Patents

Literature

41results about How to "Avoid uneven cutting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

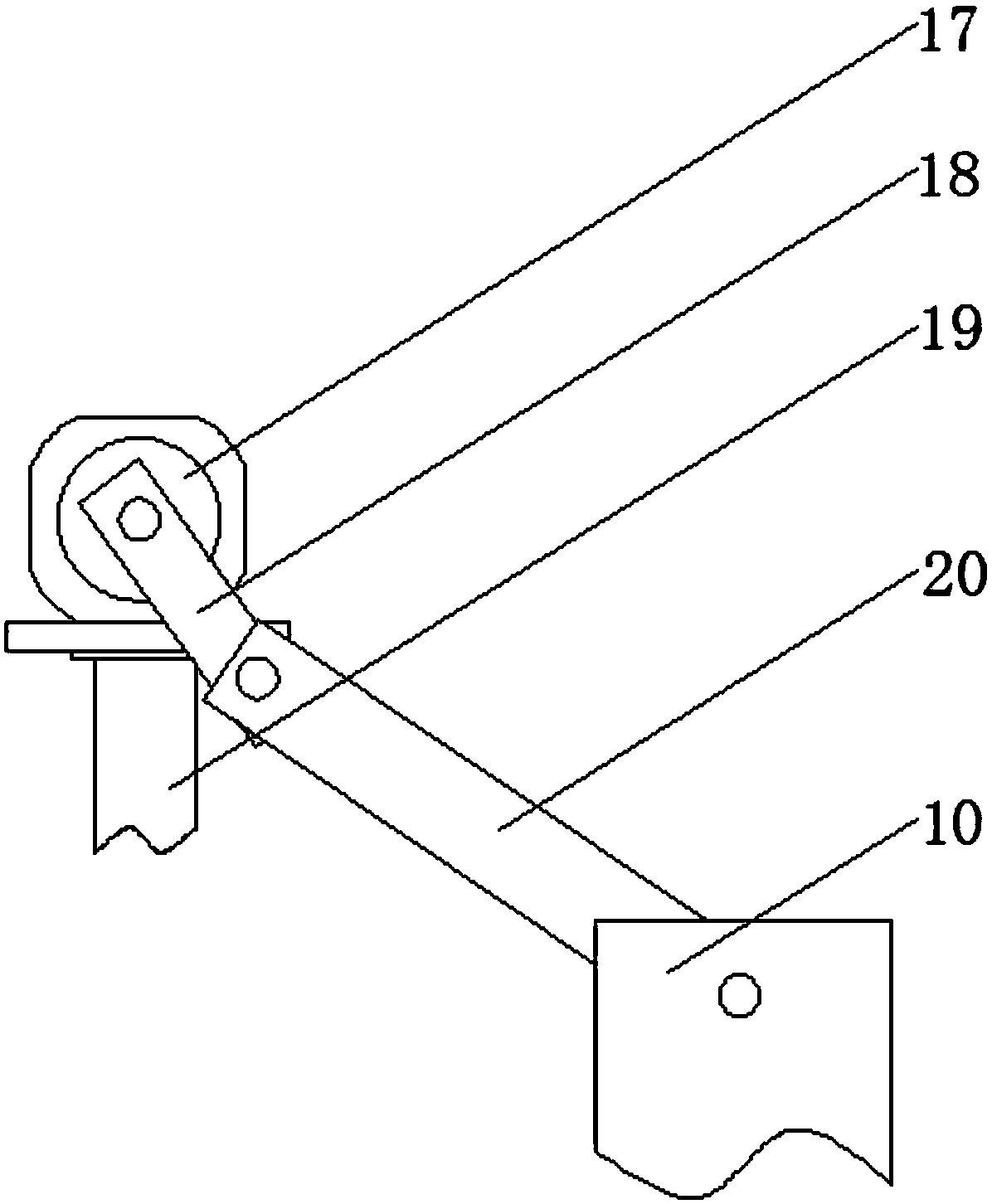

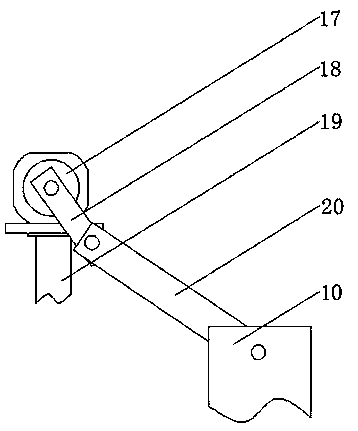

Scattering-preventing tool special for lead wire cutting

InactiveCN104037591AAvoid breaking stocksEasy to insertLine/current collector detailsWire cuttingEngineering

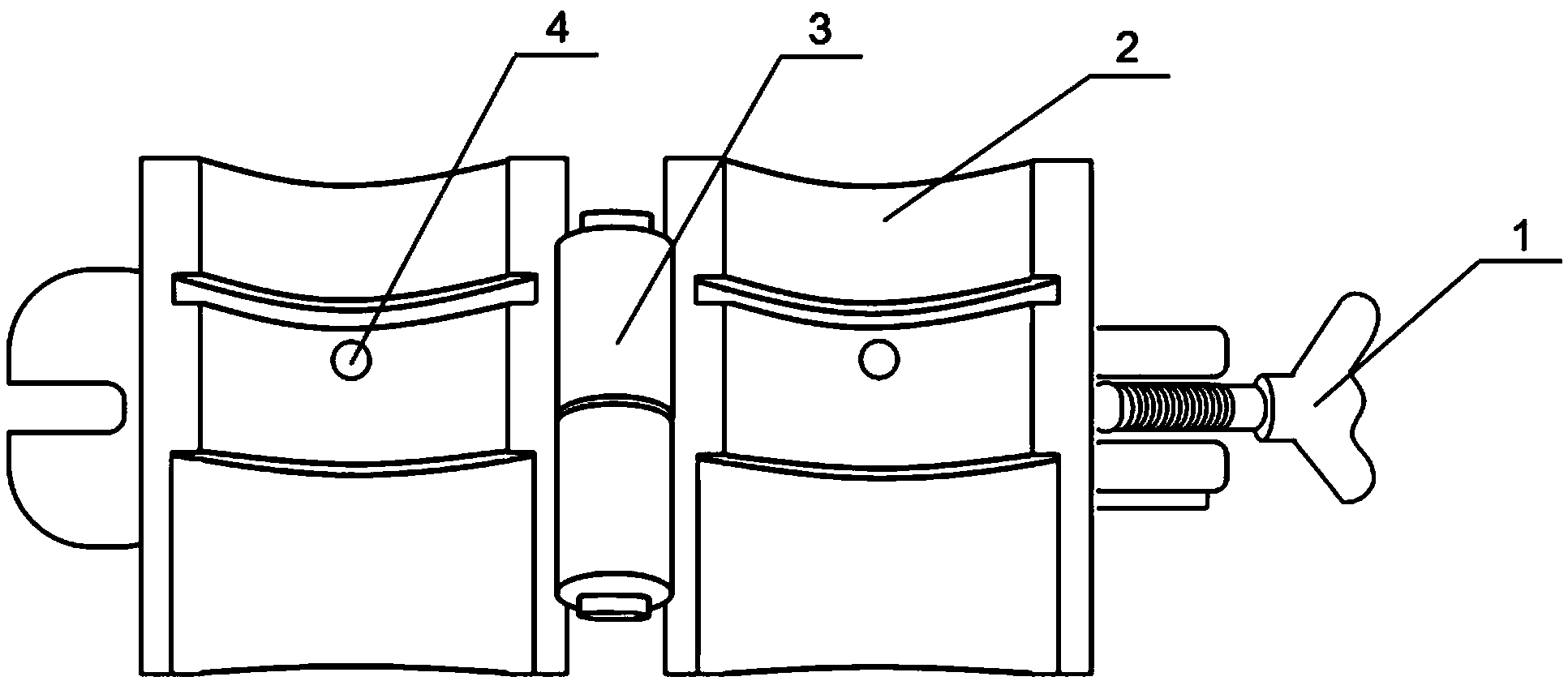

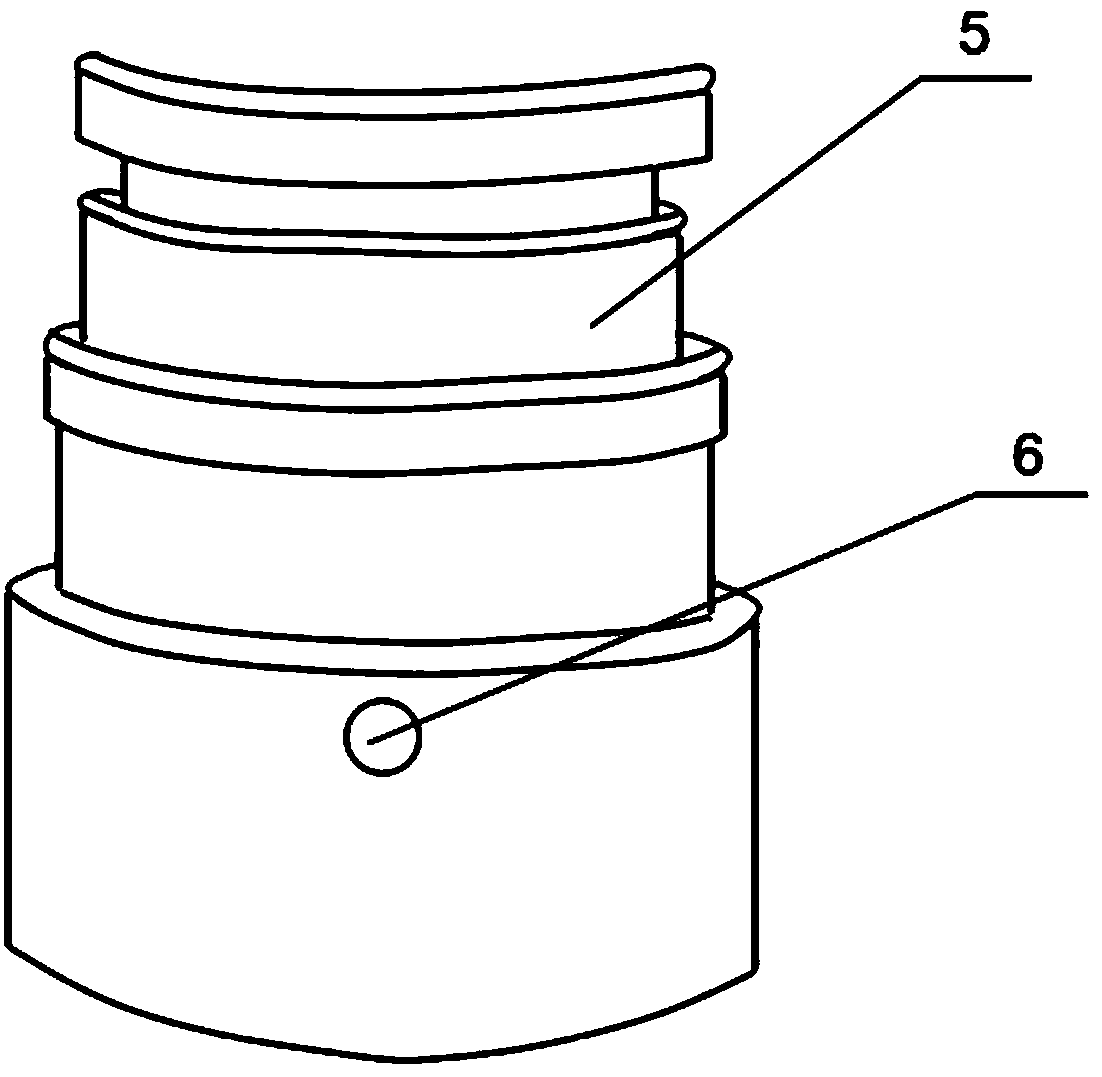

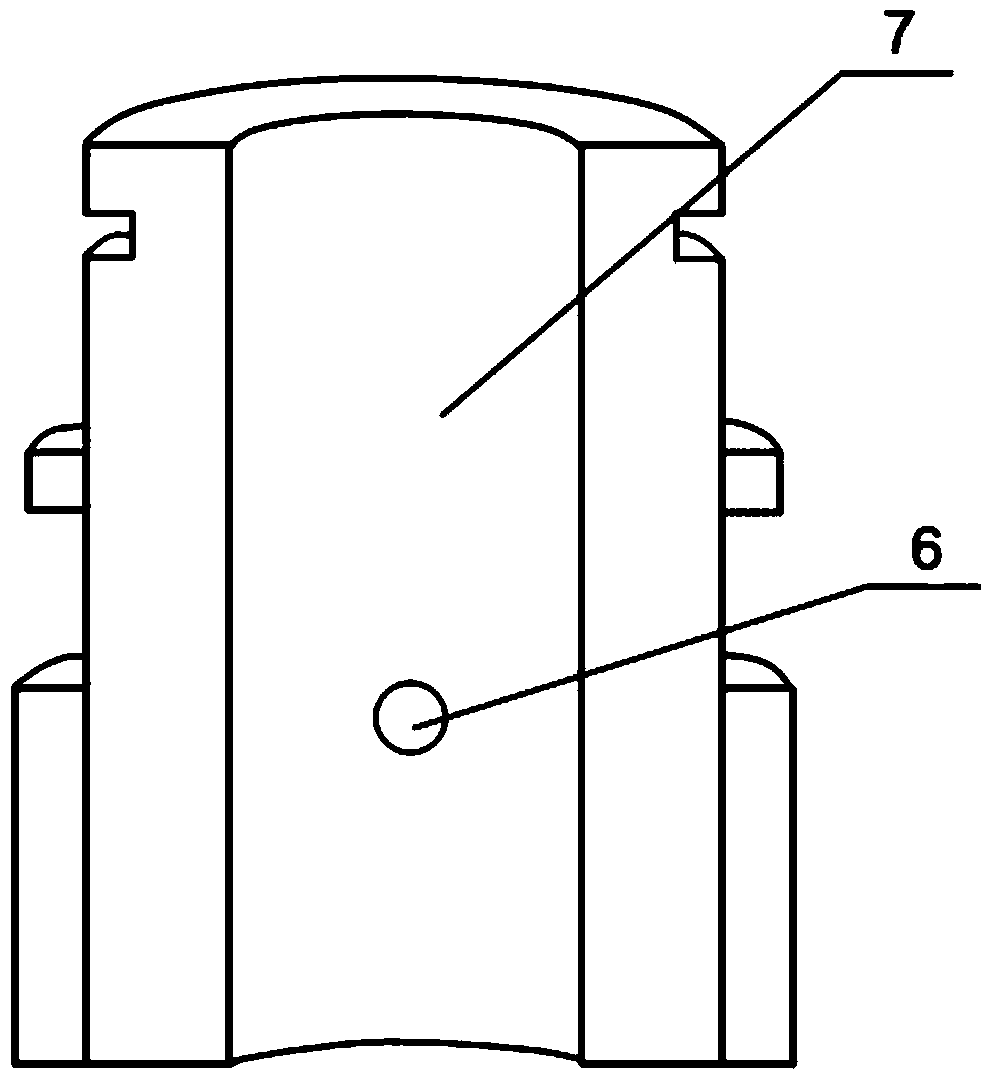

The invention relates to a scattering-preventing tool special for lead wire cutting and belongs to the field of mechanical machining devices. The scattering-preventing tool special for lead wire cutting comprises a butterfly-shaped bolt, an external clamp part, a rotary shaft, a die upper portion and a die lower portion, wherein the external clamp part is movably connected through the rotary shaft, and the butterfly-shaped bolt is installed on the side of the external clamp part. The die upper portion and the die lower portion are wrapped in the external clamp part. Compared with the prior art, the scattering-preventing tool special for lead wire cutting has the advantages of being simple in operation, flexible, convenient, durable and safe.

Owner:STATE GRID CORP OF CHINA +1

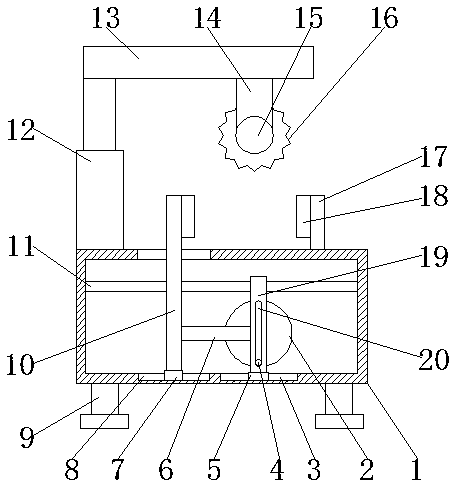

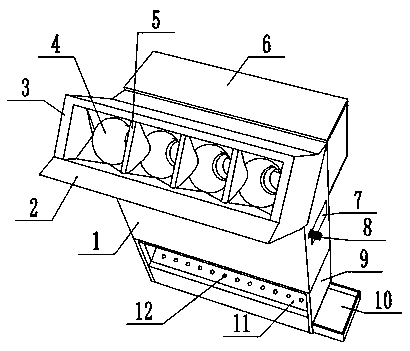

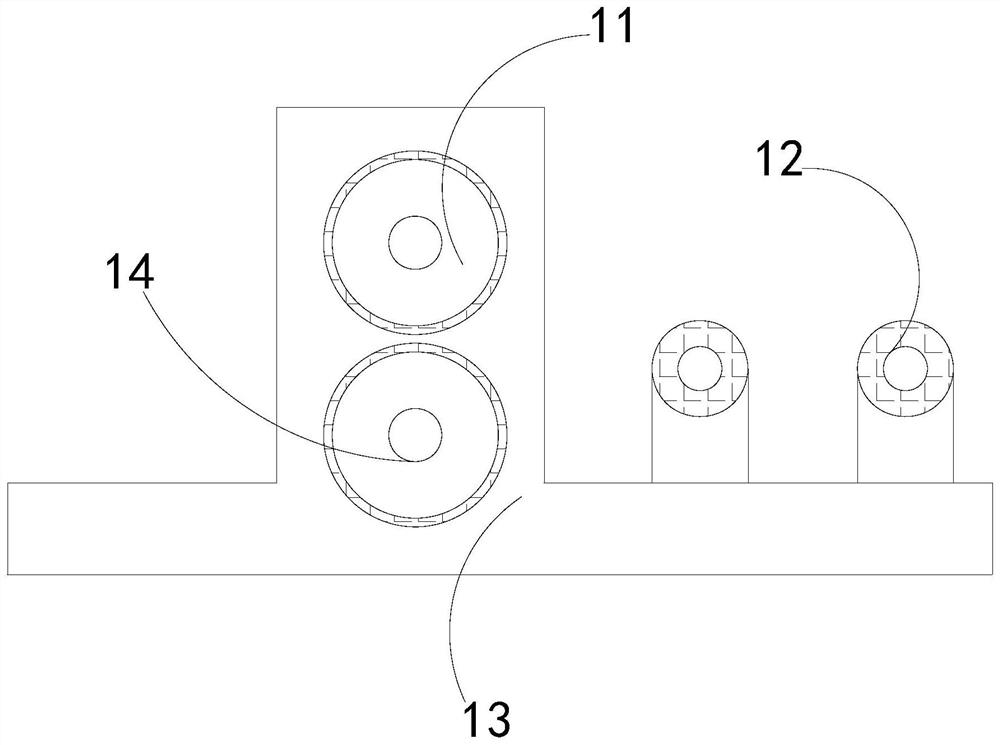

Crushing processing device for processing rice cakes

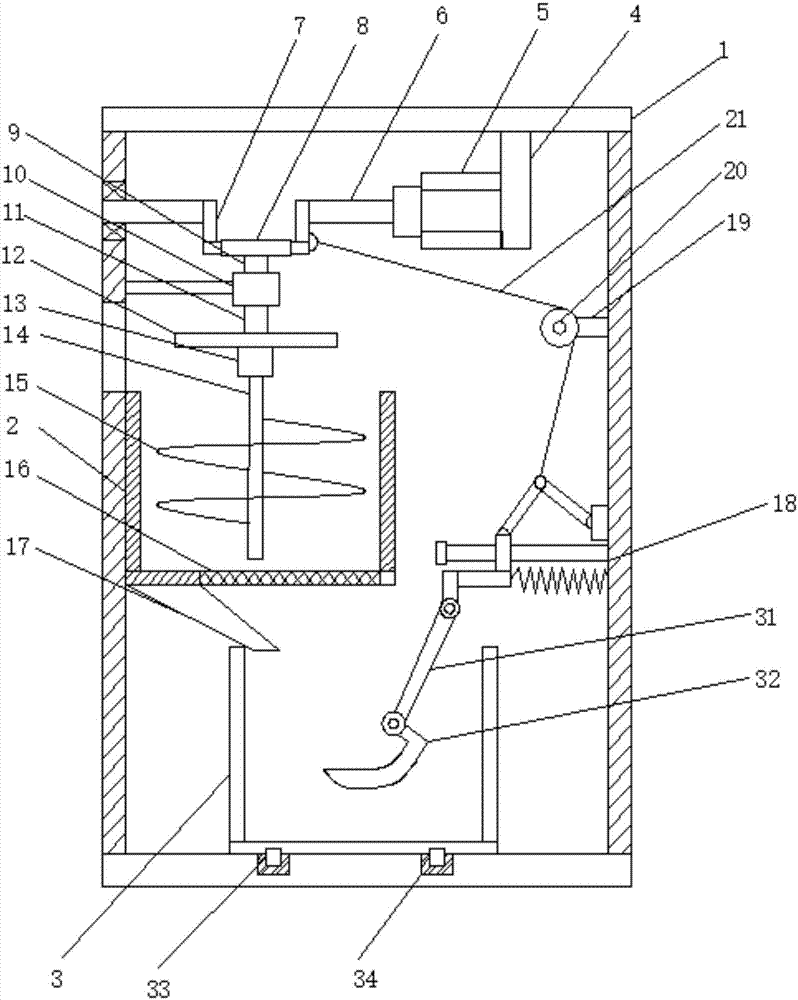

The invention discloses a crushing processing device for processing rice cakes. The crushing processing device comprises a rack, a first processing tank and a second processing tank, wherein a fixingrack is mounted at the upper end of the inner cavity of the rack; a first motor is mounted at the left end of the fixing rack; a transmission shaft is mounted at the left end of the first motor; a left side wall of the rack is fixed at the right end of the transmission shaft; an arc-shaped rod is mounted in the middle of the transmission shaft; the arc-shaped rod is sleeved by a sliding sleeve; the bottom end of the sliding sleeve is connected with a moveable pull rod; a connecting block is mounted at the bottom end of the moveable pull rod; a fixing plate is mounted on the bottom surface of the connecting block; a second motor is mounted on the bottom surface of the fixing plate; a processing rotating shaft is mounted at the bottom end of the second motor; the processing rotating shaft extends into the inner cavity of the first processing tank; and a plurality of crushing blades are mounted on the processing rotating shaft. By adopting the crushing processing device, processing on rawmaterials is completed through simulated manual operation, and the processed raw materials are relatively good in taste.

Owner:BEOSON JIANGSU FOOD SAFETY TECH CO LTD

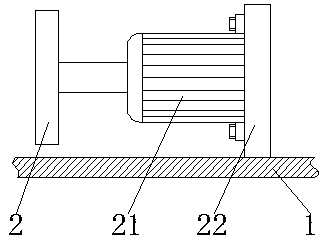

Uniform fabric cutting machine

PendingCN107687085ACrop evenlyAvoid uneven cuttingSevering textilesEngineeringStructural engineering

The invention discloses a uniform fabric cutting machine, which comprises a base; the top part of the base is fixedly connected with a supporting leg, and the top end of the supporting leg is fixedlyconnected with a supporting plate; the top part of the supporting plate is fixedly connected with a stable block, and the surface of the stable block is glidingly connected with moving blocks; the bottom parts of the moving blocks are fixedly connected with fixing devices, one of two opposite sides of the two moving blocks is fixedly connected with a connecting block; both sides of the inner wallof the connecting block are provided with chutes, and inner walls of the chutes are glidingly connected with slide blocks; one of two opposite sides of two slide blocks is fixedly connected with a machine knife. The invention relates to the technical field of fabric cutting. The fabric cutting machine changes the problem of uneven fabric cutting caused by driving the unfixed fabric often, preventsthe fabric cutting from uneven, guarantees the fabric cutting quality, improves the working efficiency, increases its functionality and reduces the enterprise cost.

Owner:曹安娜

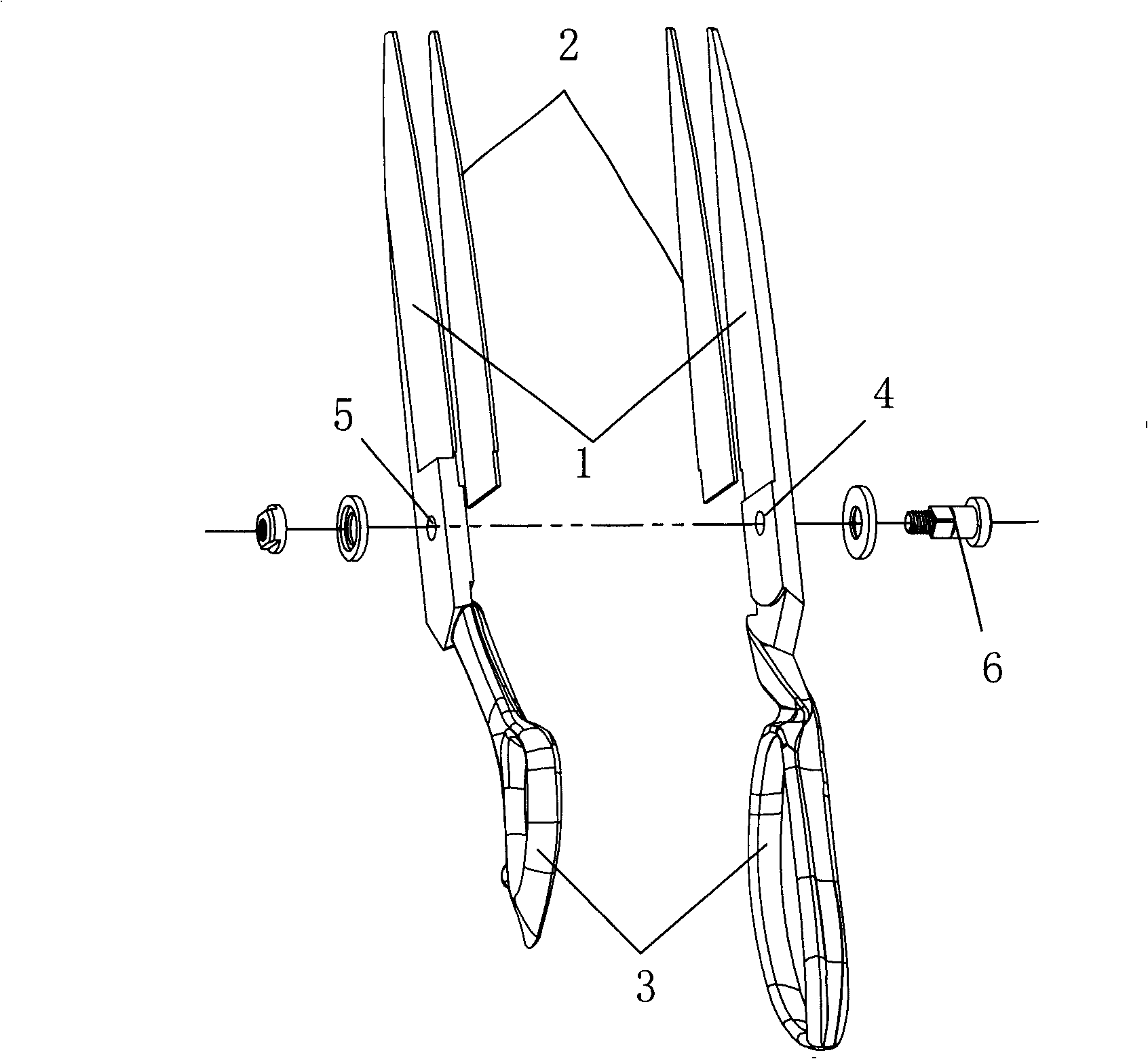

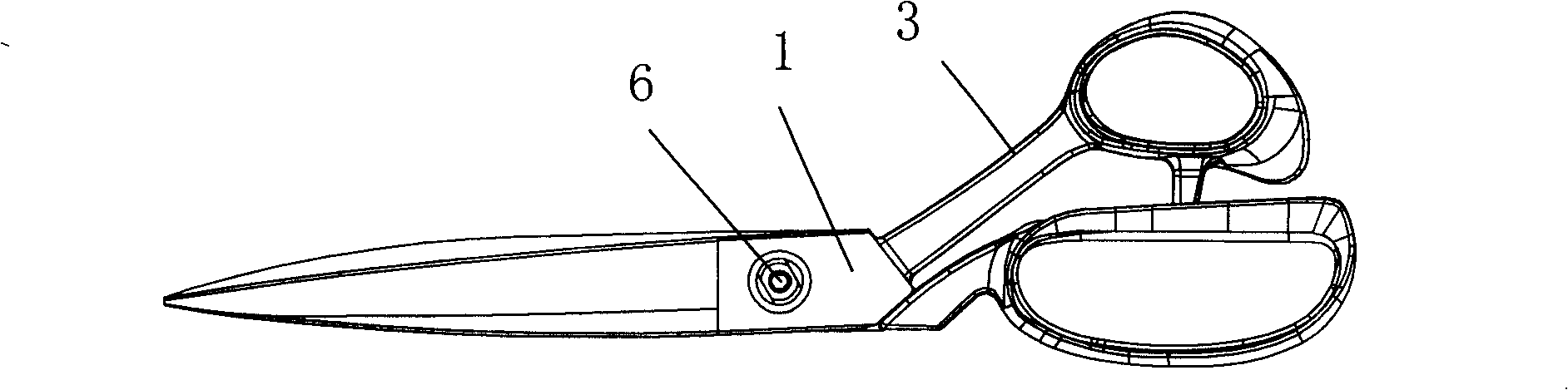

Sewing scissors and manufacturing method thereof

The invention discloses a pair of tailor scissors and a manufacturing method thereof. The structure of the tailor scissors is characterized in that: two mutually corresponding fine-casting cutter bodies are assembled by screw holes arranged at the middle parts of the cutter bodies, and then matched with a thread assembly; blades are arranged on the cutting edge positions of the fine-casting cutter bodies; the manufacturing process comprises the following steps: finely die-casting a whole scissor, cropping cutting edge steel, welding the cutter bodies with the edge steel, heat treatment, grinding inner cutting edges, finely grinding small outer cutting edges, plastic dipping, and assembling. Compared with the prior art, the tailor scissors of the invention has the following beneficial effects: the integral forming technique of a handle and an outer large bevel edge is adopted to the scissors, which reduces the loss of a disc and greatly shortens production period and lowers production cost; the head of the scissor is made from two-layer composite material; a copper plate is clamped between the two layers of the composite material; after high-temperature welding is finished, the blade part is shaped like a golden silk thread; the blade is made from composite-layer tool steel, therefore, the cutting edges are not easily collapsed or rolled up; the scissors are sharp and durable with strengthened fatigue resistance; the cutting edge is not limited by welding technique, therefore, various special steel material can be replaced at will.

