Burdock bar cutter

A strip cutting machine and burdock technology, applied in metal processing and other directions, can solve the problems of low efficiency and different sizes of cut products, and achieve the effects of improving production efficiency, saving installation space, and flexible matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

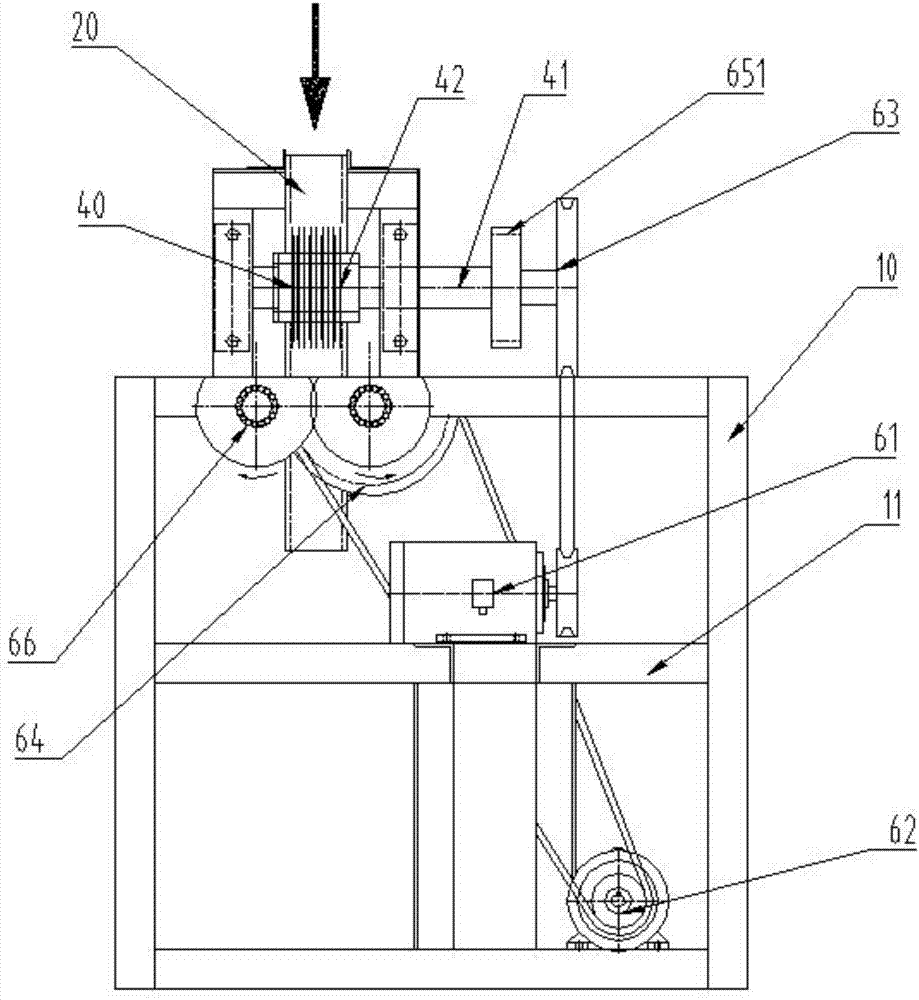

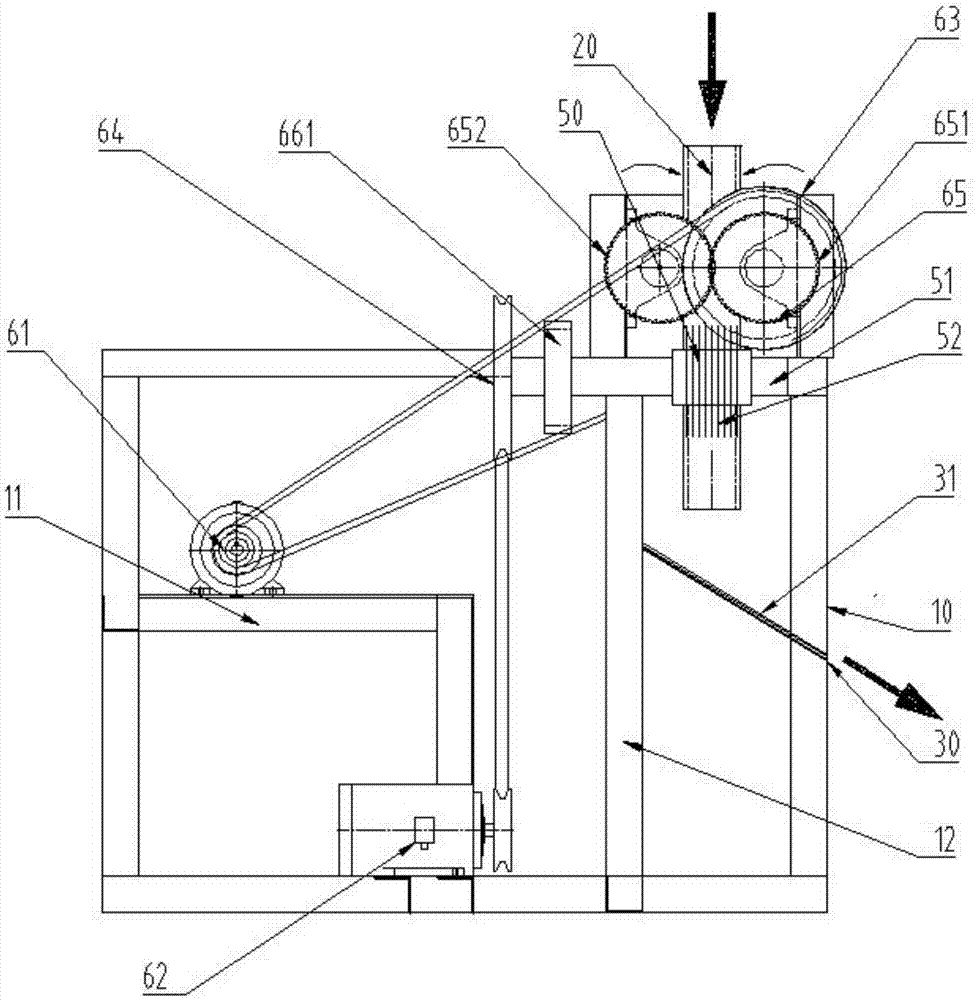

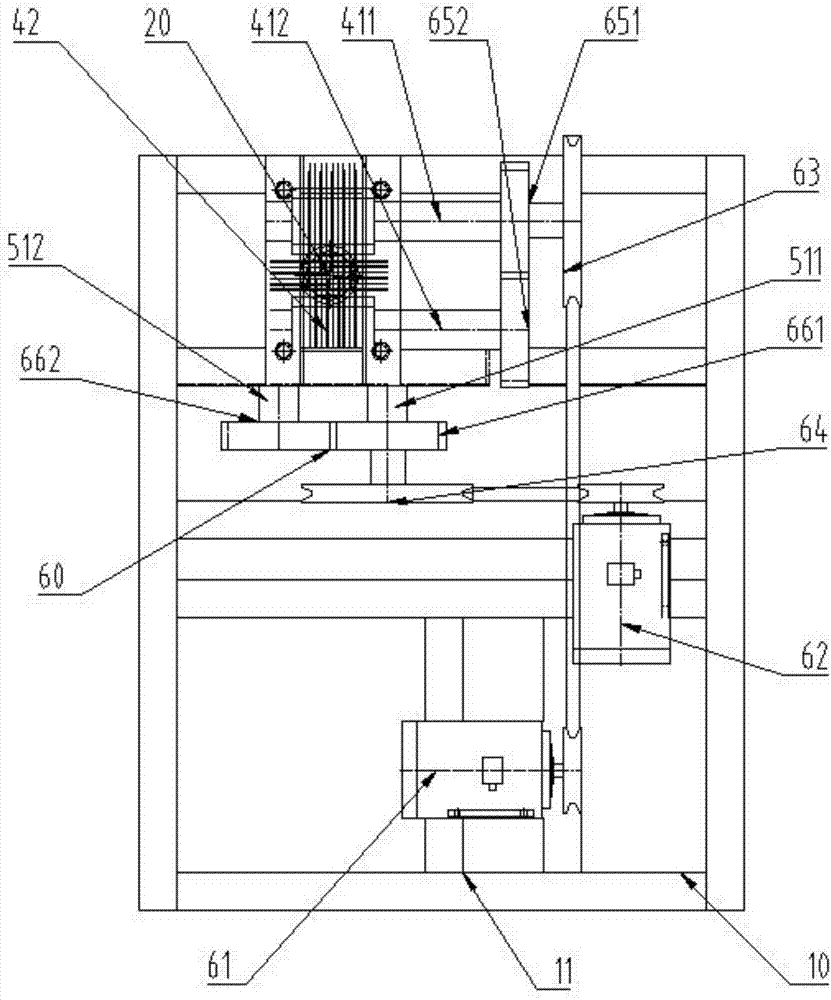

[0029] The present invention will be further described below in conjunction with the drawings.

[0030] Such as Figure 1 to 12 As shown, a burdock strip cutting machine includes a frame 10, a feed portion 20 provided on the top of the frame, a discharge port 30 provided on the side of the frame, and a slicing mechanism 40 and a strip cut inside the frame. The transmission mechanism 50 and the transmission mechanism 60 respectively drive the slicing mechanism 40 and the cutting mechanism 50 to operate; the feeding portion 20 includes a barrel 21 and a barrier strip 22. The barrel 21 is divided into a slicing matching portion 23 and a cutting The strip fitting portion 24, the slicing fitting portion 23 and the strip cutting fitting portion 24 are separated by a paddle 25, and the barrier strip 22 is fixed on the outside of the barrel 21 by a clamp 26; the slicing mechanism 40 is located directly above the strip cutting mechanism 50, The slicing mechanism 40 is two relatively movin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com