Glow discharge plasma water treatment method and device

A water treatment device, plasma technology, applied in the direction of sterilization/microdynamic water/sewage treatment, etc., can solve the problems of large power loss, high discharge voltage, low discharge voltage, etc., to reduce the structure and increase the contact area , the effect of strengthening the processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

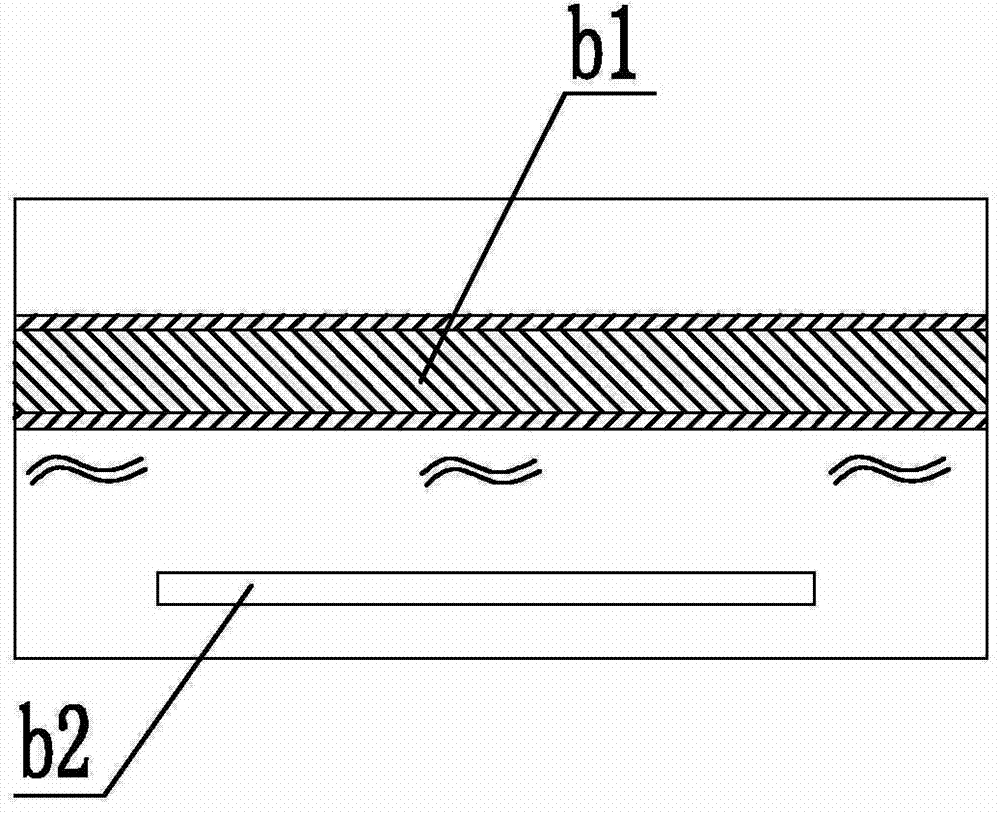

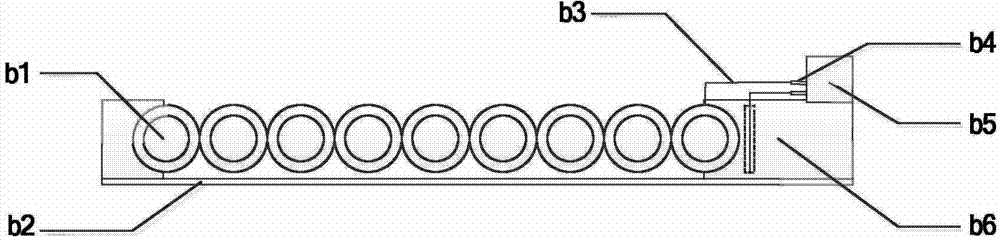

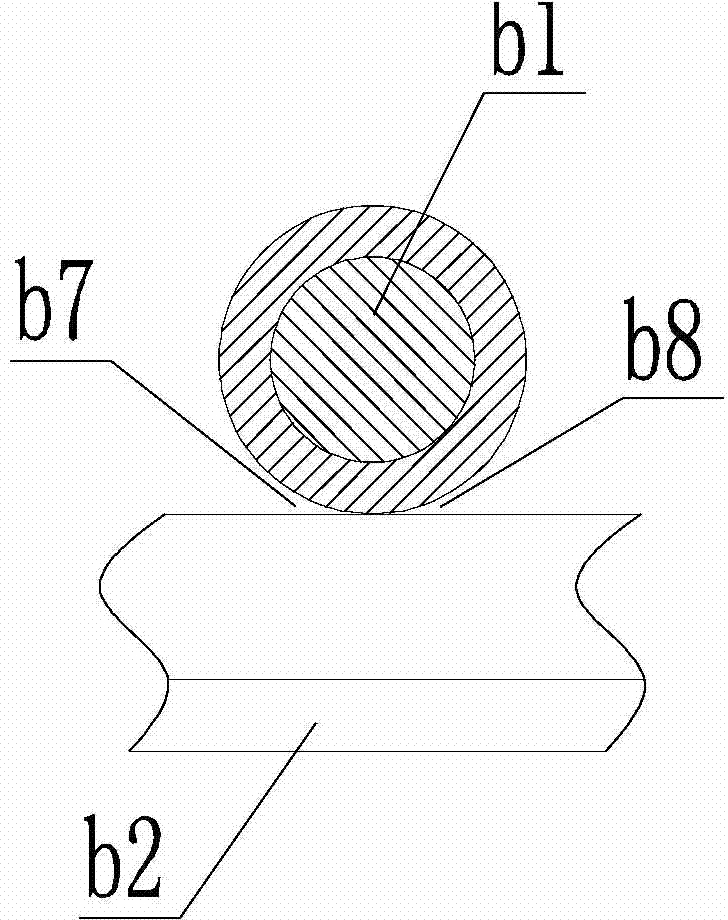

[0044] figure 1 It is a schematic diagram of the basic structure of the present invention, figure 2 for figure 1 The schematic diagram of the cross-sectional structure, image 3 A schematic diagram of the enlarged structure of a single water surface electrode, combined with figure 1 , figure 2 as well as image 3 The glow discharge plasma water treatment method of the present invention is described as follows, comprising the following steps:

[0045] After the sewage to be treated is mechanically treated, a water surface electrode b1 of the same potential is placed on the surface of the sewage. The water surface electrode is cylindrical and covered with an insulating medium. The water surface electrode b1 is connected to the positive or negative pole of the power supply; the water surface electrode b1 The electrodes b2 in the water and the water are connected with the insulating fixing device b6, and the electrode b2 in the water is connected with the wire b3 and the wa...

Embodiment 2

