Beverage bottle recovering device

A technology for recycling devices and beverage bottles, which is applied in garbage collection, household appliances, applications, etc., can solve the problem that the income of garbage classification has not been paid attention by the state, and achieve the effect of classification processing and collection, increasing recycling volume and reducing space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

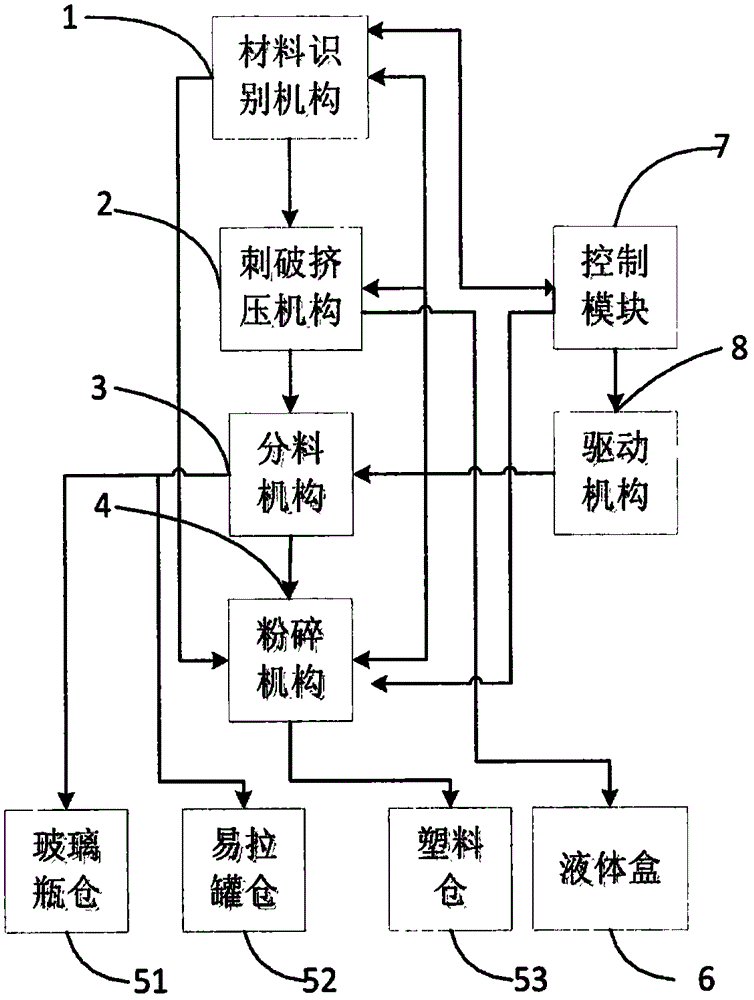

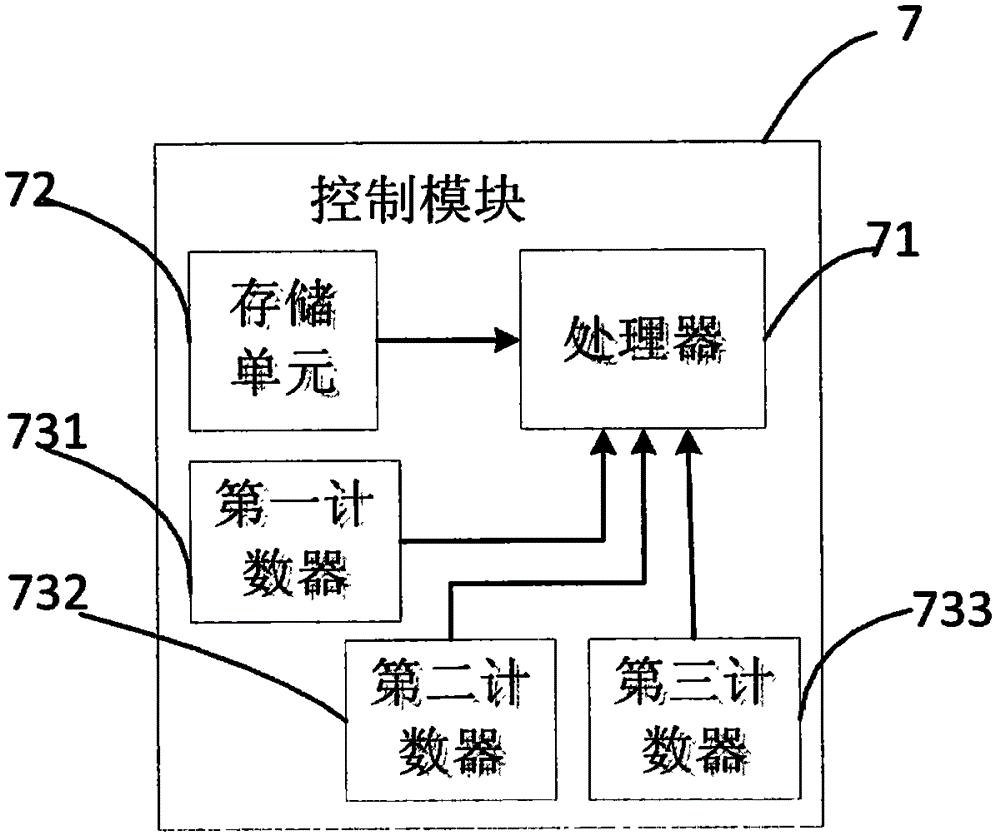

[0021] Please refer to figure 1 and image 3 , a beverage bottle recycling device, including a material identification mechanism 1, a piercing extrusion mechanism 2, a material distribution mechanism 3, a crushing mechanism 4, a glass bottle bin 51, a can bin 52, a plastic bin 53, a liquid box 6, and a control module 7 and drive mechanism 8.

