Device for producing fuel oil and gas by thermolysis of waste toner cartridge carbon powder

A toner cartridge and fuel oil technology, which is applied in the field of solid waste recycling, can solve the problems of focusing on the recycling and collection of waste toner cartridges, the hazard of waste toner cartridges is not considered, and the quality of industrial toners varies. Achieve significant economic and environmental benefits, fill the gaps in resource-based treatment technology, and achieve fast pyrolysis reaction rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

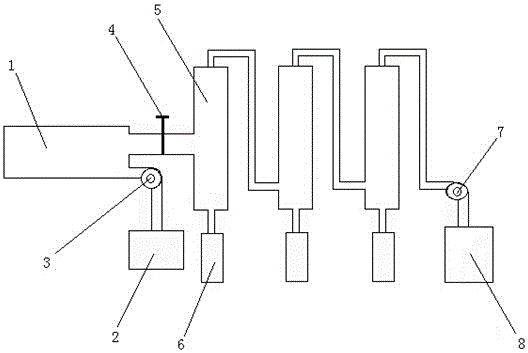

[0048] Example 1 A device for producing fuel oil and gas by pyrolysis of waste toner cartridge toner

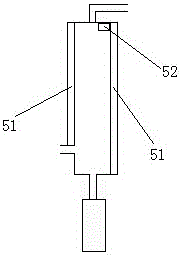

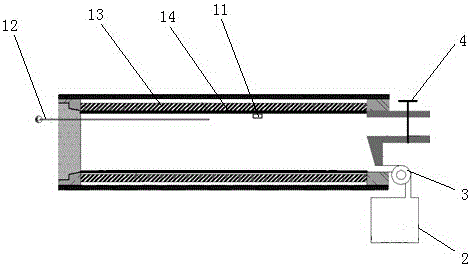

[0049] A device for producing fuel oil and gas by pyrolysis of waste toner cartridge toner, including a pyrolysis reactor (1), a solid residue storage tank (2), a powder suction pump (3), a valve (4), a condenser (5), Oil storage tank (6), vacuum pump (7), non-condensable gas collecting cylinder (8); the solid residue storage tank (2) is connected to the lower end of the pyrolysis reactor (1), and the powder suction pump (3 ) is set on the pipeline between the solid residue storage tank (2) and the pyrolysis reactor (1); the upper end of the pyrolysis reactor (1) is connected to the condenser (3) through the oil and gas delivery pipe, and the valve (4 ) is set on the oil and gas delivery pipe between the pyrolysis reactor (1) and the condenser (5); the oil storage tank (6) is connected to the bottom of the condenser (5), and the gas collection bottle (8) passes through the ...

Embodiment 2

[0050] Example 2 A device for producing fuel oil and gas by pyrolysis of waste toner cartridge toner

[0051] A device for producing fuel oil and gas by pyrolysis of waste toner cartridge toner, including a pyrolysis reactor (1), a solid residue storage tank (2), a powder suction pump (3), a valve (4), a condenser (5), Oil storage tank (6), vacuum pump (7), non-condensable gas collecting cylinder (8); the solid residue storage tank (2) is connected to the lower end of the pyrolysis reactor (1), and the powder suction pump (3 ) is set on the pipeline between the solid residue storage tank (2) and the pyrolysis reactor (1); the upper end of the pyrolysis reactor (1) is connected to the condenser (3) through the oil and gas delivery pipe, and the valve (4 ) is set on the oil and gas delivery pipe between the pyrolysis reactor (1) and the condenser (5); the oil storage tank (6) is connected to the bottom of the condenser (5), and the gas collection bottle (8) passes through the ...

Embodiment 3

[0061] Example 3 Method for producing fuel oil and gas by pyrolysis of waste toner cartridge toner

[0062] The method for producing fuel oil and gas by pyrolysis of waste toner cartridge toner, that is, the use method of pyrolysis of waste toner cartridge toner to produce fuel oil and gas is as follows:

[0063] S1. First, send the waste toner cartridge toner into the pyrolysis reactor (1), and dry it under normal pressure, specifically at 120°C, for 40 minutes;

[0064] S2. Then use the vacuum pump (7) to evacuate the pyrolysis reactor to a vacuum state (at this time, ensure that all the carbon powder remains in the pyrolysis reactor), and the vacuum degree reaches 10 -3 Pa; then use silicon molybdenum rods for heating, and the heating rate is 15°C / min;

[0065] Drying, vacuuming, and heating are carried out in sequence;

[0066] S3. The dried carbon powder is subjected to high-temperature anaerobic pyrolysis reaction under high vacuum and temperature not lower than 600 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com