Cooling table charging automatic control device and method

An automatic control device and cooling bed technology, applied in cooling bed, metal rolling, manufacturing tools, etc., can solve the problem of insufficient utilization of the cooling bed area, achieve labor saving and economic benefits, high execution efficiency, data management and analysis convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

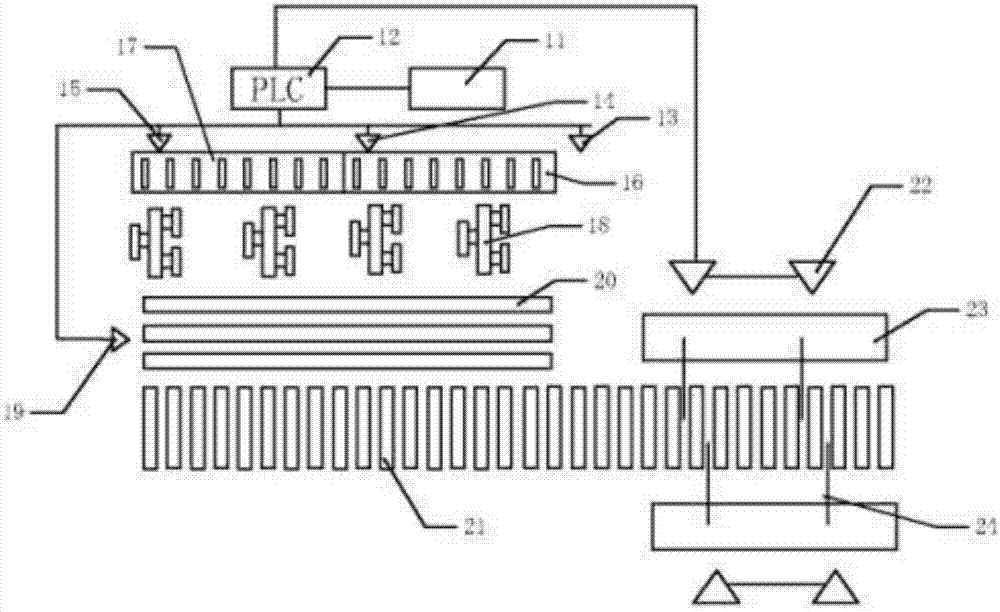

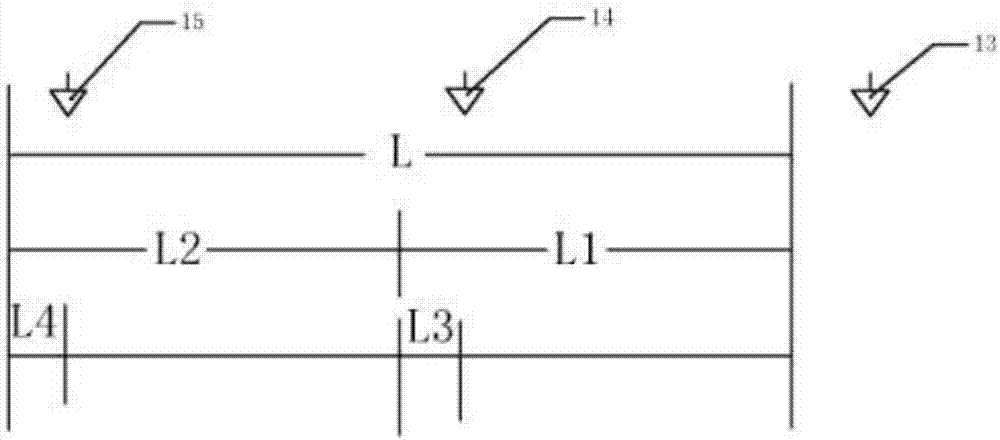

[0030] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0031] The reference signs in the accompanying drawings of the specification include:

[0032] Industrial computer 11, PLC control system 12, first hot metal detector 13, second hot metal detector 14, third hot metal detector 15, steel roller table on the first cooling bed 16, steel roller table on the second cooling bed 17 , Transition wheel 18, cooling bed detection proximity switch 19, cooling bed 20, cooling bed blanking roller table 21, cold metal detector 22, finished product collection tank 23, steel dialing device 24.

[0033] Such as figure 1 In the shown cooling bed feeding automatic control device, the steel roller table on the cooling bed and the cooling bed feeding roller table 21 are respectively installed on the front side and the rear side of the cooling bed 20, and the steel roller table on the cooling bed is evenly divide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com