Intelligent coal sample quantitative weighing device and method

A quantitative weighing and coal sample technology, applied in measuring devices, automatic feeding/discharging weighing equipment, weighing, etc., can solve the problems of accuracy and weighing efficiency to be improved, and achieve accurate, reliable and comprehensive Automatic intelligent quantitative weighing, high efficiency and precision, and high control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

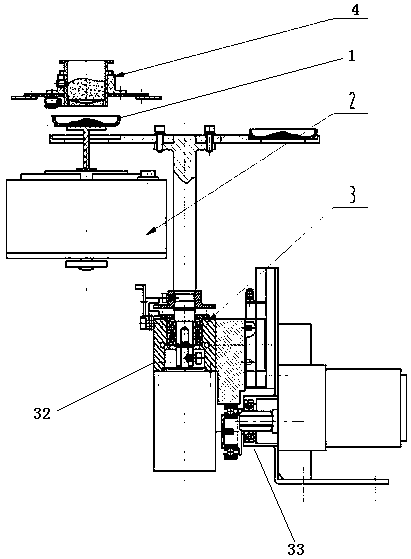

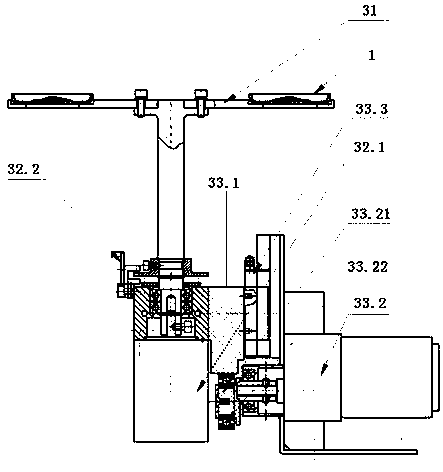

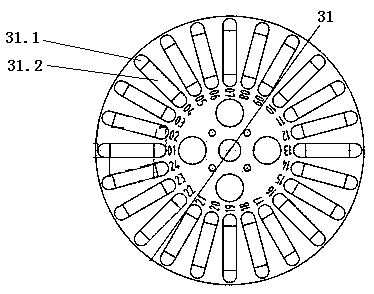

[0042] Combine below Figure 1 to Figure 6 Embodiments of the present invention are described in detail.

[0043] The intelligent coal sample quantitative weighing device includes a porcelain boat 1 for holding coal samples and a weighing component 2 for weighing the coal samples in the porcelain boat 1, and is characterized in that it also includes placing the porcelain boat 1 on the scale The lifting and rotating mechanism 3 that removes the porcelain boat 1 from the weighing assembly 2 and the vibrating sampling mechanism 4 that adds coal samples to the porcelain boat 1 by vibration. The vibrating sampling mechanism 4 is located on the scale Right above the heavy component 2, the ceramic boat 4 is placed on the weighing component 2 with the movement of the lifting and rotating mechanism 3, and receives the coal sample that vibrates and falls from the vibrating sampling mechanism 4. The weighing component 2, the lifting and rotating mechanism 3 and the vibration The sample ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com