Paper box bottom seal film laminating machine

A technology for sealing film machines and carton boxes, which is used in papermaking, paper/cardboard containers, container manufacturing machinery, etc., can solve problems such as uneven cross-section, easy falling off of plastic films, wear and smoothing of the upper and lower surfaces of the mechanism, and achieves increased Flatness, avoid the effect of uneven cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

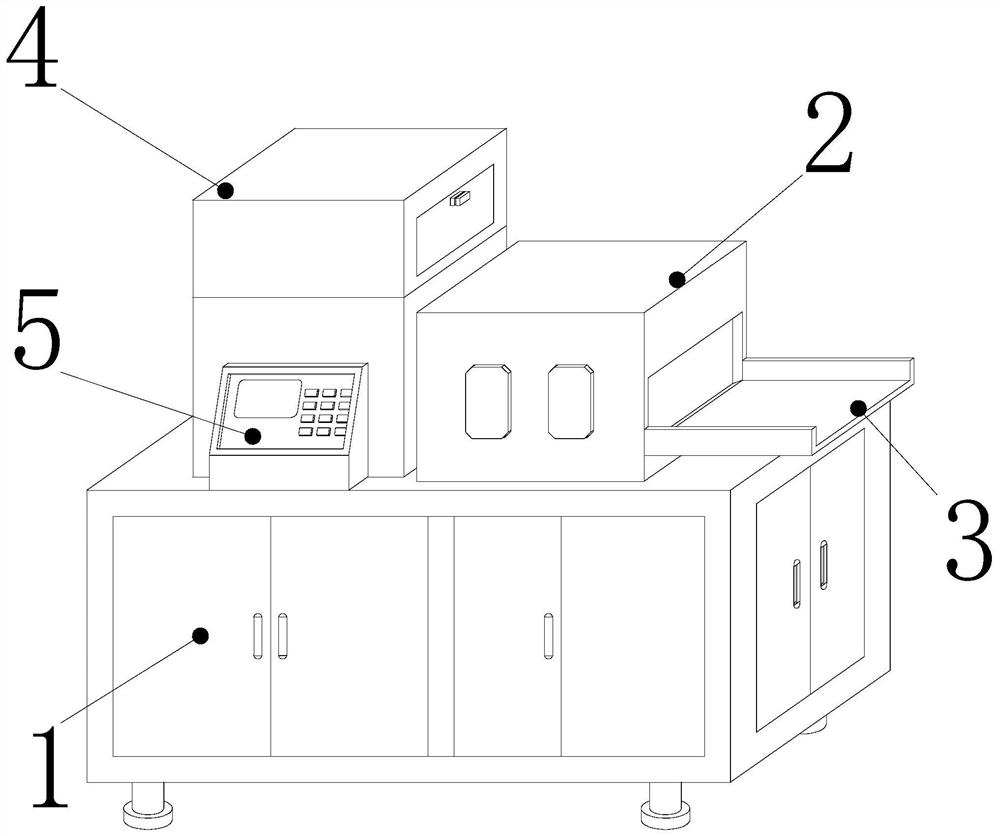

[0026] Such as Figure 1-Figure 5 As shown, the present invention provides a carton bottom sealing and laminating machine, the structure of which includes a machine base 1, a box unpacking device 2, a receiving plate 3, a cladding device 4, and a controller 5, and the bottom bolts of the box unpacking device 2 Connected to the right side of the upper end of the machine base 1, the outer periphery of the left port of the receiving plate 3 is embedded and connected to the inside of the right side of the box remover 2, and the right side of the covering device 4 is embedded and connected to the left side of the box remover 2, The rear end of the controller 5 is welded to the middle of the front end of the coating device 4 .

