Clothing processing device

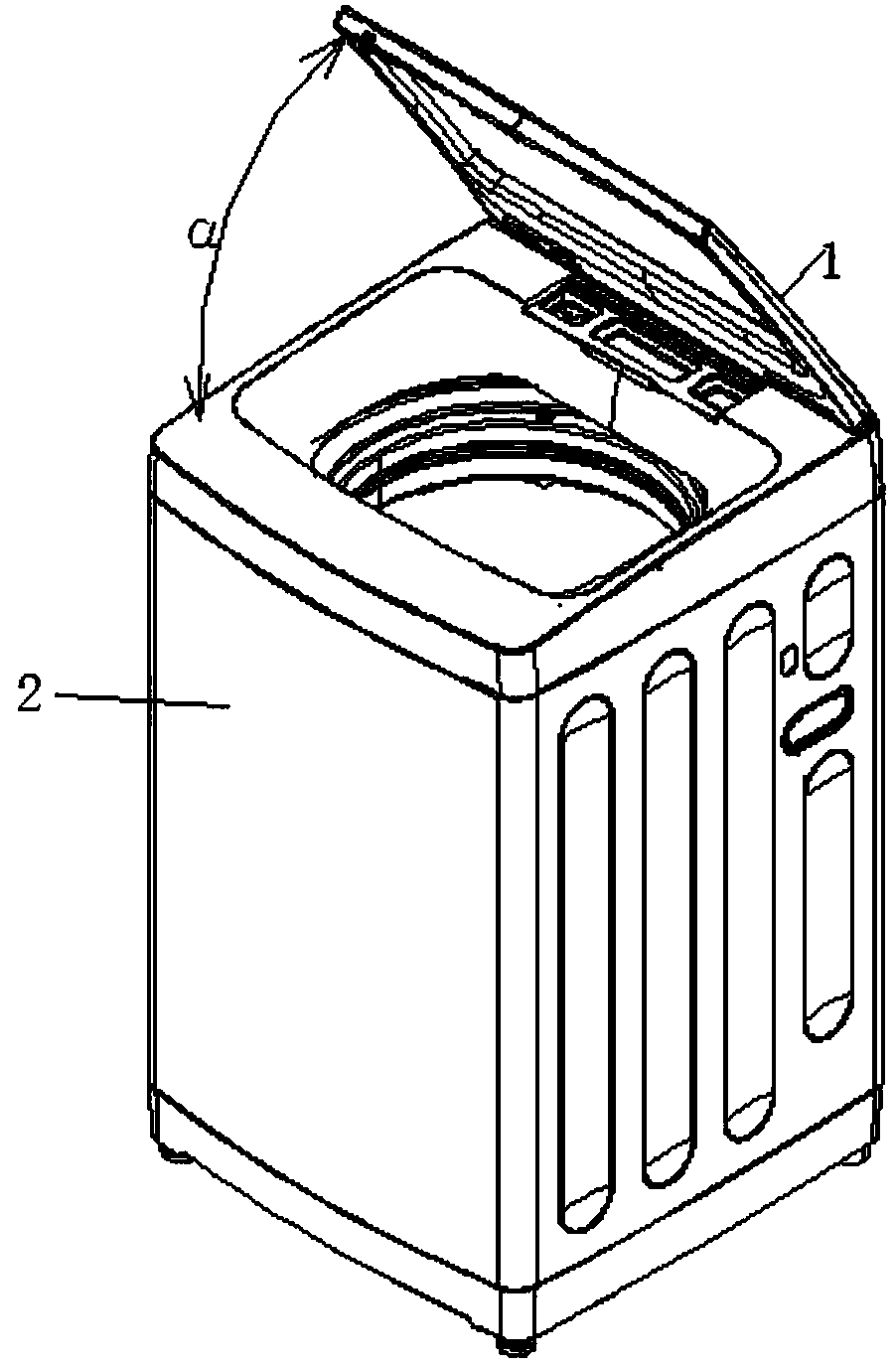

A technology of clothes processing device and damping device, which is applied in washing devices, other washing machines, textiles and paper making, etc. It can solve the problems that the door cover cannot be parked at any angle, the door cover has no power assistance, and is inconvenient to use, so as to achieve the goal of opening the door cover Easy, Reduced Strength, Visible Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

