Automatic rubbing ball feeding device

An automatic feeding and rubbing technology, which is applied in the direction of spherical grinder, transportation and packaging, grinding feed movement, etc., can solve the problems of difficult workpiece positioning, movement, difficult operation, high scrap rate, etc., and achieve accurate feeding position , Reduce labor and save cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

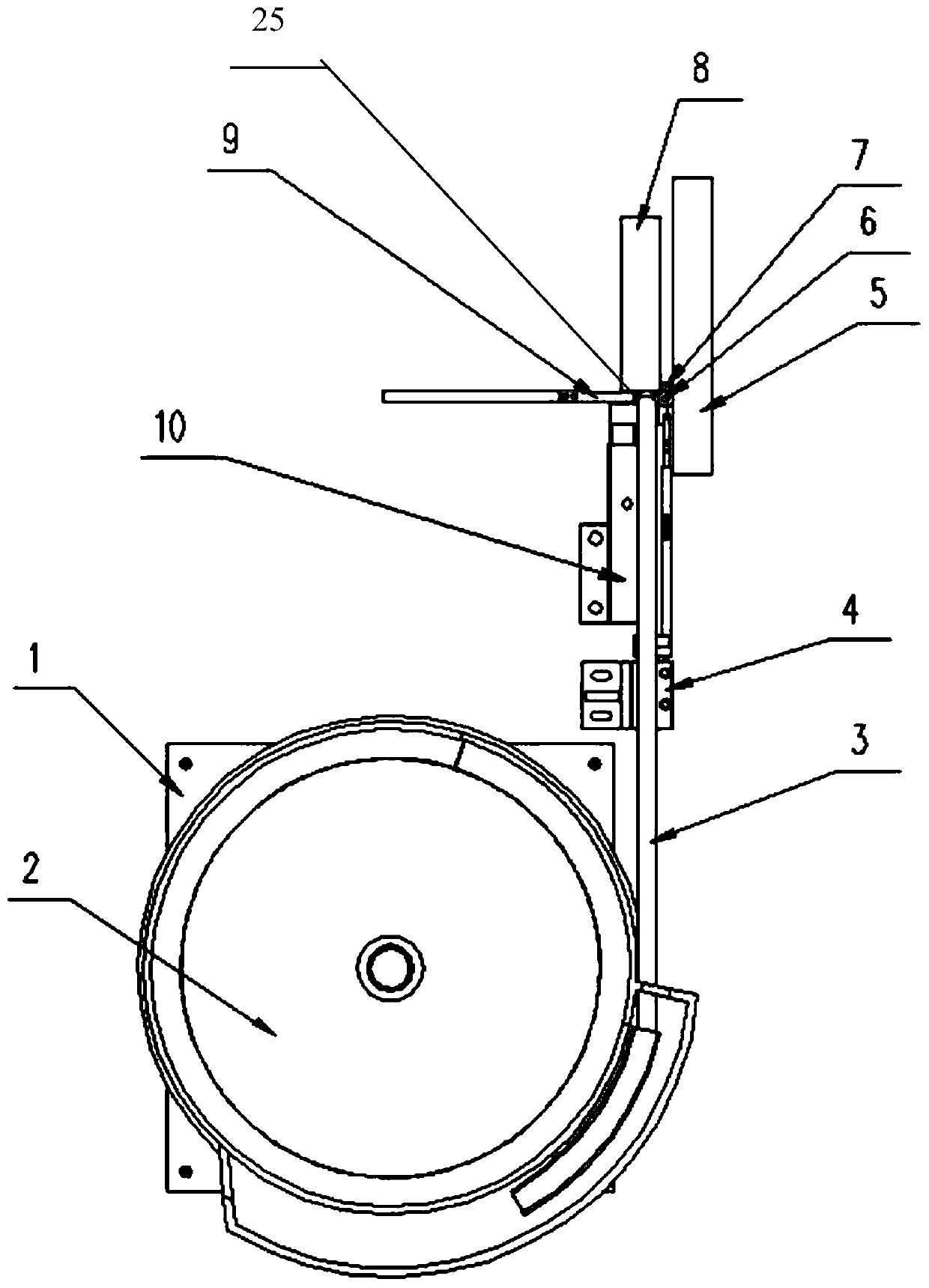

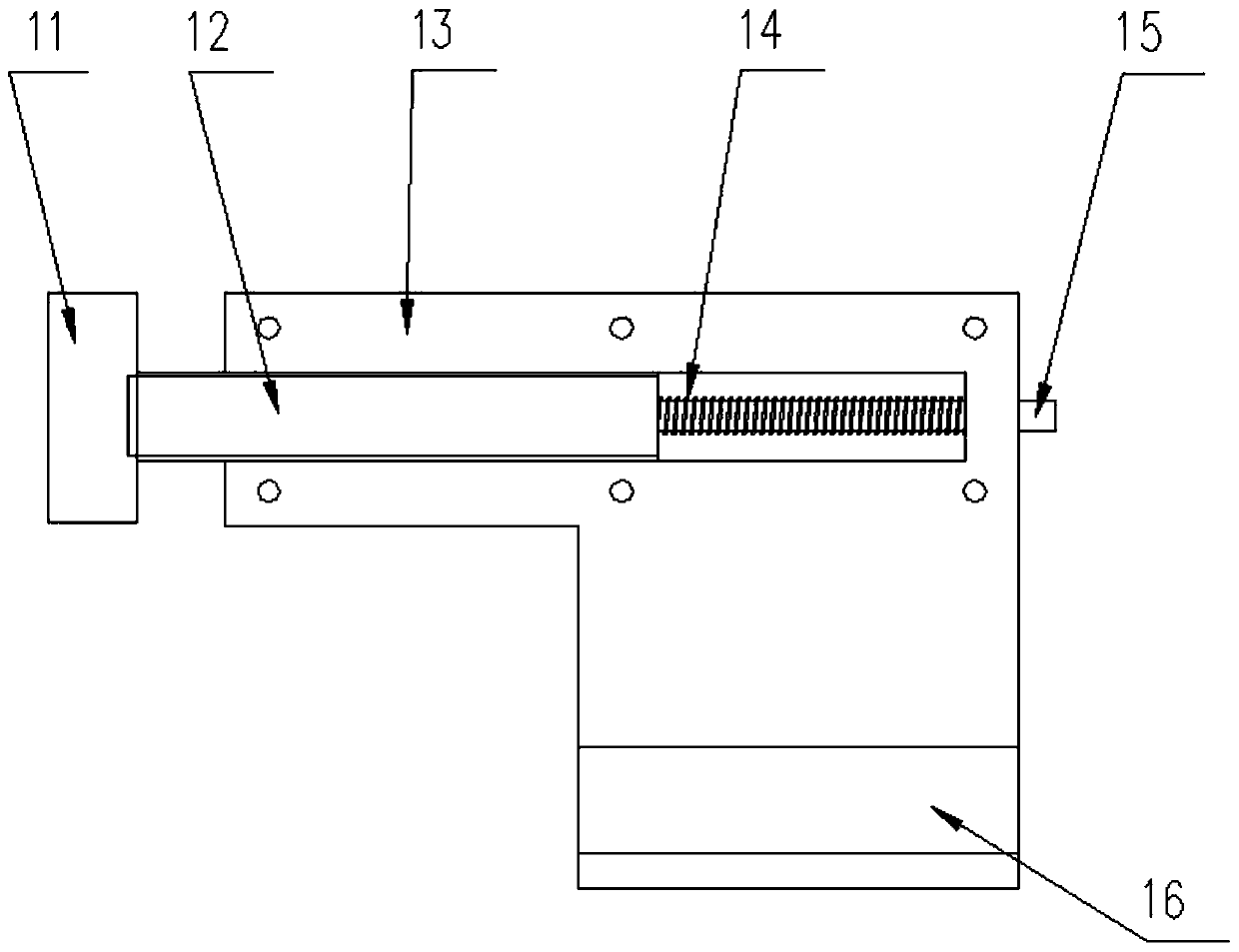