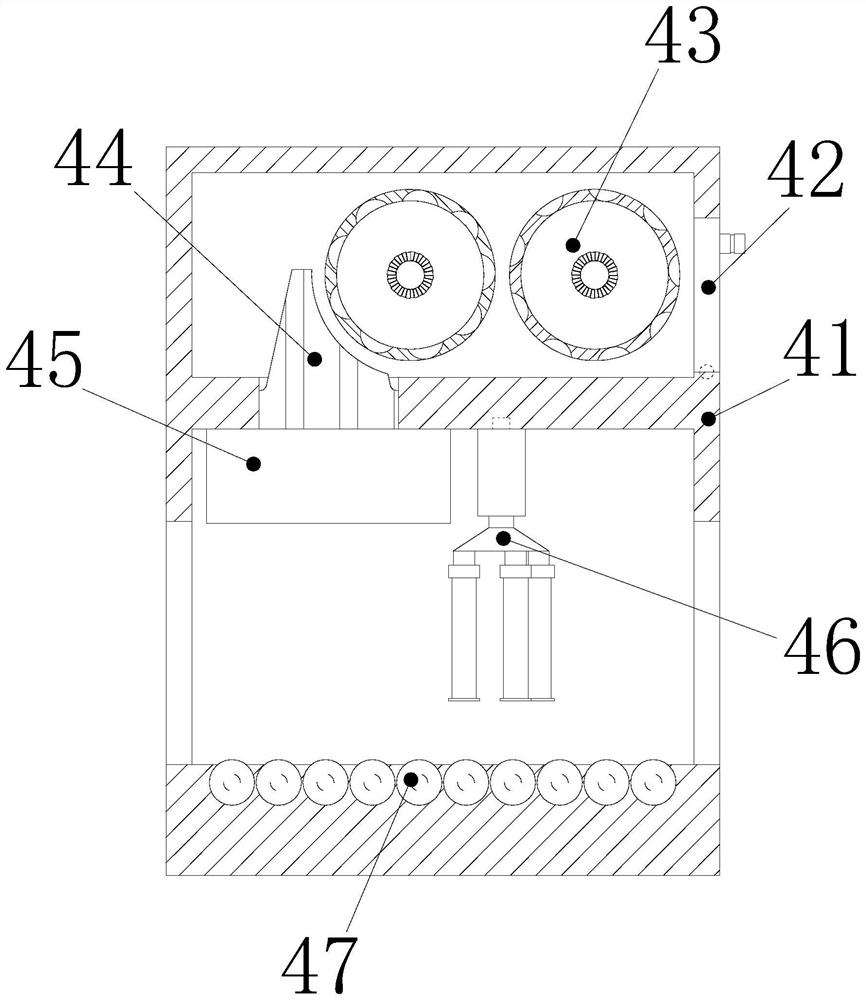

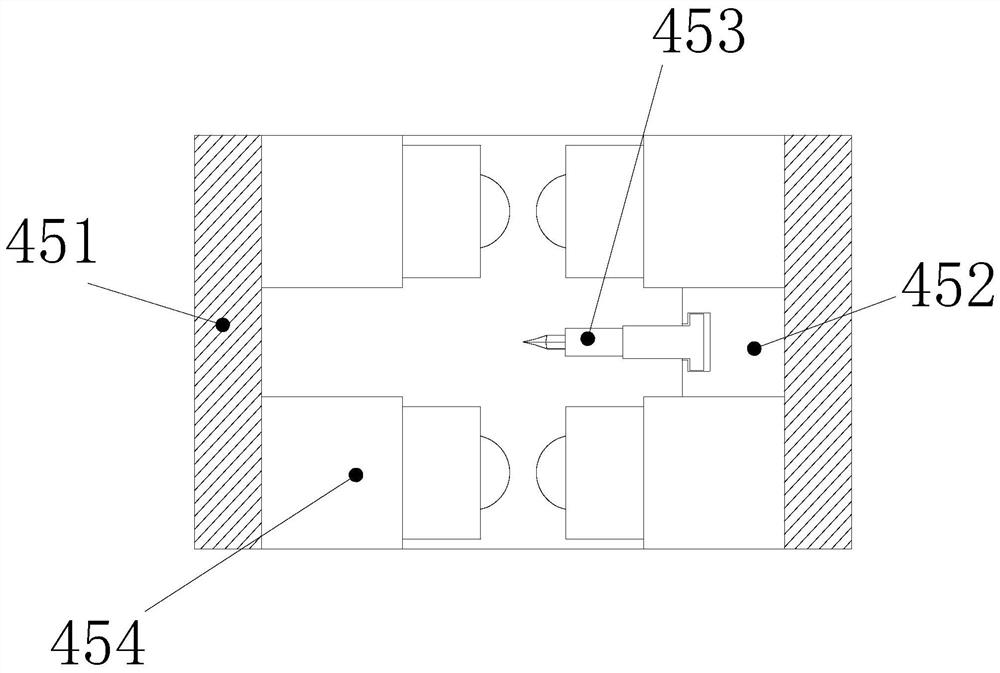

[0027] The coating device 4 includes a housing 41, an opening and closing cover 42, a film feeding shaft 43, a guide block 44, a cutting device 45, a winding roller 46, and a transmission shaft 47. The bottom end of the opening and closing cover 42 is movabl...

Embodiment 2

[0034] Such as Figure 6-Figure 7 Shown:

[0035] Wherein, the smoothing ball a45 includes a spherical shell b1, a blowing block b2, a squeezing ball b3, and a convex ball b4. The side ends of the blowing block b2 are embedded and connected to both sides of the inner wall of the spherical shell b1. The periphery of b3 is snapped and connected to the upper end of the blowing block b2, and the inside of the convex ball b4 is welded and connected to the outer wall surface of the extruded ball b3. Squeeze to the lower left while maintaining balance.

[0036] Wherein, the blowing block b2 includes a bottom pipe b21, an outer ring b22, a closing membrane b23, a connecting piece b24, and a supporting piece b25. The bottom end of the outer ring b22 is welded to the upper surface of the bottom pipe b21, and the lower end of the closing membrane b23 The wall is glued and connected to the middle of the upper surface of the inner wall of the outer ring b22, the top of the connecting pie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com