Owner:FUDING DAJI KNIFE & SCISSORS HARDWARE

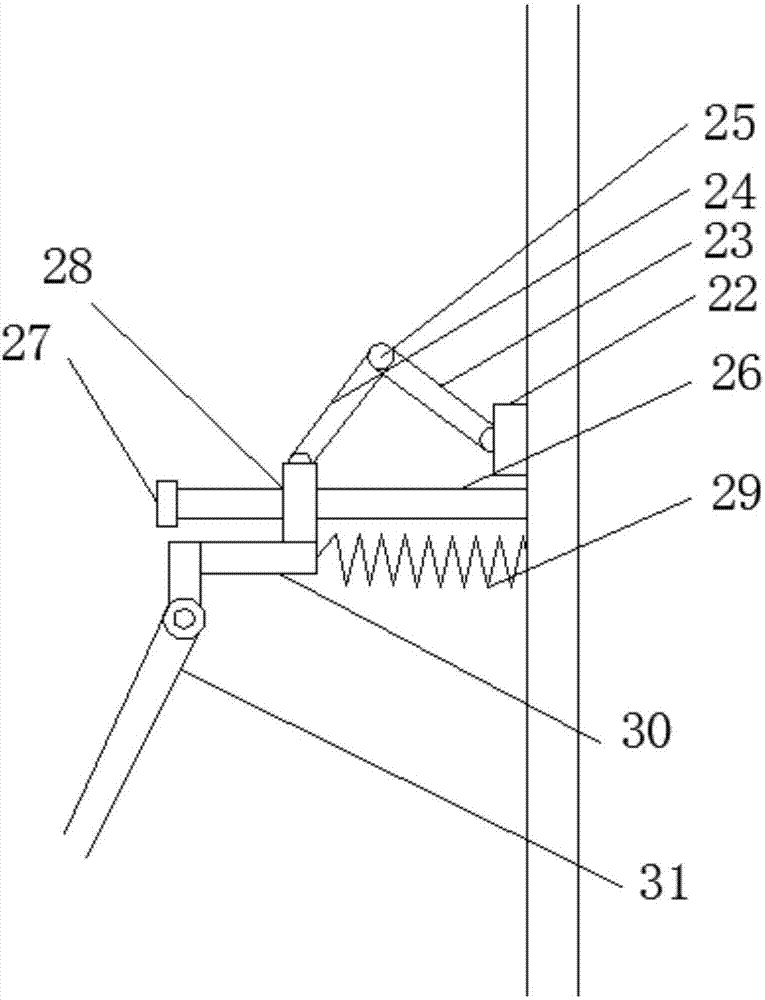

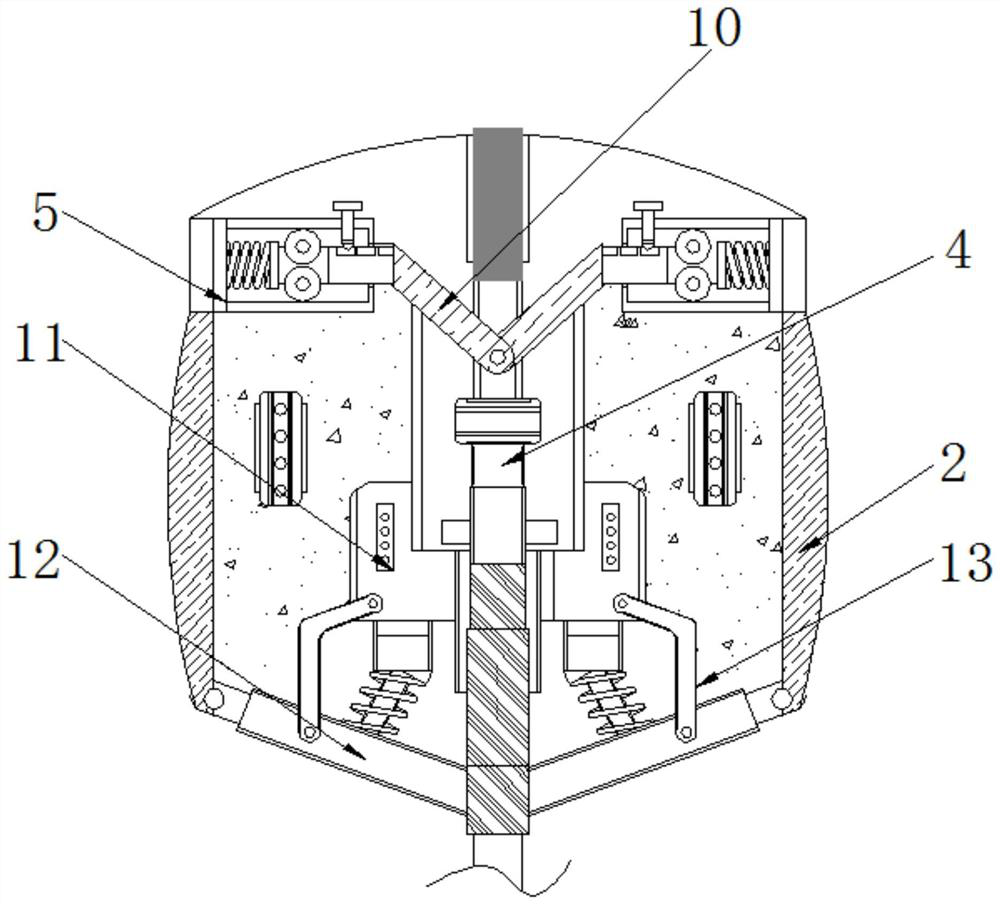

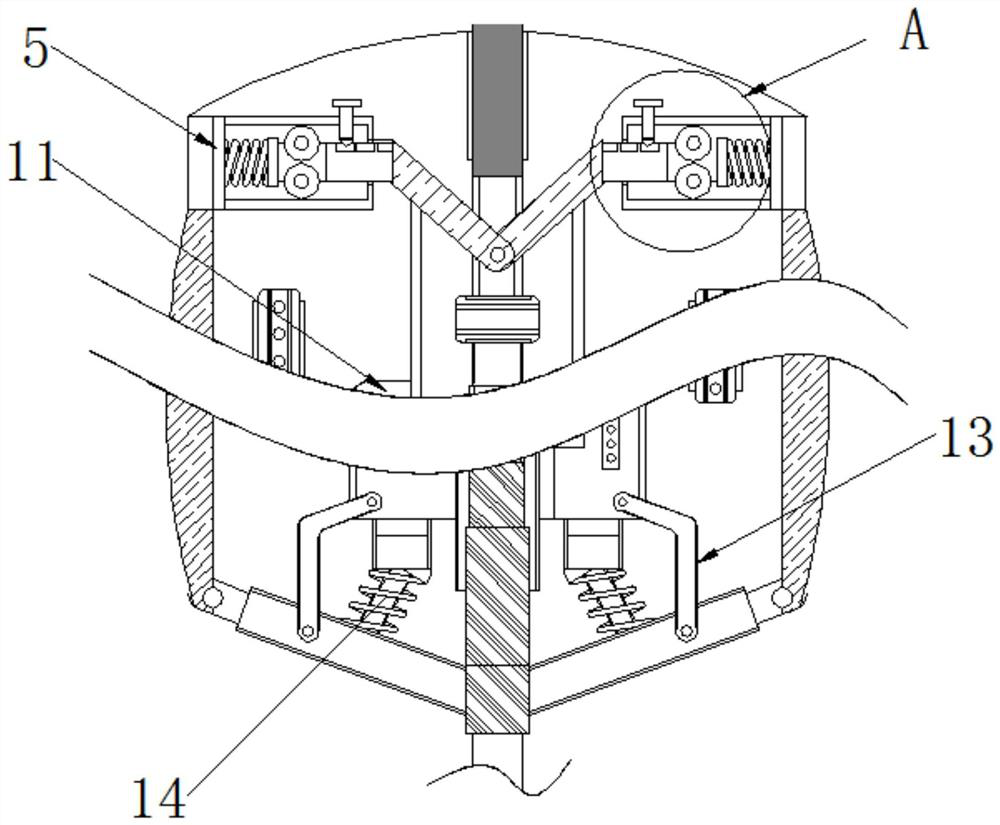

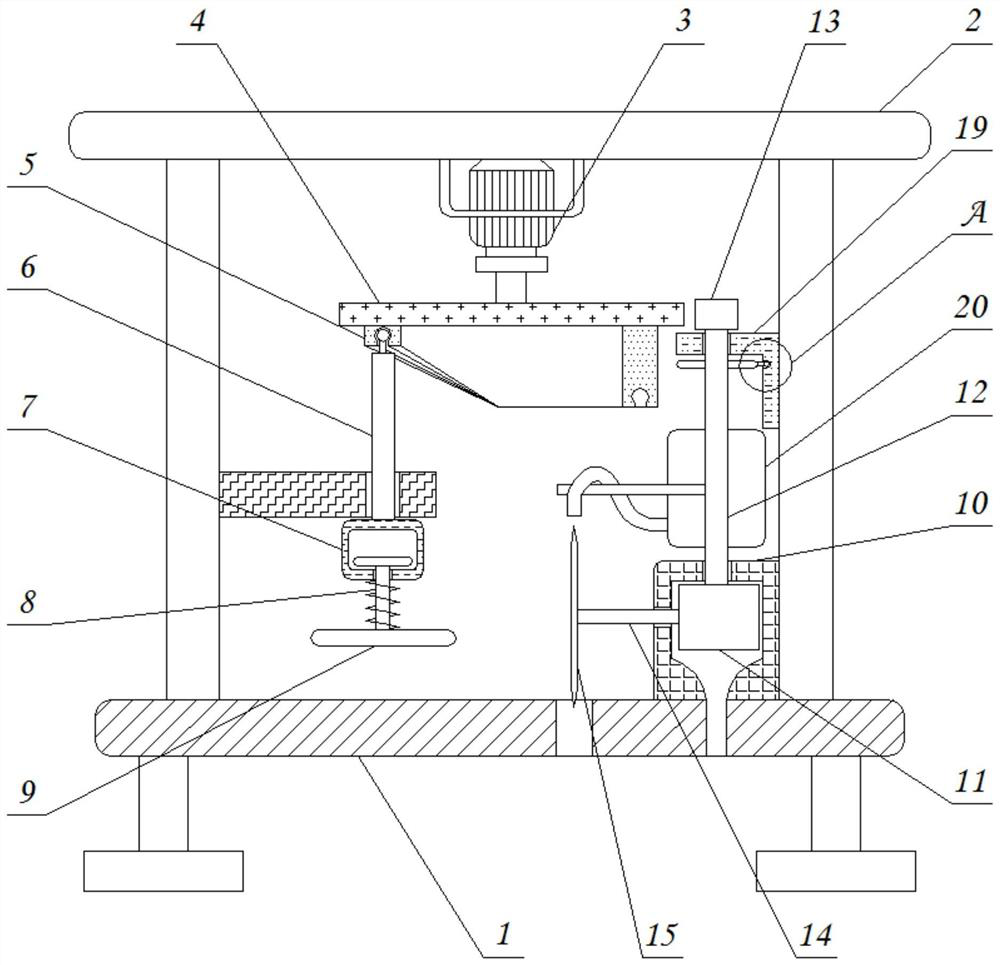

Metal workpiece machining device utilizing thread cutting

InactiveCN111774673APrevent disengagementImprove textureThread cutting feeding devicesThread cutting machinesScrew threadMechanics

The invention belongs to the technical field of thread cutting, and particularly relates to a metal workpiece machining device utilizing thread cutting. A mounting frame is arranged in a chuck, an adjusting plate is arranged in the chuck, a sliding column is movably connected to the inner wall of the mounting frame, a limiting seat is fixedly connected to the inner wall of the mounting frame, a limiting spring is movably connected to the interior of the limiting seat, a limiting column is movably connected to one side of the limiting spring, a clamping groove is formed in the surface of the limiting column, a clamping column is movably connected to the interior of the clamping groove, an adjusting rod is rotationally connected to the position, located on the surface of the sliding column,of one end of the limiting column, the adjusting rod penetrates through the interior of a supporting seat, and a first rotating rod is rotationally connected to the surface of the sliding column and located on one side of the mounting frame. During use, the water outlet amount of a water outlet pipe can be automatically controlled, the phenomenon that much water is wasted during treatment is avoided, and convenience is brought to thread cutting of a bolt column.

Owner:缪笑燕

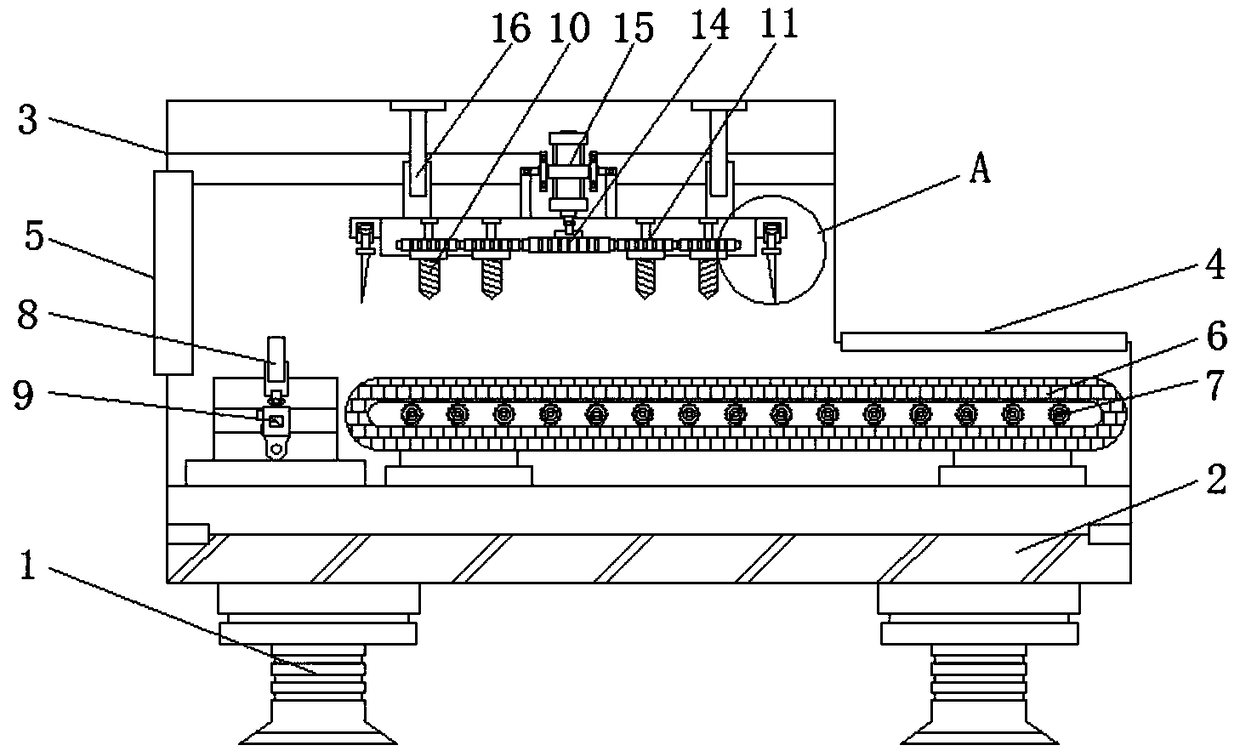

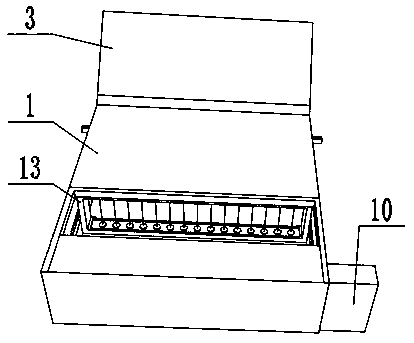

Punching and slitting integrated device for processing paper trays

InactiveCN108973214AStable supportImprove drilling efficiencyBag making operationsBox making operationsPunchingEngineering

The invention discloses a punching and slitting integrated device for processing paper trays. The device comprises supporting blocks, a conveying belt, drill bits and a third gear; a supporting base is arranged at the upper portions of the supporting blocks, a shell is fixed to the upper portion of the supporting base, the right side of the shell is provided with a feeding port, and the left sideof the shell is provided with a discharging port; first gears are installed at the inner side of the conveying belt, the conveying belt is located at the inner side of the shell, a telescopic limitingblock is installed at the left side of the conveying belt, and a hydraulic machine is arranged at the lower portion of the telescopic limiting block; a second gear is fixed to the upper portion of each drill bit, the drill bits are arranged above the conveying belt, a slitting sheet is arranged at the right side of each second gear, and a spring is installed at the upper portion of each slittingsheet; a motor is arranged above the third gear, and hydraulic rods are installed at the left side of the motor. The punching and slitting integrated device for processing the paper trays has the advantages that the punching efficiency is high, the paper trays can be automatically conveyed, and the punching and slitting are integrated.

Owner:安徽徽之润纸业有限公司

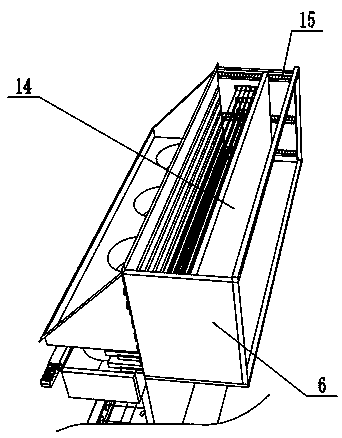

Cloth cutting device for garment production and processing

ActiveCN114575136ASolve the problem of uneven cuttingRealize full flat cuttingSevering textilesLiquid/gas/vapor textile treatmentTextile technologyElectric machinery

The invention discloses a cloth cutting device for garment production and processing, and relates to the technical field of garment textile, the cloth cutting device comprises a base, the top of the base is fixedly connected with a tank body, the top of the tank body is rotatably connected with a cover body, and the middle position of the inner side surface of the cover body is fixedly connected with an anti-driving mechanism; an anti-wrinkle mechanism is fixedly connected to the inner side face of the tank body, the anti-wrinkle mechanism comprises a first motor, a rotating shaft of the output end of the first motor is fixedly connected with an air cylinder, a sliding rod is fixedly connected to the surface of the air cylinder, and a shearing assembly is slidably connected to the surface of the sliding rod. According to the cloth cutting device for garment production and processing, through cooperative use of the anti-driving mechanism, the shearing assembly, the anti-wrinkle mechanism, the dispersion assembly and other mechanisms, the problem that due to the fact that wrinkles on the surface of cloth are many, the cloth cannot be cut neatly is solved; and the problem of uneven cloth cutting caused by the fact that the cloth is easily driven in the cutting process of the cutting knife is solved.

Owner:颍上尚高服饰有限公司

Cutting device for wood processing

PendingCN108312240AGood fixed effectEasy to useSawing componentsCircular sawsElectric machineryWood processing

The invention discloses a cutting device for wood processing. The cutting device for wood processing comprises a bottom box; an electric telescopic rod is fixedly connected to the left side of the topof the bottom box; a supporting plate is fixedly connected to the top of the electric telescopic rod; a fixed rod is arranged on the right side of the bottom of the supporting plate; a first motor isfixedly connected to the bottom of the fixed rod; a cutting disc is fixedly connected to the output end of the first motor; and a baffle is fixedly connected to the bottom of the inner wall of the bottom box. Through cooperative use of a rotary plate, a cylinder, a connecting rod, a first pressing rod, a sliding rod, a second pressing rod, a pressing block, a movable rod, a third sliding chute, asecond motor and the baffle, the problem of a poor wood fixing effect of an existing wood cutting device is solved, the wood cutting device has the advantage of good wood fixing effect, the situationthat wood is not smoothly cut due to shaking in the cutting process is avoided, users use the cutting device conveniently, and practicability of the wood cutting device is improved.

Owner:JIANGSU MINGLE FLOOR

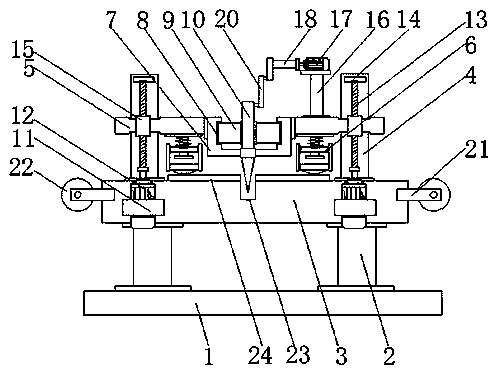

Anti-staggering cutting equipment with continuous cutting function for hollowed-out transparent lace fabric production

InactiveCN109487523AAvoid uneven cuttingThe problem of uneven cutting is preventedSevering textilesArchitectural engineering

The invention discloses anti-staggering cutting equipment with a continuous cutting function for hollowed-out transparent lace fabric production, and relates to the technical field of fabric cutting.The cutting equipment comprises a base. The top of the base is fixedly connected with supporting legs, the top ends of the supporting legs are fixedly connected with a supporting plate, the top of thesupporting plate is fixedly connected with stabilizing blocks, the surfaces of the stabilizing blocks are slidingly connected with movable blocks, the bottoms of the movable blocks are fixedly connected with fixing devices, the opposite sides of the two movable blocks are fixedly connected with connecting blocks, and sliding grooves are formed in the two sides of the inner walls of the connectingblocks. According to the anti-staggering cutting equipment with the continuous cutting function for hollowed-out transparent lace fabric production, the problem that usually fabric is driven as the fabric is not firmly fixed, so that the fabric is not uniformly cut is changed, non-uniform cutting of the fabric is avoided, the cutting quality of the fabric is guaranteed, the working efficiency isimproved, the functionality of the equipment is improved, and the enterprise cost is reduced.

