Novel garlic peeling device

A technology for garlic and garlic peel, which is applied in the field of new garlic processing machinery, can solve the problems of high energy consumption and equipment cost, heating and drying, and long peeling time, and achieves the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The core of the invention is a more convenient and efficient garlic peeling device, which can complete the efficient peeling operation of garlic without pretreatment. Compared with existing products, the device has the characteristics of low cost and high processing efficiency because it does not need an air compressor to blow skin.

[0011] In order to enable those in the technical field to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

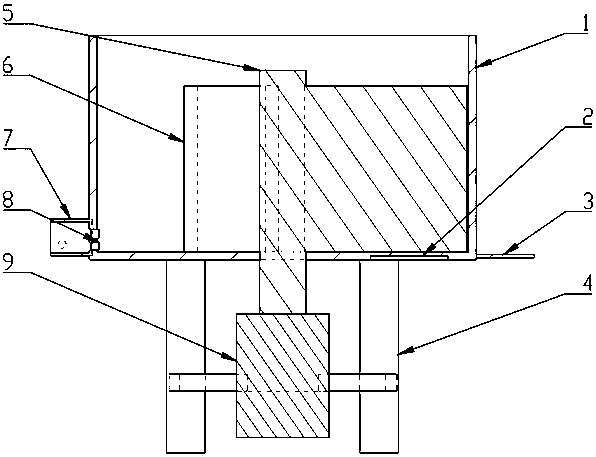

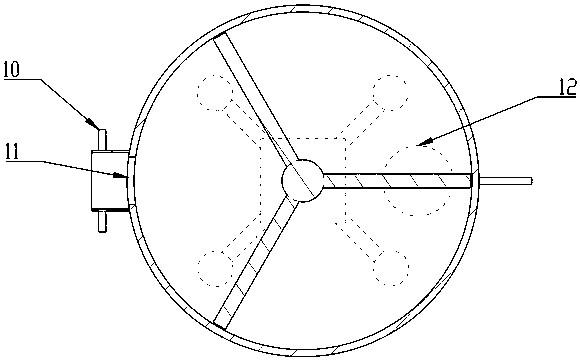

[0012] Please refer to figure 1 and figure 2 , figure 1 and figure 2 It is a structural principle diagram of a garlic deep processing device provided by a specific embodiment of the present invention.

[0013] The power generated by the motor 9 is transmitted to the rubber plate 6 via the transmission shaft 5 . Three rubber plates at 120° to each other rotate and drive the garlic to move along wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com