Veneer rolling and softening device

A pressurizing device and veneer technology, applied in the manufacture of veneer, wood processing appliances, manufacturing tools, etc., can solve the problems of different size, area asymmetry, warping and deformation of veneer, etc., to improve the yield, Avoid the effect of uneven cutting and deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

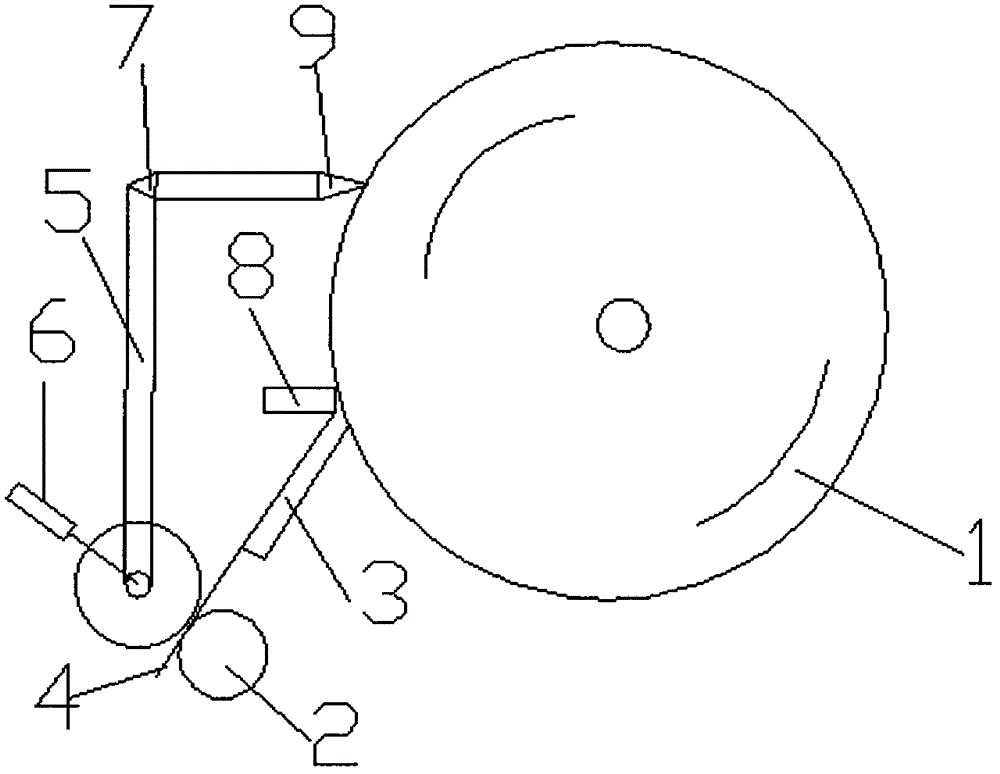

[0013] according to figure 1 Shown, the present invention mainly comprises:

[0014] The veneer rolling softening device includes: the rotary cutter 2 and the pressure ruler 8. The lower left end of the log 1 is provided with the rotary cutter 2 and the pressure ruler 8. The rotary cutter 2 passes through the veneer 4 It is movably connected with the small extrusion roller 3, the small extrusion roller 3 is movably connected with the large extrusion roller 5 through the veneer 4, the large extrusion roller 5 is fixedly connected with the pressing device 6, and the large extrusion roller 5 is fixed with the driving device 7 To connect, the driving device 7 is fixedly connected with the contact wheel 9, and the contact wheel 9 is movably connected with the log 1.

[0015] The pressurizing device 6 consists of a pneumatic system.

[0016] Little extruding roller 3 is made by hard material, as stainless steel etc., and diameter is 30mm.

[0017] The big squeeze roller 5 runs sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com