Owner:苏州优捷纺织品有限公司

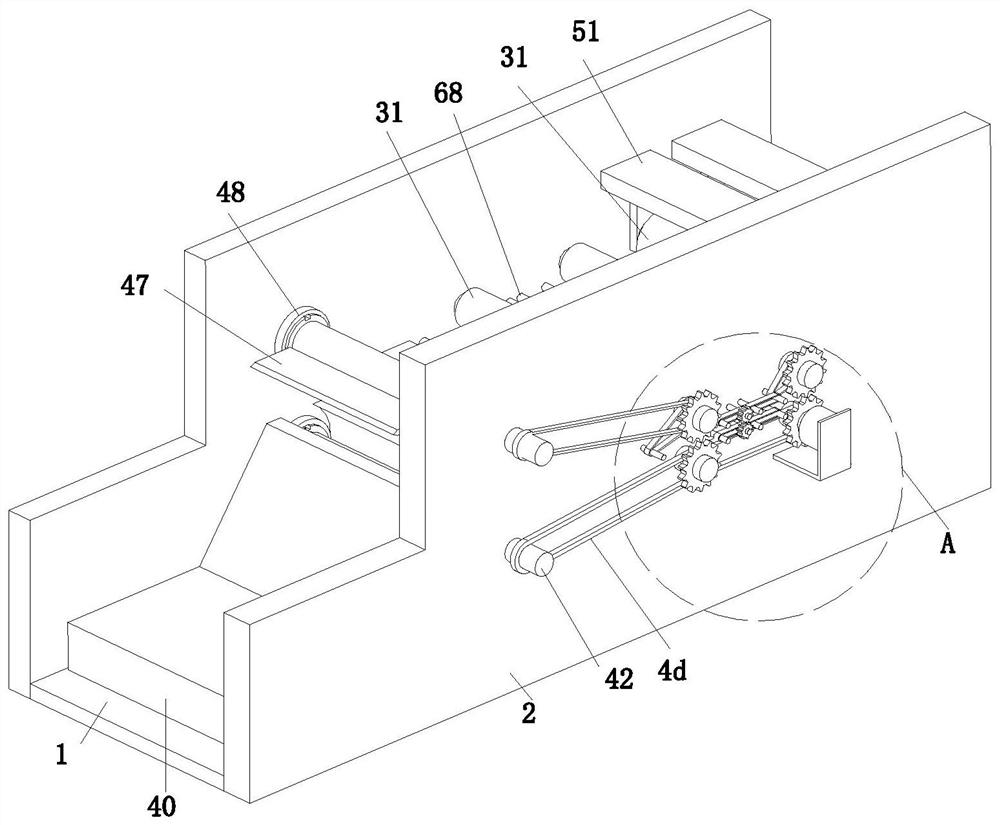

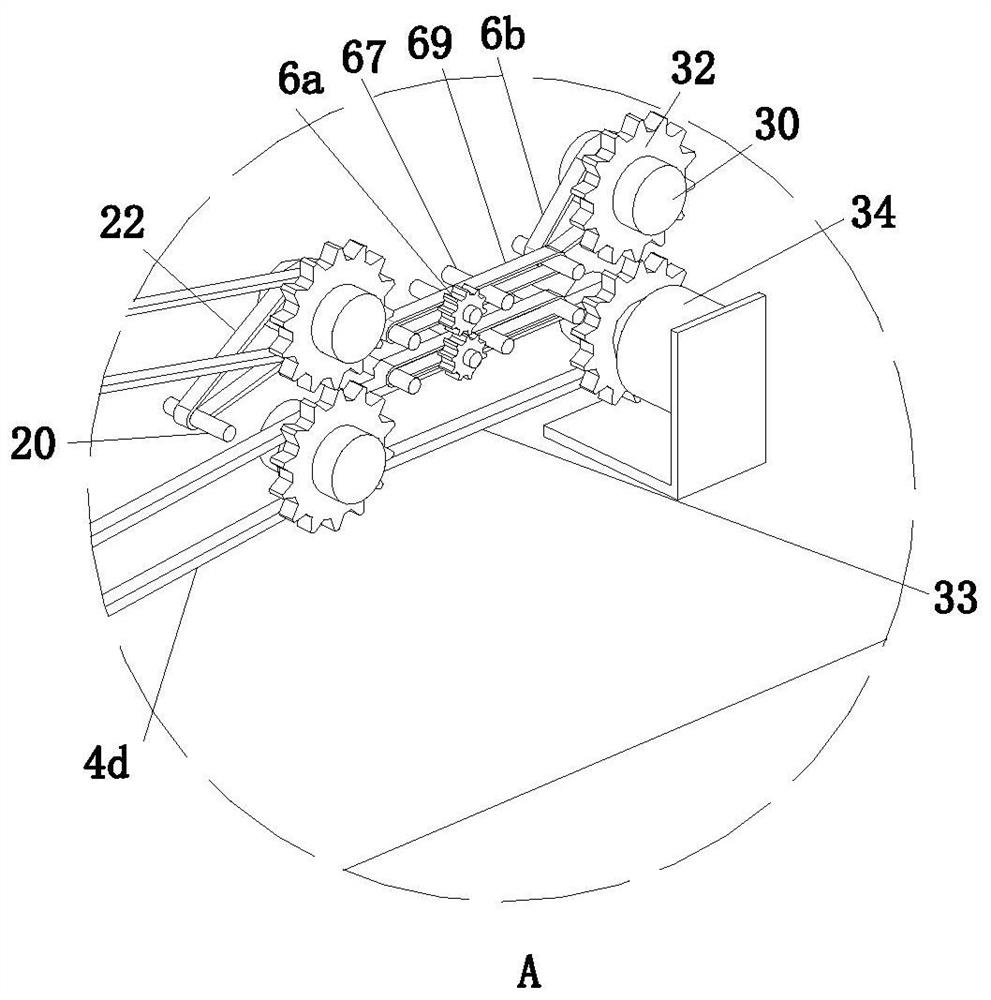

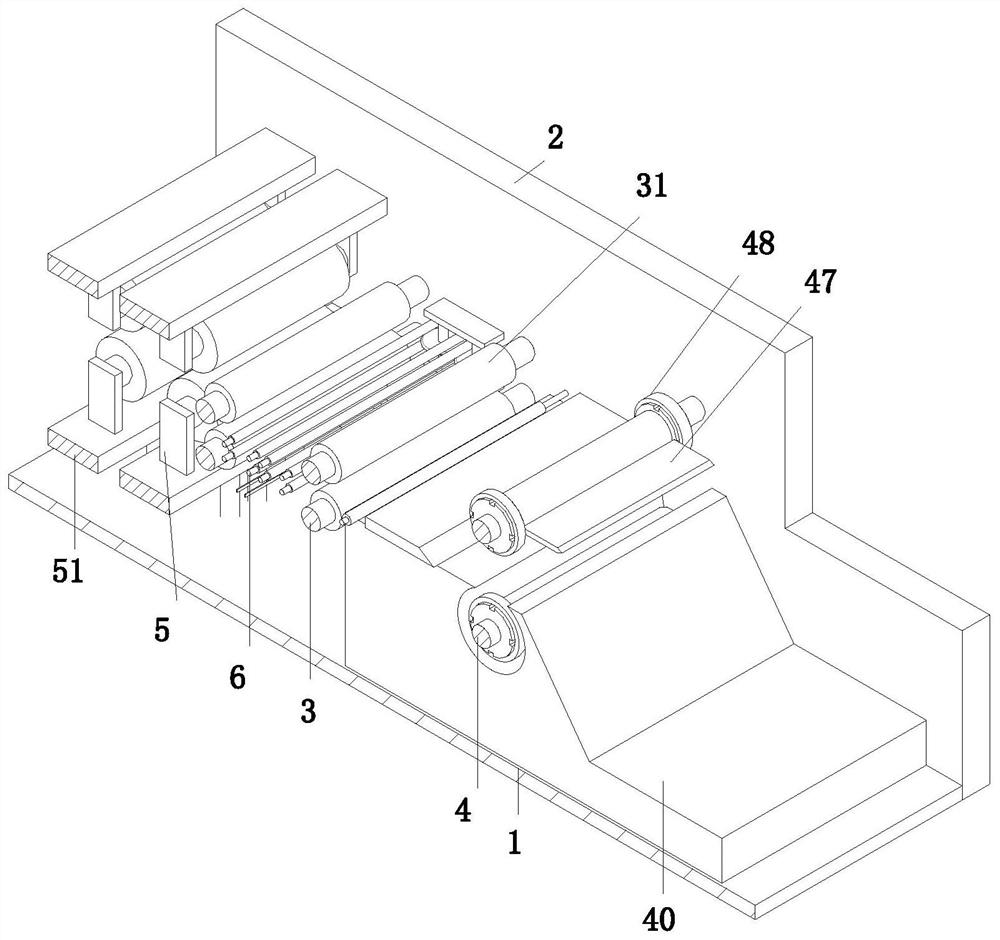

High-temperature-resistant paper-plastic composite bag manufacturing and cutting processing equipment and cutting processing method

InactiveCN113085264AEasy to cutAvoid the phenomenon of single cutting lengthBag making operationsPaper-makingMechanical engineeringIndustrial engineering

The invention relates to high-temperature-resistant paper-plastic composite bag manufacturing and cutting processing equipment and a cutting processing method. The high-temperature-resistant paper-plastic composite bag manufacturing and cutting processing equipment comprises a bottom plate, an L-shaped working plate, a conveying mechanism, a cutting mechanism, a bonding mechanism and a folding mechanism. According to the high-temperature-resistant paper-plastic composite bag manufacturing and cutting processing equipment and the cutting processing method, the cutting mechanism capable of adjusting length of a paper-plastic composite bag is adopted to cut the paper-plastic composite bag, the phenomenon that the cutting length is single when cutting is carried out on the paper-plastic composite bag is avoided, meanwhile, the folding mechanism and the bonding mechanism are adopted to be combined to bond the paper-plastic composite bag together, then the folding into a three-dimensional structure is carried out, then flattening is carried out on a folded paper-plastic composite barrel, and therefore cutting of the paper-plastic composite bag is facilitated, and the phenomenon of uneven cutting caused by uneven folded edges when the paper-plastic composite cylinder is cut into the paper-plastic composite bag is avoided.

Owner:汤斌斌

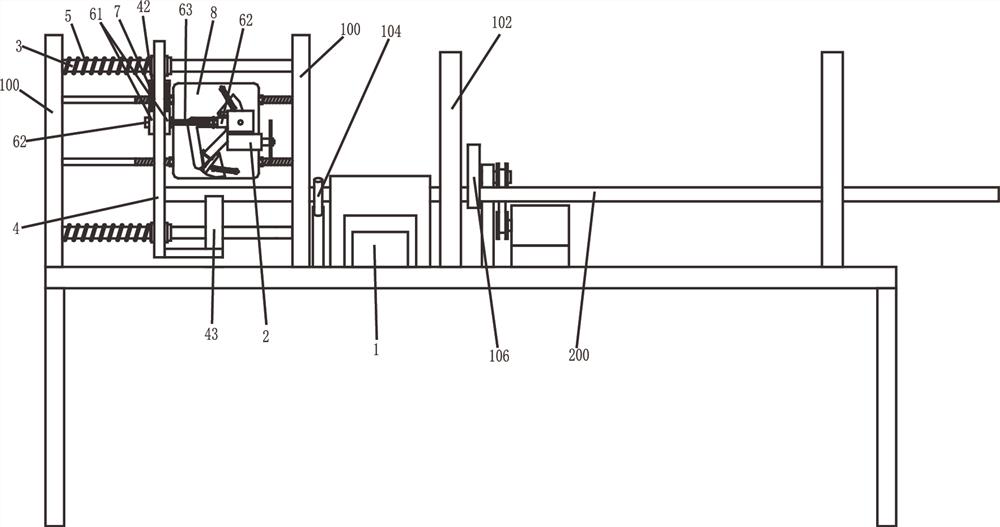

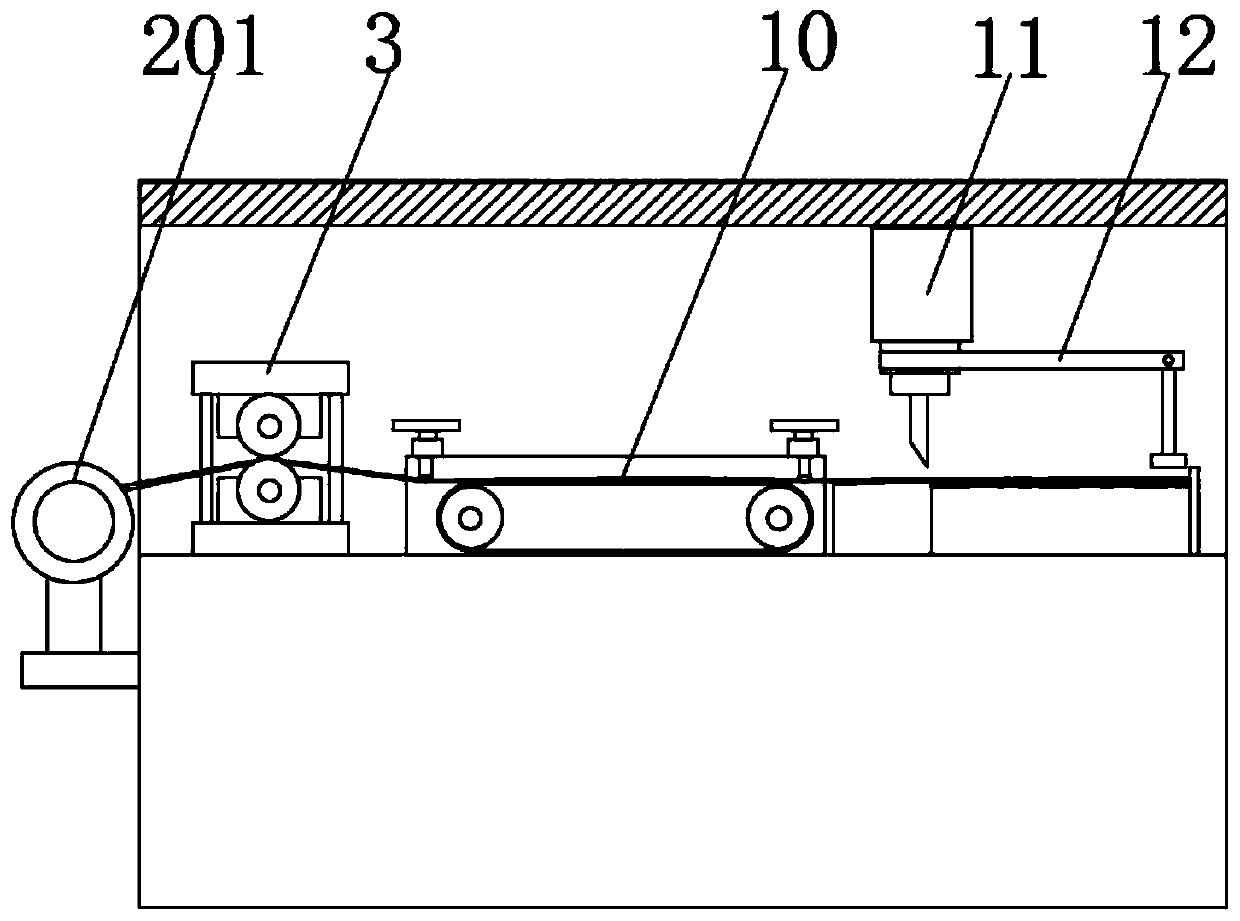

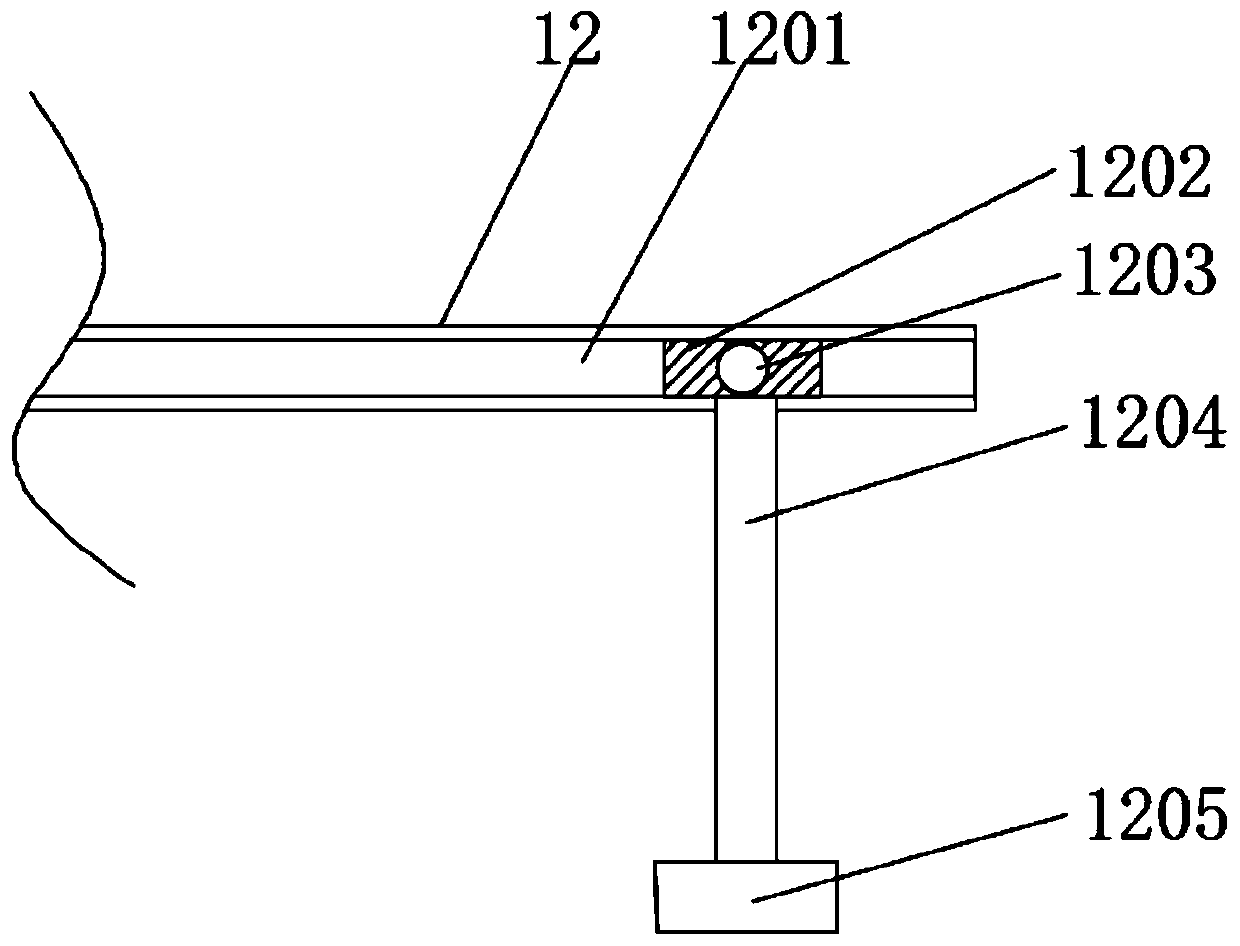

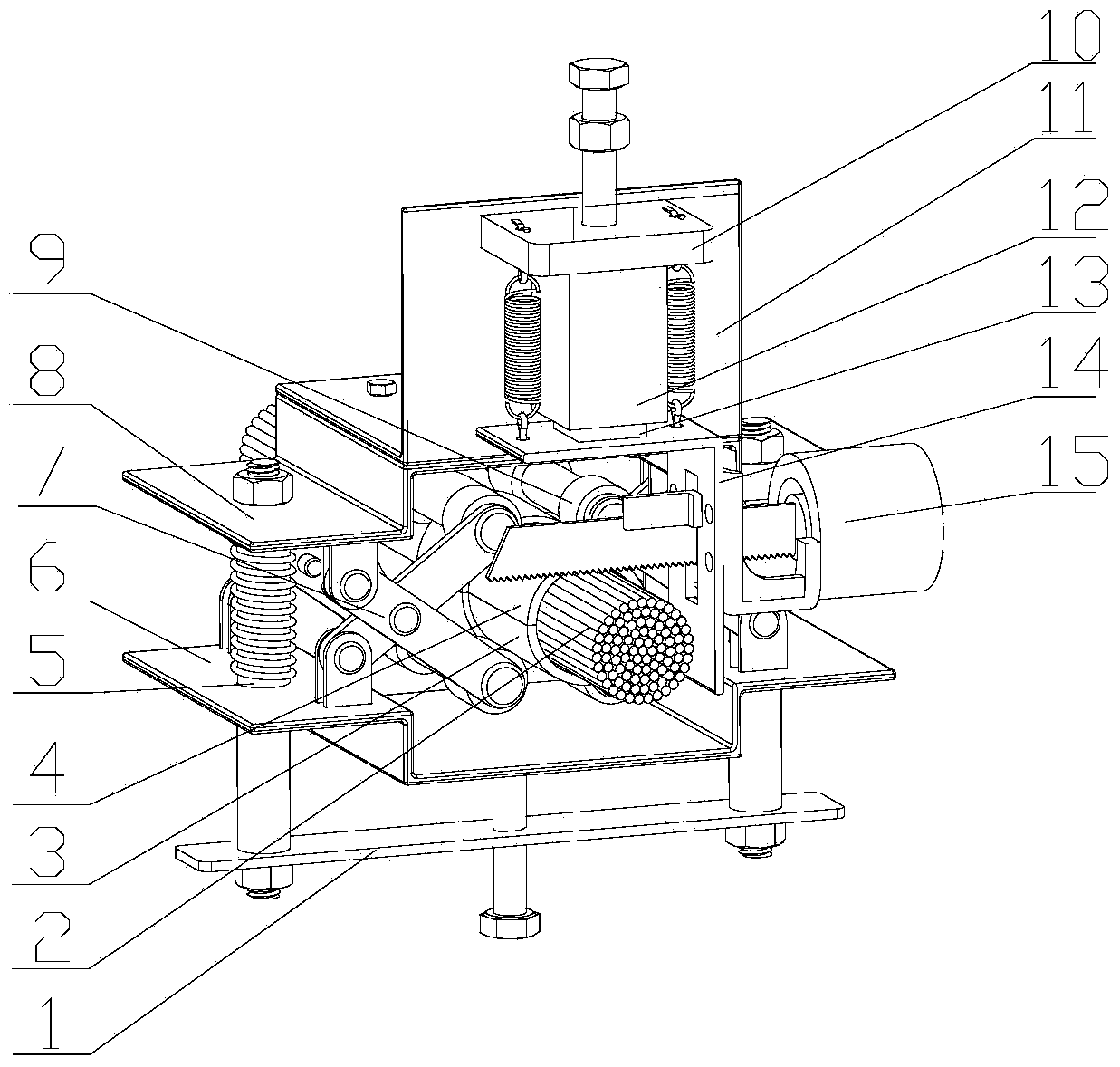

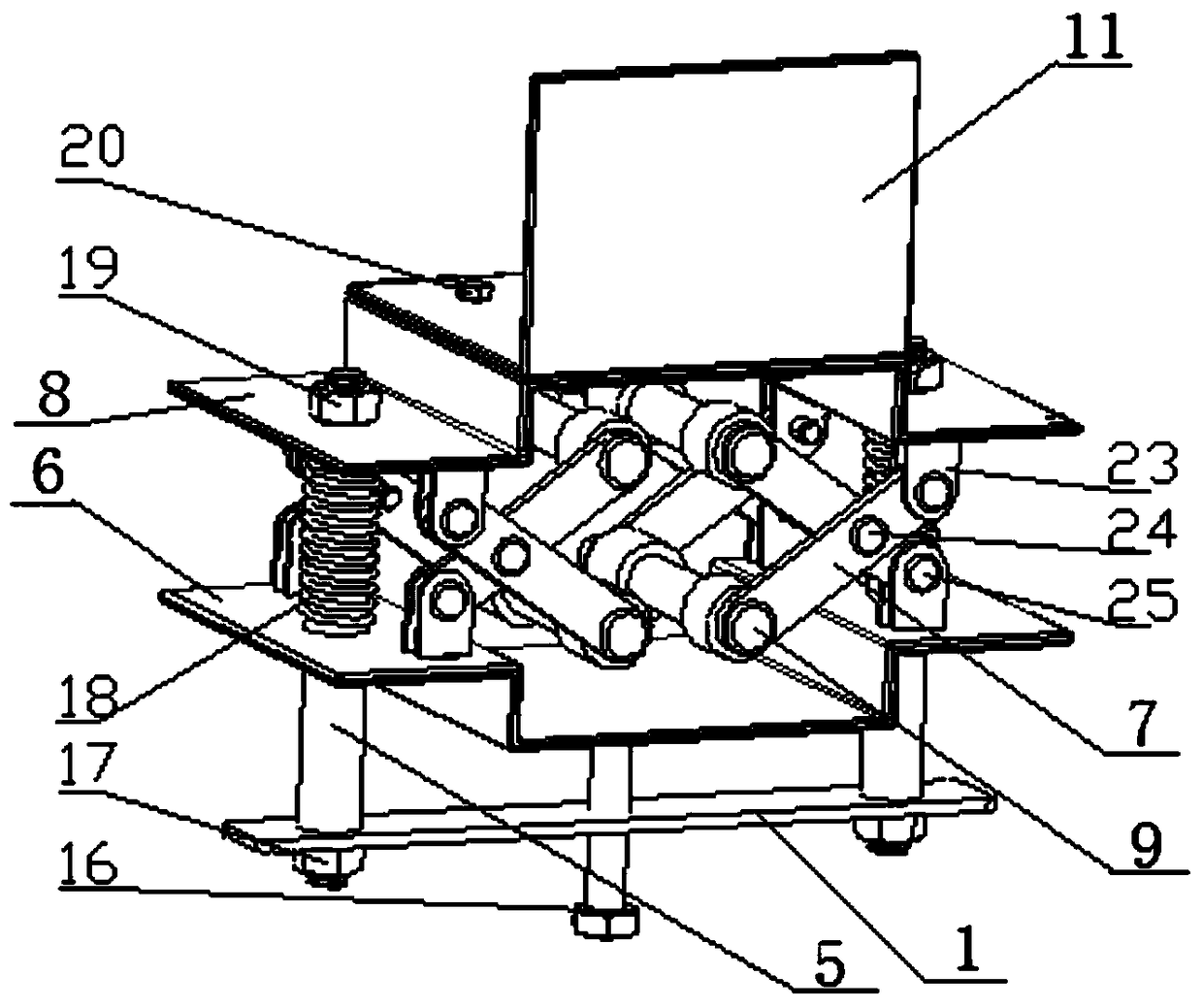

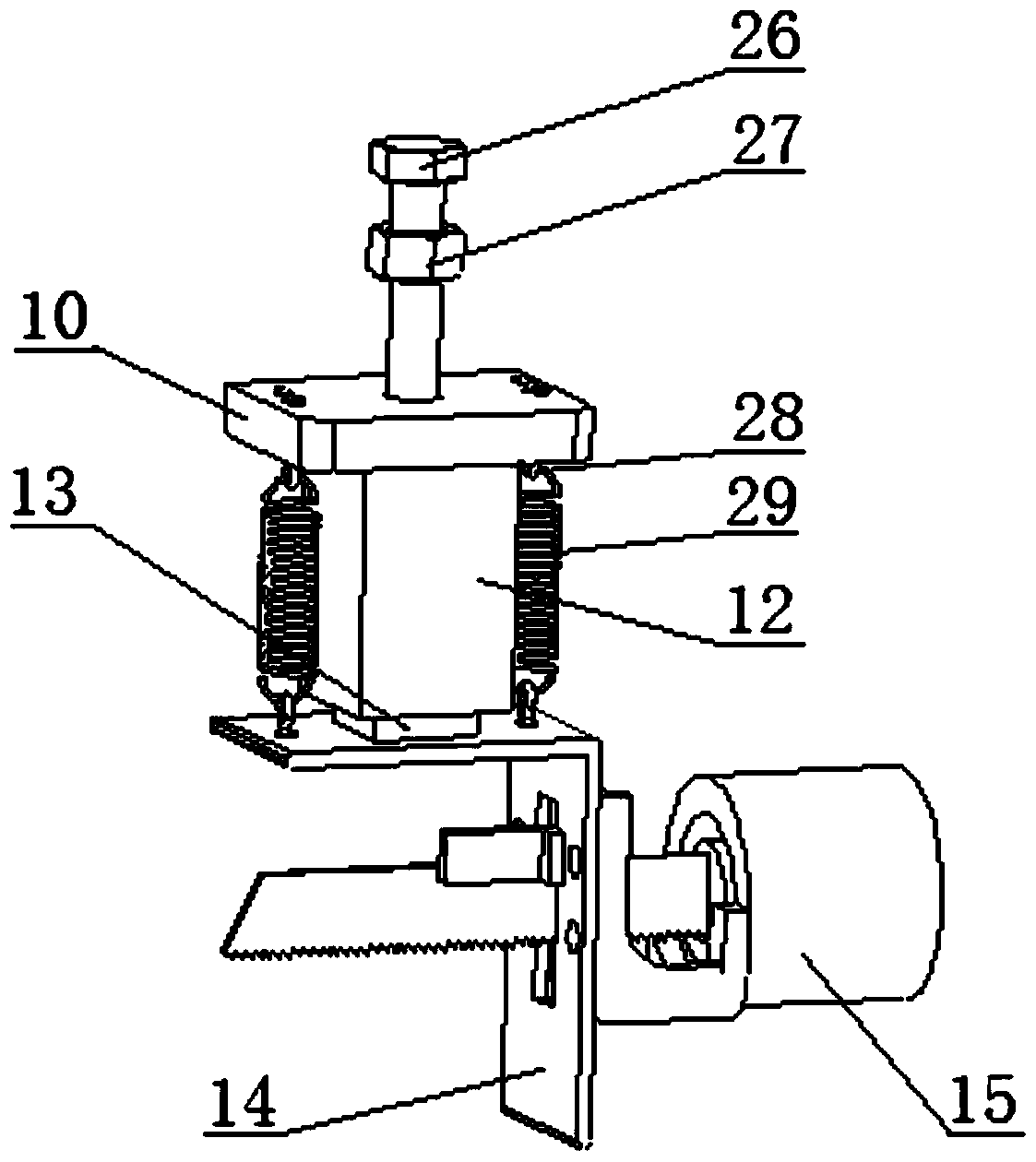

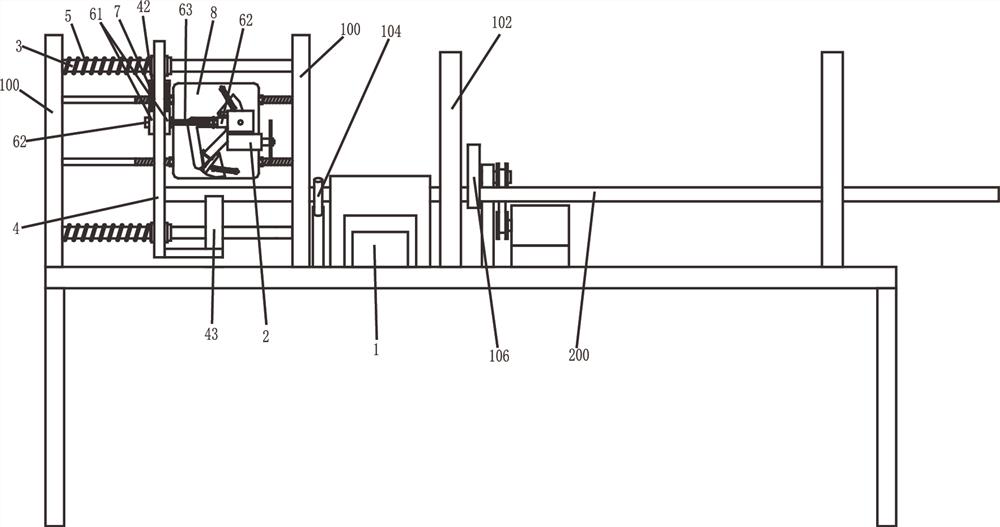

Automatic copper pipe cutting equipment

ActiveCN113182596AAvoid uneven cuttingImprove processing efficiencyTube shearing machinesShearing machine accessoriesPipe fittingElectric machinery

The invention discloses automatic copper pipe cutting equipment. The equipment comprises a pipe conveying device and a cutting mechanism, the cutting mechanism comprises a cutting blade driven by a motor, the automatic cutting equipment further comprises a guide rod parallel to the conveying direction of the pipe conveying device, a top plate is arranged on the guide rod in a sliding mode, a first reset elastic piece is arranged on one side of the top plate, a sliding assembly capable of vertically sliding is arranged on the top plate, a second reset elastic piece is arranged between the sliding assembly and the top plate, the sliding assembly is connected with a cutting mechanism, a guide plate perpendicular to the top plate is arranged on one side of the top plate, a circulating guide groove is formed in the guide plate, a guide block is arranged in the circulating guide groove, the guide block is connected with the cutting mechanism through a fixed rod, the circulating guide groove comprises a cutting guide groove and a reset guide groove, and a one-way limiting structure is arranged at a joint of the cutting guide groove and the reset guide groove. The automatic copper pipe cutting equipment can ensure that the cutting length is accurate and improve the machining efficiency.

