Continuous precipitation separation inclined tube

A technology of sedimentation separation and sedimentation tube, applied in the direction of sedimentation separation, separation method, sedimentation tank, etc., can solve the problems of easily disturbed suspended sediment, affecting sedimentation effect, and high water treatment cost, achieving good effluent quality and improving sedimentation effect. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

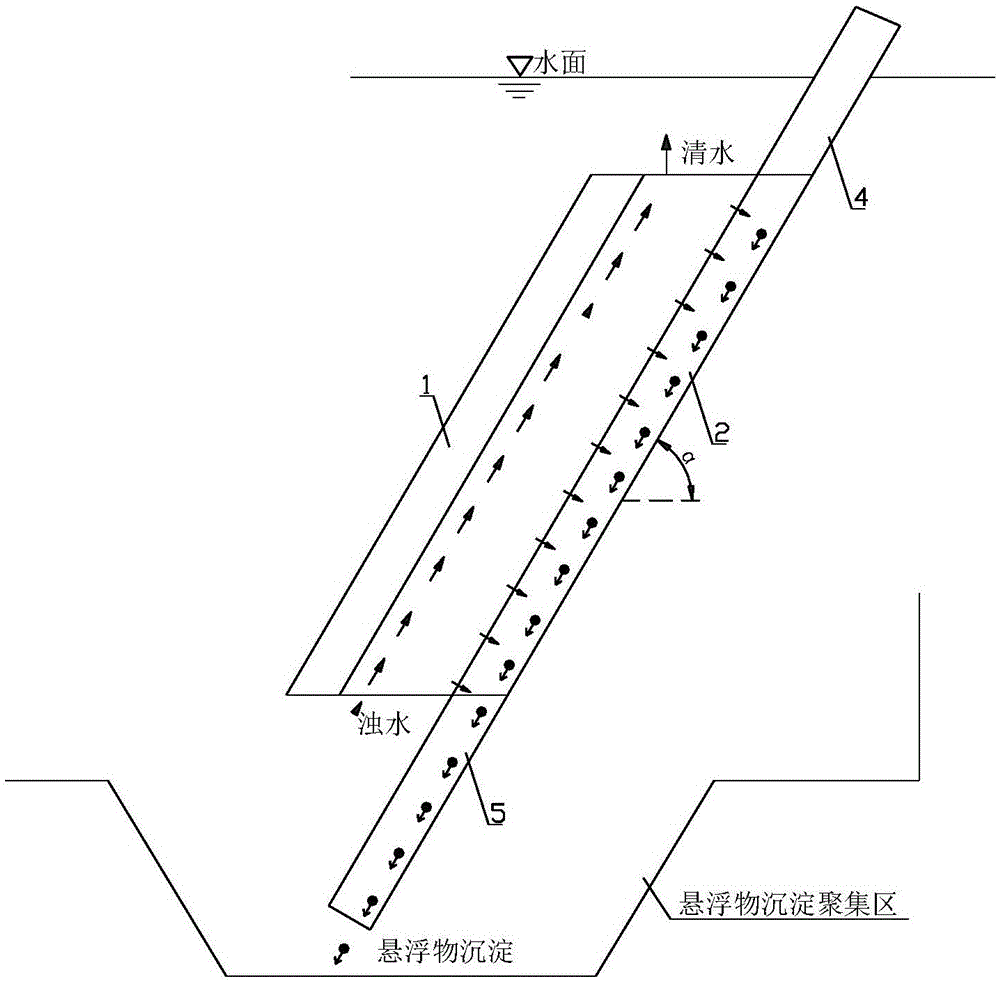

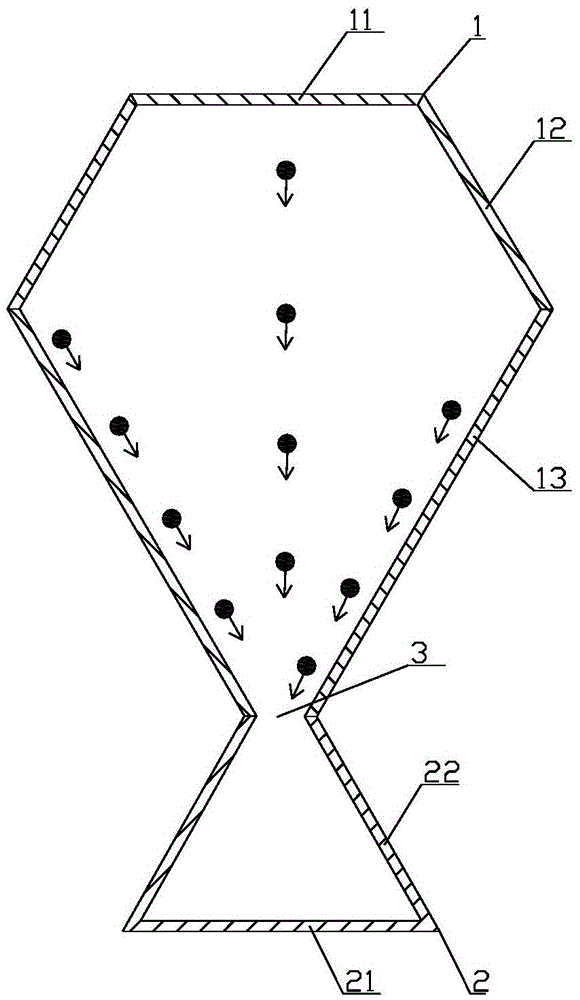

[0016] Such as figure 1 and figure 2 As shown, a continuous sedimentation and separation inclined tube, an inclined tube sedimentation and separation device, which includes a sedimentation pipe 1 and a sludge pipe 2 fixed side by side and parallel below the sedimentation pipe 1, and the sedimentation pipe 1 and the sludge pipe 2 are integrated. , easy to manufacture, low production cost; the inclined pipe main body 1 is placed obliquely in the sedimentation tank, the angle between the sedimentation pipe 1 and the horizontal plane is α, and α is 60°, and the water flows obliquely upward in the sedimentation pipe 1, and the water in the water flow Under the joint action of water flow and gravity, the suspended matter settles rapidly downward, which has the best sedimentation and separation effect; the side wall of the sedimentation pipe 1 and the mud pipe 2 is connected with the sedimentation pipe 1 and the mud pipe 2 The sliding mudway 3; the sliding mudway 3 separates the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com