Peanut peeling equipment

An equipment and technology for peanuts, which are applied in the directions of shelling, pod removal, cleaning methods and utensils, etc., can solve the problems such as the inability to collect peanut skins in a centralized manner and the unclean equipment peeling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

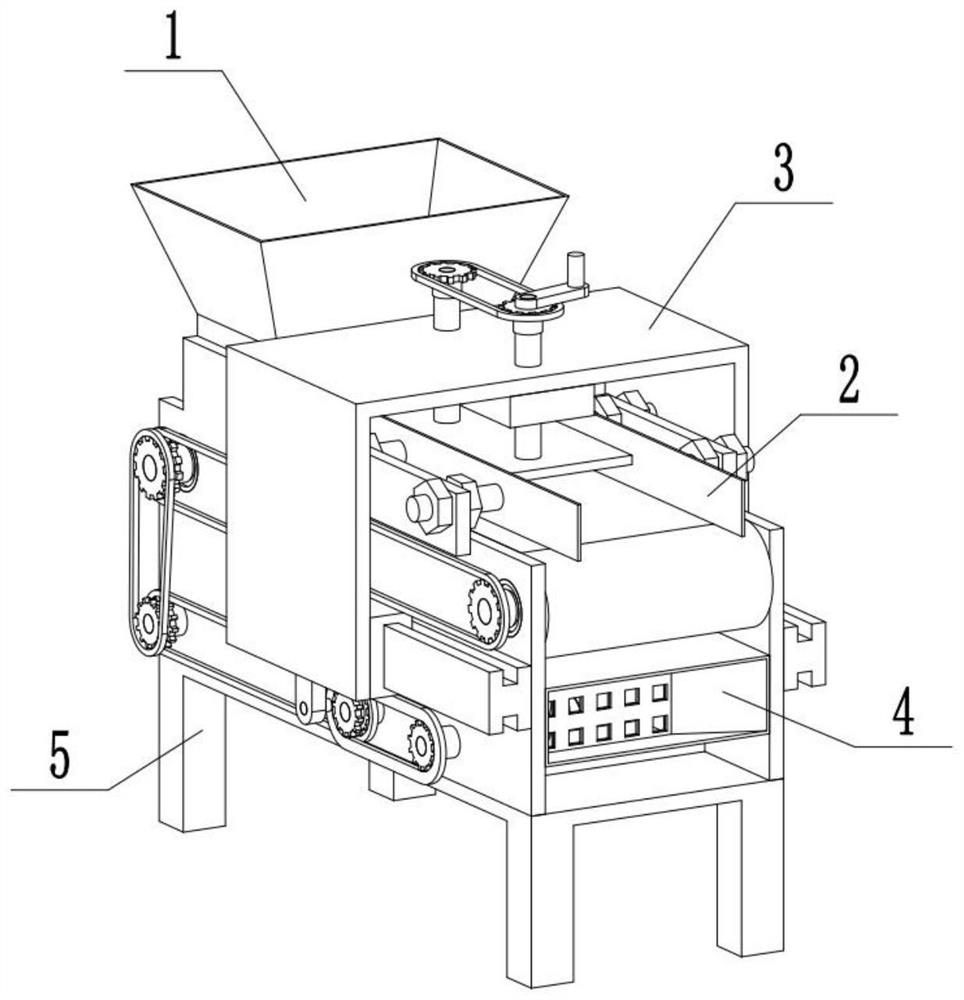

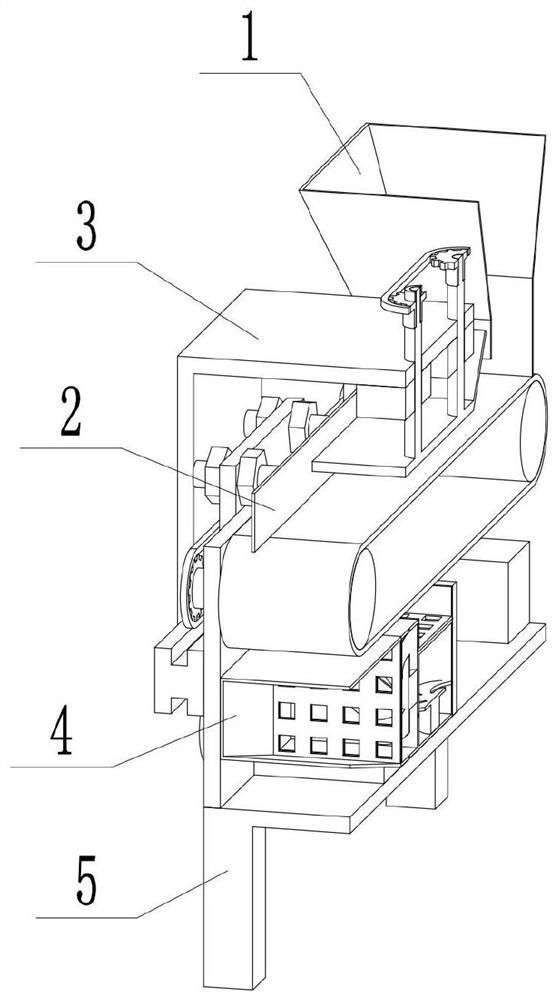

[0034] Combine below Figure 1-16 Description of this embodiment, a peanut peeling device, including a feeding device 1, a blocking device 2, a peeling device 3, a dust collector 4, and a base 5, the feeding device 1 is connected to the peeling device 3, and the feeding device 1 is connected with the base 5, the blocking device 2 is connected with the base 5, the peeling device 3 is connected with the base 5, and the dust suction device 4 is connected with the base 5.