Owner:诸暨市志冠汽配有限公司

Cropping and edge-folding device for clothing trademark processing

InactiveCN110883835AEasy to replaceMeet the needs of cuttingSevering textilesMetal working apparatusAgricultural engineeringStructural engineering

The invention discloses a cropping and edge-folding device for clothing trademark processing. The cropping and edge-folding device for clothing trademark processing comprises a body and a bearing table arranged on one side of the body. A trademark winding shaft is fixedly mounted on the bearing table, a guide mechanism is mounted on one side of the upper surface of the body, a smooth transfer mechanism is mounted on one side of the guide mechanism, a cutting bearing table is mounted on one side of the guide mechanism, a conveying mechanism is mounted on one side of the cutting bearing table, adispensing mechanism and an edge-folding mechanism are separately arranged on two sides of the conveying mechanism, and a material collecting table is arranged at one end of the conveying mechanism.A cropping device is mounted at the upper end of the cutting bearing table. The cropping device comprises an air cylinder, the lower end of the air cylinder is fixedly connected to a mounting seat, afirst groove is formed in the lower surface of the mounting seat, a connecting block is inserted into the first groove, and the lower end of the connecting block is fixedly connected to a cropping knife. By arranging a series of structures, the position of the cropping knife can be changed conveniently to meet different trademark cropping demands. The cropping knife is conveniently replaced, so that the cropping and edge-folding device is convenient to operate and the cropping efficiency is improved.

Owner:义乌市永大商标织造有限公司

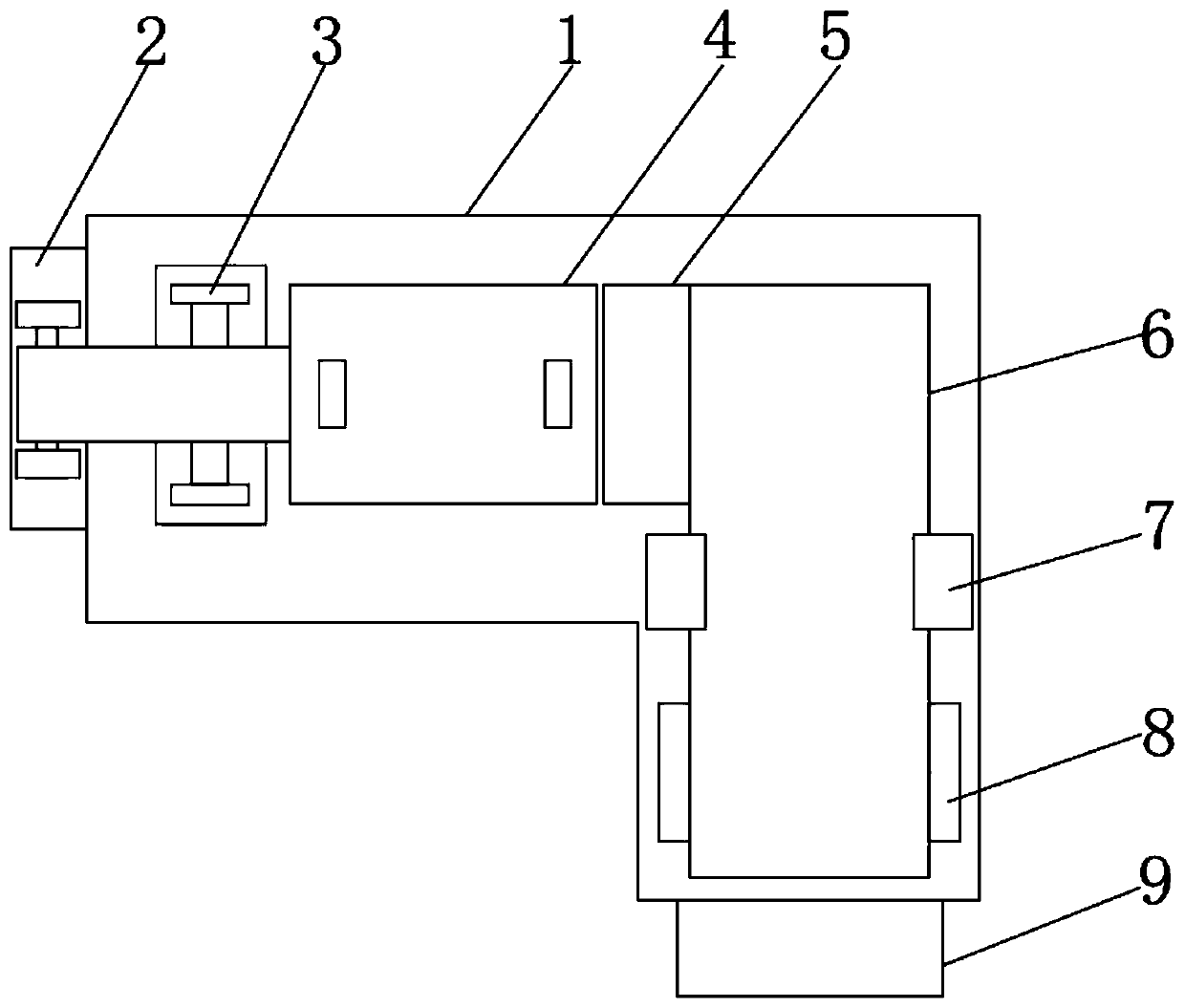

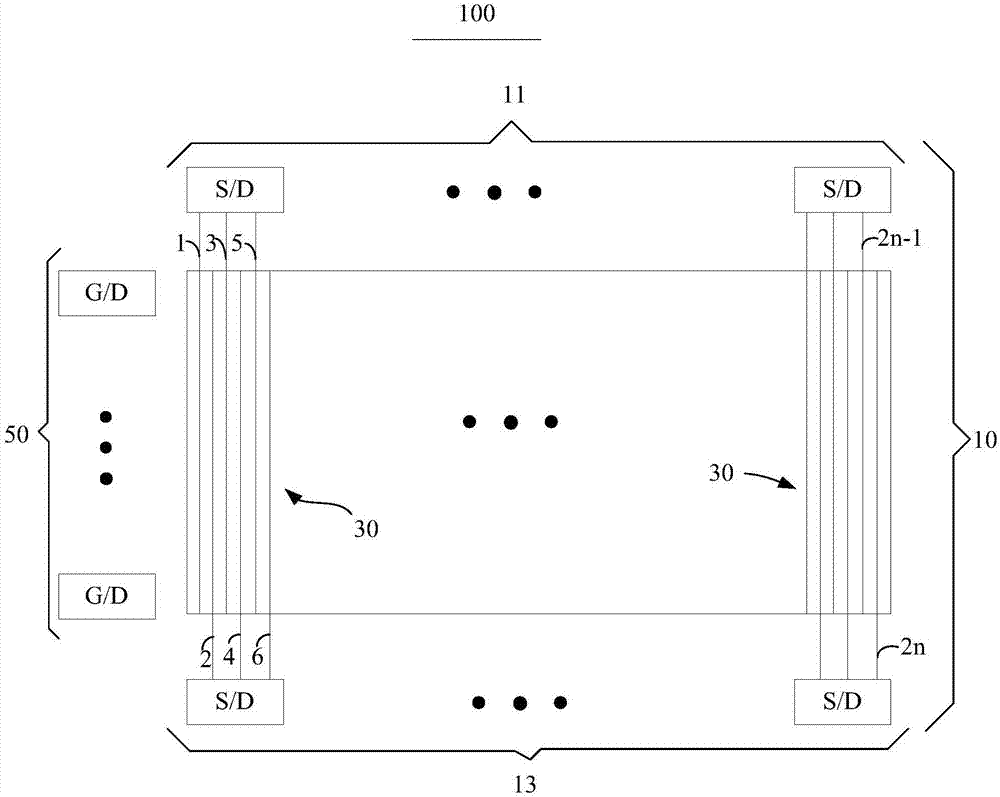

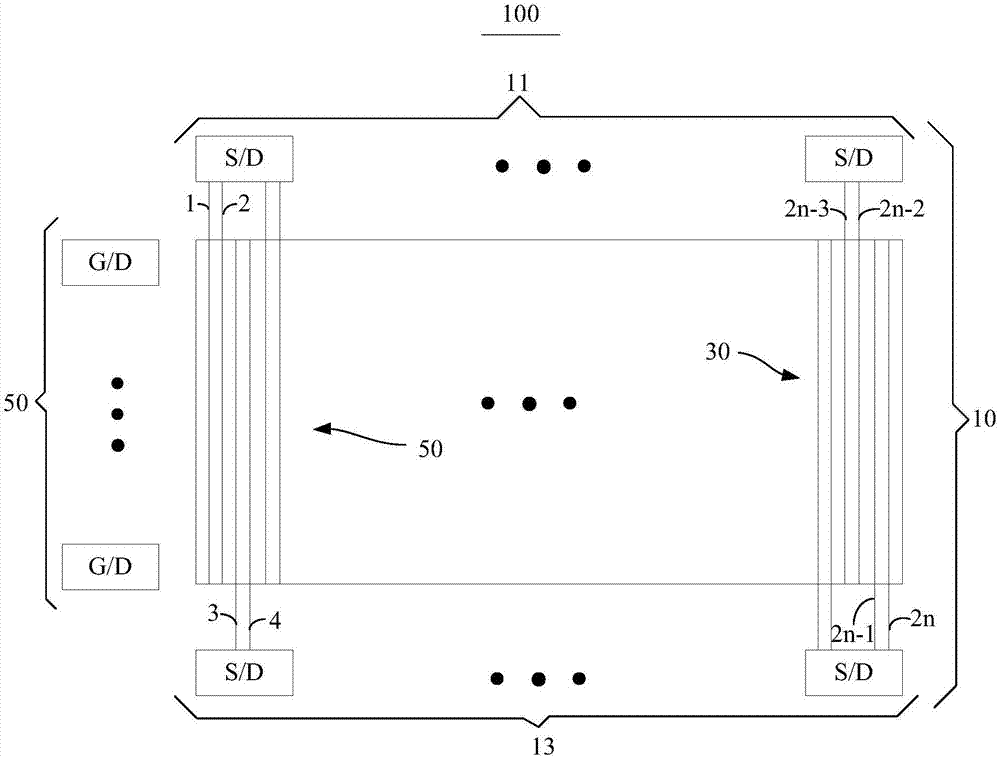

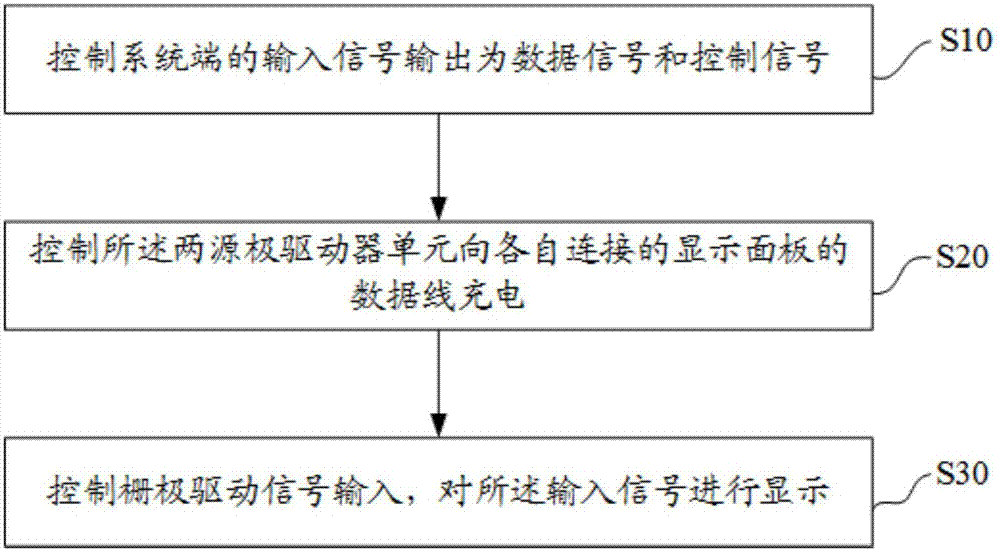

Driving method of display panel, driving device, and display device

InactiveCN107424581AAvoid inconsistent voltage attenuation onImprove the display effectStatic indicating devicesCharge voltageUltrasound attenuation

The invention provides a driving method of a display panel, a driving device, and a display device. The display panel comprises two-source driver units, which are disposed on the two opposite sides of the display panel, and the two-source driver units are connected with the data lines of the display panel in an up-down alternate way, or a left-right alternate way. During display driving, under control of a processor, input signals of a system end are output as data signals and control signals. According to the data signals, the two-source driver units are used to charge the correspondingly connected data lines of the display panel, and finally, according to the control signals, gate driving signal input is controlled. The input signals are displayed, and during the driving display of the display panel, the two-source driver units on the two sides of the display panel are used to provide charging voltage to the correspondingly connected data lines of the display panel, and therefore a problem of non-uniform segmentation caused by gamma voltages and the inconsistent attenuation of the voltages of the data line is prevented, and the display effect of the panel is improved.

