Cropping and edge-folding device for clothing trademark processing

A hemming device and trademark technology, applied in metal processing, cutting of textile materials, textiles and paper making, etc., can solve the problems of reducing cutting efficiency, damaging trademark tape, and affecting cutting accuracy, so as to avoid uneven cutting and improve The effect of cutting efficiency and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

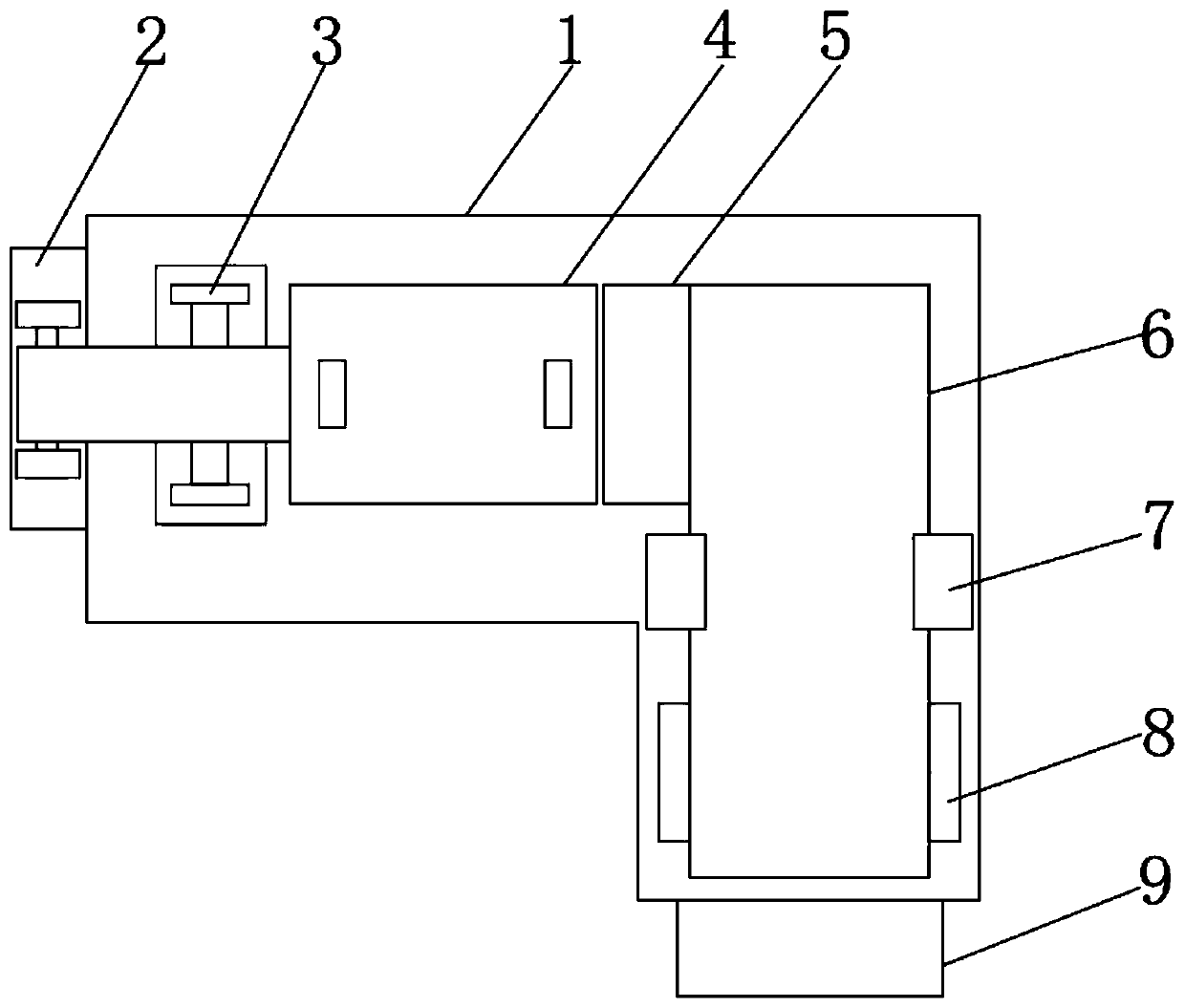

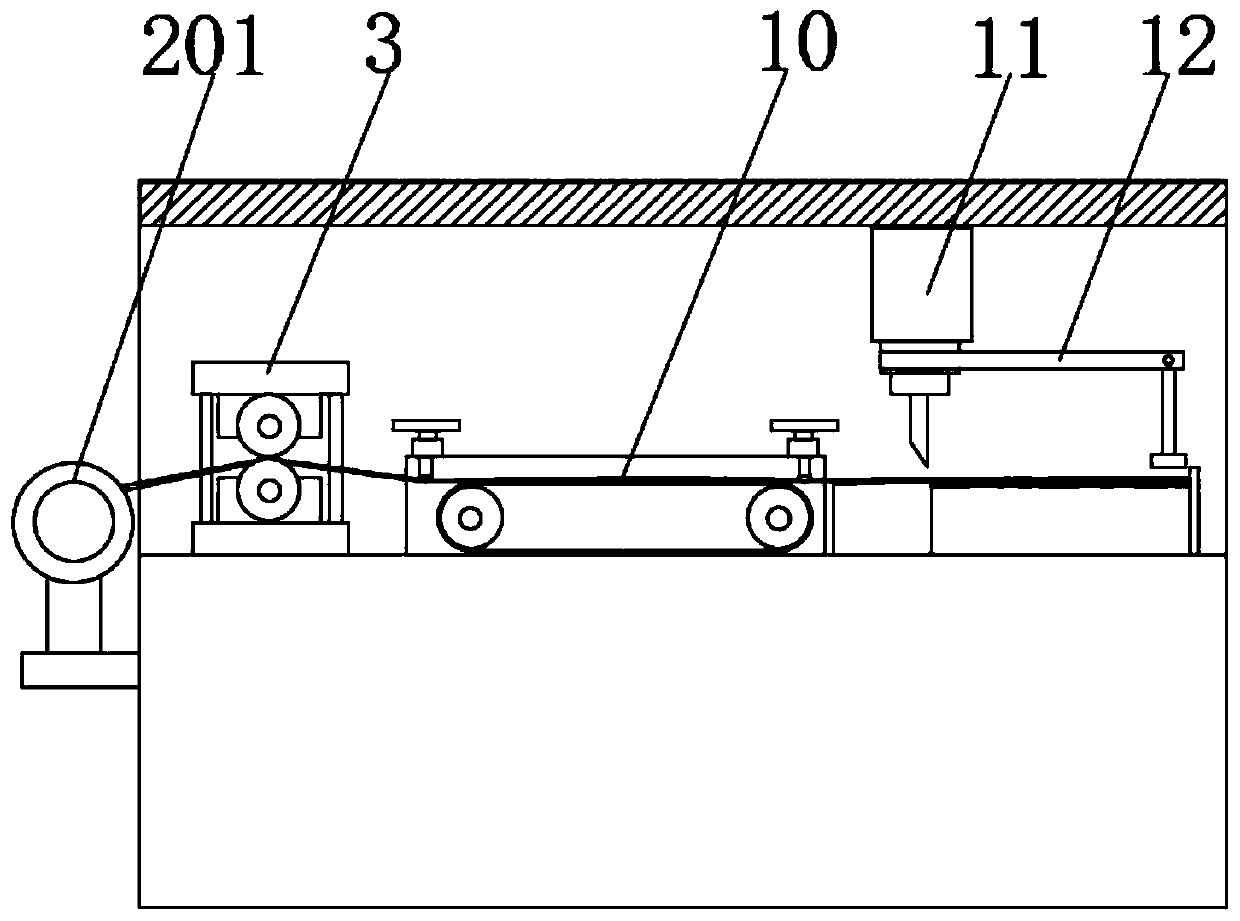

[0027] Such as Figure 1 to Figure 6 As shown, the cutting and flanging device for clothing trademark processing in this embodiment includes a body 1 and a bearing platform 2 arranged on one side of the body 1. A trademark winding shaft 201 is fixedly installed on the bearing platform 2, and the upper surface side of the body 1 A guide mechanism 3 is installed, a leveling transmission mechanism 4 is installed on one side of the guide mechanism 3, a cutting platform 5 is installed on one side of the guide mechanism 3, a conveying mechanism 6 is installed on one side of the cutting platform 5, and the two sides of the conveying mechanism 6 are respectively arranged Dispensing mechanism 7 and hemming mechanism 8, one end of conveying mechanism 6 is provided with collecting table 9;

[0028] A cutting device 11 is installed on the upper end of the cutting table 5, and the cutting device 11 includes a cylinder 1108. The lower end of the cylinder 1108 is fixedly connected with a mou...

