Full-automatic polishing machine

A polishing machine, fully automatic technology, applied in surface polishing machine tools, grinding/polishing equipment, grinding/polishing safety devices, etc., can solve problems such as low production efficiency, inability to meet modern production, and high labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

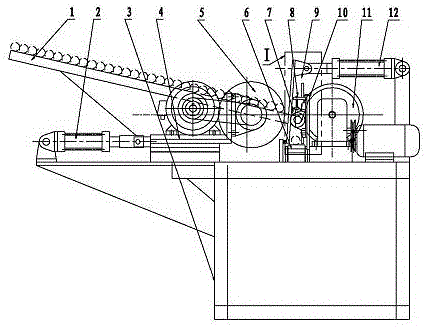

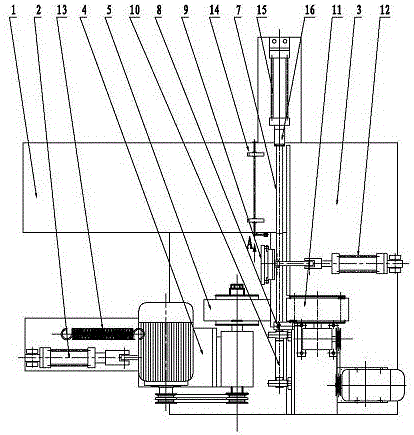

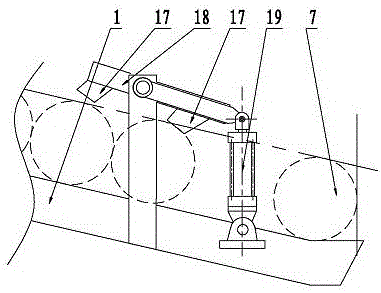

[0022] exist figure 1 and figure 2 In the full-automatic polishing machine shown, the frame 3 is a cuboid frame-shaped structural member made of steel, which is the basic component of the equipment. The frame 3 is rotatably supported with a clamping wheel 11, and the clamping wheel 11 Installed on the output shaft of the transmission box, the transmission box is fixedly installed on the frame, and the clamping wheel 11 is driven to rotate by the drive motor and the transmission box; on the frame 3, a polishing wheel is also radially supported relative to the clamping wheel 11 Seat 4, the polishing wheel seat 4 is movably supported on the frame 3 through the guide rail pair, the polishing wheel seat 4 is connected to the driving device 2 in transmission, the driving device 2 is a cylinder, and the two ends of the cylinder are respectively connected to the frame 3 and the polishing wheel seat 4 , between described polishing wheel seat 4 and frame 3, be connected with spring 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com