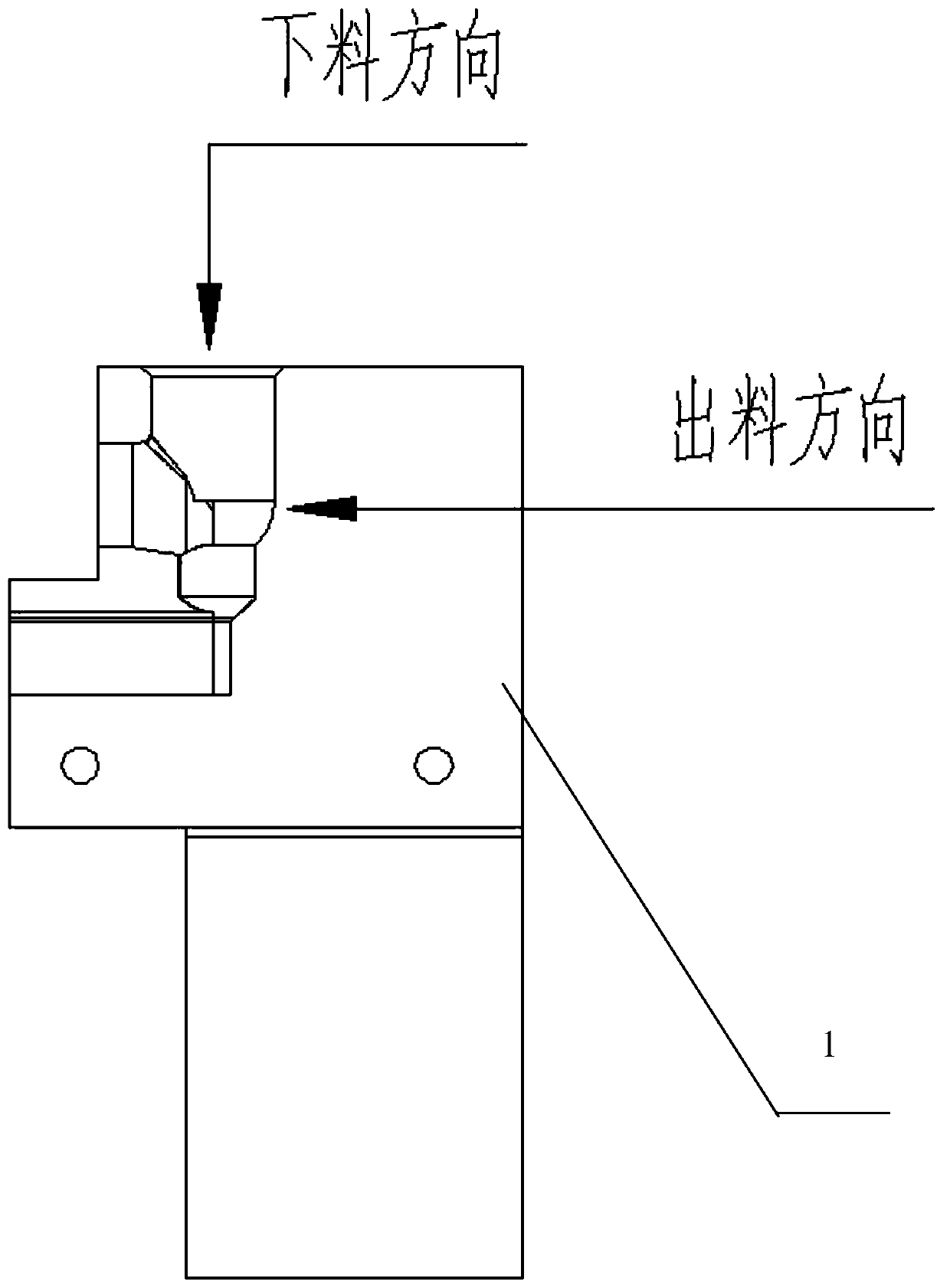

[0024] exist Figure 1 to Figure 6 In the schematic diagram of the present invention shown, a vibrating disc 2 is arranged on the vibrating disc frame body 1, the discharge port of the vibrating disc is connected with the elbow 3, the spherical surface to be processed 6 passes through the elbow, and the spherical surface is to be processed The bottom of the part is placed in the bracket 25, that is, the A position 26 in the bracket. The two side walls at the position of bracket A are arc-shaped surfaces, and the tightening mechanism 10 is placed on one side of the push plate 9 of the machine tool, and the tightening mechanism is fixed on the bed body. The tightening mechanism includes a tightening and fixing block 11 , a tightening and fixing block connecting plate 12 , a fixing frame 13 , a spring A14 , a spring connecting rod 15 and a fixing seat 16 . The tightening mechanism is arranged on one side of the push plate of the machine tool, and the fixing seat of the tightenin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com