Linear cutting device for 3D printing metal false tooth

A 3D printing and wire cutting technology, applied in the field of denture processing, can solve the problems of uneven cutting, unable to ensure the stability of dentures, uneven cutting of dentures, etc., and achieve the effect of improving the level of flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to further understand the features, technical means, and specific objectives and functions achieved by the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

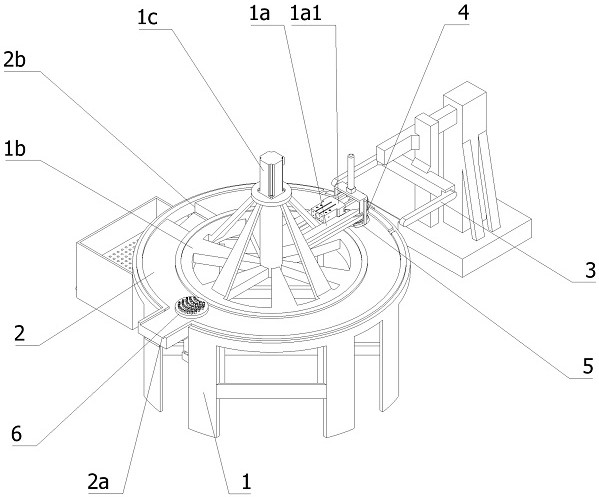

[0044] Such as Figure 1-Figure 11 As shown, this application provides:

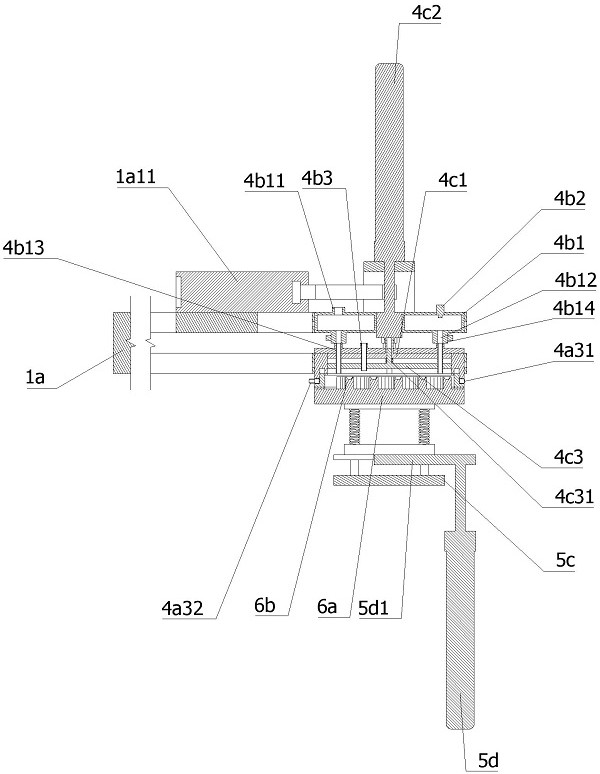

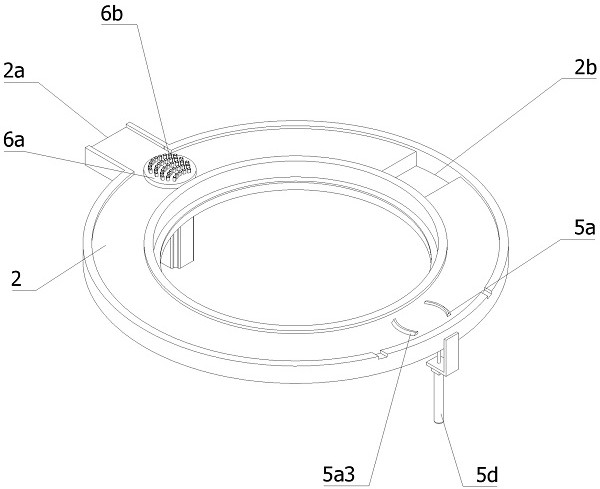

[0045] The wire-cutting device for 3D printing metal dentures includes a ring-shaped conveying track 2 arranged on the support 1 for conveying the workpiece 6 and a wire-cutting machine 3 arranged beside the ring-shaped conveying track 2. The processed piece 6 is specifically printed The denture 6b on the base plate 6a is respectively provided with a feed port 2a and a discharge port 2b on the annular conveying track 2, and an adjustment arm 1a with a clamping mechanism 1a1 is also provided on the support 1, and the adjustment arm 1a It can rotate along the axis of the circular conveying track 2 on the support 1 and can move ver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com