Fire-fighting lamp process

A fire-fighting lamp and process technology, applied in the direction of manufacturing tools, auxiliary molding equipment, ceramic molding machines, etc., can solve the problems of easy deviation, damage to the shape of the lamp blank, loss, etc., to avoid springback, ensure universality, improve The effect of practicality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

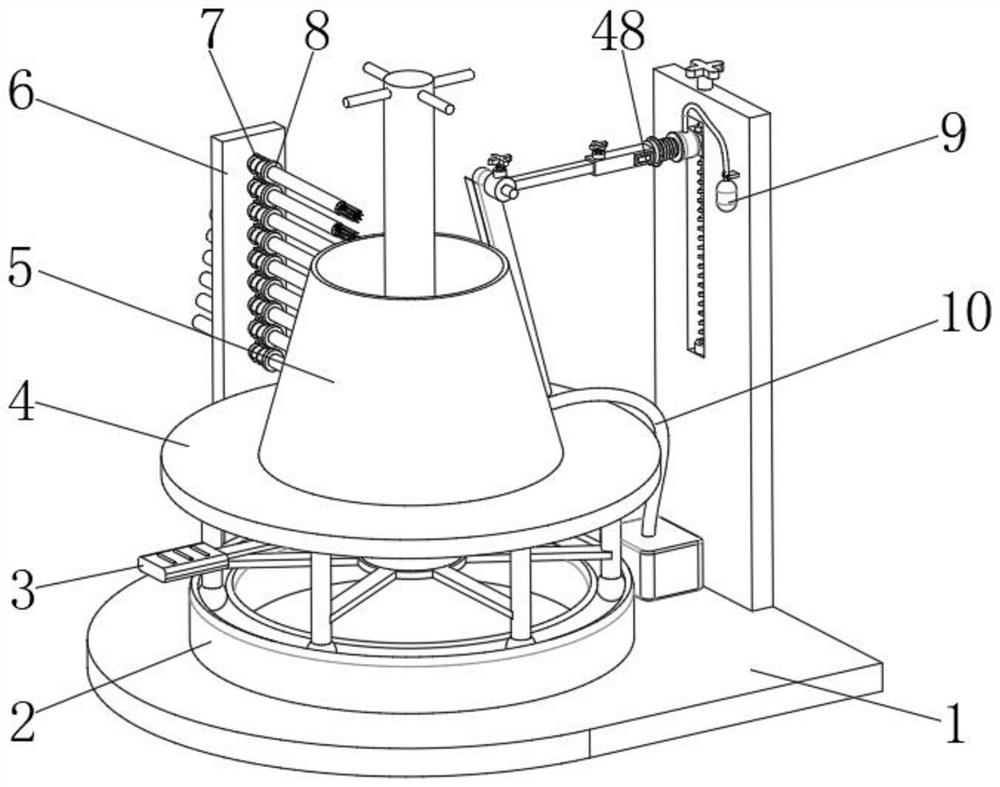

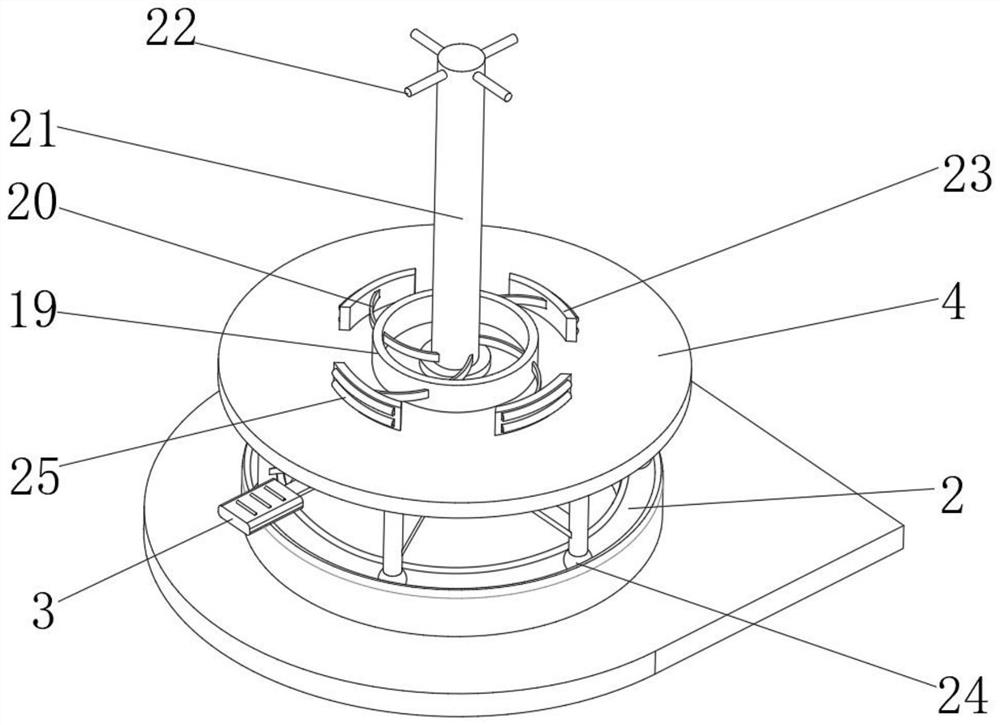

[0062] A fire lamp process forming equipment, such as Figure 1-7 As shown, it includes a base 1 and a turntable 4 for supporting the lamp blank 5, the outer wall of the top of the base 1 is fixed with an annular slide 2 by screws, and the outer wall of the bottom of the turntable 4 is fixed with more than four uniform circumferences by screws. Distributed sliding ball rods 24, the bottom outer wall of the sliding ball rod 24 is slidably connected to the top inner wall of the annular sliding seat 2; the top outer wall of the base 1 is fixed with a mounting frame 11 by screws, and a scraper mechanism is installed on one side of the mounting frame 11, The turntable 4 is provided with a positioning mechanism for positioning the lamp blank 5 . The positioning mechanism includes a central turning rod 21 and more than four arc-shaped support plates 23 . The central turning rod 21 is rotatably connected to the inner wall of the turntable 4 . And the center pivot bar 21 coincides with...

Embodiment 2

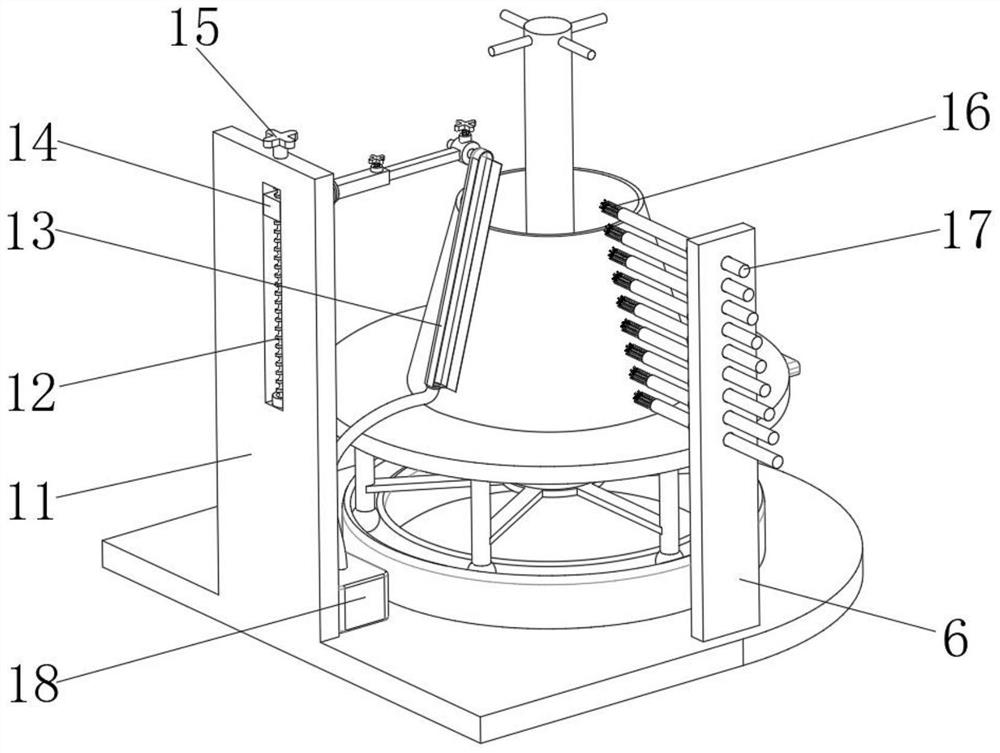

