Efficient inclined plate oil removal and sand settlement apparatus

A technology of inclined plate and sand settling, which is applied in the direction of settlement tanks, etc., and can solve problems such as high sand density, more oily dirt attached to sand particles, and complex structures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

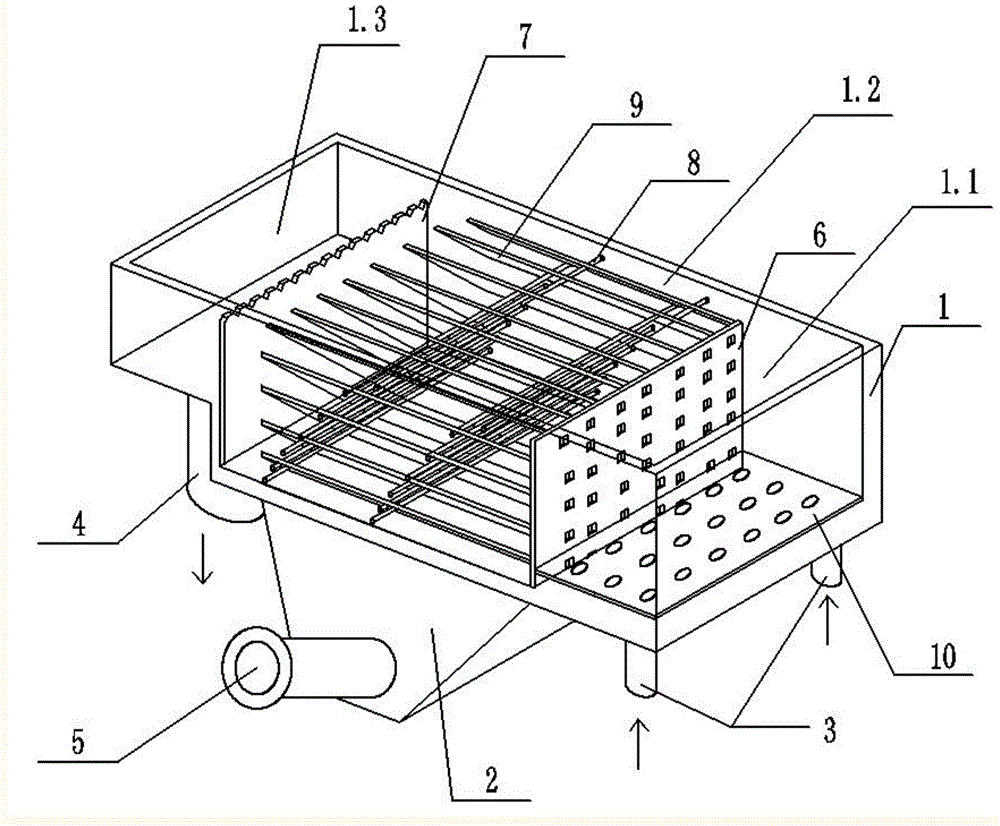

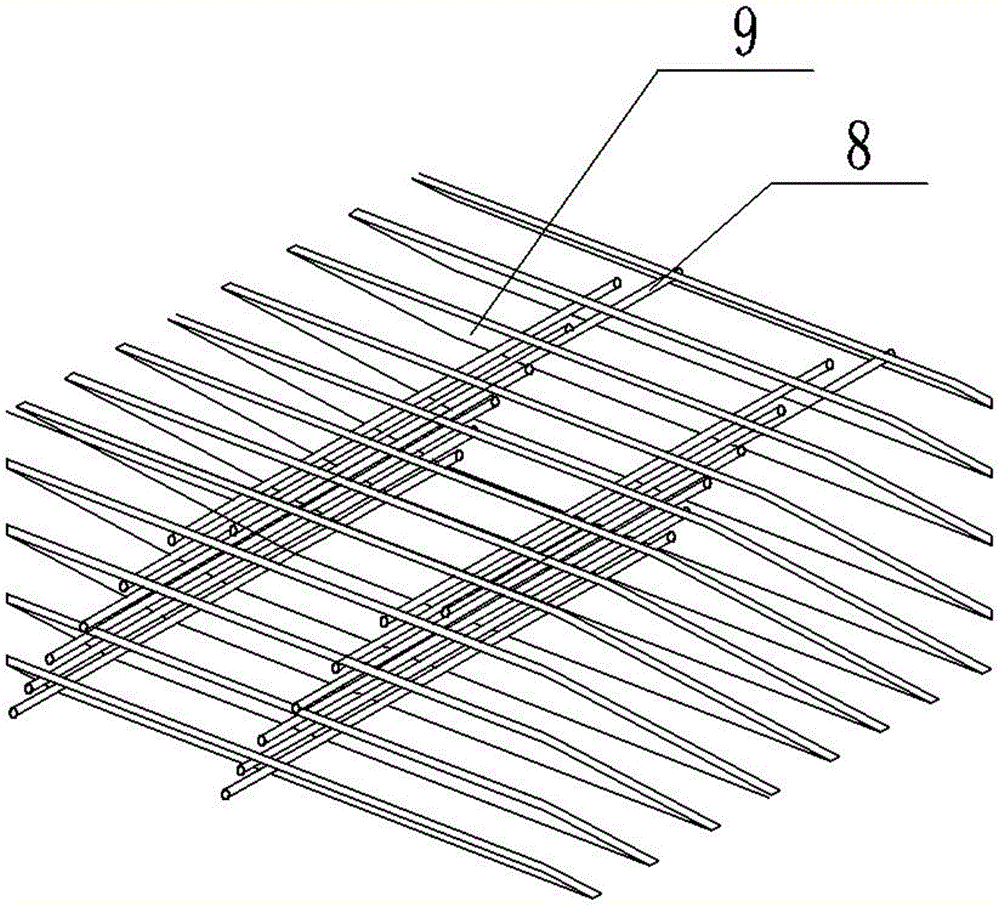

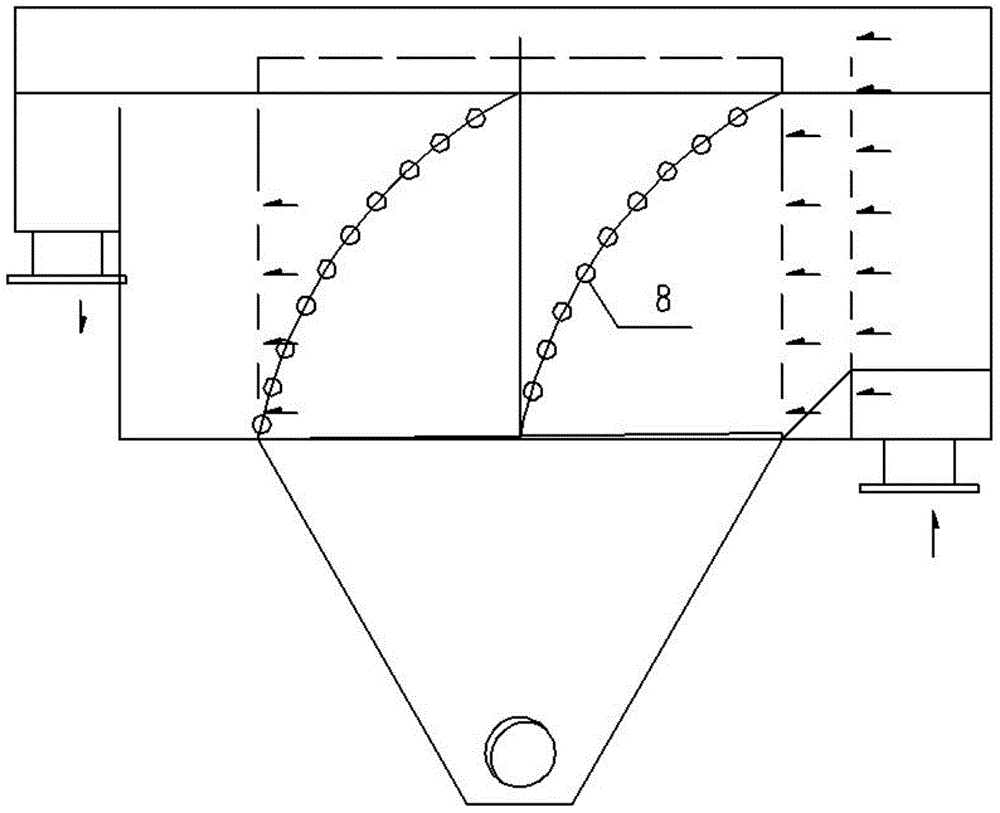

[0034] Taking the rapid sand-setting and oil-removing inclined plate device of the present invention as an example, the water inlet pipe enters the device from two 200mm water inlet pipes, and passes through the water inlet distribution weir with a length of 1800mm and a width of 1100mm. Water distribution square hole, the water evenly enters the inclined plate reaction zone. The special inclined plate is installed according to the horizontal angle of 50 degrees, and the distance between the two connected inclined plates is 60mm. The inclined plate is made of 0.5mm thick 316 steel plate. The vortex columns distributed according to the Archimedes spiral between the special inclined plates are connected in series. The sand particles in the water collide and rub against each other first in different directions and then in the same direction. In addition, under the action of hydraulic scouring, the oil film (organic matter) attached to the surface of the sand particles will be qui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com