Rice huller

The technology of a grain hulling machine and a machine body is applied in the field of grain hulling machines, which can solve the problems of low production efficiency, high inclusion rate of rice husks, rough grains and incomplete separation and discharge of rice husks, etc., and achieves the effect of improving the efficiency of grain husking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

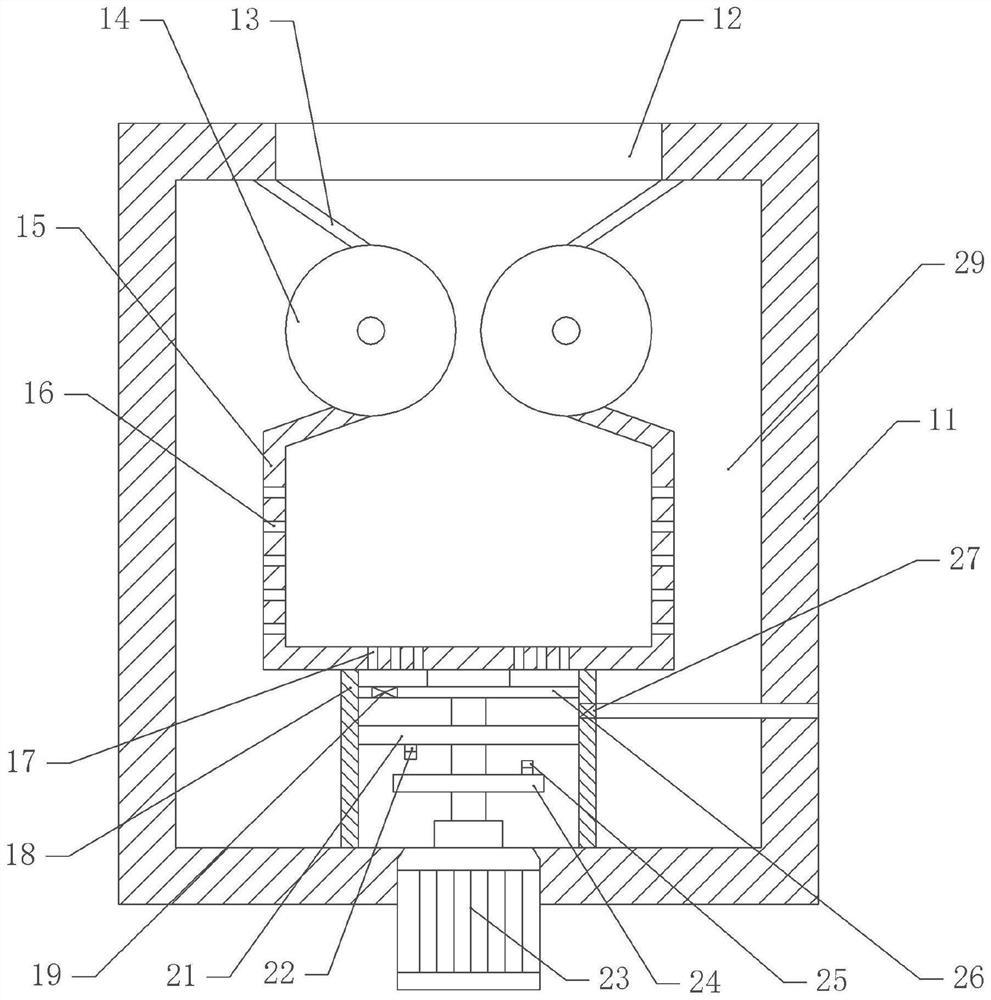

[0038] A rice huller, such as attached figure 1 As shown, it includes a frame and a body 11 fixed on the frame by bolts, and an opening 12 is arranged on the upper part of the body 11 .

[0039] Several driving parts are fixed on the body 11. In this embodiment, the driving parts are single-phase motors 23 and there are two single-phase motors 23 (not shown in the figure). The output shafts of the single-phase motors 23 are coaxially fixed with a The rubber roller 14 below 12 forms a gap between adjacent rubber rollers 14, and several scrapers 13 are arranged on the body 11. One end of the scraper 13 is fixed on the body 11, and the other end of the scraper 13 is against the rubber roller 14. The scrapers 13 are inclined and two adjacent scrapers 13 are arranged in a conical shape.