Owner:HKC CORP LTD +1

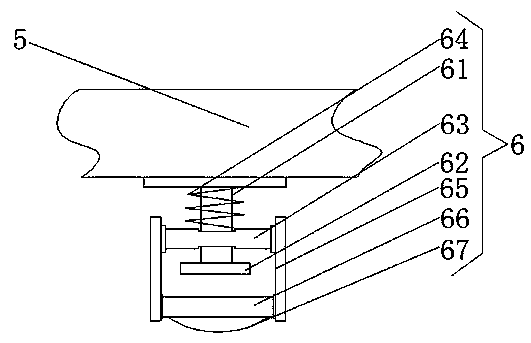

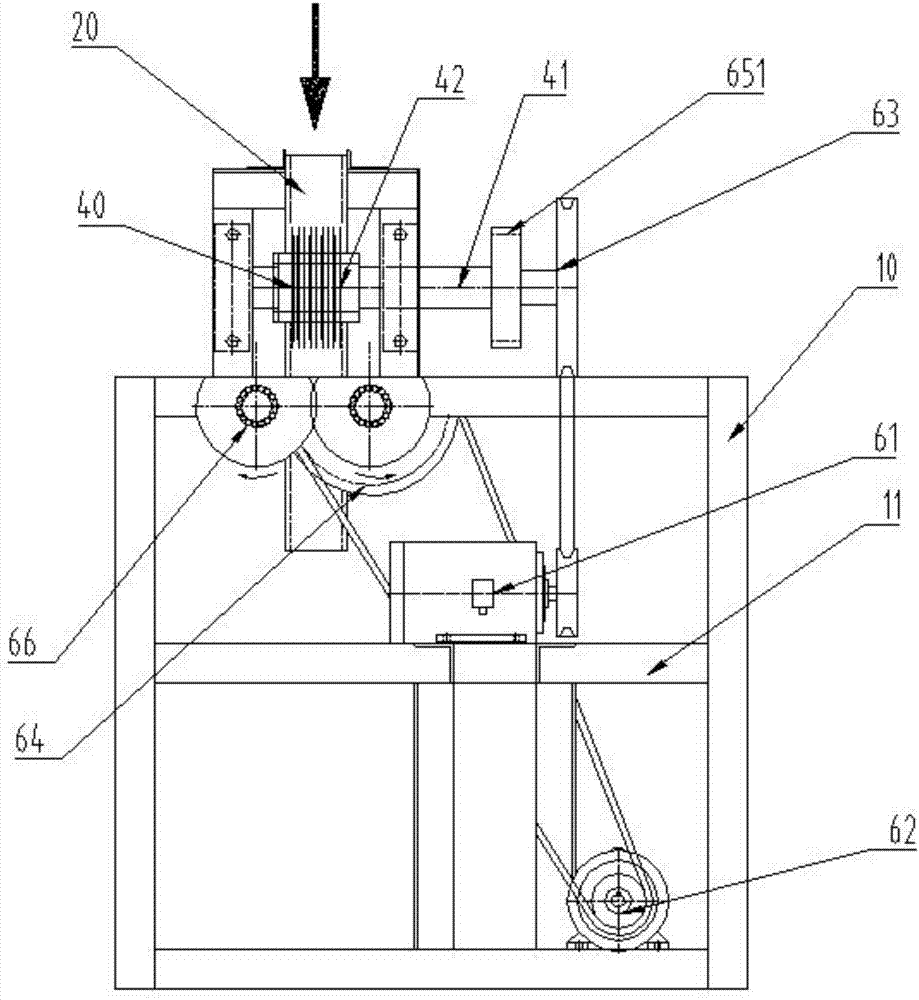

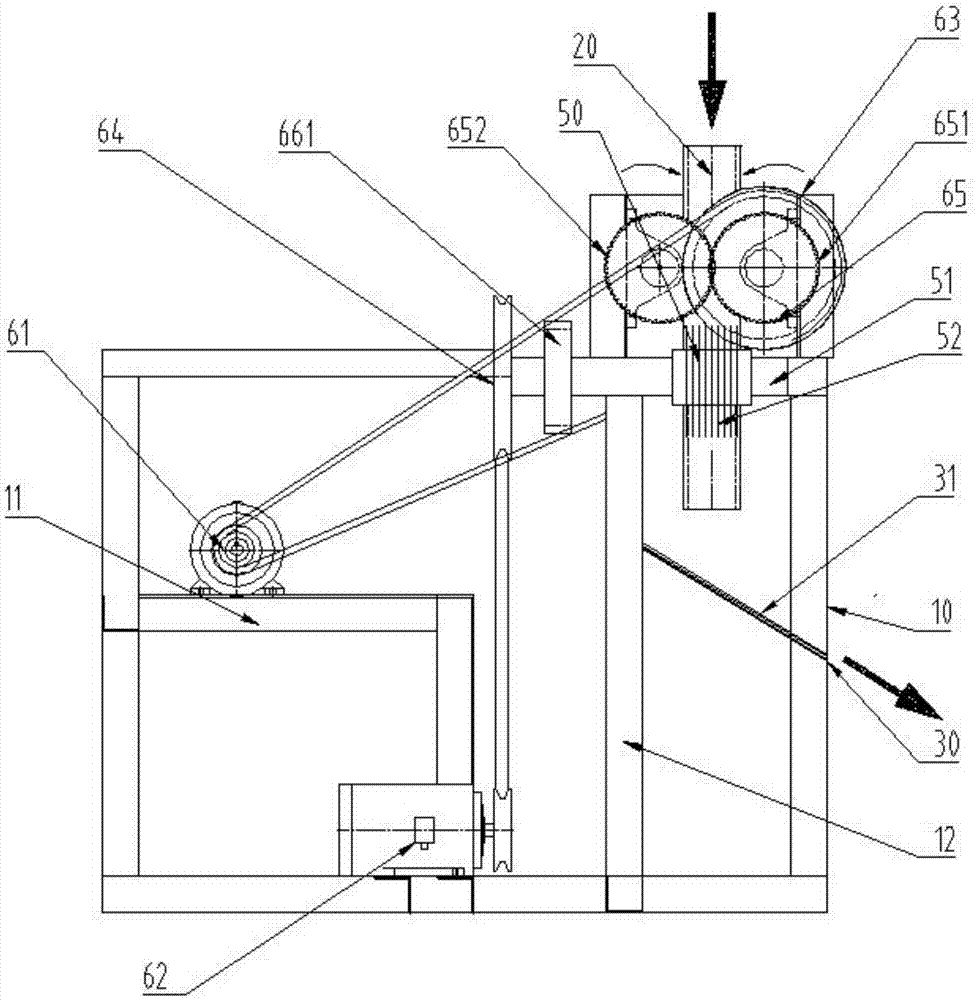

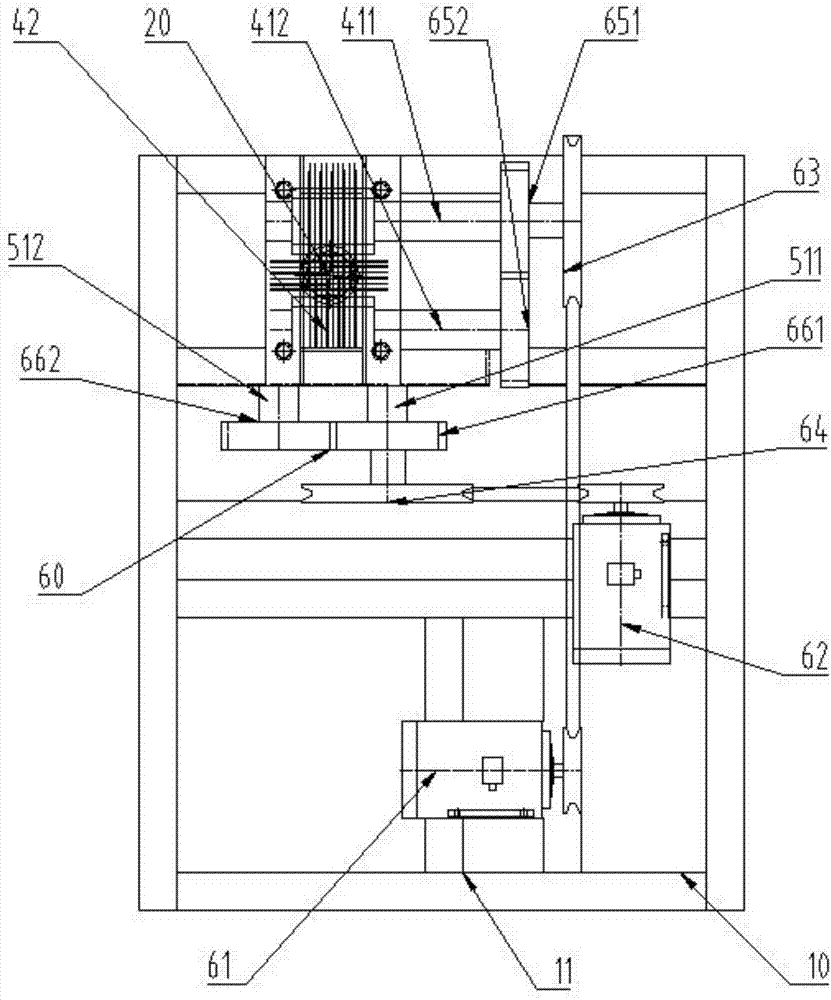

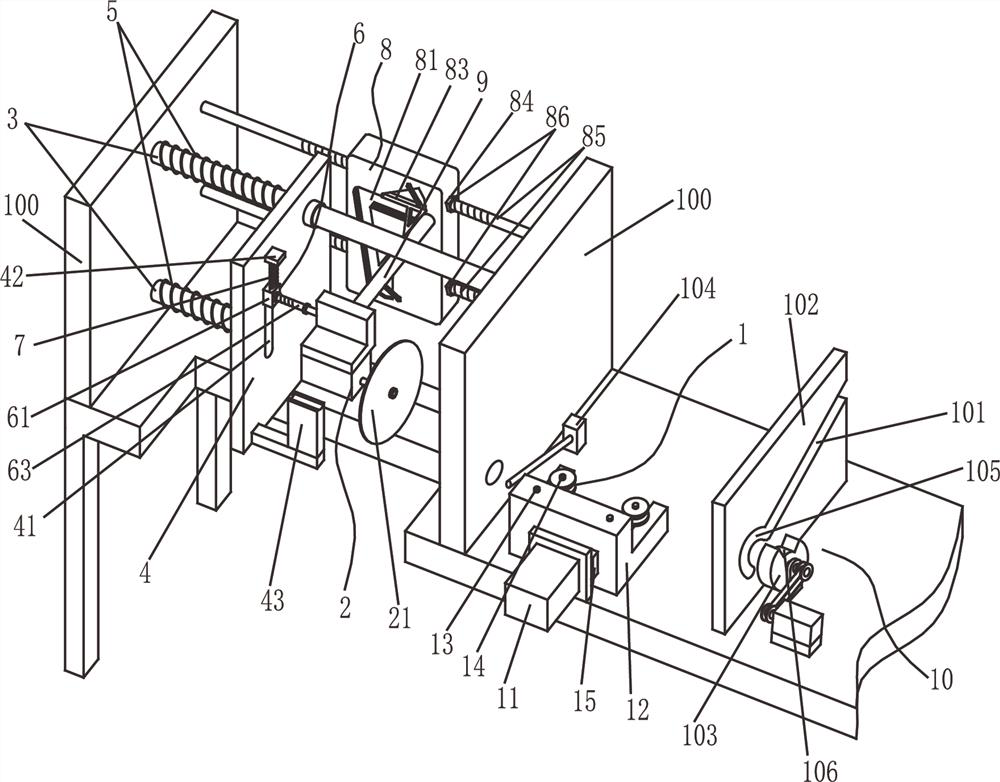

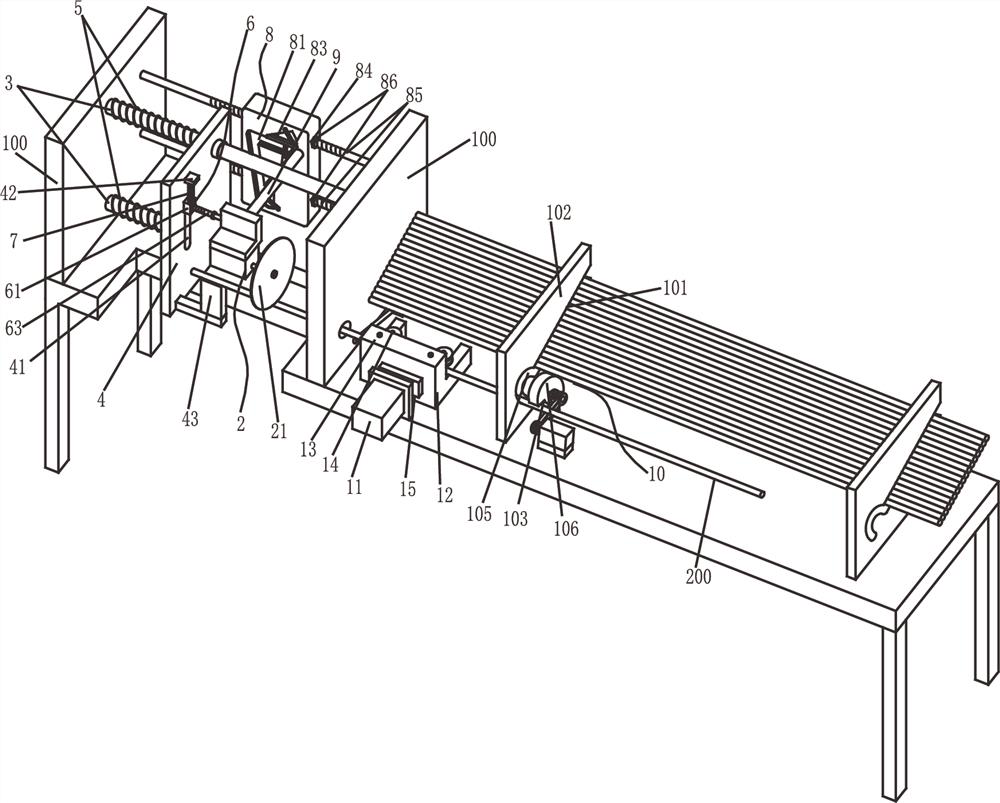

Burdock bar cutter

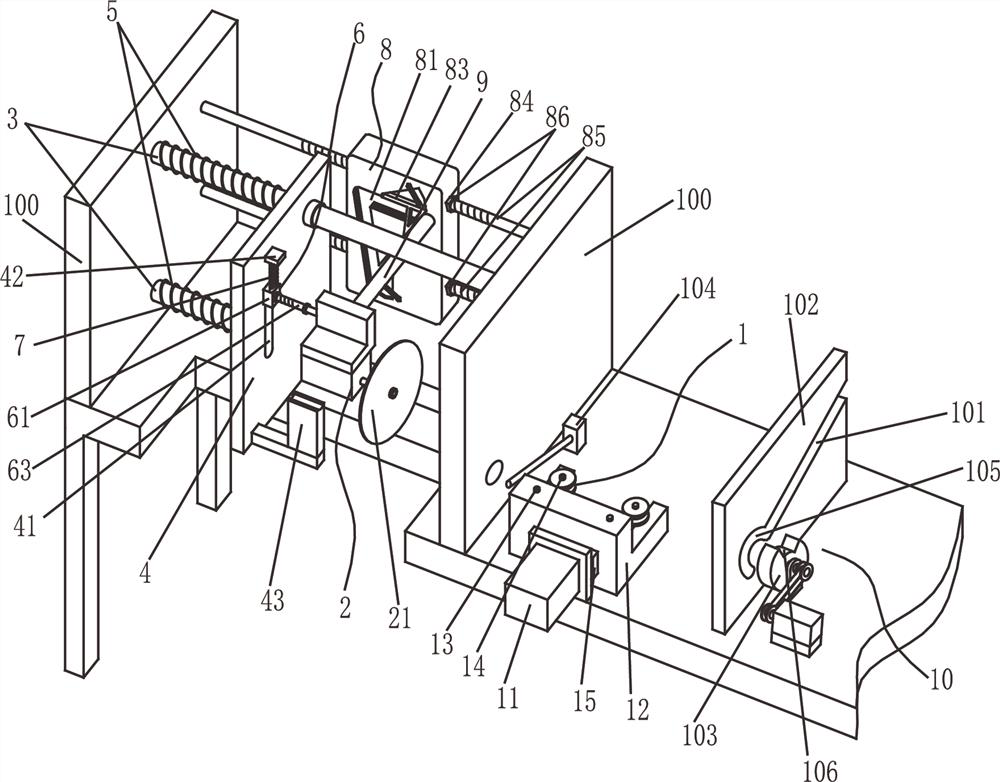

PendingCN107297767ALow installation accuracy requirementsSmall vibrationMetal working apparatusMechanical engineeringEngineering

The invention discloses a burdock bar cutter. The burdock bar cutter comprises a rack, a feeding part arranged on the top of the rack, a discharge port formed in the side face of the rack, a slicing mechanism, a bar cutting mechanism and a transmission mechanism, wherein the slicing mechanism, the bar cutting mechanism and the transmission mechanism are arranged in the rack; burdock is subjected to slicing and bar cutting through the slicing mechanism and the bar cutting mechanism in sequence, and the materials are discharged from the discharge port through a guide plate; the special feeding part is adopted, the burdock can be prevented from entering a non-cutting passage to block a tool and influence processing, a pusher arranged in the middle of a feed cylinder can prevent the phenomenon that the bottom of the burdock is cut off by the bar cutting mechanism at the lower end due to the action of gravity in the slicing process, and it is guaranteed that the finished burdock product conforms to the specification requirements; a matched cylinder sleeve ensures mutual matching of the burdock and the feed cylinder, and the phenomenon that due to the fact that in the cutting process, the burdock shakes, cutting is conducted non-uniformly is prevented. The whole mechanism can achieve burdock bar cutting automatically, the quality of the processed finished product is guaranteed, and the production efficiency is improved.

Owner:温立超

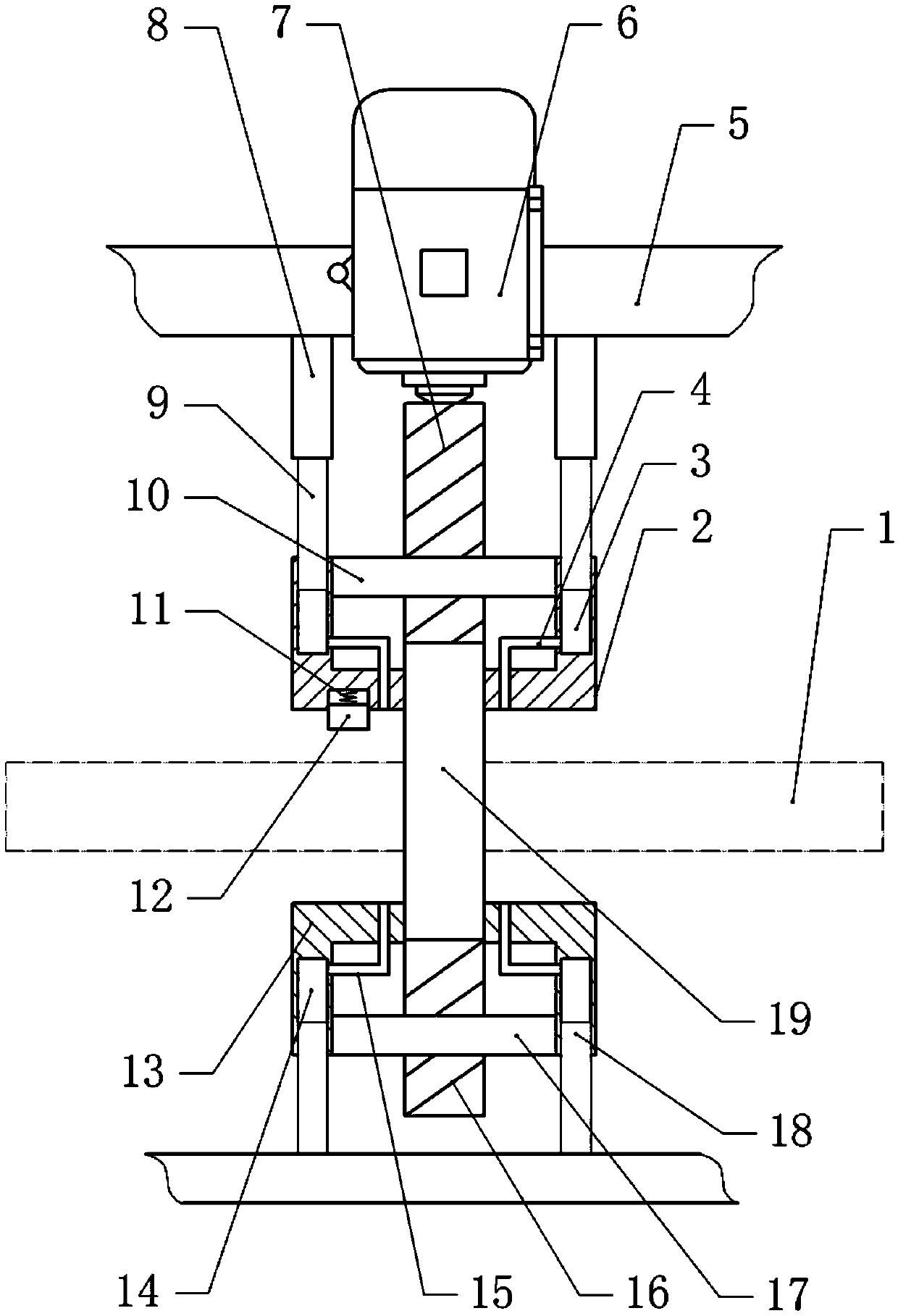

A large-section wire stripper

ActiveCN104993429BReduce crimp qualityFlat sectionLine/current collector detailsApparatus for removing/armouring cablesMechanical engineering

Owner:CHINA ELECTRIC POWER RES INST +2

Grid leveling device

ActiveCN110871291AAvoid cleaningAvoid artificialShearing machinesMaintainance and safety accessoriesEngineeringPush switch

The invention relates to the technical field of grid weaving manufacturing, and discloses a grid leveling device which comprises a frame body, a first screw rod for fixing a cutting knife and a driving mechanism for driving the first screw rod. The driving mechanism drives the first screw rod to drive a cutting edge of the cutting knife to align with a grid; at least two fixing mechanisms are arranged on the frame body on the outer side of the first screw rod, and pressing mechanisms are slidably connected to the lower parts of the fixing mechanisms; each pressing mechanism comprises a U-shaped frame with an opening facing upwards and a connecting plate in threaded connection with the first screw rod, wherein the connecting plate is fixed on the upper part of the U-shaped frame, the side wall of the U-shaped frame is provided with an air cavity which forms an inflator structure with the fixing mechanism, and the air cavity communicates with an air pipe facing the lower part of the U-shaped frame; the cutting knife penetrates through the lower part of the U-shaped frame, and the bottom of the U-shaped frame is also provided with a button switch electrically connected with the driving mechanism. Edge unevenness of the cutting part can be avoided in the cutting process of the grid, and meanwhile the damage to operators is avoided.

Owner:GUANGZHOU ZHUOYUE POWER NEW ENERGY CO LTD

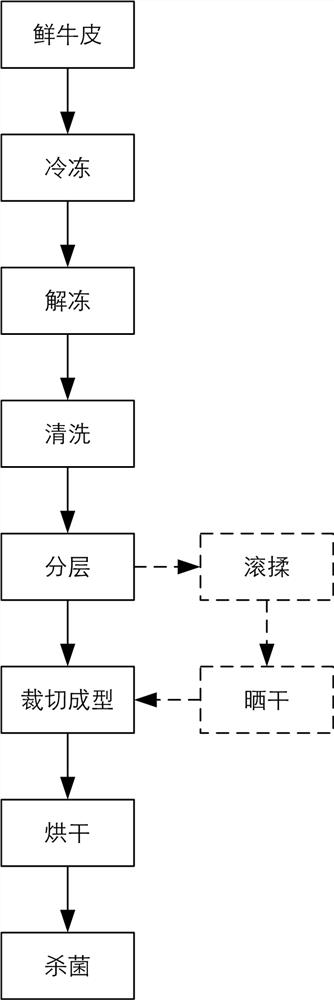

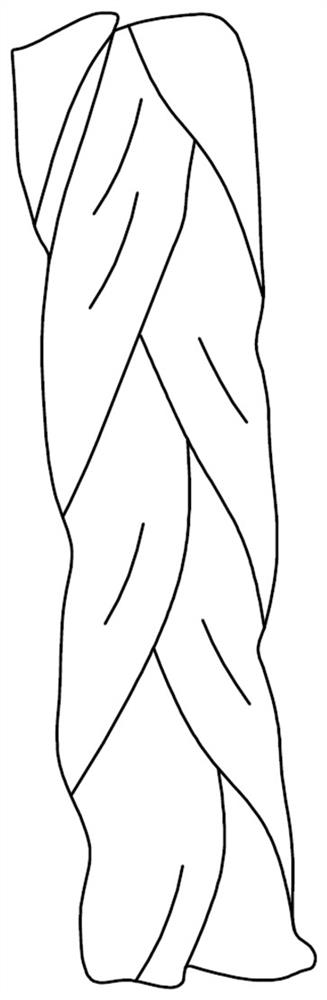

Preparation method and preparation system of fresh peel chews

PendingCN114831213AImprove palatabilityGood for healthFeeding-stuffRind cutting-off apparatusNutritionEngineering

The invention discloses a preparation method and a preparation system of fresh skin chews. The preparation method comprises the steps of freezing, unfreezing, cleaning, layering, cutting and forming, drying, sterilizing and the like. According to the preparation system, fresh barks serve as raw materials, and the fresh barks are divided into first-layer barks and second-layer barks through layering equipment in a mechanical unhairing mode. According to the preparation method, no chemical process treatment is carried out, and no chemical substance harmful to pets is contained. Nutrient substances of the pure natural fresh skin are not damaged, and the product is richer in nutrition. The main nutrient substance of the fresh cow leather is collagen, and the product is more beneficial to the body health of pets. The fresh skin chew has a rich beef flavor, can better arouse the appetite of pets, and is higher in palatability.

Owner:JIANGXI HUAHENG PET FOODS CO LTD

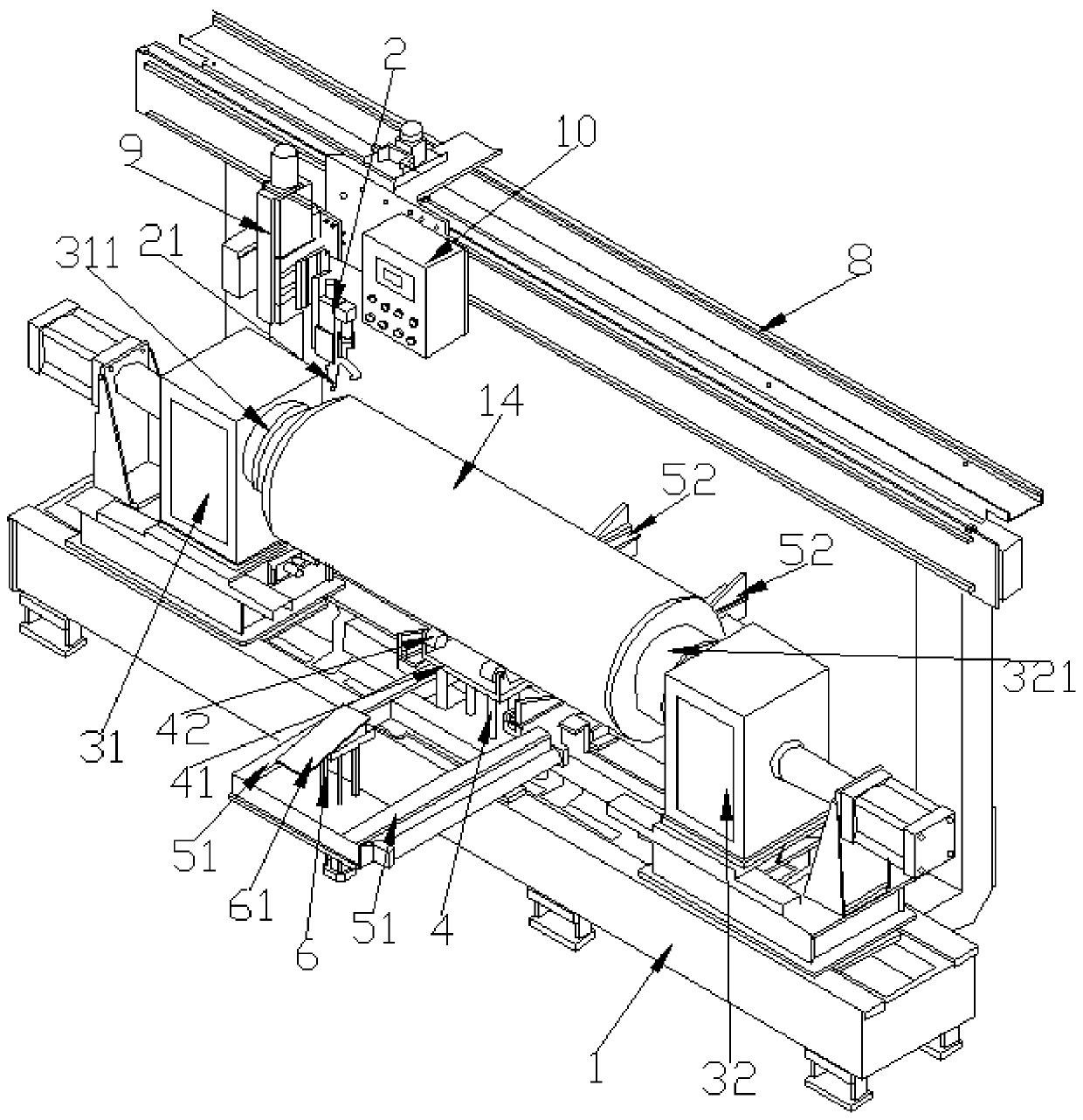

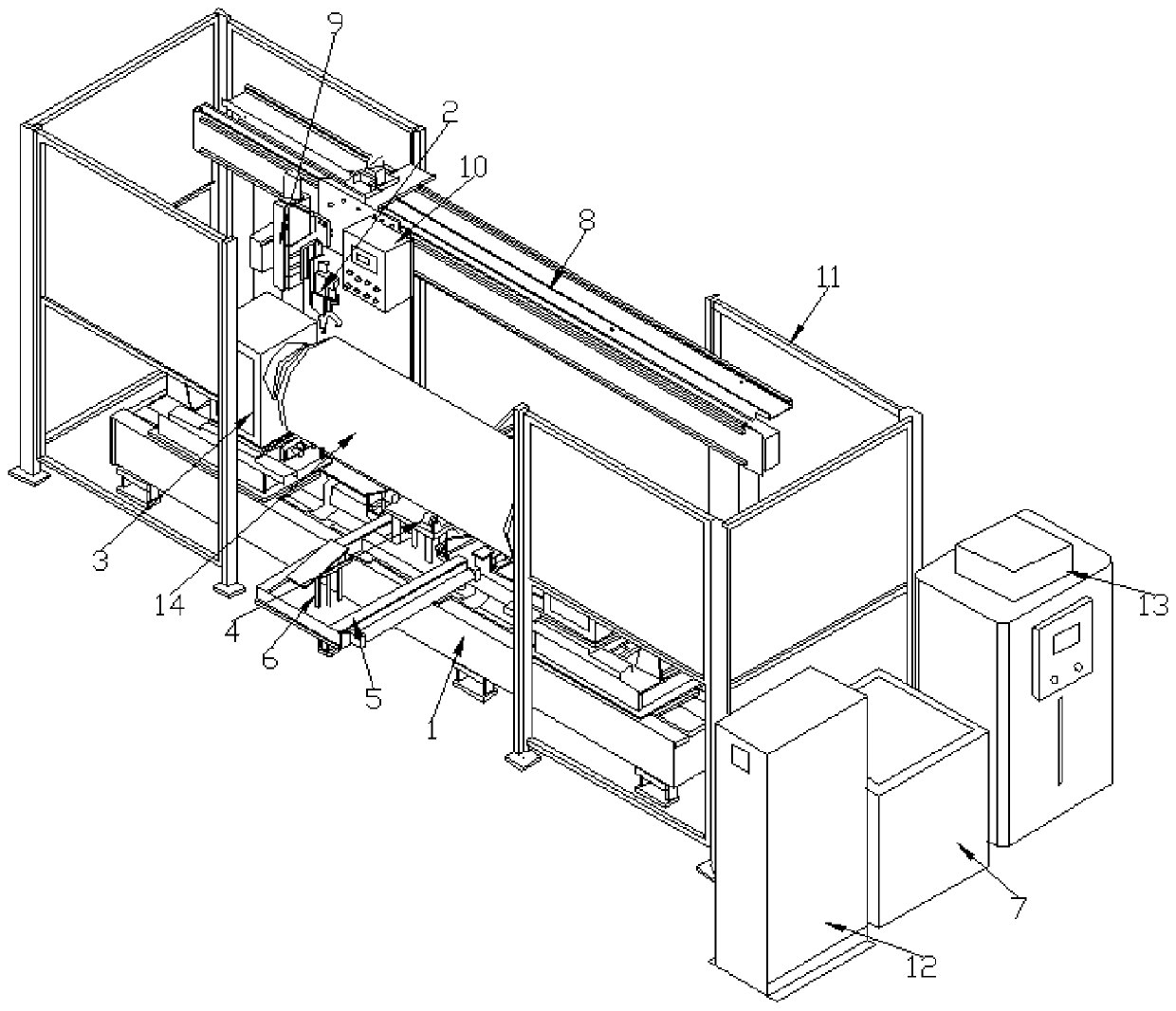

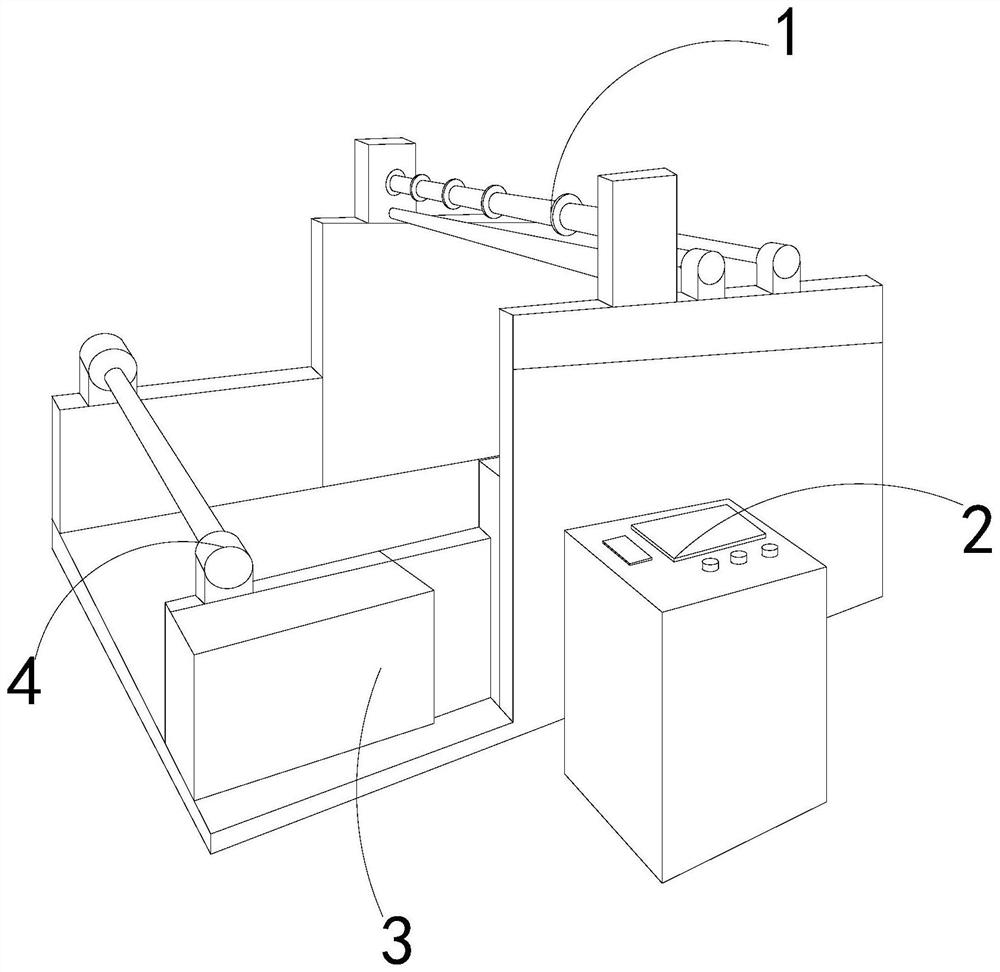

Run-on plate cutting device and cutting method

PendingCN111421246AAvoid uneven cuttingAvoid missed cutsLaser beam welding apparatusEngineeringStructural engineering

The invention provides a run-on plate cutting device and a cutting method and relates to the technical field of cutting devices. The technical problem that in the prior art, when a cutting machine ismanually held in hand to cut run-on plates at the positions of arc starting and arc extinguishing of straight welding of a water tank inner container, the potential safety hazard is relatively high issolved. The cutting device comprises a support, a cutting mechanism and a supporting and rotating mechanism, wherein the cutting mechanism and the supporting and rotating mechanism are supported on the support; the supporting and rotating mechanism is used for clamping the two ends of a to-be-machined piece and can drive the to-be-machined piece to rotate; the position of a cutting head on the cutting mechanism can be adjusted; and when the cutting head is adjusted to a preset position, the to-be-machined piece on the supporting and rotating mechanism is rotated so that the run-on plate on the to-be-machined piece can be subjected to cutting treatment. The run-on plate cutting device and the cutting method are used for achieving cutting on the run-on plates of straight welding of the water tank inner container, the accuracy and stability of cutting is improved, and safety is improved.

Owner:GREE ELECTRIC APPLIANCES WUHAN +1

Alumite cutting machine

PendingCN113954151AAvoid uneven cuttingMetal working apparatusElectrostatic chargesThin membraneEngineering

The invention discloses an alumite cutting machine. The alumite cutting machine structurally comprises a material fixing mechanism, a guide rail, a base and a cutting tool, the guide rail is fixedly embedded in the inner side of the material fixing mechanism, the cutting tool is in sliding fit with the outer surface of the guide rail, the bottom of the material fixing mechanism is attached to the upper surface of the base, through reverse thrust generated by the inner side of an alumite film roll to an adsorption disc, the adsorption disc can slide and contract inwards along a lower fixing block, and when the bottom of the adsorption disc is tightly attached to the upper surface of the lower fixing block, the adsorption disc can generate adsorption force on the inner side of the alumite film roll; and the blade can slide and contract inwards along the frame through reverse thrust generated by the alumite film roll on the blade, so that the static electricity is guided into a guide strip through cooperation of a block body and a wire, and the static electricity can be guided into the ground due to the fact that the guide strip is long.

Owner:林荥

Uniform-thickness slicing device for kiwi fruit processing

The invention discloses a uniform-thickness slicing device for kiwi fruit processing, and relates to the technical field of kiwi fruit processing. The problem that kiwi fruits are likely to be accumulated during mechanical feeding during production line batch production and affect cutting uniformity is solved. The device specifically comprises a shell and a feed hopper, an auxiliary frame is welded at the top end of the shell, the feed hopper is welded at the top end of the auxiliary frame, a discharging frame is welded at the bottom end of the shell, a side box is welded on the outer wall ofone side of the auxiliary frame, a transverse cutting mechanism is arranged in the side box, a plurality of isolation strips are adhered to the inner wall of the feed hopper, an elastic sleeve is arranged on the side wall of each isolation strip, the top end of each isolation strip is of an arc-shaped structure, and each elastic sleeve is of an elliptical sleeve structure. The device can adapt tokiwi fruits of an elliptical structure, protects the surface layers of the kiwi fruits, reduces the descending speed of the kiwi fruits, avoids the phenomenon that the kiwi fruits are damaged before slicing, and avoids the phenomenon that the cutting is not uniform due to cutting shaking during transverse cutting.

