Method for simultaneously preparing phenol-rich biomass oil and biomass charcoal for adsorbing heavy metal ions by microwave pyrolysis of poplar sawdust

A technology for adsorbing heavy metals and biomass oil, which is applied in the field of comprehensive utilization of resources, can solve the problems of low resource utilization, only consider or ignore the comprehensive utilization of biomass oil and biomass carbon, etc., to achieve recycling, clean performance, and The effect of alleviating the pressure on resources and the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1: A kind of method of microwave pyrolysis poplar sawdust simultaneously prepares the biomass oil rich in phenol and is used for absorbing the biochar of heavy metal ion, concrete steps are as follows:

[0026] (1) Poplar sawdust was crushed, placed in a nitrogen atmosphere at 400°C for 30 minutes to obtain pyrolysis gas and pyrolysis solids, and the pyrolysis solids were cooled to obtain biochar; the microwave power was 1500W, and the nitrogen flow rate was 300 mL / min;

[0027] (2) Pass the pyrolysis gas in step (1) into a condensation pipe connected to a circulating condensation pump at a temperature of -5°C to quickly condense and separate to obtain liquid biomass oil and biomass gas fuel;

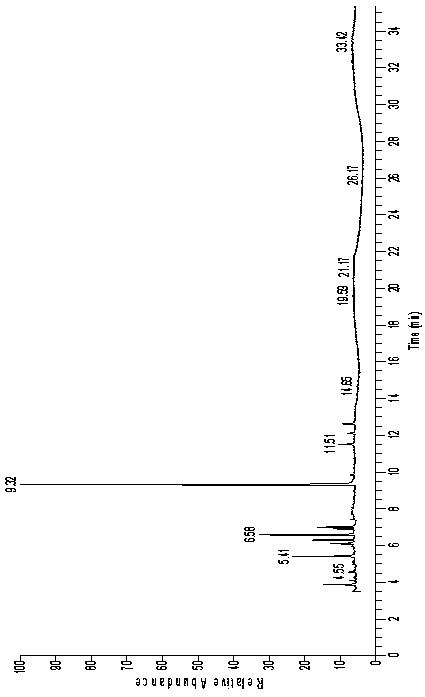

[0028] The GC-MS collection of illustrative plates of present embodiment biomass oil composition sees figure 1 ,from figure 1 It can be seen that the peak value of biomass oil is less, which means that there are fewer components, which highlights the advantages of mi...

Embodiment 2

[0031] Embodiment 2: A kind of method of microwave pyrolysis poplar sawdust simultaneously prepares the biomass oil rich in phenol and is used for absorbing the biochar of heavy metal ion, and concrete steps are as follows:

[0032] (1) Poplar sawdust was crushed, placed in a nitrogen atmosphere at a temperature of 500°C for 45 minutes to microwave pyrolysis to obtain pyrolysis gas and pyrolysis solids, and the pyrolysis solids were cooled to obtain biochar; the microwave power was 1000W, and the nitrogen flow rate was 200mL / min;

[0033] (2) Pass the pyrolysis gas in step (1) into a condensation pipe connected to a circulating condensation pump at a temperature of -1°C to quickly condense and separate to obtain liquid biomass oil and biomass gas fuel;

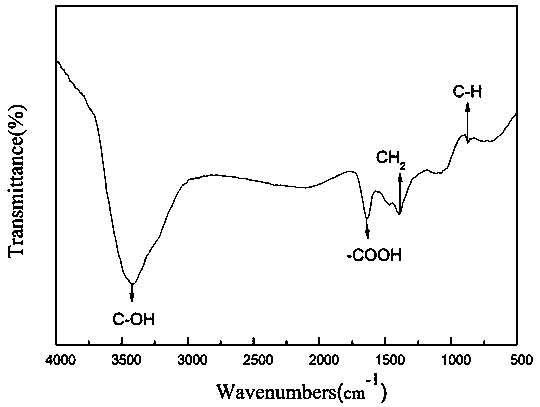

[0034] In this embodiment, the content of phenol in the liquid biomass oil is 49.05%, and CO and H in the biomass gaseous fuel are measured by gas chromatography. 2 The total volume content of biochar is 57.19%, and the spec...

Embodiment 3

[0036] Embodiment 3: A kind of method of microwave pyrolysis poplar sawdust simultaneously prepares the biomass oil rich in phenol and is used for absorbing the biochar of heavy metal ion, and concrete steps are as follows:

[0037] (1) Poplar sawdust was crushed and placed in a nitrogen atmosphere at 600°C for microwave pyrolysis for 60 minutes to obtain pyrolysis gas and pyrolysis solids, and the pyrolysis solids were cooled to obtain biochar; the microwave power was 2000W, and the nitrogen flow rate was 400mL / min;

[0038] (2) Pass the pyrolysis gas in step (1) into a condensation pipe connected to a circulating condensation pump at a temperature of -3°C to quickly condense and separate to obtain liquid biomass oil and biomass gas fuel;

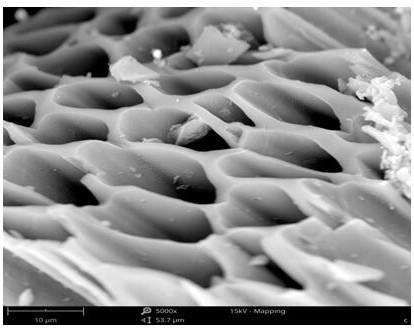

[0039] The scanning electron micrograph of the present embodiment biochar is shown in image 3 ,from image 3It can be seen that the surface of biomass charcoal under this pyrolysis condition is smooth and has uniform pores;

[0040] T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com