[0040] A separation cylinder 15 is arranged in the body 11, and a cavity 29 is formed between the separation cylinder 15 and the body 11. The cavity 29 is communicated with a negative pressure tu...

Embodiment 2

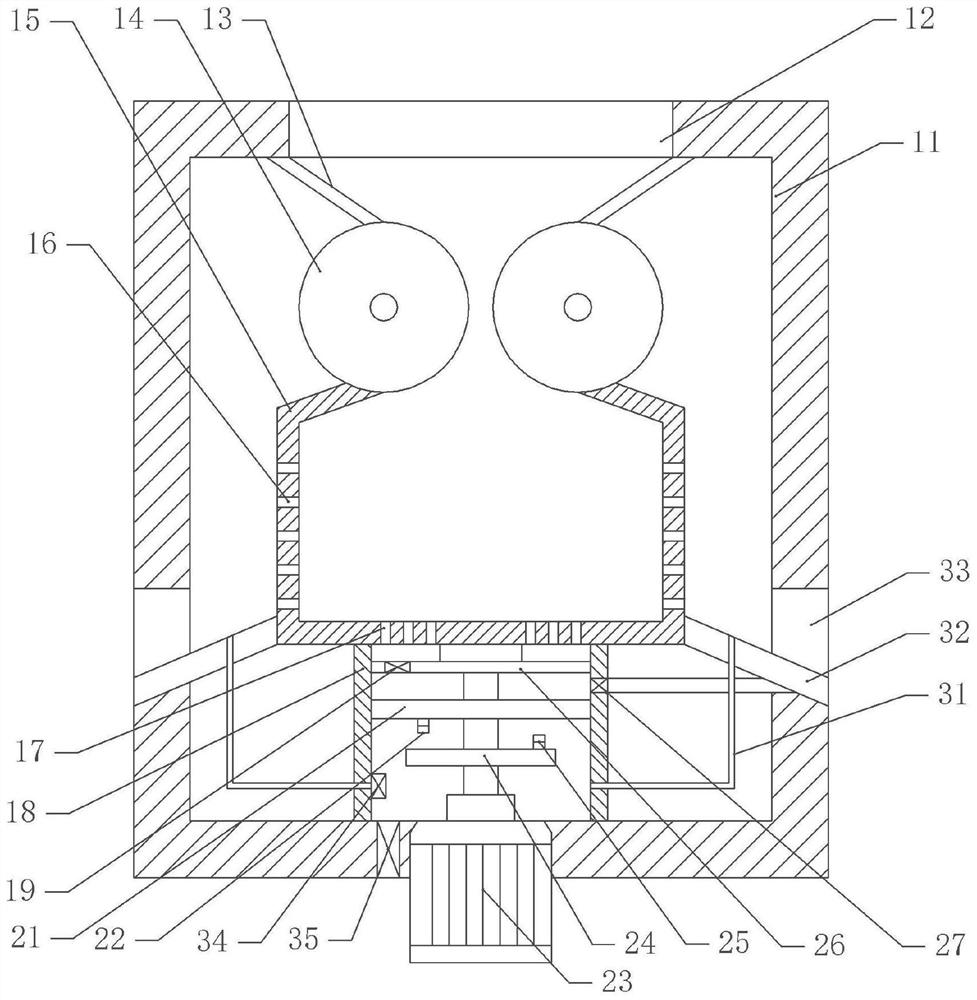

[0047] The difference between embodiment two and embodiment one is that, as attached figure 2 As shown, the screw on the support cylinder 18 is fixed with the second air outlet check valve 34 located below the second partition 21, the second air outlet check valve 34 is connected with the air pipe 31, and the air outlet end of the air pipe 31 faces the upper part of the body 11. 11 is fixed with a second air intake one-way valve 35 located below the second partition 21 , and the second air intake one-way valve 35 communicates with the support cylinder 18 .

[0048] The side wall of the body 11 is provided with some discharge openings 33, and the screws in the discharge openings 33 are fixed with an inclined drain plate 32, the drain plate 32 is arranged in a ring, and one side of the drain plate 32 is rotatably matched with the separation cylinder 15, and the drain plate There are several passages on the 32, and the width of the passages decreases successively from top to bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com