Owner:六安鑫隆果业股份有限公司

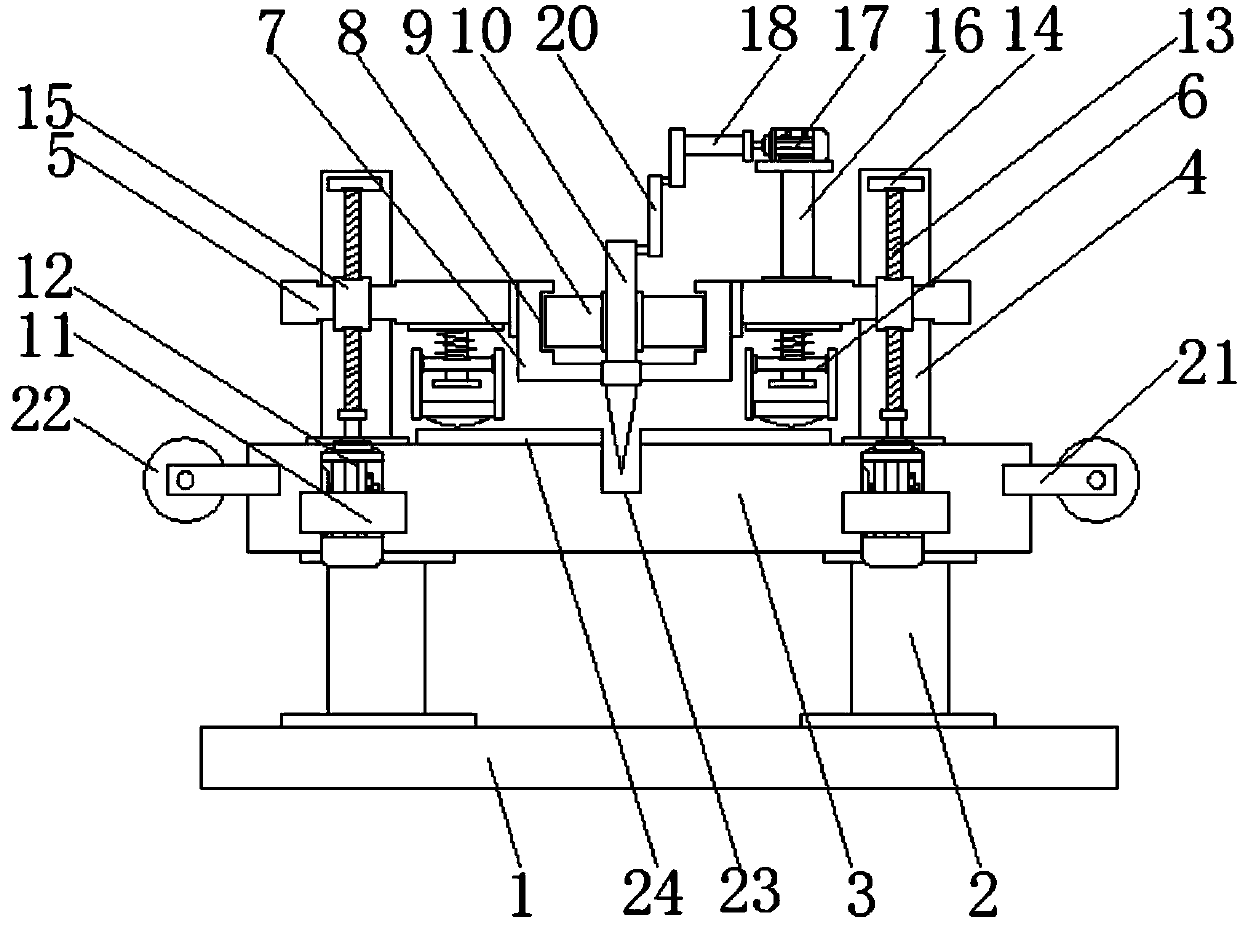

A computer circuit board cutting device for automatically fixing circuit boards

ActiveCN112223391BAchieve a fixed effectAvoid uneven cuttingMetal working apparatusElectric machineryControl theory

The invention relates to the technical field of computer accessories, and discloses a computer circuit board cutting device for automatically fixing circuit boards, including a workbench, a top plate is arranged above the workbench, and a first motor is fixedly connected to the bottom of the top plate , the bottom of the first motor is rotatably connected with a turntable, the bottom of the turntable is fixedly connected with an arc track, the left side of the bottom of the arc track is movably connected with a movable rod, and the bottom of the movable rod is fixedly connected with a movable The bottom of the movable sleeve is plugged with an extruding rod, the bottom of the extruding rod is fixedly connected with a splint, the right side of the top of the workbench is fixedly connected with a fixed track, and the inside of the fixed track is provided with a second motor. Through the cooperation of the first motor, turntable, arc track, movable rod, movable sleeve, extrusion rod and first spring, the splint is driven to fix the circuit board, thereby achieving the effect of using the splint to fix the circuit board and preventing the circuit board from being cut incorrectly. uniform.