[0074] A fire lamp process forming equipment, such as Figure 1-7 As shown, in order to better clean the surface of 05; this embodiment makes the following improvements on the basis of Embodiment 1: the top outer wall of the base 1 is fixed with a cleaning frame 6 by screws, and the inner wall of one side of the cleaning frame 6 is fixed with screws. The cleaning rod 50 is fixed in an adjustable plug-in connection. The circumferential outer wall of the cleaning rod 50 is integrally provided with annular protrusions 53 distributed at equal distances. The outer wall of the annular protrusion 53 is rotatably connected with a cleaning roller 54. The cleaning roller The outer wall of the column 54 is sleeved and fixed with a cleaning air bag 51 with an air valve, and the circumferential outer wall of the cleaning air bag 51 is bonded with evenly distributed arc brushes 52, and the arc brushes 52 are adapted to the position of the outer wall of the lamp blank 5; By arranging the cle...

Embodiment 3

[0076] A fire lamp technology molding process, such as Figure 1-10 shown, including the following steps:

[0077] S1: The green body raw materials are divided by weight, and the slurry is prepared into mud sticks;

[0078] S2: vacuum roughening the prepared product;

[0079] S3: the mud strips after vacuum roughening are extruded and refined by a vacuum mud mixer for a second time;

[0080] S4: Cut the obtained mud into the stainless steel mold as needed;

[0081] S5: The steel mold containing mud is transported to the roller pressing equipment for pressing;

[0082] S6: the pressed steel mold is placed in a baking room to bake the blanks and then demoulded to obtain lamp blanks 5;

[0083] S7: processing the lamp blank 5 through the fire-fighting evacuation ceramic lamp molding equipment described in Example 1 or Example 2;

[0084] S8: the treated lamp blank 5 is subjected to glaze, printing, and glaze firing treatments in sequence to obtain a ceramic lamp product;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com