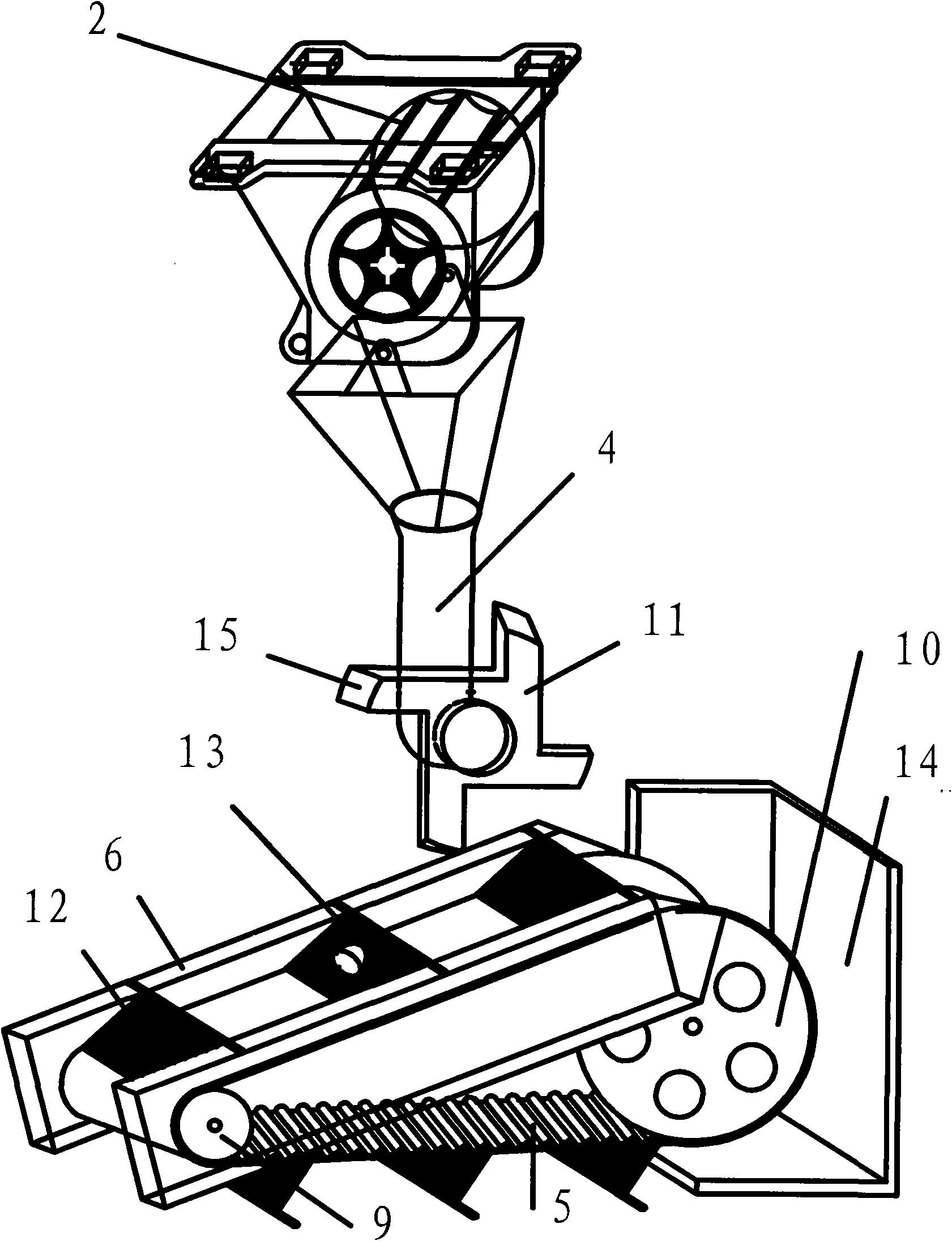

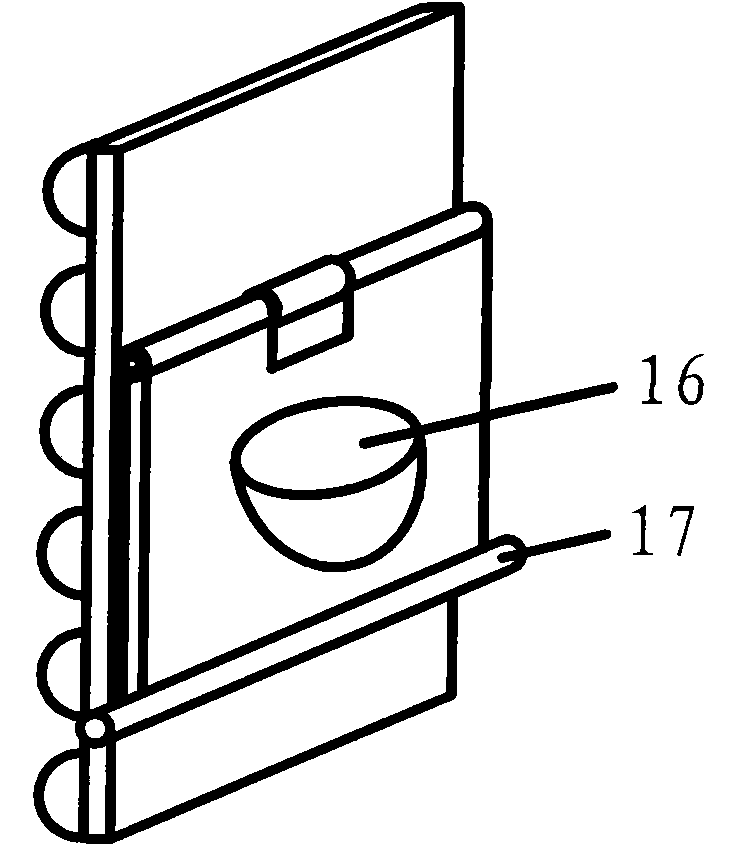

[0018] figure 1 It shows a schematic diagram of the overall structure of an embodiment of the present invention in which two conveyor belts are used to transport seeds and fertilizers in division of labor. The basic structure of this embodiment includes a seed picker 1, a fertilizer picker 2, a seed conduit 3, a fertilizer conduit 4, a conveyor belt 5, a guard plate 6, a seed grid plate 7, a fertilizer grid plate 8, a front lower end pulley 9, a rear belt round 10. When working and running, the seed picker 1, the fertilizer picker 2 and the rear pulley 10 adopt synchronous transmission, and the seeds fall through the seed picker 1 and the seed conduit 3 onto the conveyor belt equipped with a seed grid, and the fertilizer passes through the fertilizer picker 2 1. Fertilizer conduit 4 falls on the conveyer belt that fertilizer grid plate 8 is installed, seed, fertilizer grid plate are staggered back and forth on the conveyer belt conveying direction, and conveyer belt is transp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com