Owner:杭州富凌科技有限公司

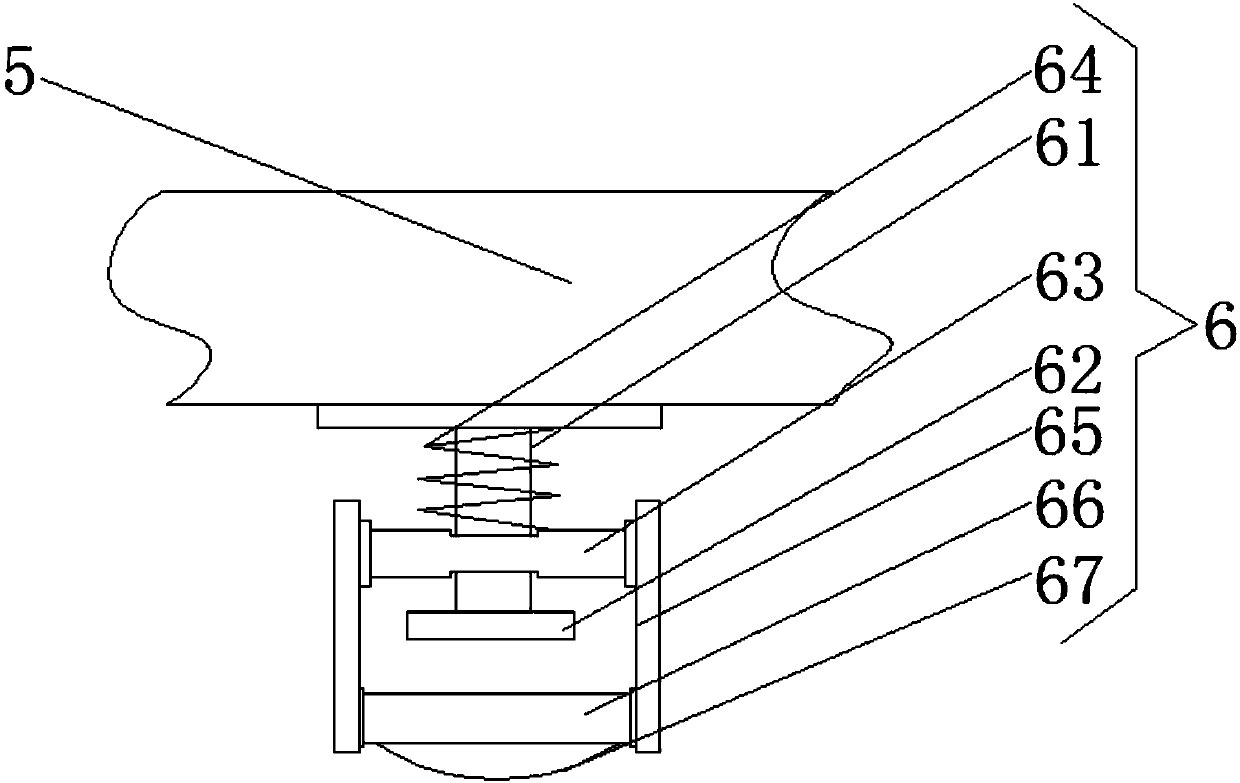

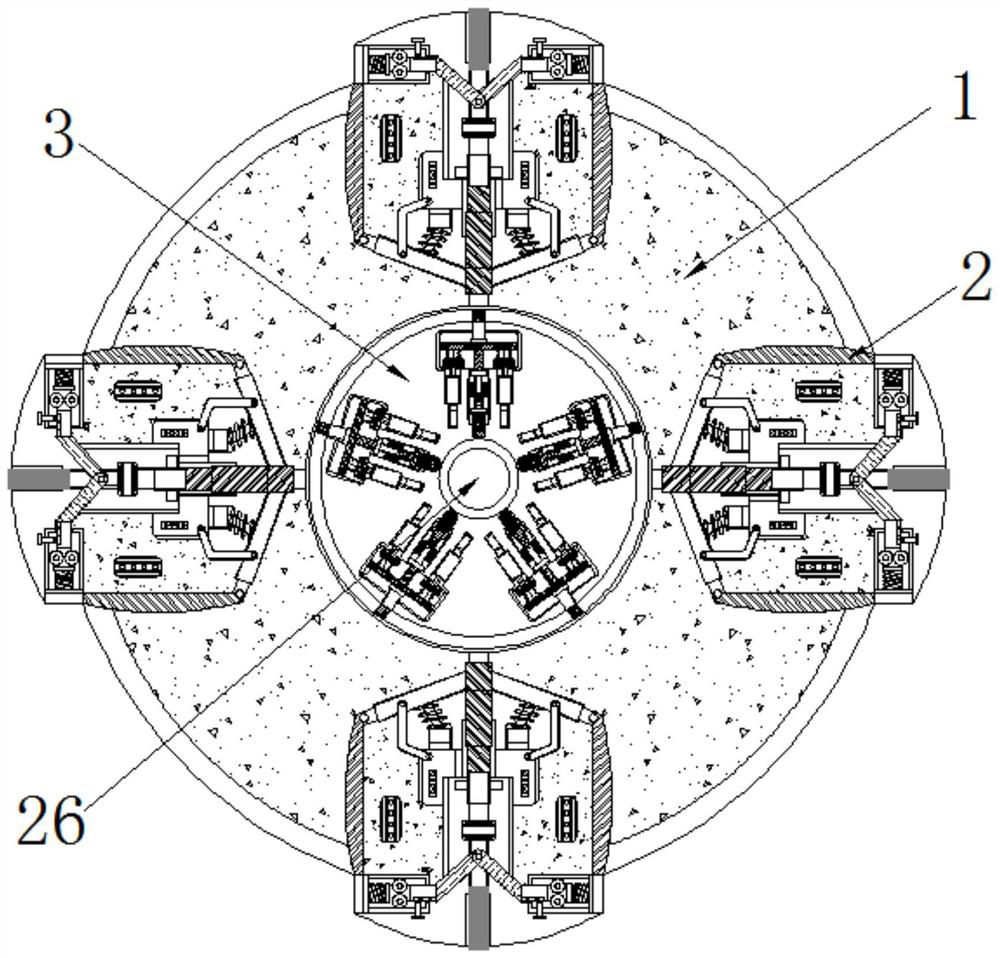

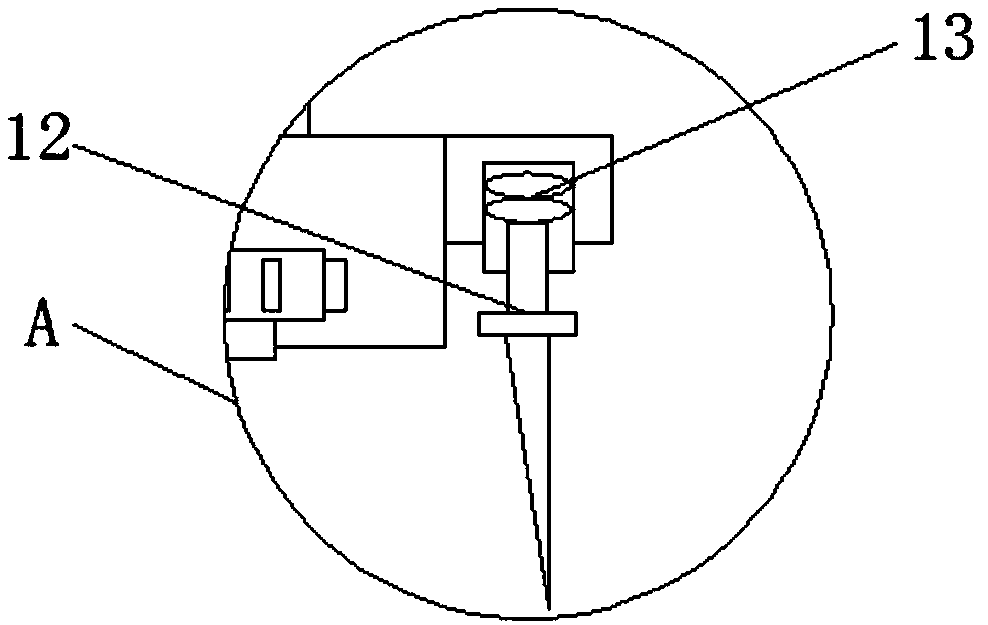

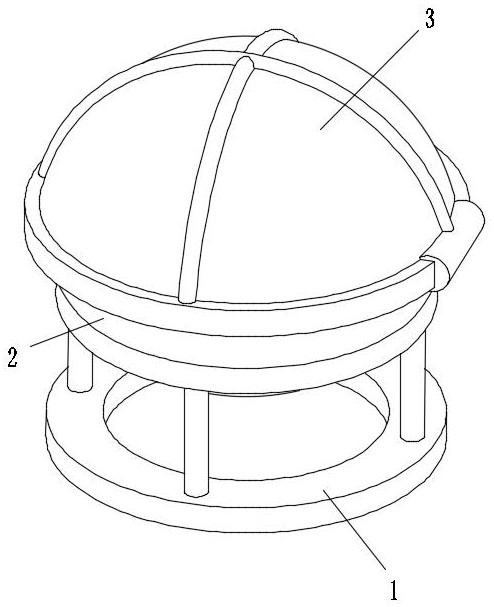

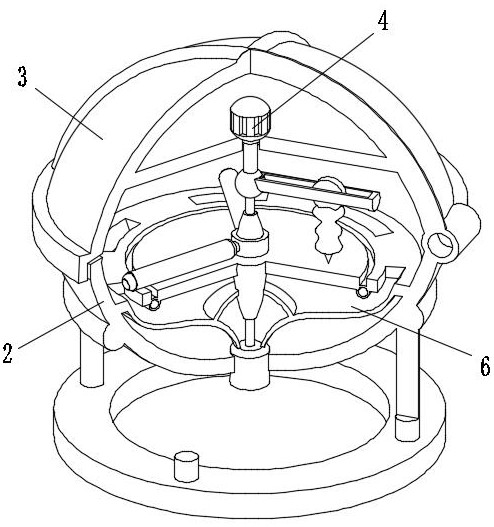

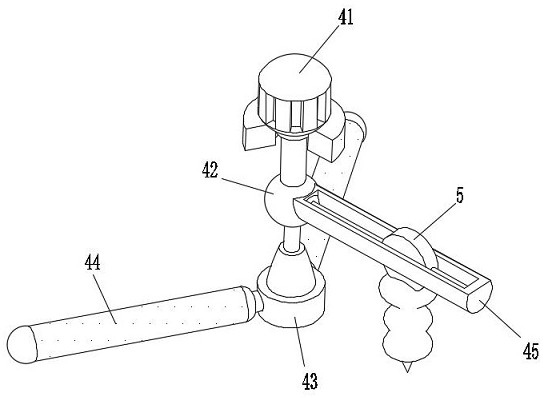

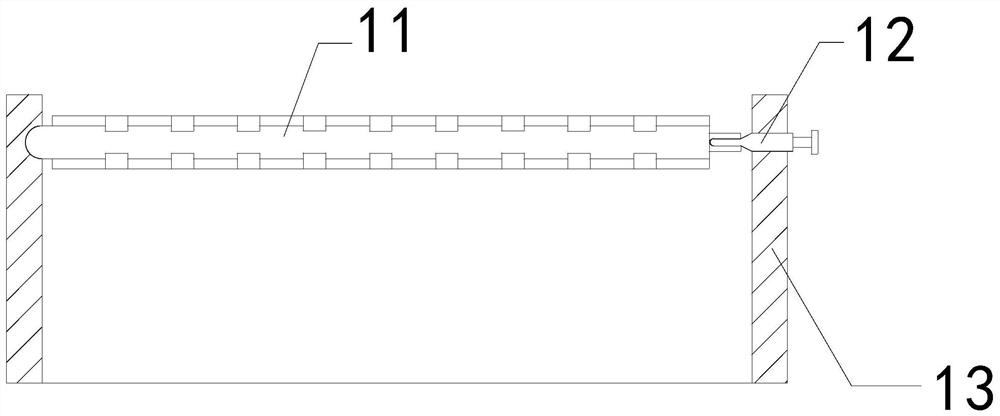

Linear cutting device for 3D printing metal false tooth

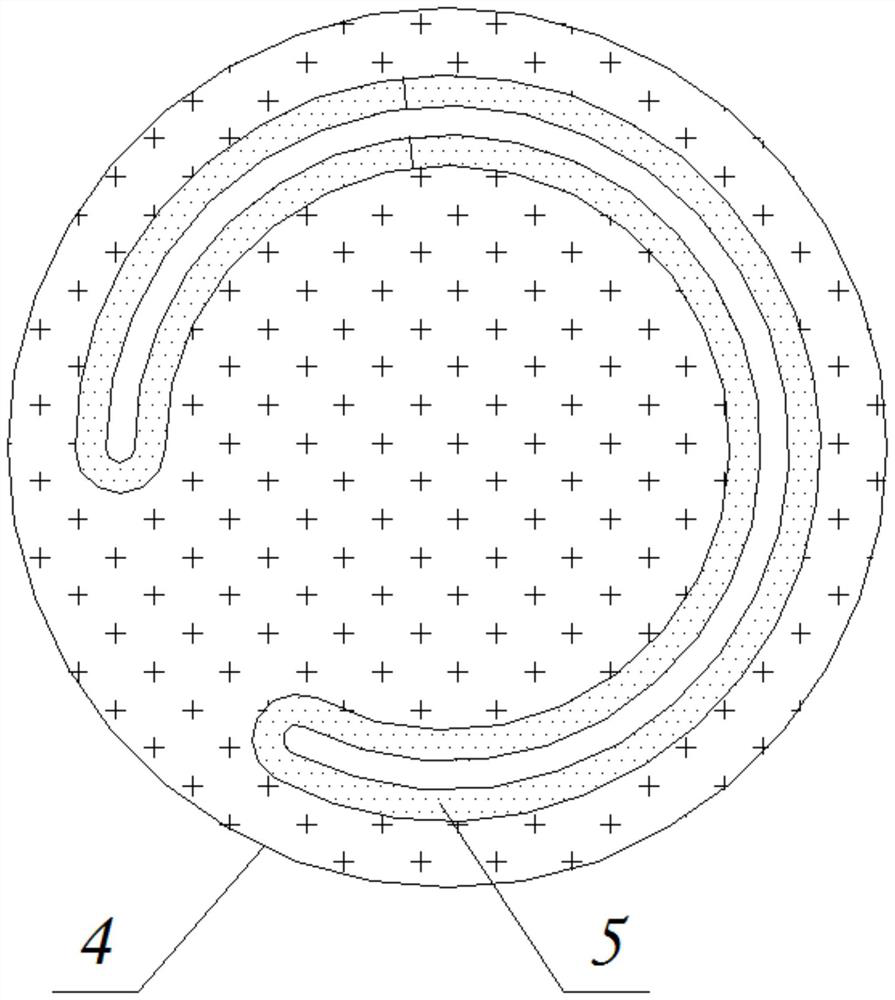

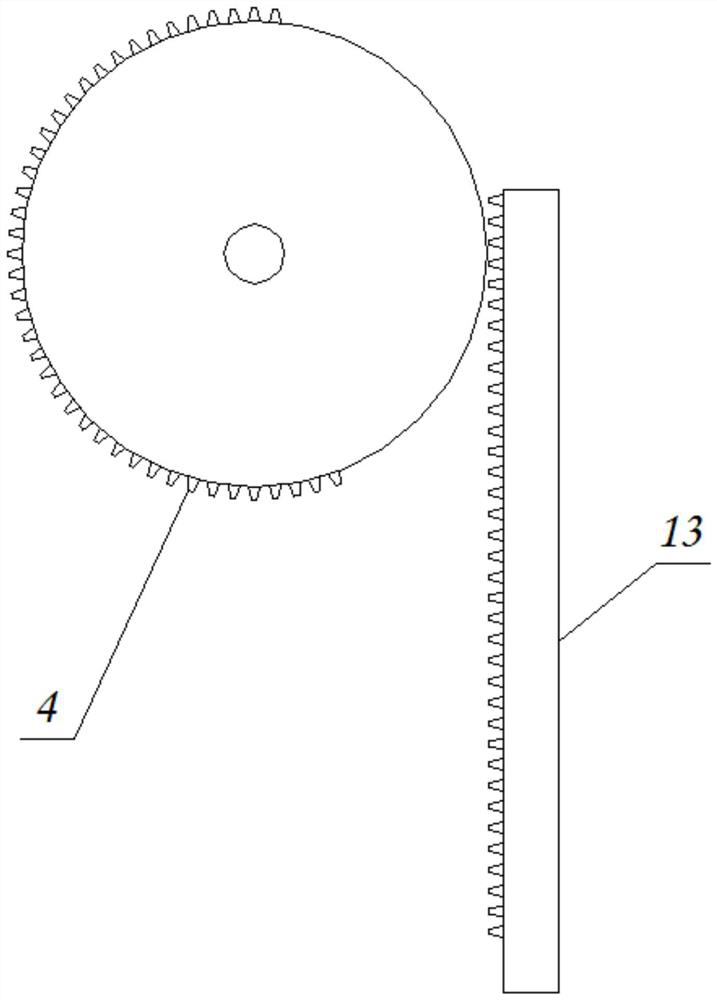

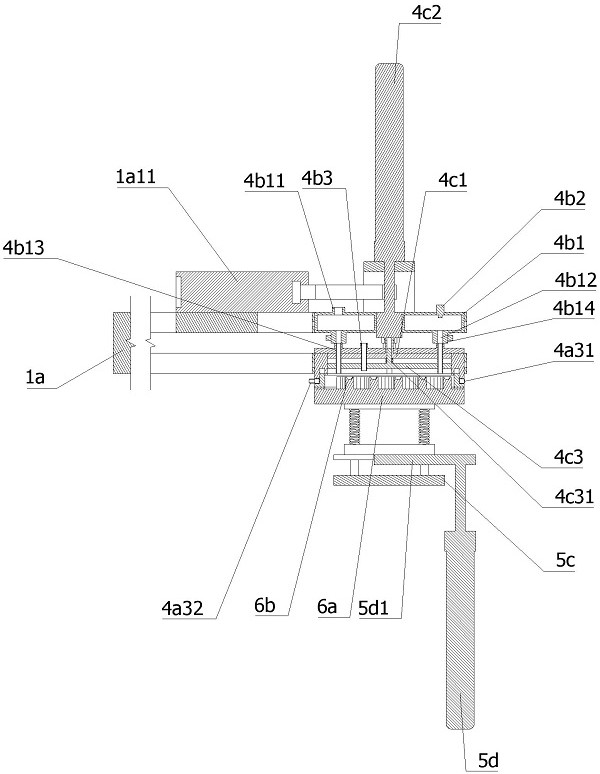

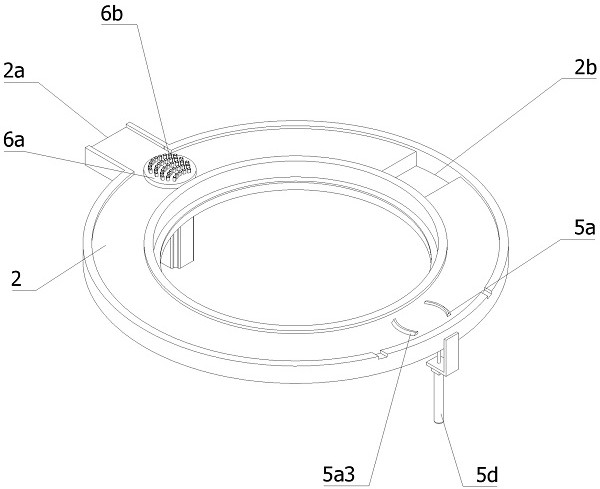

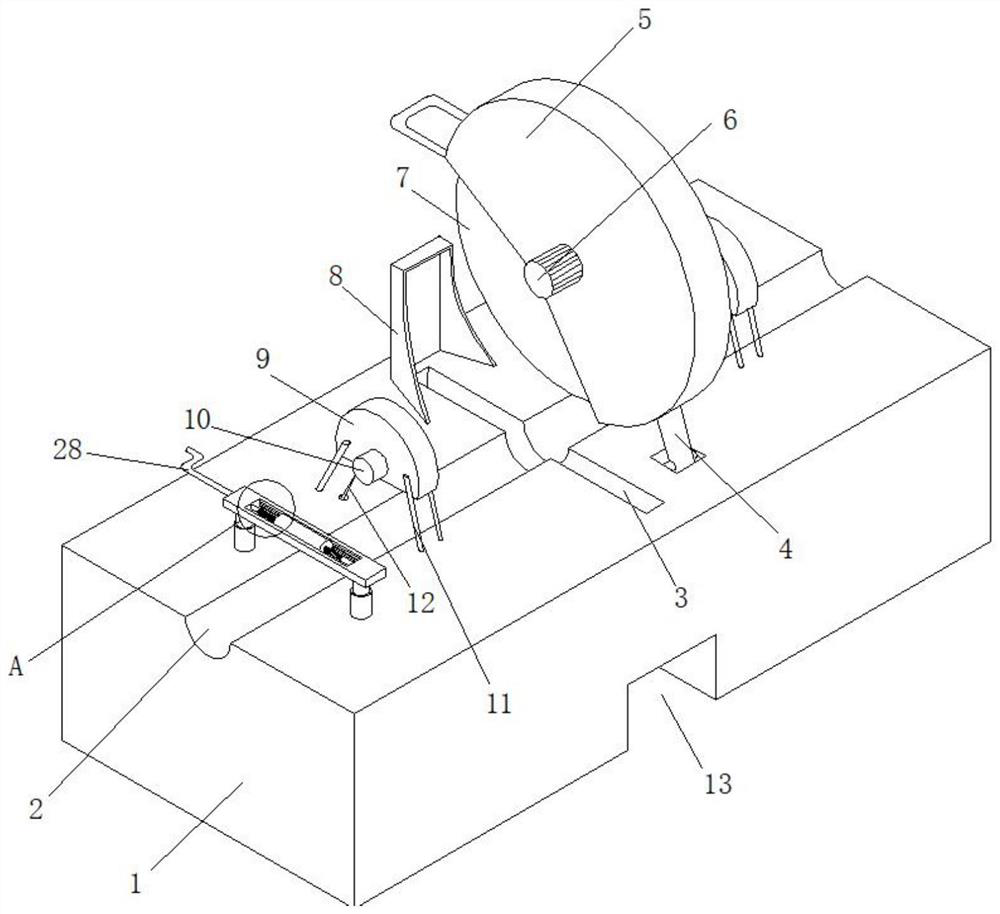

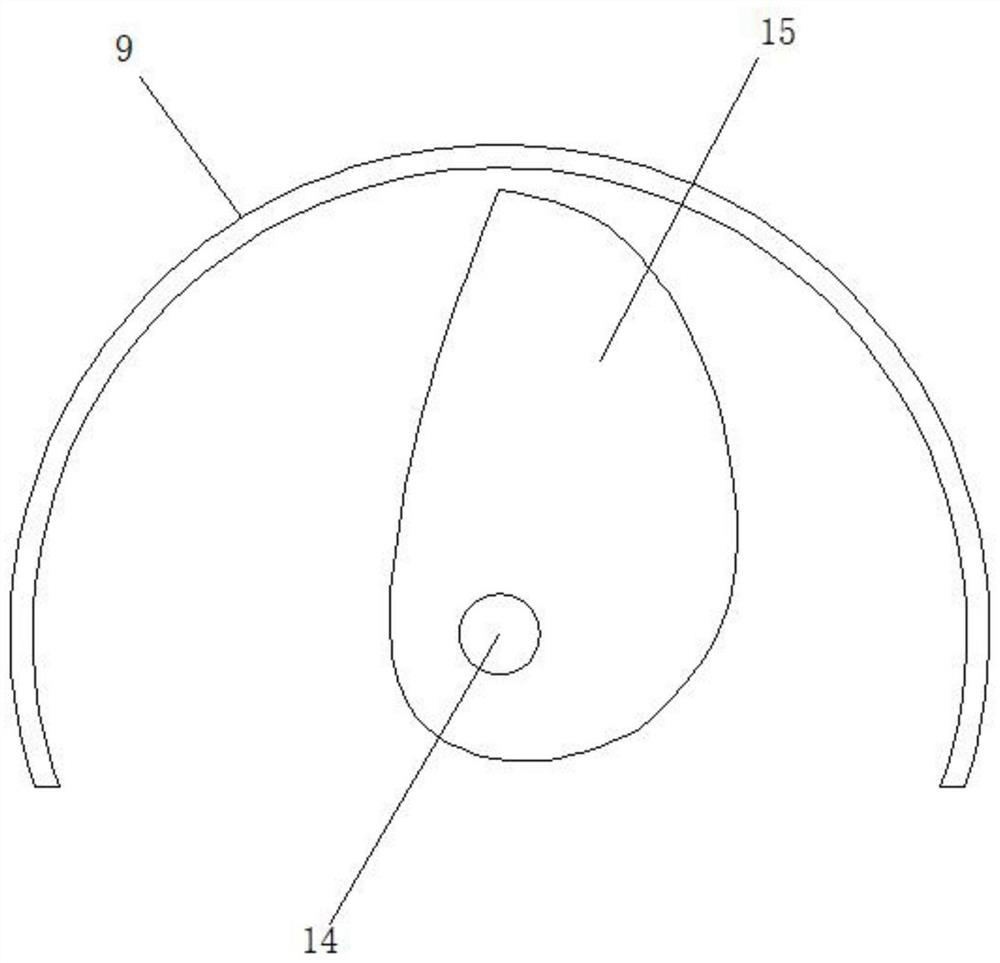

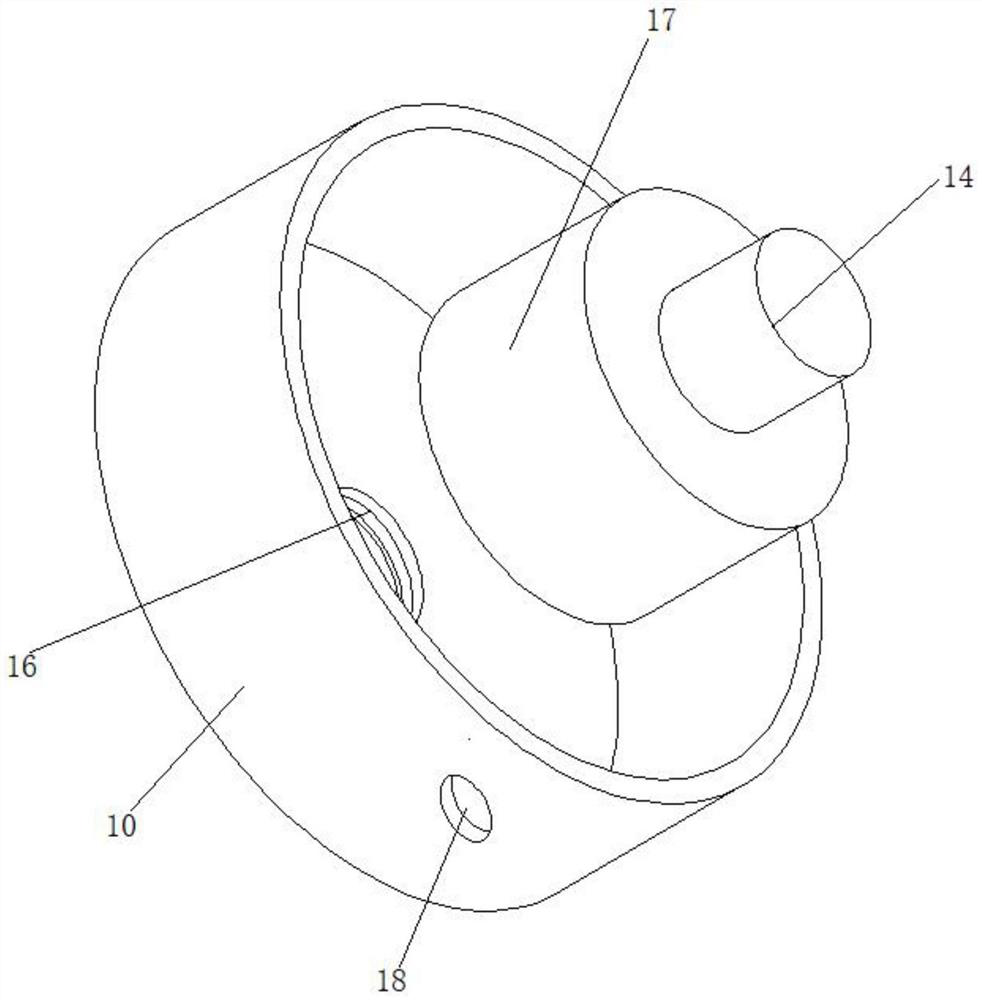

ActiveCN114260526AAchieve stabilityAchieve stabilizationIncreasing energy efficiencyElectrical-based auxillary apparatusMachine partsWire cutting

The invention relates to the field of false tooth machining, in particular to a wire cutting device for 3D printing of metal false teeth, which comprises an annular conveying track arranged on a support and a wire cutting machine, a machined part is specifically a false tooth printed on a base disc, and the annular conveying track is respectively provided with a feed port and a discharge port. An adjusting arm with a clamping mechanism is further arranged on the support, a rotating driving device and a lifting driving device which are used for driving the adjusting arm to rotate and driving the adjusting arm to vertically move are further arranged on the support, and the fixing device comprises a containing mechanism, a freezing mechanism and a pressing mechanism. According to the denture cutting machine, through cooperation between the containing mechanism and the freezing mechanism and downward pressing of ice blocks frozen together through the downward pressing mechanism, stability of a basal disc and a denture is achieved when the denture cutting machine cuts the denture, the situation that the root of the denture is uneven when the denture is cut is avoided, the denture cutting efficiency is improved, and the denture cutting machine is suitable for large-scale production. And the completeness of the false tooth is ensured.

Owner:AI JIA DENTAL LAB

Rapid cutting device for copper bar

PendingCN113843449AAvoid uneven cuttingImprove cut qualityShearing machinesMaintainance and safety accessoriesElectric machineStructural engineering

The invention discloses a rapid cutting device for a copper bar, and relates to the field of copper bar cutting. The rapid cutting device comprises a body, the top of the body is rotatably connected with a connecting column through a spring, one side of the connecting column is fixedly provided with a protective frame, the middle position of one side of the protective frame is provided with a rotating motor, and the output end of the rotating motor is connected with a cutting knife; and a feeding groove is formed in the middle position of the top of the body. Arranged pull columns are pulled towards one side, the pull columns are rotated to enable sliding blocks to enter second sliding grooves, then limiting of the pull columns is completed, meanwhile, the pull columns drive ropes to pull, the ropes drive rotating rollers to rotate, the rotating rollers drive limiting plates to rotate, the limiting plates rotate to fix the copper rod in the feeding groove, and the steps are repeated; and the steps are repeated on the other set of limiting plate, so that the two ends of the copper bar at the cutting position are fixed, the phenomenon that cutting is uneven due to displacement of the copper bar during cutting is avoided, and then the cutting quality is improved.

Owner:红旗集团江西铜业有限公司

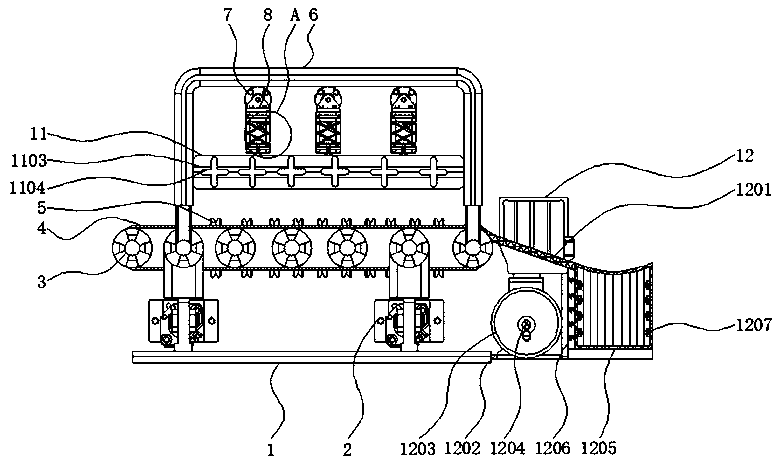

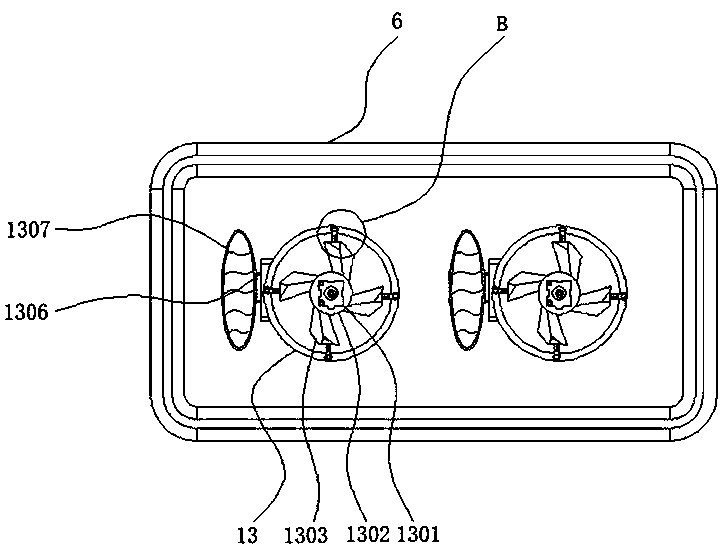

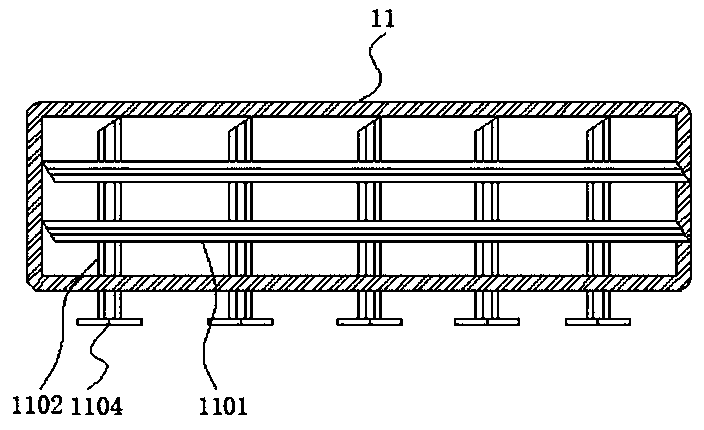

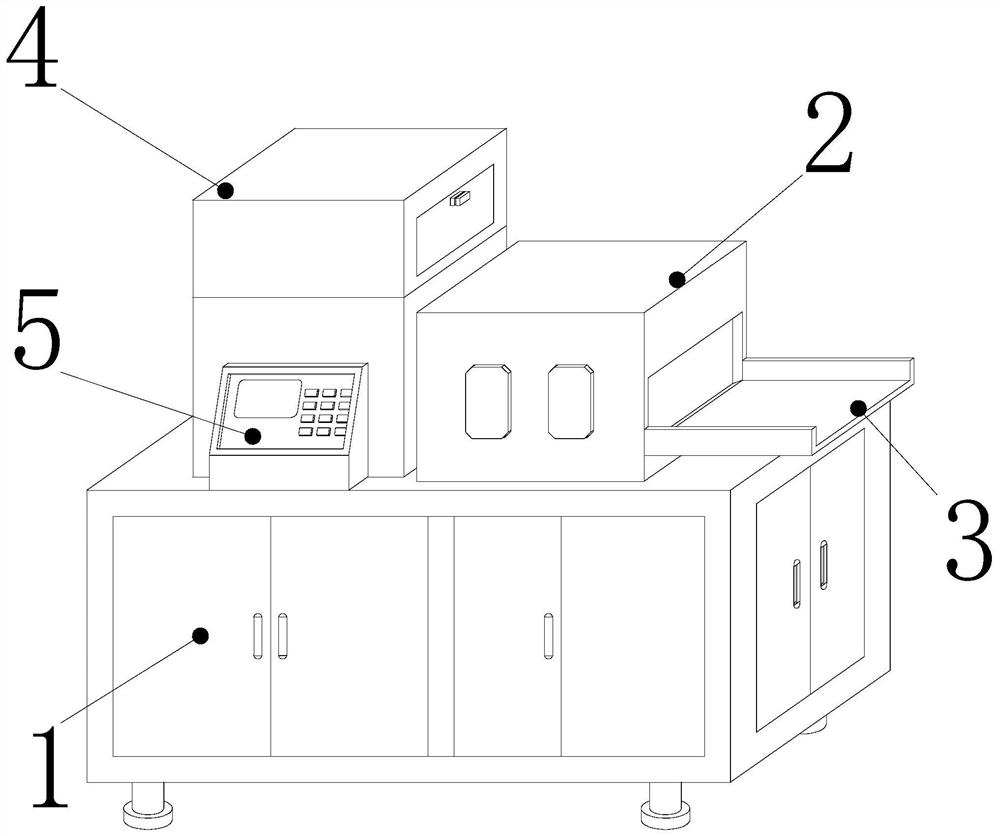

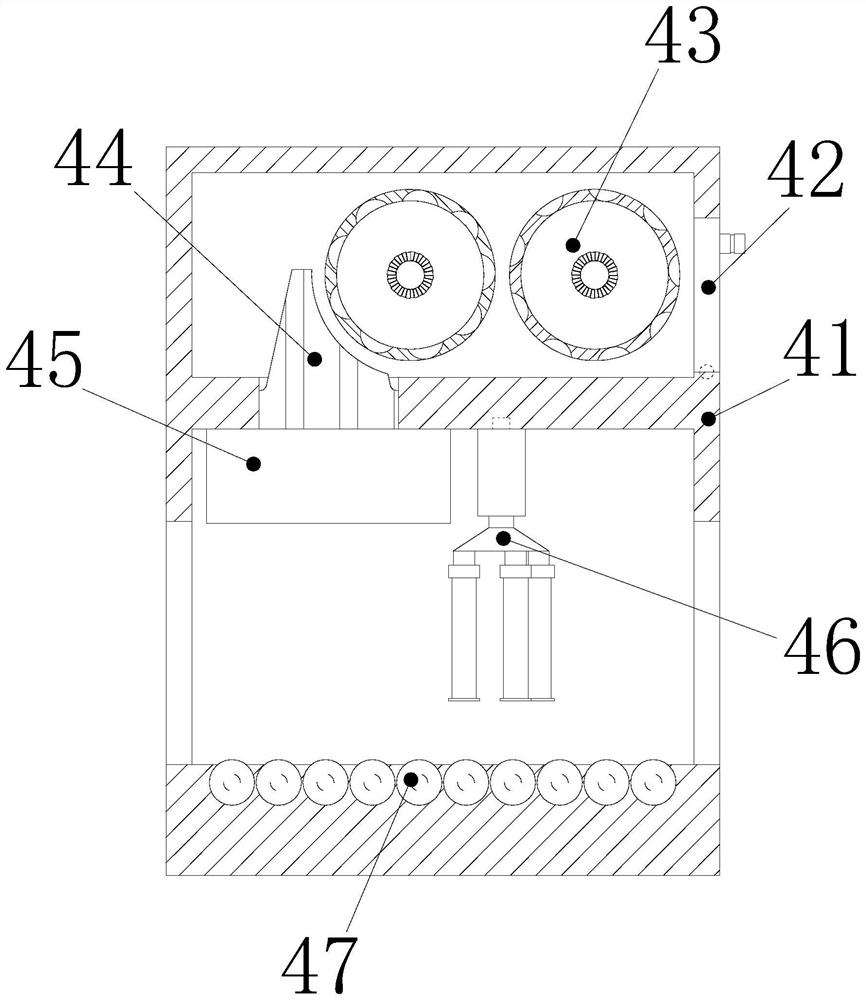

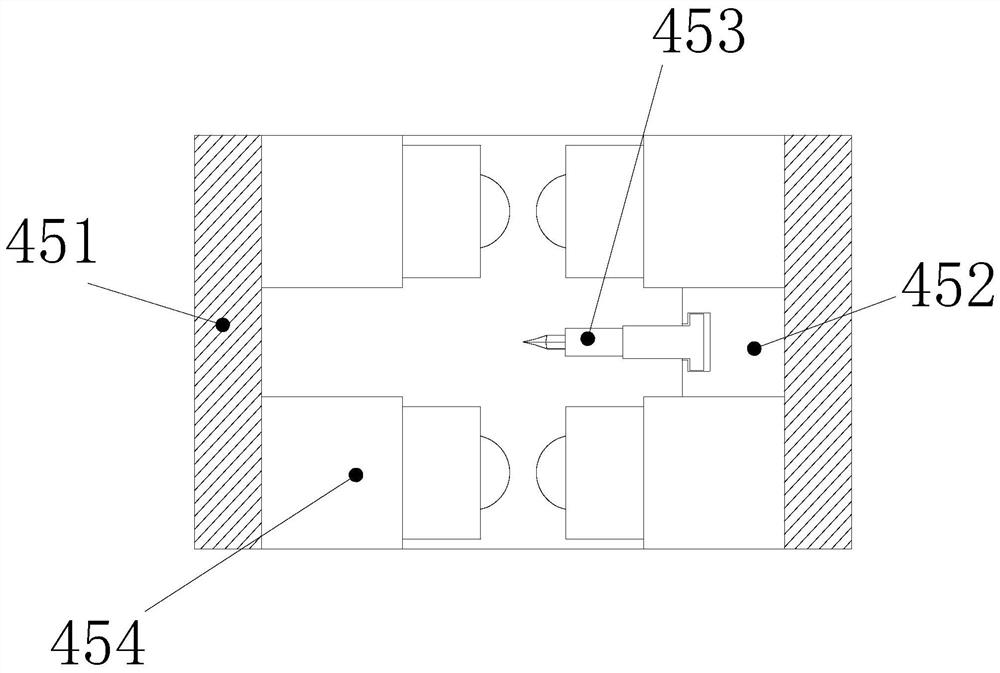

Food processing uniform cutting device with heat dissipation function

InactiveCN109849068AAvoid cumbersome processImprove work efficiencyMetal working apparatusEngineeringMechanical engineering

The invention relates to a food processing uniform cutting device with a heat dissipation function. The device comprises a base, a protective cover, a cutting mechanism, a sorting and collecting mechanism and a heat dissipation mechanism, wherein supporting rods are mounted above the base, the base and the supporting rods are fastened through nuts, motors are mounted above the supporting rods, a conveying belt is arranged on the periphery of the motors, concave blocks are arranged on the outer walls of the conveying belt, and the conveying belt and the concave blocks are glued together. The food processing uniform cutting device with the heat dissipation function has the beneficial effects that the cutting mechanism is arranged, by moving cross handles, movable blades fixed at one ends ofthe movable cross handles slide on fixed blades through sliding grooves, so that a worker can adjust the distance between the blades according to requirements of a customer or own needs, food with different sizes can be realized during cutting, people can conveniently make and store the food, and the complicated process where the people need to carry out further processing in the later period is avoided.

Owner:LAIWU VOCATIONAL & TECHNICAL COLLEGE

Ultrasonic slitting machine for cloth

InactiveCN111826942AQuality improvementAvoid stickingTextile selvedgesSevering textilesEngineeringPhysics

The invention discloses an ultrasonic slitting machine for cloth. The structure of the ultrasonic slitting machine comprises a rotating mechanism, a control console, a fixing frame and a winding rod,wherein the rotating mechanism is provided with a cutting mechanism, transmission rods, a fixing plate and a compression mechanism. Cloth acts on bent plates to compress the bent plates, then compression rods extrude a balance rod, then a spring acts on a stress block, thus air in a sealing groove is discharged through the stress block and acts to a bent groove, fine scraps are blown to flow out from two sides, thus the fine scraps are prevented from being adhered to the slit cloth, the phenomenon that the quality of the slit cloth is poor is further avoided, the influences of the fine scrapson the cut cloth are reduced, in addition, each sliding ball is of a shaft-shaped structure, a triangular structure is distributed on the outer side of each sliding ball, then the grabbing force on the cloth is enhanced, the cloth is prevented from sliding, so that the cloth is smooth, the phenomenon of irregular slitting is avoided, the reduction of tensile strength of cloth strips is prevented,the probability of edge scattering is reduced, and the quality of the cloth is prevented from being affected.

Owner:任丘市庆信亨商贸有限公司

A copper tube automatic cutting equipment

ActiveCN113182596BAvoid uneven cuttingImprove processing efficiencyTube shearing machinesShearing machine accessoriesPipe fittingElectric machinery

The invention discloses an automatic copper pipe cutting device, which comprises a pipe fitting conveying device and a cutting mechanism. The cutting mechanism includes a cutting piece driven by a motor. The automatic cutting device also includes a guide rod parallel to the conveying direction of the pipe fitting conveying device. The guide rod The upper slide is provided with a top plate, one side of the top plate is provided with a first return elastic member, the top plate is provided with a sliding assembly that can slide vertically, a second return elastic member is provided between the sliding assembly and the top plate, and the sliding assembly is connected with a cutting mechanism. A guide plate vertical to the top plate is arranged on one side of the top plate, and a circular guide groove is arranged on the guide plate, and a guide block is arranged in the circular guide groove, and the guide block is connected to the cutting mechanism through a fixed rod, and the circular guide groove includes a cutting guide groove and a reset guide groove, A one-way limiting structure is arranged at the junction of the cutting guide groove and the reset guide groove. This copper pipe automatic cutting equipment can ensure accurate cutting length and improve processing efficiency.

Owner:诸暨市志冠汽配有限公司

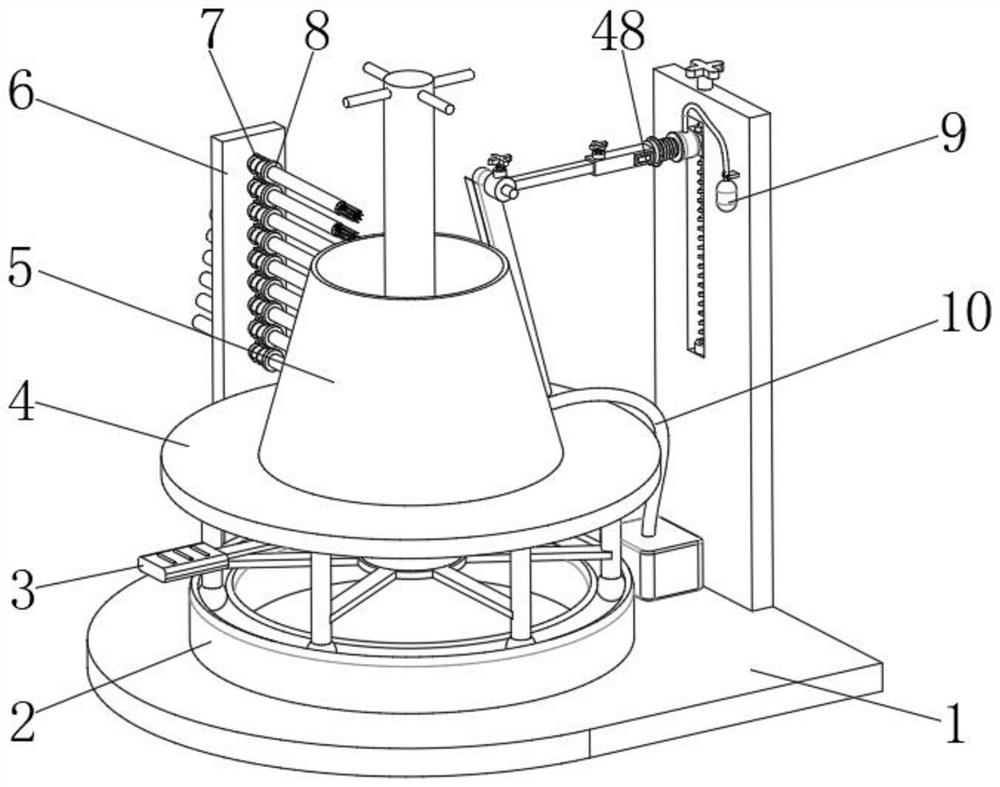

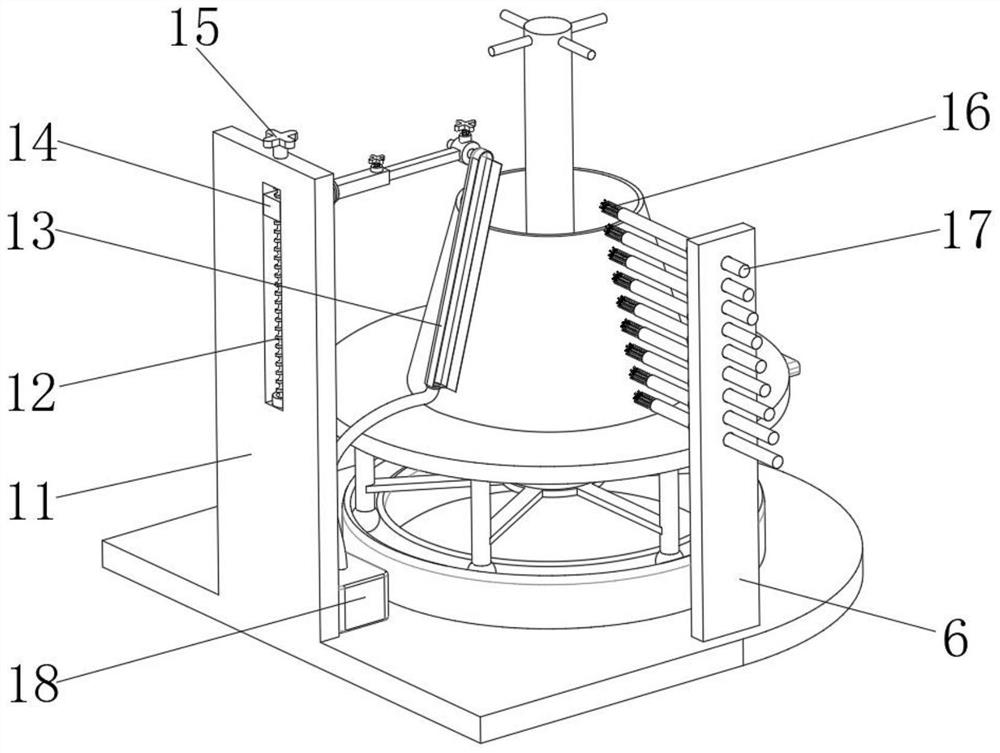

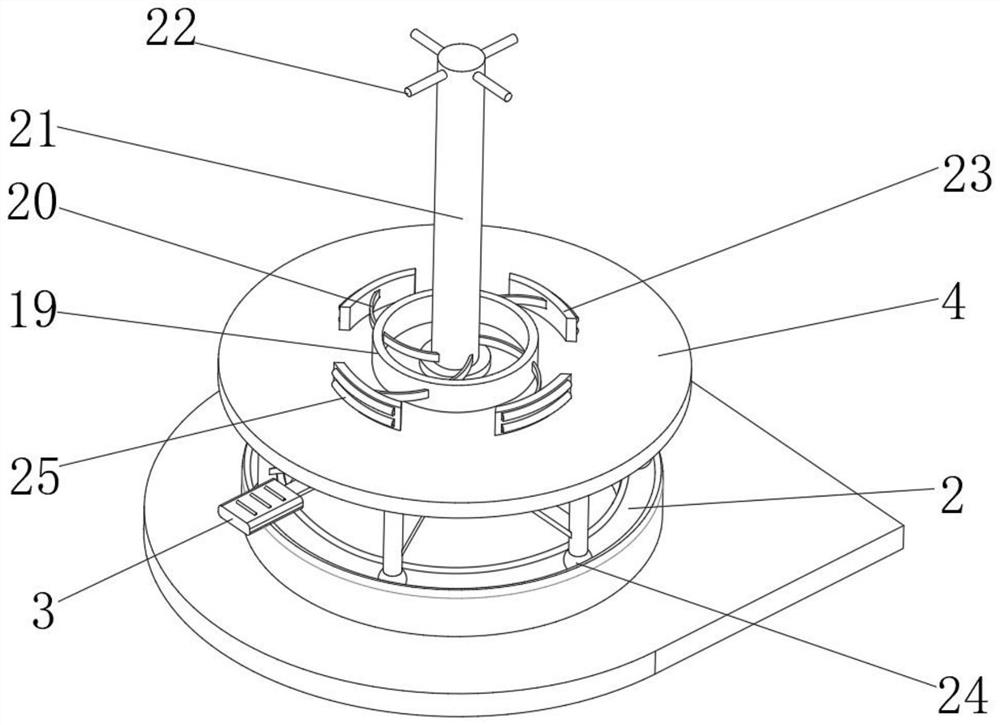

Fire-fighting lamp process

PendingCN114074372AAvoid uneven cuttingImprove cutting effectAuxillary shaping apparatusStructural engineeringMechanical engineering

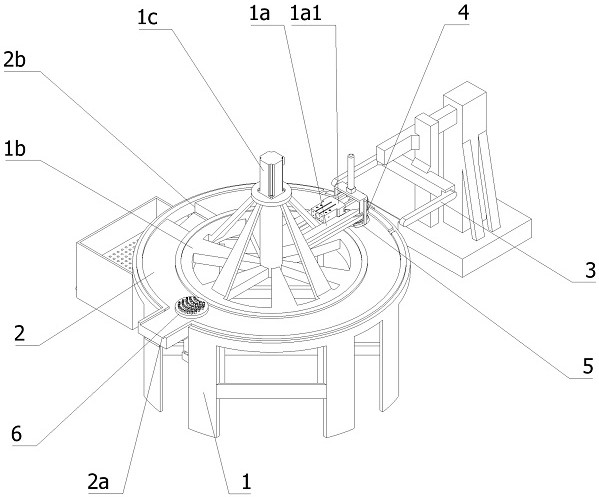

The invention discloses a fire-fighting lamp process, and relates to the technical field of ceramic lamp processing. The invention aims to improve the cutting effect, the equipment comprises a base and a rotary table used for bearing a lamp blank, an annular sliding base is fixed to the outer wall of the top of the base through screws, four or more sliding ball rods which are evenly and circumferentially distributed are fixed to the outer wall of the bottom of the rotary table through screws, and the outer walls of the bottoms of the sliding ball rods are slidably connected to the inner wall of the top of the annular sliding base; a mounting frame is fixed to the outer wall of the top of the base through screws, and the process comprises the following steps of taking green body raw materials by weight and pulping the raw materials to prepare mud strips; carrying out vacuum crude smelting on the prepared material; and carrying out secondary extrusion pugging on the mud strips subjected to vacuum coarse pugging by using a vacuum pugging machine. By arranging the rotary table, the sliding ball rods and other structures, a lamp blank can be conveniently placed on the rotary table, the circumferential side wall of the lamp blank makes contact with a scraper mechanism in the mode of rotating the rotary table, and therefore the phenomenon of uneven cutting is avoided, and the cutting effect is improved.

