Method and device for determining length of gasification working face in underground coal gasification process

An underground gasification and working face technology, applied in coal gasification, underground mining, earth drilling and mining, etc., can solve the problem of difficulty in the length of the gasification working face, and achieve simple and easy realization, good monitoring and operation processing, The Effect of Increasing the Content of Effective Components in Gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

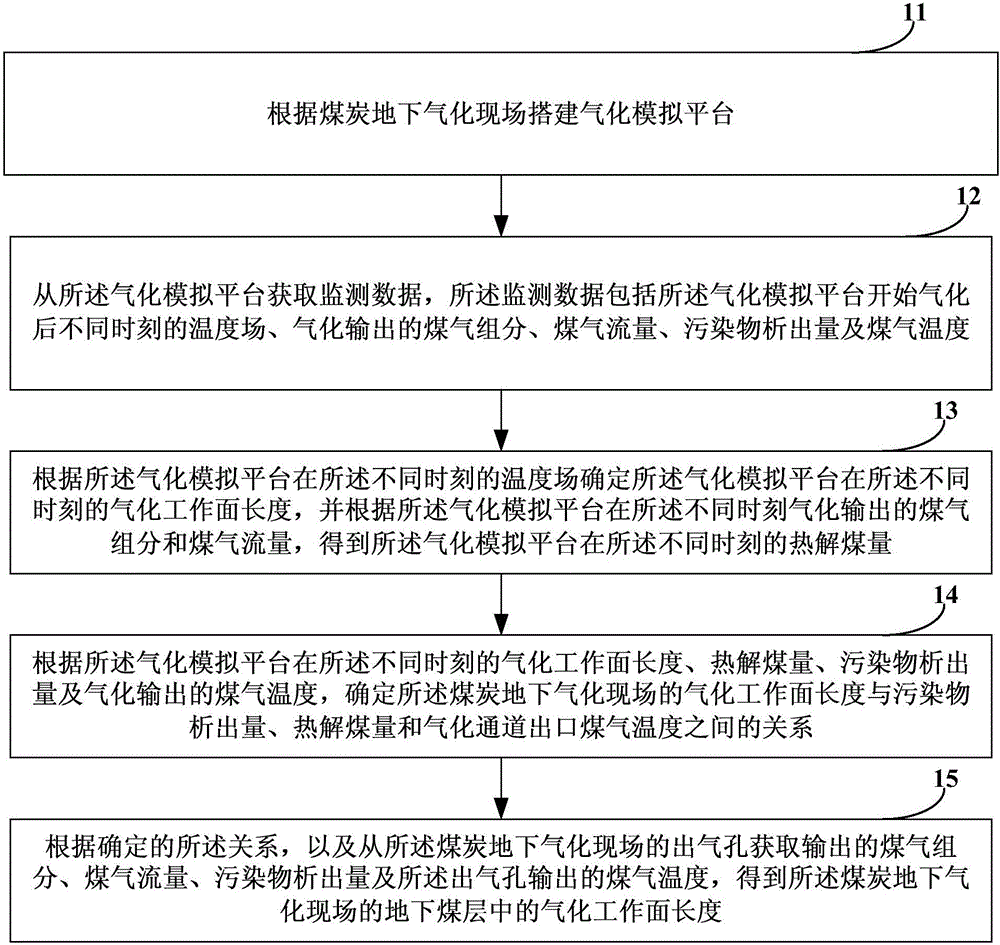

[0029] see figure 1 The method for determining the length of the gasification working face in the underground coal gasification process provided by the embodiment of the present invention may include step 11 to step 15.

[0030] In step 11, a gasification simulation platform is built according to the underground coal gasification site.

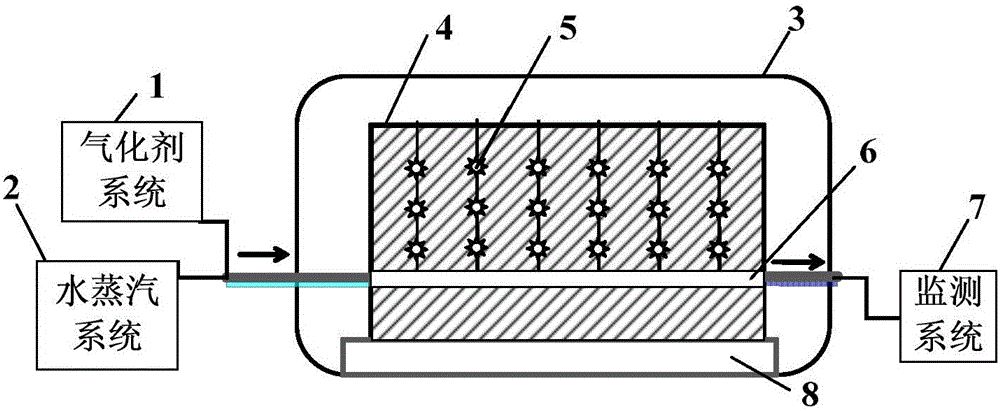

[0031] Wherein, the gasification simulation platform may include a simulated coal seam, a gasification channel, a temperature sensor, a gasification agent system, a water vapor system, and a monitoring system, and the coal in the simulated coal seam comes from the underground coal seam of the underground coal gasification site , the gasification channel and the temperature sensor are arranged in the simulated coal seam, the first end of the gasification channel is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com