Ultrasonic slitting machine for cloth

An ultrasonic and slitting machine technology, which is applied in the cutting of textile materials, textile and papermaking, fabric surface trimming, etc., can solve problems such as low production efficiency, low production yield, and loose edges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] like Figure 1-Figure 5 Shown:

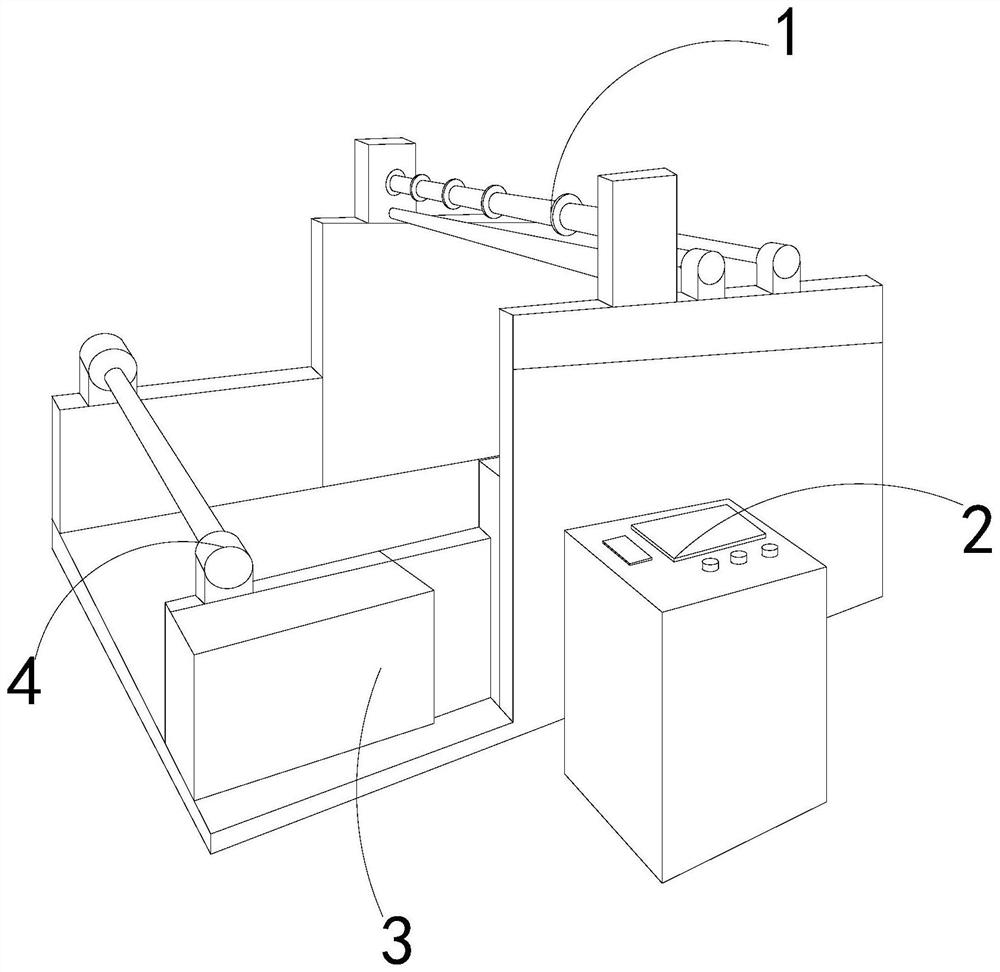

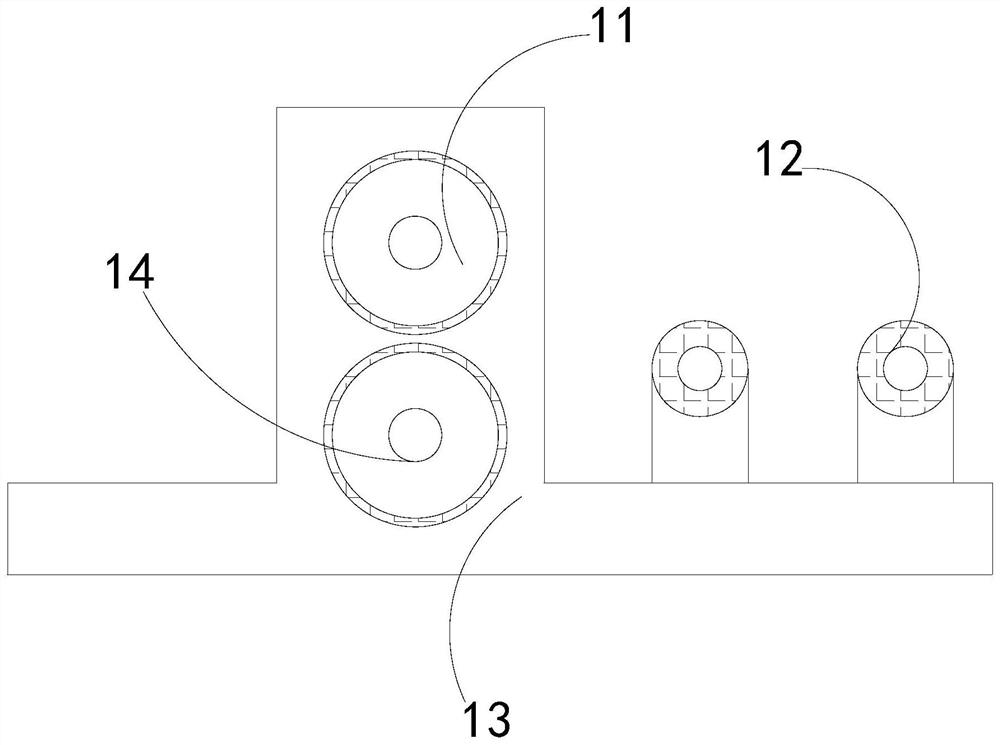

[0024] The present invention is an ultrasonic cloth slitting machine, its structure includes a rotating mechanism 1, a console 2, a fixed frame 3, a winding rod 4, the winding rod 4 is embedded in the upper end of the fixed frame 3, and the shrinking console 2 is located at On the side of the fixed frame 3, the rotating mechanism 1 is embedded in the upper right side of the fixed frame 3, and the winding rod 4 is parallel to the rotating mechanism 1, and the rotating mechanism 1 is provided with a cutting mechanism 11, a transmission rod 12, a fixed Plate 13, compression mechanism 14, described cutting mechanism 11 fits on the upper end of transmission rod 12, and described compression mechanism 14 is fixed on the inside of fixing plate 13, and described transmission rod 12 is positioned at the left end of cutting mechanism 11, and described fixing plate 13 is positioned at the right side upper end of fixed mount 3, and described transm...