Owner:辽宁大工教育产业有限公司

Paper box bottom seal film laminating machine

InactiveCN112936991AImprove smoothnessAvoid uneven cuttingPaper-makingBox making operationsThin membraneEngineering

The invention discloses a paper box bottom seal film laminating machine. The machine structurally comprises a machine base, a box disassembling device, a bearing plate, a coating device and a controller, wherein the bottom end of the box disassembling device is connected to the right side of the upper end of the machine base through bolts, the periphery of a left side port of the bearing plate is fixedly connected to the interior of the right side of the box disassembling device in an embedded mode, the right side of the coating device is fixedly connected to the left side of the box disassembling device in an embedded mode, the rear end of the controller is welded and connected to the middle of the front end of the coating device, the top end of a cutting device is fixedly connected to the center of the lower end of a guide block in an embedded mode, the top end of a winding roller is movably matched with the right side of the lower end of the middle of the shell, and the rear end of a transmission shaft is movably clamped in the upper portion of the bottom end of the shell. A passing plastic film is smoothed through a plurality of smoothing blocks of a smoothing mechanism, a certain friction fixing effect is achieved on the film during cutting, meanwhile, smoothing balls in the smoothing blocks can rotate to a certain degree along with the plastic film, the defect caused by abrasion of a fixed point due to long-term friction of the plastic film is avoided, and the film wrinkling phenomenon caused by unsmooth smoothing during cutting is prevented.

Owner:黄伟彬

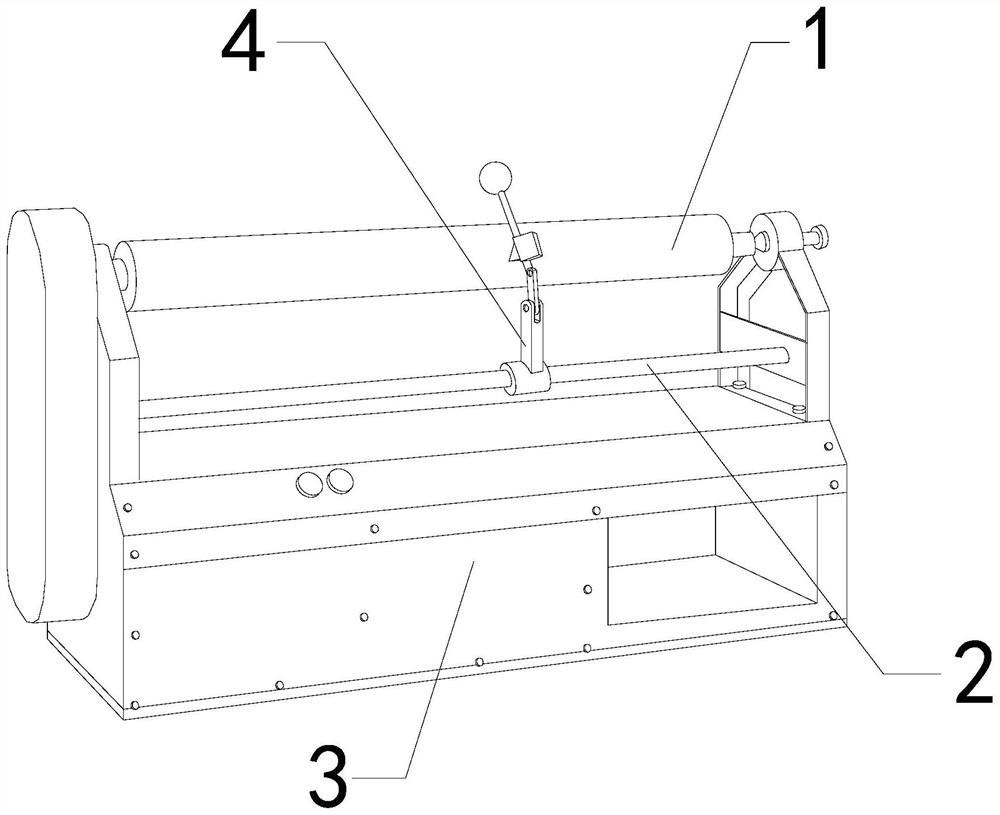

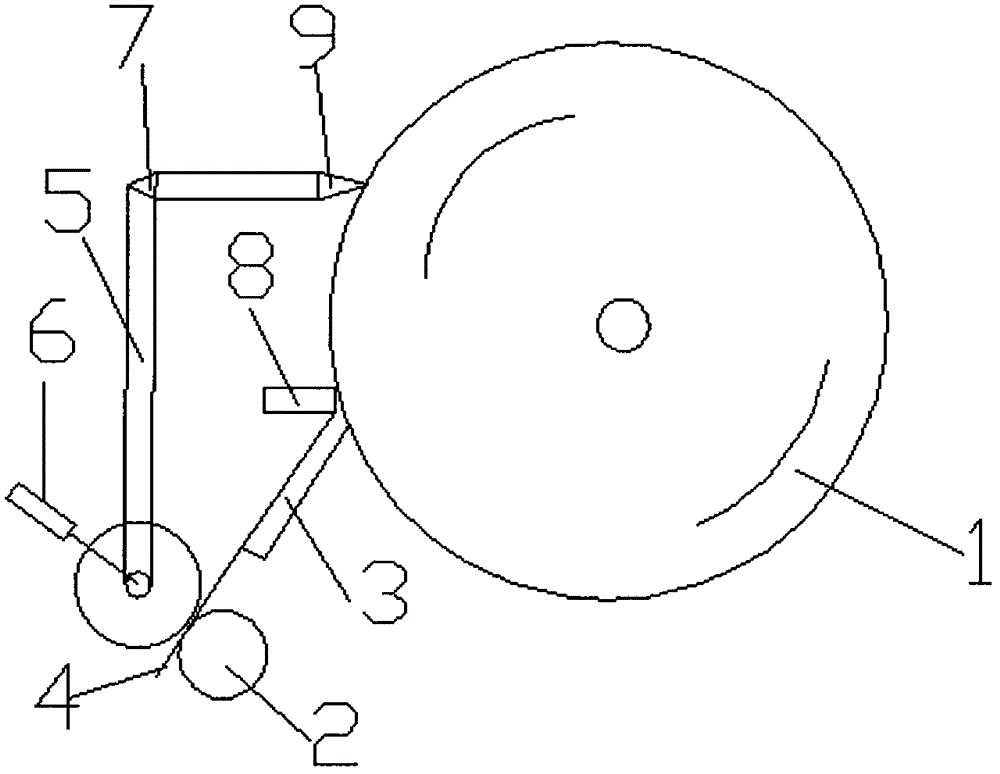

Veneer rolling and softening device

The invention discloses a veneer rolling and softening device which comprises a veneer lathe rotary cutter and a pressure bar. The veneer lathe rotary cutter and the pressure bar are arranged at the lower left end of a log. The veneer lathe rotary cutter is movably connected with a small squeeze roller through veneer. The small squeeze roller is movably connected with a large squeeze roller through the veneer. The large squeeze roller is fixedly connected with a pressure device and further fixedly connected with a driving device. The driving device is fixedly connected with a contact wheel. The contact wheel is movably connected with the log. According to the veneer rolling and softening device, in the rotary cutting process of the veneer, cracks are generated in the veneer so that stress can be eliminated, and the veneer becomes soft and flat. The yield of the veneer is increased, and the uneven cutting phenomenon caused by curling of non-softened veneer can be avoided. In the splicing process, the phenomenon that veneer edge warping is caused by curling, and accordingly bonding of splicing seams is bad is avoided. In the gluing process, plywood deformation caused by uneven internal stress is avoided.

Owner:潘杨基

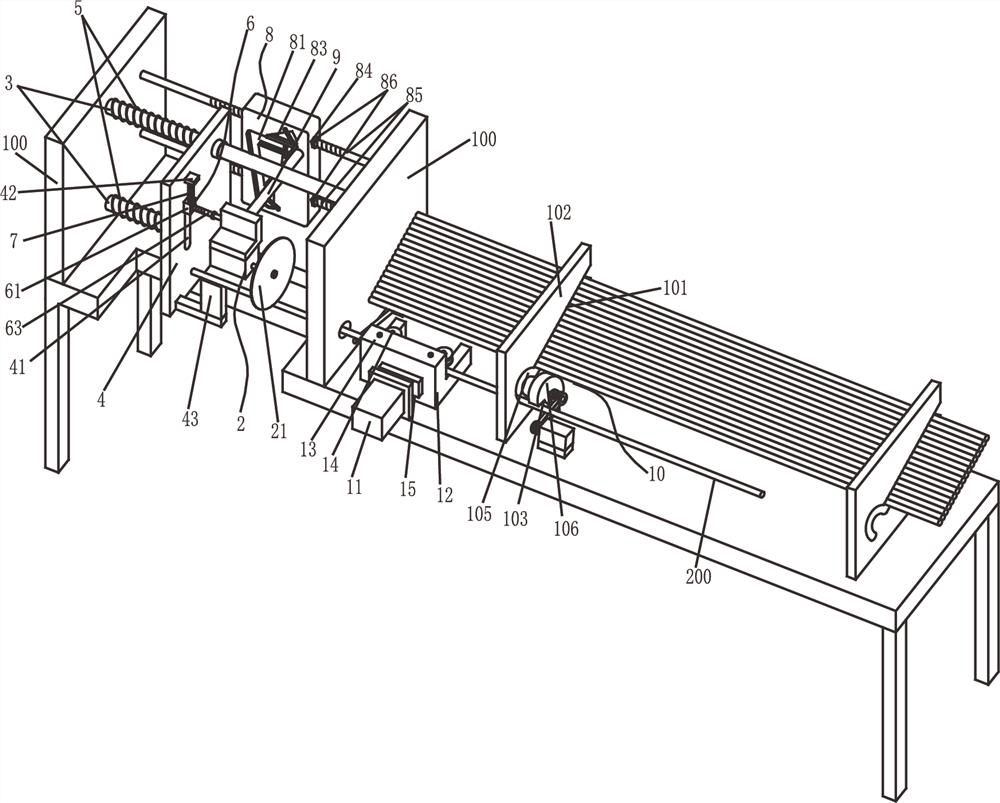

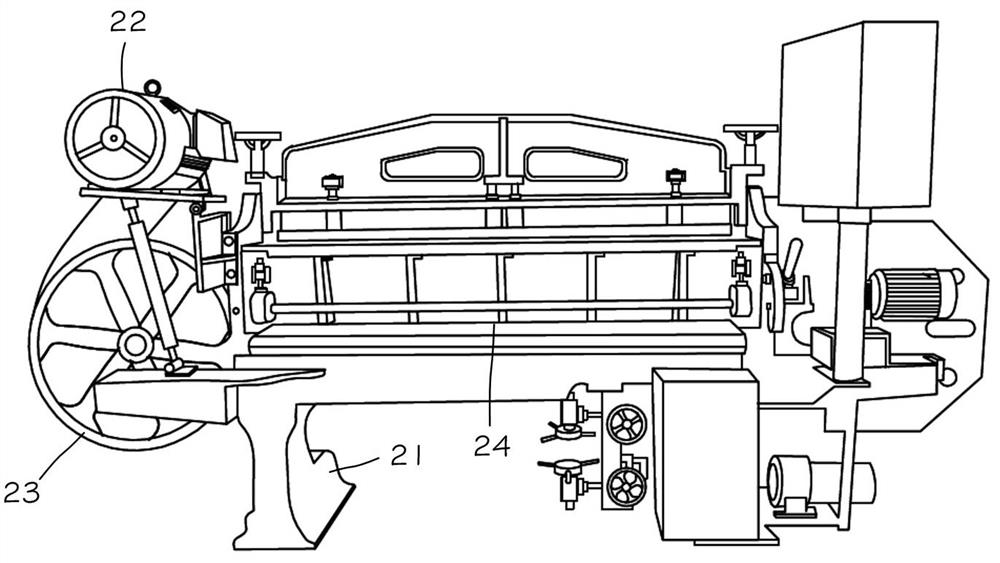

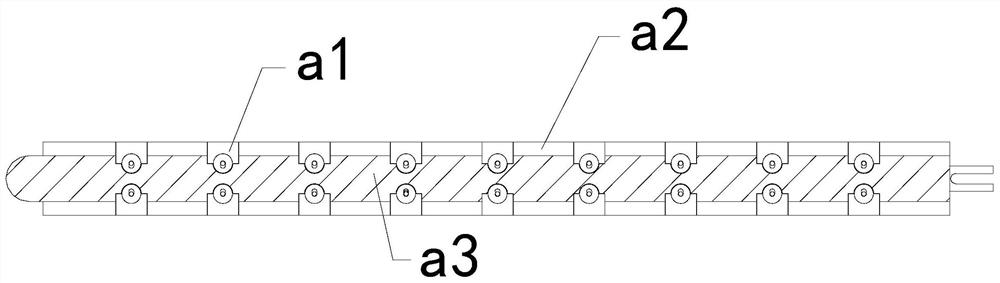

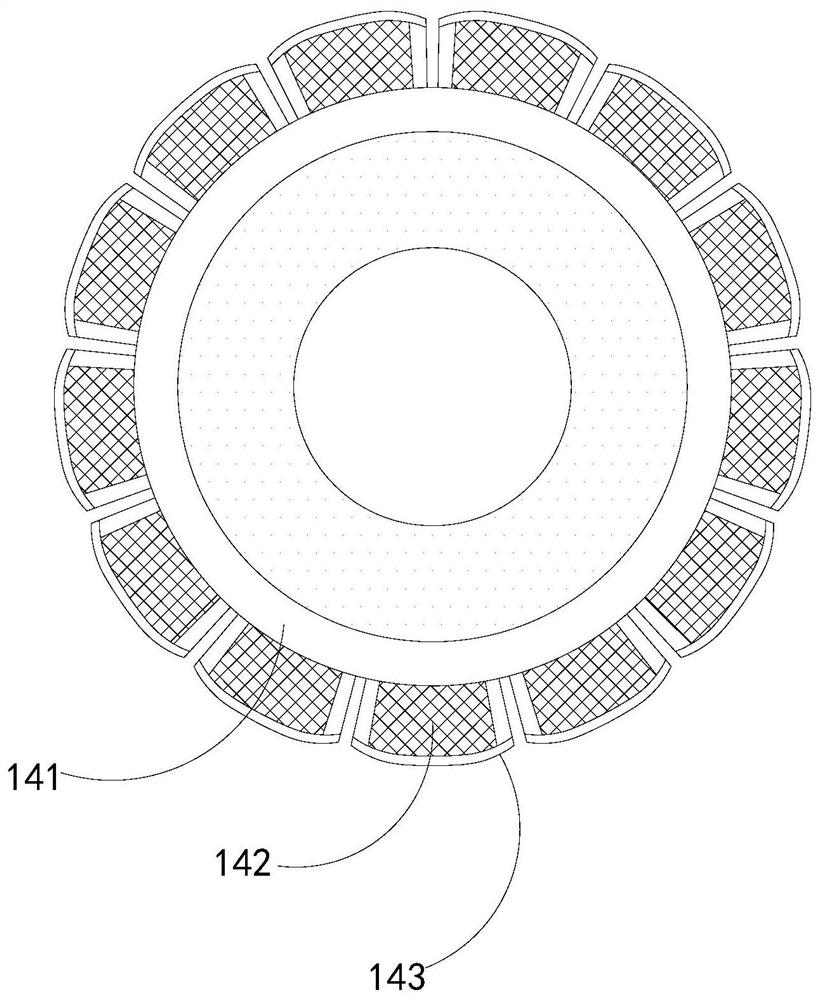

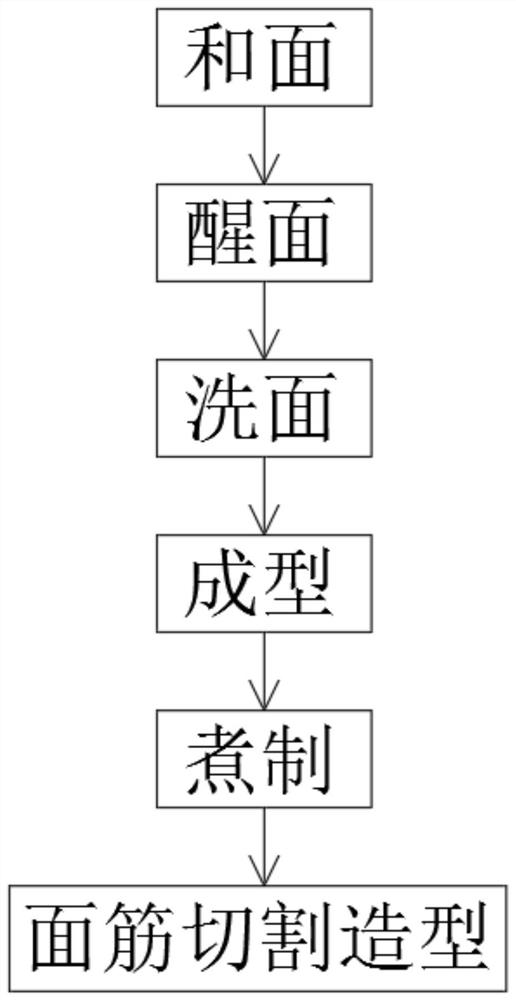

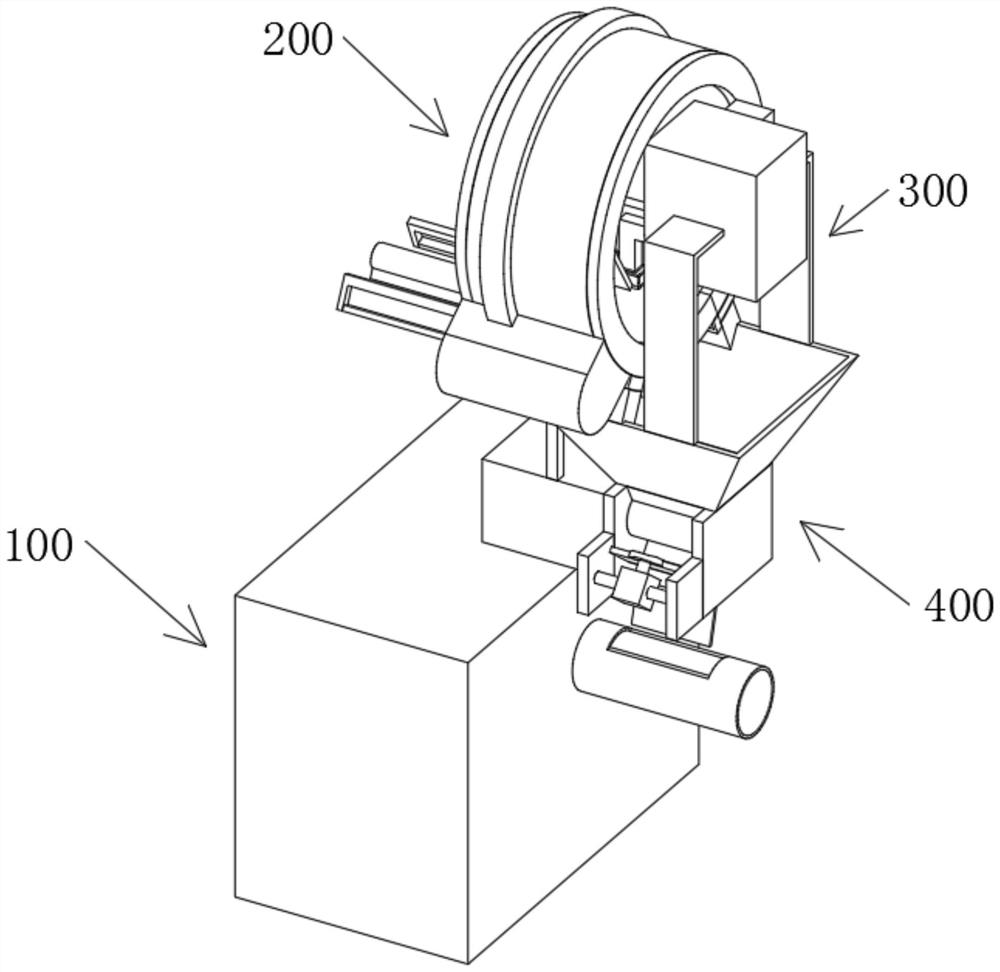

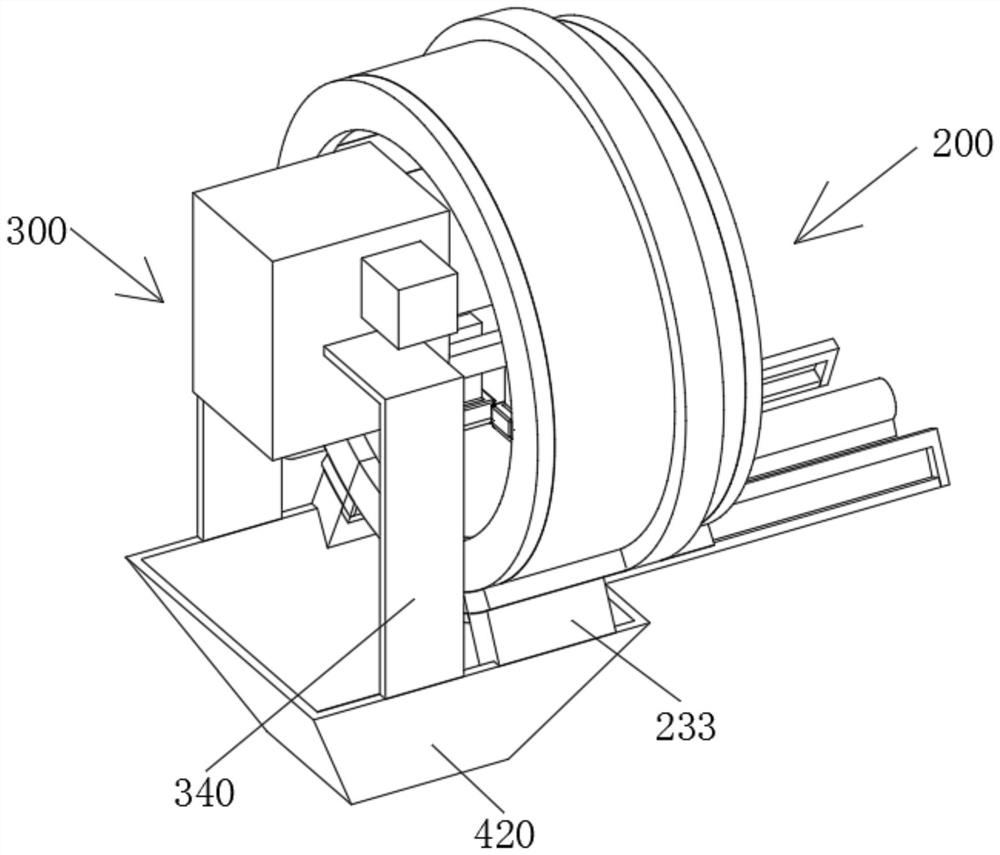

Wet gluten production method and gluten beating and winding all-in-one machine thereof

The invention relates to the technical field of wet gluten production, and in particular relates to a wet gluten production method and a gluten beating and winding all-in-one machine thereof; and the wet gluten production method comprises the production steps of dough kneading, dough standing, dough washing, forming, cooking and gluten cutting and shaping. According to the invention, through a placement module and a gluten beating module of the gluten beating and winding all-in-one machine, washed gluten can be placed on the placement module; then gluten dough is beaten through the gluten beating module; in this way, the toughness of the gluten dough is improved; wet gluten is more chewy; the taste of the gluten is easily improved; furthermore, the gluten is difficultly broken in subsequent processing; processing of the gluten is easily executed; an output end of a first motor is fixedly connected with a first gear in meshing transmission with a gear ring in a sleeving mode; and during processing, the first motor can enable a rolling cylinder to rotate, so that the gluten dough can be turned over when being beaten, all parts of the gluten dough can be beaten conveniently, the gluten beating effect can be easily improved, and the use is convenient.

Owner:SUZHOU WANSHEN FLOUR PROD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com