Continuous collecting and winding device for woven fabrics in stentering and setting machine

A technology of a stenter setting machine and a winding device, which is applied in the directions of winding strips, transportation and packaging, thin material processing, etc., which can solve problems affecting the work efficiency of weaving production and troublesome operation, so as to improve convenience and avoid Noise pollution, the effect of ensuring work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

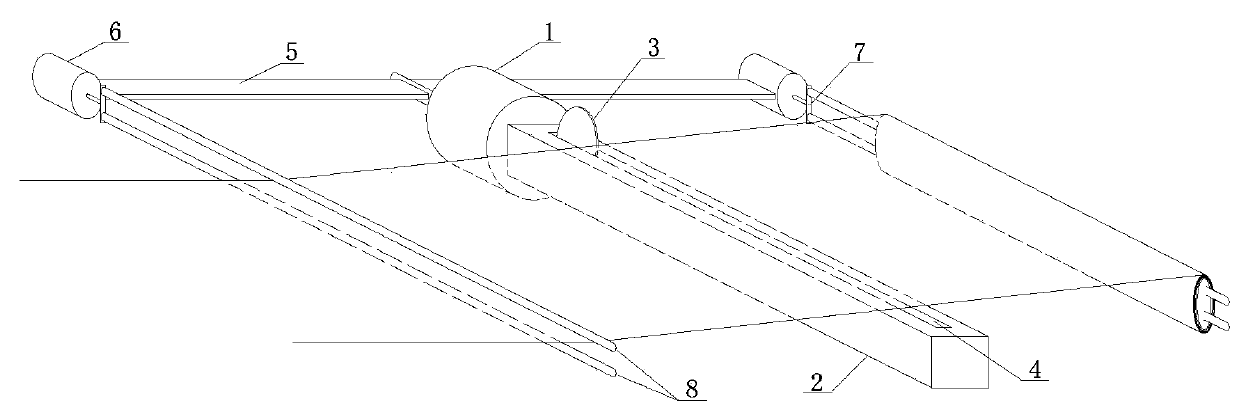

[0018] The present invention has designed a kind of weaving cloth continuous collection and winding device in the stenter setting machine, such as figure 1 As shown, it specifically includes a main rotating motor 1, a linear guide rail box 2, an electronically controlled rotary cutter head 3, and two sets of winding storage devices.

[0019] Wherein, one of the ends of the linear guide rail box 2 is fixedly connected with the main rotating motor 1 body, and the straight line where the linear guide rail box 2 is located is collinear with the straight line where the rotating shaft on the main rotating motor 1 is located, and the main rotating motor 1 rotates The shaft and the linear guide box 2 are respectively set on both sides of the main rotating motor 1 body; on one side of the linear guide box 2, a chute 4 is arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com