Leaf removing, skin cutting and stalk scraping type straw skin-stalk separation device and method

A technology for separating device and straw, which is applied in optical device exploration, cutting equipment, transportation and packaging, etc. It can solve the problems of incomplete separation of straw, low production capacity and poor separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

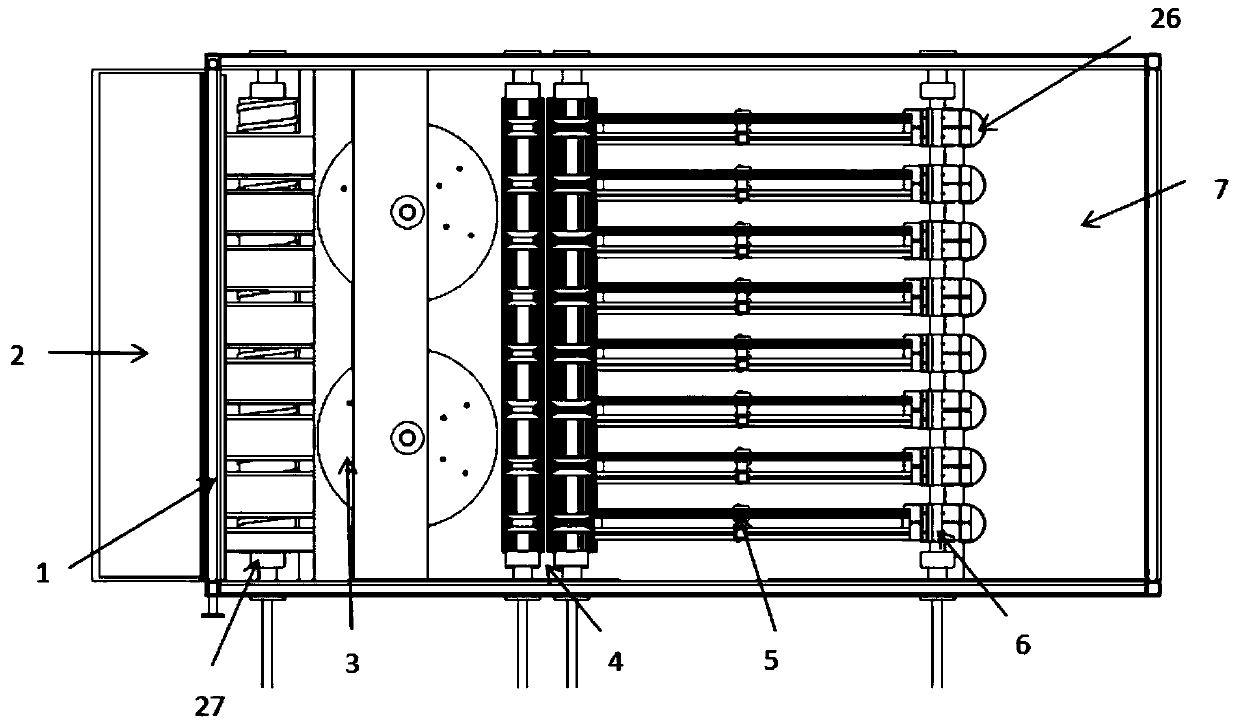

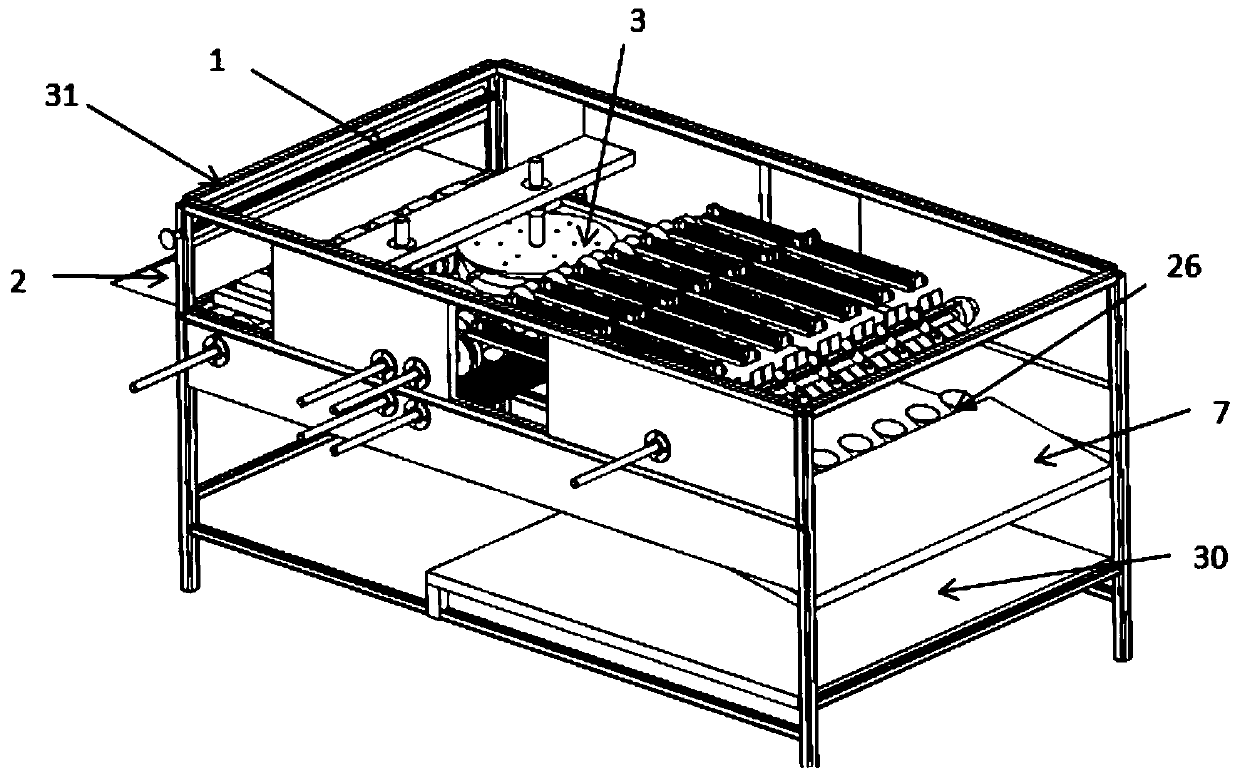

[0088] Example 1: see Figure 1-2 , In the present embodiment, a deleafing, peeling, and scraping type straw husk separation device includes a feeding device, a defoliation device, a positioning and cutting device, a clamping device, a scraping device, and a collecting device; the feeding device , the leaf removing device 3, the positioning and cutting device 4, the clamping device 5, and the scraping device 6 are sequentially installed on the frame 31; the collecting device is installed on the frame and is located under the scraping device 6; the feeding device uses The straw is fed into the defoliation device 3; the defoliation device 3 is used for straw defoliation, tearing the straw blades, tearing off the leaves, and sending the straw into the positioning and cutting device 4; The positioning and cutting device 4 is used for positioning and cutting the straw, longitudinally cutting the straw, and sending the straw into the clamping device; the clamping device 5 is used fo...

Embodiment 2

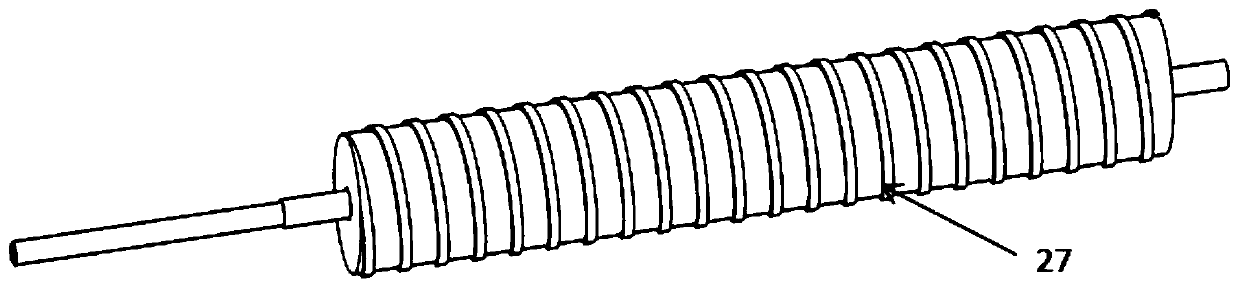