[0050] On the basis of embodiment 1, the present invention provides a kind of plasma water treatment device adopting the method of embodiment 1, such as Figure 4 As shown, the plasma water treatment device of this embodiment includes a container 3, a water inlet 1 and a water outlet 2 are arranged on the container 3, and an underwater electrode 12 is arranged in the sewage in the container 3, and the underwater electrode 12 is a bare plate-shaped Conductor material; the water surface electrode 7 of the same potential is placed on the surface of the sewage in the container 3. The water surface electrode 7 is cylindrical and is wrapped with an insulating medium. The water surface electrode 7 is in direct contact with the sewage, and the outer surface of the water surface electrode 7 is in contact with the water surface. A gap is formed, and after electrification, a glow discharge is generated in the gap to generate plasma and active particles, and the plasma and active particles...

Embodiment 3

[0056] Figure 7 A schematic diagram of another plasma water treatment method provided by the present invention; Figure 7 , another kind of glow discharge plasma water treatment method provided by the present invention comprises the following steps:

[0057] After the sewage to be treated is mechanically treated, the water surface electrodes a7 arranged in parallel are placed on the surface of the sewage. The water surface electrodes a7 are cylindrical and covered with an insulating medium. On the positive or negative pole of the power supply; the water surface electrode a7 is in direct contact with the sewage, and there is a gap between the outer surface of the water surface electrode a7 and the water surface, turn on the power supply, adjust the voltage to between 3kV-5kV, and after reaching the initial discharge voltage, Glow discharge will be generated in the aforementioned gap, plasma and active particles will be generated, and the sewage will be treated in depth by usi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com