Winnowing screening device for waste power battery

A power battery and wind screening technology, which is used in battery recovery, separation of solids from solids by airflow, and sieving, etc., to reduce environmental pollution, save processing time, and save labor and material costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

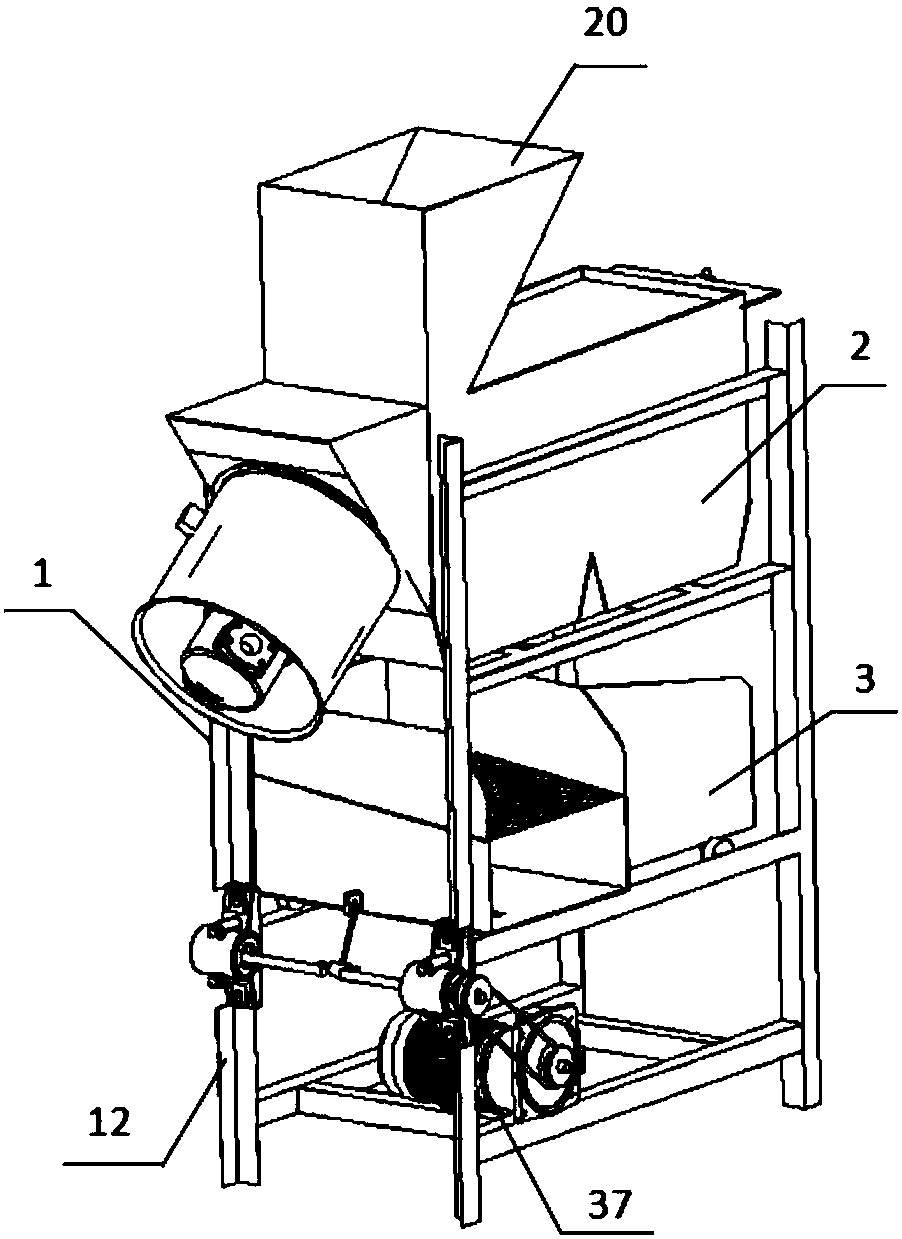

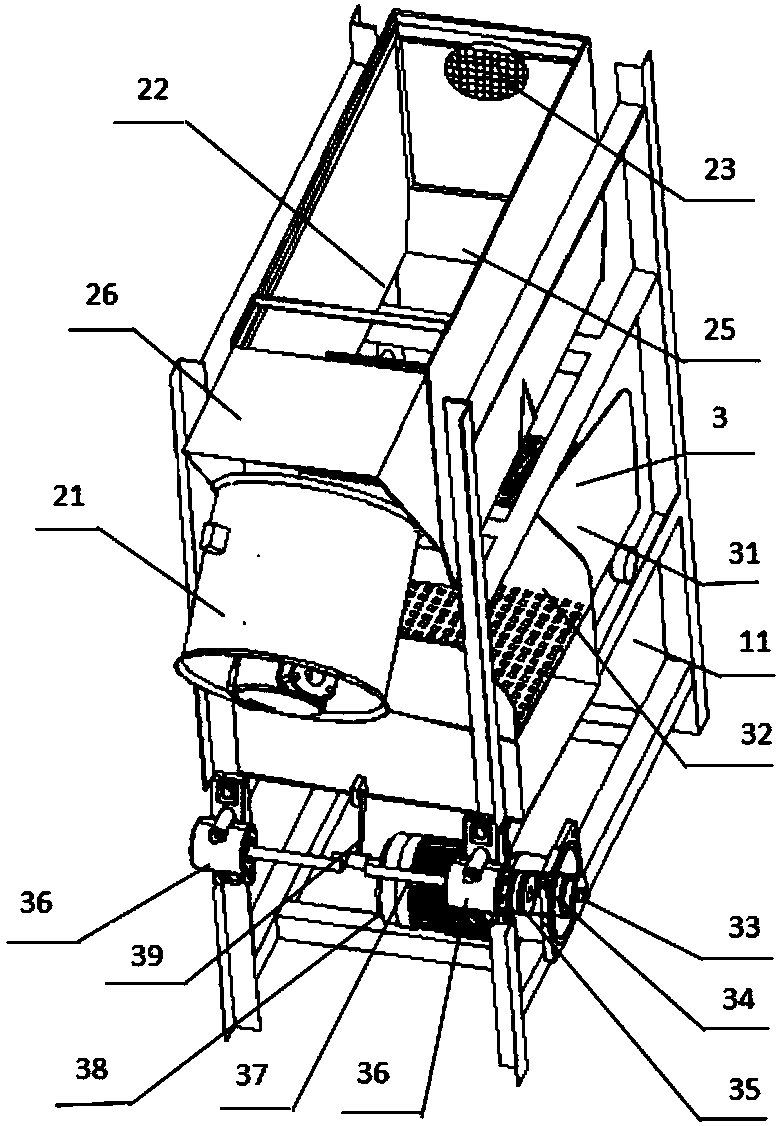

[0032] see figure 1 with figure 2 , a winnowing and screening device for waste power batteries, comprising a frame 1, a winnowing device 2 and a layered screen 3, the layered screen 3 comprising a light material layered screen 31, a heavy material layered screen 32 and a transmission device, the frame 1 is a frame welded by angle iron, and is divided into upper, middle and lower layers, the upper layer is equipped with a wind separation device 2, the middle layer is installed with a light material layered screen 31 and a heavy material layered screen 32, and the lower layer is installed transmission.

[0033] The middle layer of the frame 1 is provided with two rails 11, and four pulleys 311 are arranged on the lower side of the layered screen 31, and the four pulleys 311 are arranged on the left and right sides of the layered screen 31 moving direction, and the two pulleys on each side 311 slides on track 11.

[0034]The transmission device includes a motor pulley 33 , a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com