[0089] Example 2: see Figure 1-4 , the difference between this embodiment and Embodiment 1 is that the straw husk and rang separation device also includes a turning mechanism 1, which is installed on the frame 31 and located above the feeding table 2, including a turning shaft and a turning shaft installed on the turning shaft. on the flip plate. When encountering straw with a large cross-section, the straw can be pushed into the separation device through the turning mechanism 1. The purpose of setting the turning mechanism 1 at the feeding table is to facilitate the feeding of the straw; the feeding device includes a feeding table 2 And the feeding roller 27, the feeding table 2 and the feeding roller 27 are arranged in front and back, and the straw enters the defoliation device 3 through the feeding table 2 under the action of the feeding roller 27; the surface of the feeding roller 27 is designed with a spiral convex The helical protrusion has a pitch of 55mm and a height...

Embodiment 3

[0090] Example 3: see Figure 1-6 The difference between this embodiment and Embodiment 1 or 2 is that: the leaf removal devices 3 are two groups, and are arranged side by side along the width direction of the frame 31, and each group of leaf removal devices 3 includes two upper and lower gaps. The blade removal disks 11 are provided with six rectangular grooves in a circular array on the opposite surfaces of the two blade removal disks 11. The friction plate 10 is installed in the rectangular grooves. The blade removal shaft 12 is installed on the away surface of the blade disc 11 , and the blade removal shaft 12 drives the blade removal disc 11 to rotate. The leaf removing shaft 12 rotates under the driving of the motor, and then drives the leaf removing disc to rotate, and the friction plate tears the leaves off the straw. The two leaf-removing discs 11 arranged up and down rotate in opposite directions at the same speed, which further improves the tearing of the straw by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com