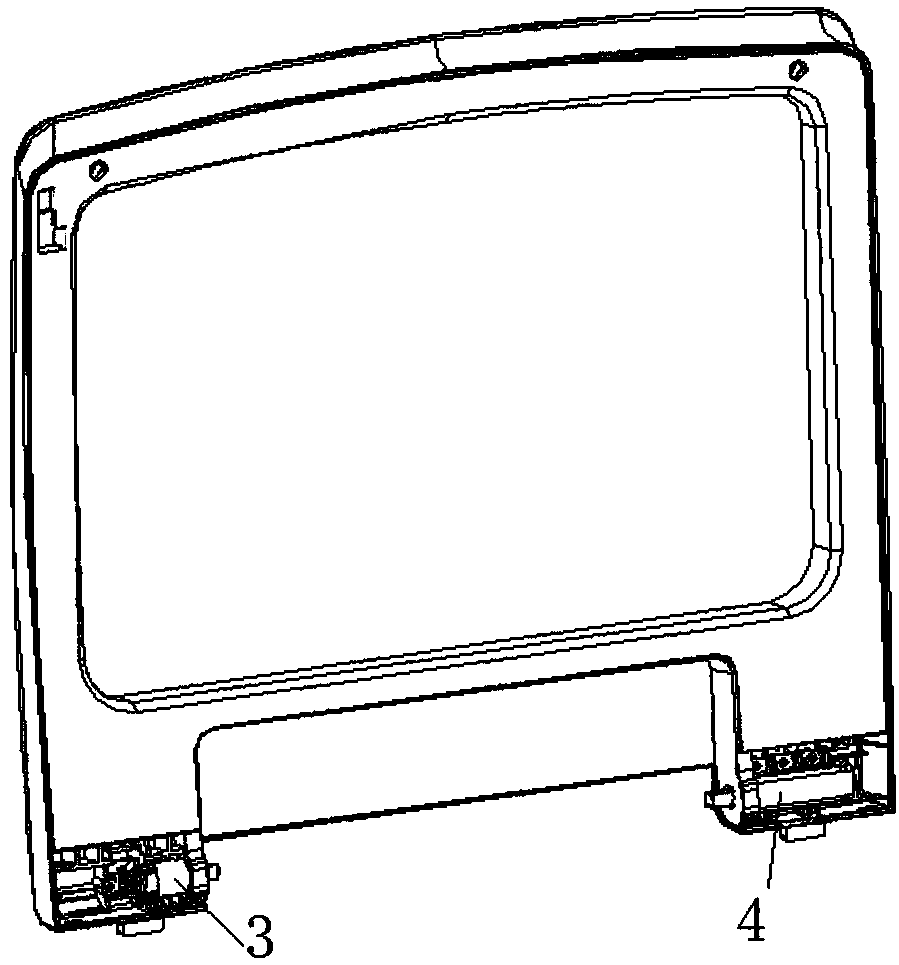

Embodiment 1

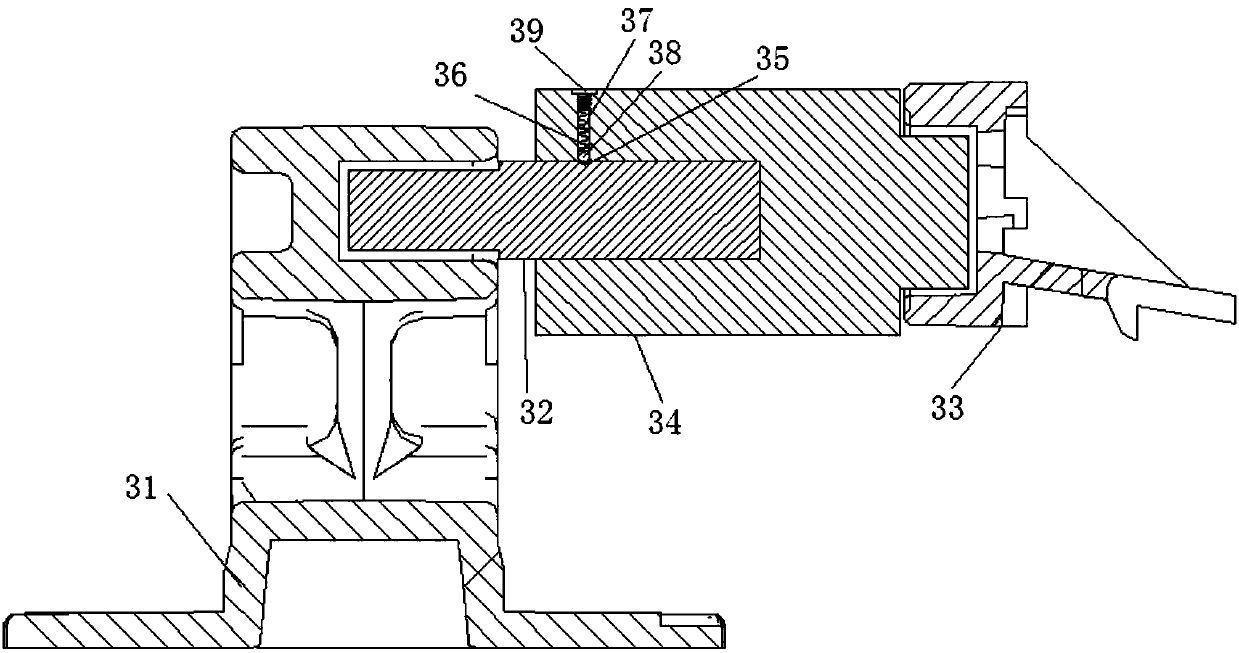

[0043] Such as image 3 , Figure 4 As shown, the damper device described in this embodiment includes a damper shell 33 and a damper 34 fixed in the damper shell 33, the damper shell 33 is provided with a limiting groove, the damper 34 is inserted into the limiting groove, and the damper 34 In the limit groove, no rotational movement of the shaft in the circumferential direction can be generated. The angle control part is the sinking groove 35 located on the circumferential surface of the first shaft 32 in contact with the damper 34. The sinking grooves 35 are evenly distributed on the first shaft 32, the more sinking grooves 35 there are, the more the door cover 1 can be positioned; The elastic member 37 located in the limiting hole 36, the limiting member 38 in contact with the elastic member 37 and the sinker 35, the blocking member 39 located at the end of the elastic member 37 away from the first shaft 32, a small part of the limiting member 38 It can be located in the ...

Embodiment 2

[0046] Such as Figure 5 , Figure 6 As shown, the damper device described in this embodiment includes a damper shell 33 and a damper 34 fixed in the damper shell 33, the damper shell 33 is provided with a limiting groove, the damper 34 is inserted into the limiting groove, and the damper 34 No rotational movement in the circumferential direction of the shaft can be generated in the limiting groove. The angle control part is the sinking groove 35 located on the end face of the first shaft 32 in contact with the damper 34. The sinking grooves 35 are evenly distributed on the first shaft 32 On the end face of the sinker groove 35, the more the number of sinking grooves 35, the more angles the door cover 1 can be positioned at; The elastic piece 37 in the hole 36, the stopper 38 that is in contact with the elastic piece 37 and the sink groove 35, the stopper 39 that is positioned at the end of the elastic piece 37 away from the first shaft 32, a small part of the stopper 38 can ...

Embodiment 3

[0049] When the user pushes the door cover 1 or presses the door cover 1, the force is greater than the preset value, the limit ball is squeezed, and the spring is compressed, leaving the sinking groove 35 and entering the adjacent sinking groove 35, as the force continues, the limit Ball constantly repeats this motion, until door cover 1 is opened to the position of predetermined angle, at this moment, spring recovers deformation, extrudes limit ball and enters sinker 35 again, realizes the parking of door cover 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com