[0022] The material identification mechanism 1 is respectively connected with the piercing and pressing mechanism 2 and the control module 7 . The piercing and extruding mechanism 2 is respectively connected with the distributing mechanism 3 and the crushing mechanism 4 . The material distribution mechanism 3 is respectively connected with the glass bottle compartment 51 and the can compartment 52 . The crushing mechanism 4 is respectively connected with the material distribution mechanism 3 , the plastic bin 53 and the control module 7 .

[0023] The liquid box 6 is communicated with the piercing and pressing mechanism 2 through a c...

Embodiment 2

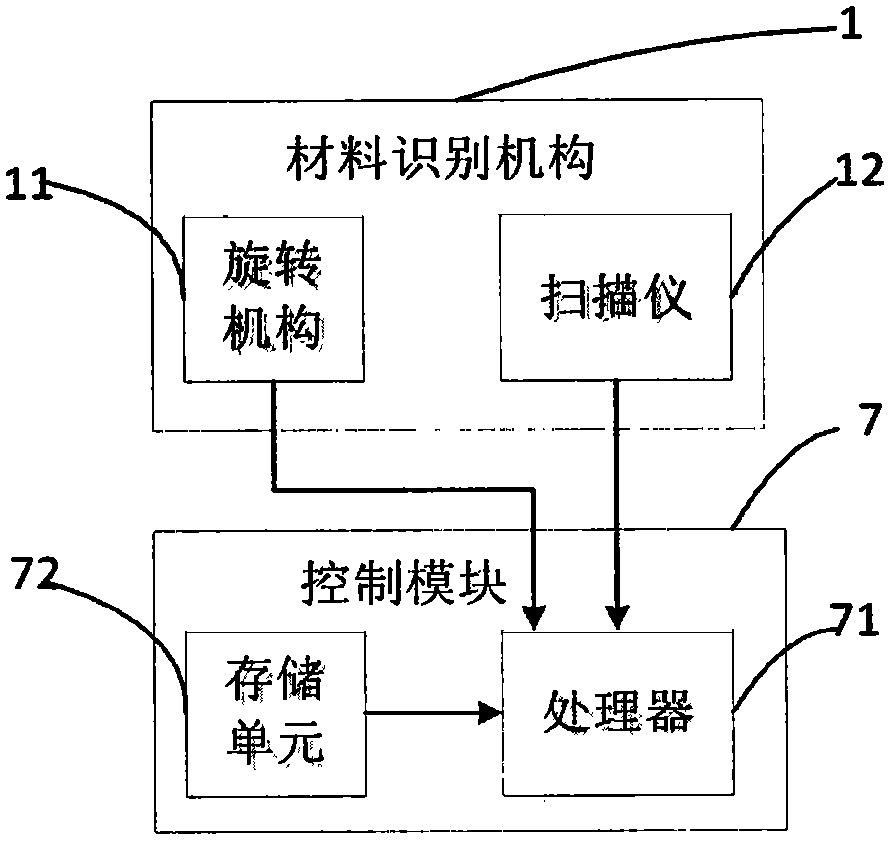

[0027] like figure 2 As shown, the difference between this embodiment and the first embodiment is that the material identification mechanism 1 of the beverage bottle recycling device is provided with a feed port that can be opened and closed, and the material identification mechanism 1 also includes a rotating mechanism 11 and a scanning device for scanning materials. Scanner 12 for identification information. The feed port is connected with the control module 7 . The rotating mechanism 11 is connected with the feed port and the driving mechanism 8, respectively. The driving mechanism 8 is used to drive the rotating mechanism 11 to rotate slowly. When the material rotates in the rotating mechanism 11, the scanner 12 scans the identification information of the rotating material, effectively realizing a comprehensive scanning of the material. In this embodiment, the bottom of the rotating mechanism 11 is provided with a trigger sensor connected to the control module 7, and th...

Embodiment 3

[0034] The difference between this embodiment and other embodiments is that the beverage bottle recovery device further includes a human body infrared sensor connected to the processor 71 , and the feed port of the material identification device 1 is provided with a discharge gate connected to the processor. The processor 71 is used to control the opening of the discharge gate while receiving the infrared sensing information of the human body infrared sensor, so as to realize that when a person approaches the beverage bottle recovery device, the beverage bottle recovery device can run safely; and the infrared sensing information sent by the human body infrared sensor is: The continuous information and its duration is the time when the human body infrared sensor senses the human body infrared information, that is, after the human body infrared sensor cannot sense the human body infrared information, the human body infrared sensor will no longer send the infrared sensing informati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com