specific Embodiment approach 2

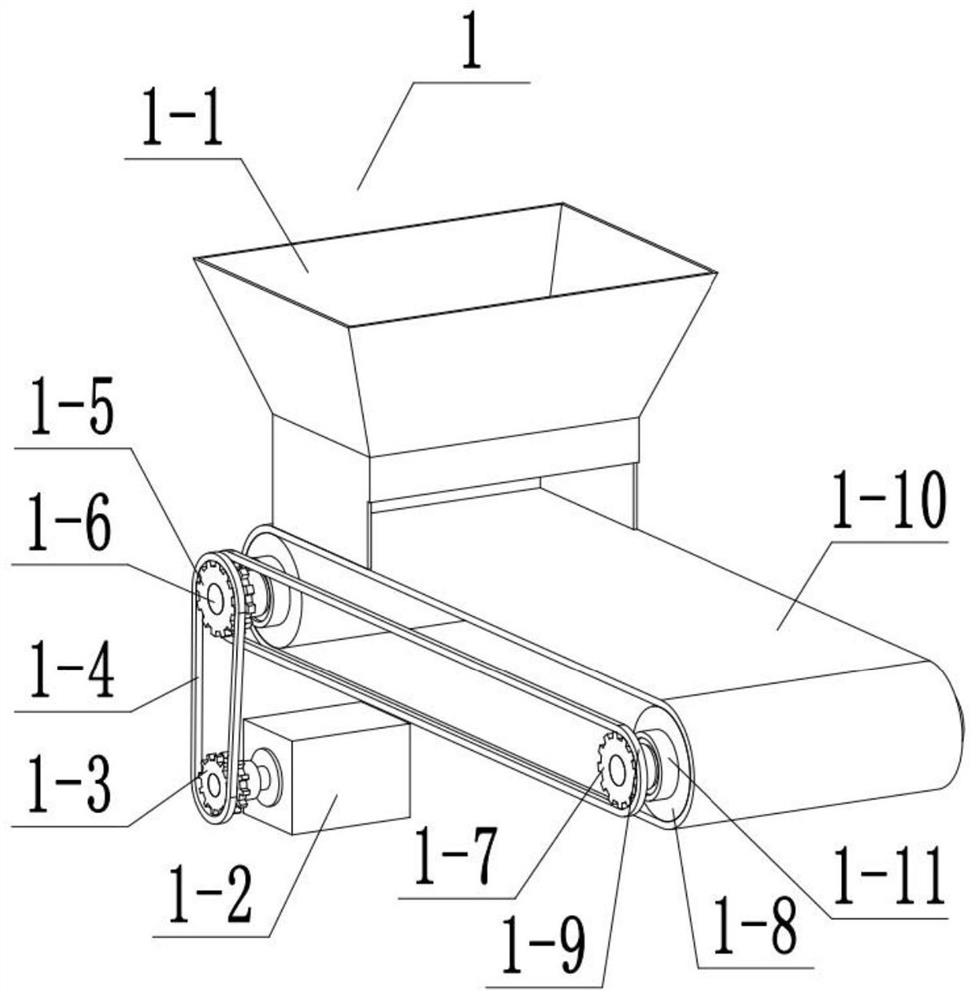

[0036] Combine below Figure 1-16Describe this embodiment, this embodiment will further explain the first embodiment, the feeding device 1 includes a feeding port 1-1, a feeding motor 1-2, a motor gear 1-3, a feeding chain A1-4, a feeding gear A1- 5. Feeding shaft A1-6, feeding gear B1-7, feeding shaft B1-8, feeding chain B1-9, feeding belt 1-10, bearing 1-11, feeding port 1-1 placed on feeding belt 1-10 Above, the feeding motor 1-2 is fixedly connected with the motor gear 1-3, the motor gear 1-3 is connected with the feeding chain A1-4, the feeding chain A1-4 is connected with the feeding gear A1-5, and the feeding gear A1-5 is connected with the The feeding shaft A1-6 is fixedly connected, the feeding gear B1-7 is fixedly connected with the feeding shaft B1-8, the feeding gear B1-7 is connected with the feeding chain B1-9, the feeding gear A1-5 is connected with the feeding chain B1-9, The feeding rotating shaft A1-6 and the feeding rotating shaft B1-8 are all rotationally ...

specific Embodiment approach 3

[0039] Combine below Figure 1-16 Describe this embodiment, this embodiment will further explain the first embodiment, the material blocking device 2 includes a right baffle 2-1, a baffle shaft A2-2, a baffle fixing plate A2-3, an adjusting nut 2-4, Left baffle plate 2-5, baffle plate shaft B2-6, baffle plate fixing seat B2-7, right baffle plate 2-1 is welded to baffle plate axis A2-2, baffle plate fixing plate A2-3 is connected to baffle plate axis A2 -2 sliding connection, the baffle shaft A2-2 is threaded with the adjustment nut 2-4, the left baffle 2-5 is welded to the baffle shaft B2-6, the left baffle 2-5, the baffle shaft B2-6 are connected to The baffle fixing seat B2-7 is slidingly connected, the adjusting nut 2-4 is threadedly connected with the baffle shaft B2-6,

[0040] Adjust the adjustment nut 2-4 so that the baffle shaft A2-2 drives the right baffle 2-1 to move, and the baffle shaft B2-6 drives the left baffle 2-5 to move, preventing the peanuts from rolling d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com