Embodiment 2

[0031] like Figure 6-Figure 7 Shown:

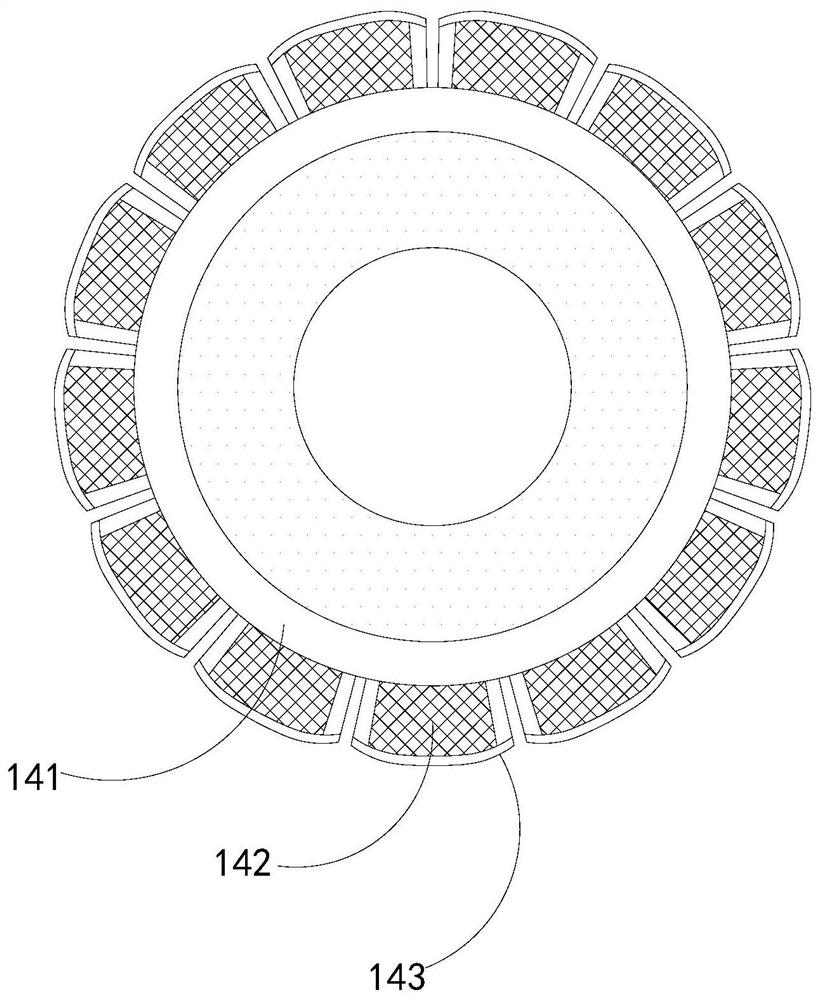

[0032] Wherein, the cutting mechanism 11 is provided with a rotating shaft 111, a cutting disc 112, an extruding mechanism 113, and a cutting blade 114. , the cutting blade 114 is fixed inside the rotating shaft 111, the pressing mechanism 113 is attached to the upper end of the compression mechanism 14, the cutting blade 114 is located in the middle of the cutting disc 112, and is located on the same vertical line as the compression mechanism 14 On the top, fix the cloth while cutting to prevent the flatness of the cloth from affecting the cutting.

[0033]Wherein, the extruding mechanism 113 is provided with a spring rod a1, a fixed ring a2, a sponge ring a3, a connecting shaft a4, and a sliding ball a5, the spring rod a1 is embedded on the outside of the fixed ring a2, and the sponge ring a3 is attached Closed on the outside of the fixed ring a2, the sliding ball a5 is installed inside the connecting shaft a4, the spring rod a1 is e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com