Embodiment 2

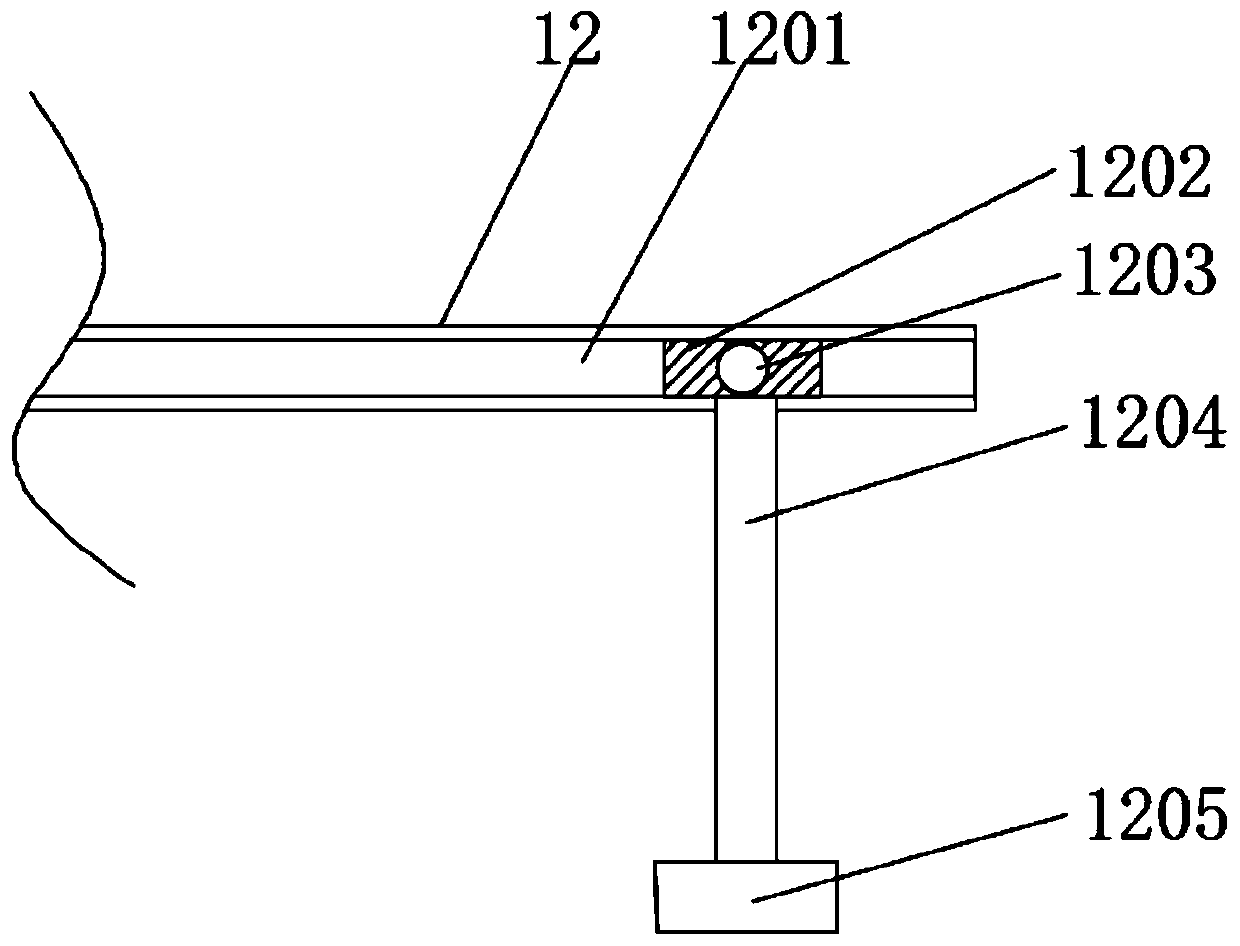

[0036]The structure of the cutting and flanging device for clothing trademark processing in this embodiment is basically the same as the structure of the cutting and flanging device for clothing trademark processing in Embodiment 1, the difference is that: the flattening transmission mechanism 4 includes a conveyor belt 10 and a flattening device 13, The leveling device 13 includes an adjustment block 1303, the adjustment block 1303 is internally threaded with a third threaded rod 1302, the upper end of the third threaded rod 1302 is fixedly connected with a rotary knob 1301, the lower end of the third threaded rod 1302 is fixedly connected with a backing plate 1304, and the backing plate 1304 The lower end is fixedly connected with a second connecting rod 1305, and the lower end of the second connecting rod 1305 is fixedly connected with a leveling head 1306, and a spring 1307 is fixedly connected between the backing plate 1304 and the upper surface of the transmission mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com