High-temperature-resistant paper-plastic composite bag manufacturing and cutting processing equipment and cutting processing method

A technology of paper-plastic composite bags and processing equipment, which is applied in bag making, papermaking, paper/cardboard containers, etc., and can solve the problem of uneven cutting edges of paper-plastic composite bags and the adjustment of the degree of inability to cut, paper-plastic composite bags The problem of single cutting length is achieved to avoid the effect of cutting the edge irregularly and avoiding the unevenness of the cutting place

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

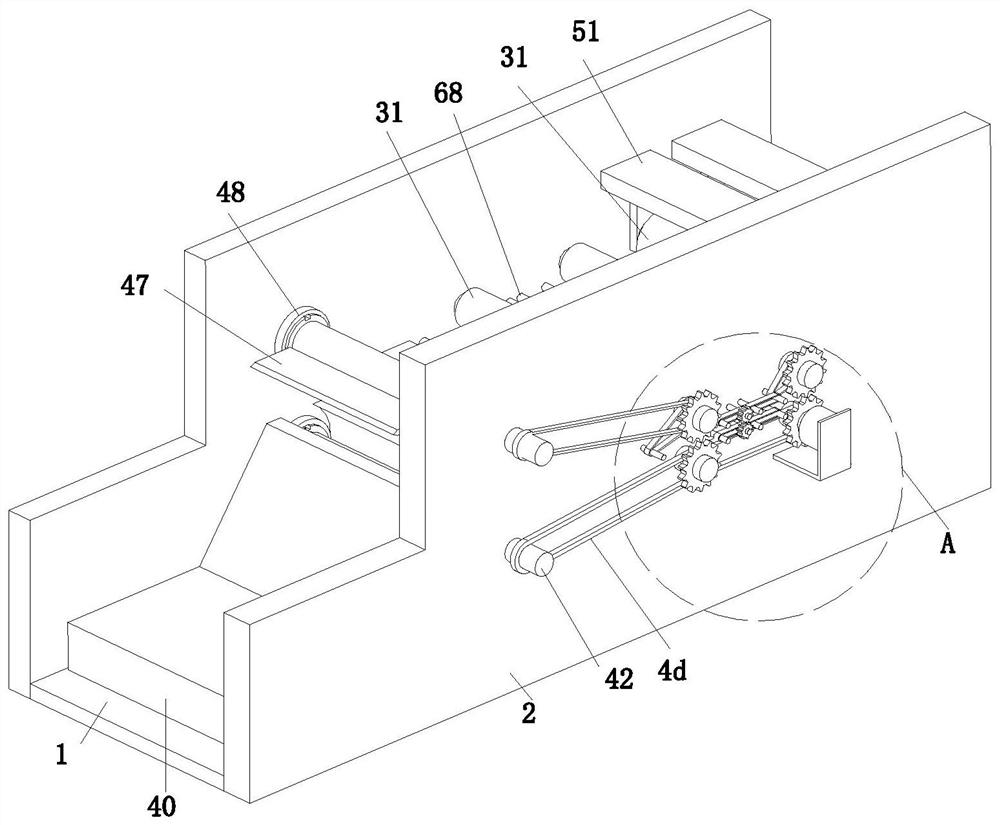

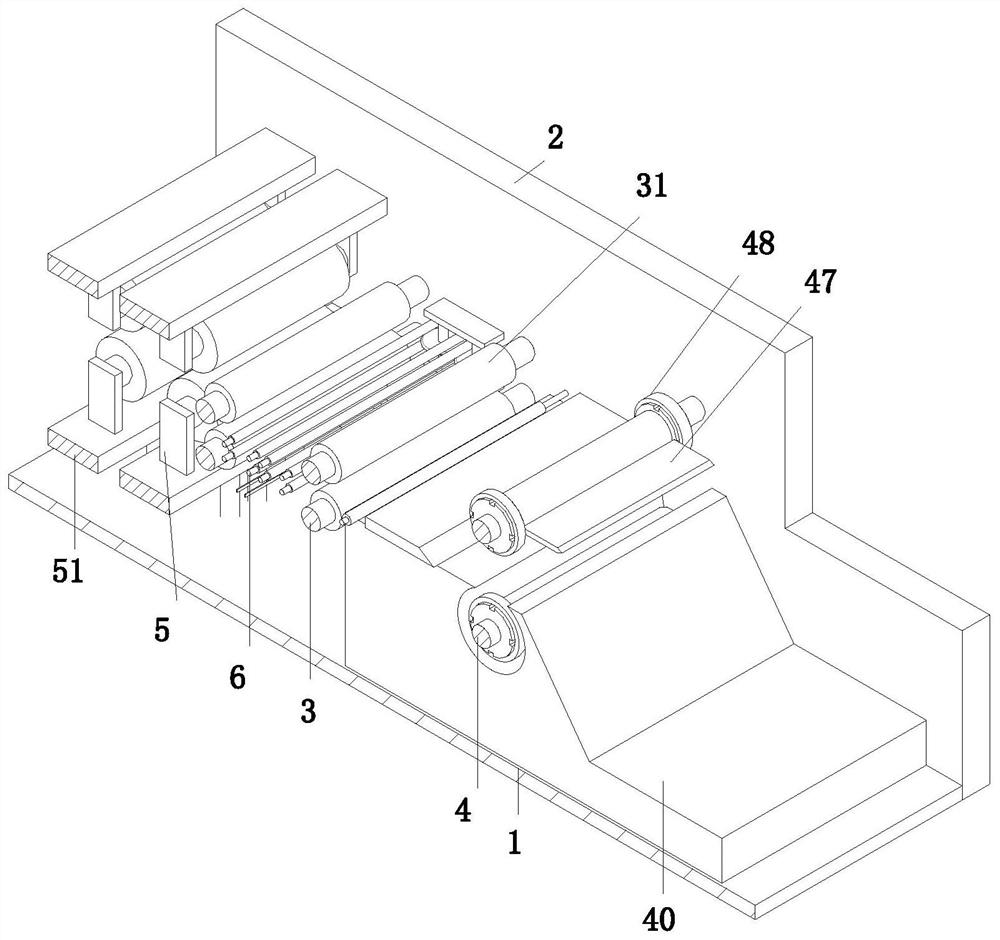

[0032] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, the following combination Figure 1 to Figure 8 , to further elaborate the present invention.

[0033]A high-temperature-resistant paper-plastic composite bag production cutting processing equipment, including a base plate 1, an L-shaped working plate 2, a transmission mechanism 3, a cutting mechanism 4, a bonding mechanism 5 and a folding mechanism 6, the front and rear of the bottom plate 1 L-shaped working boards 2 are installed symmetrically on the ends, and a bonding mechanism 5, a transmission mechanism 3 and a cutting mechanism 4 are arranged between the L-shaped working boards 2 in sequence from left to right, and a folding mechanism 6 is arranged between the L-shaped working boards 2;

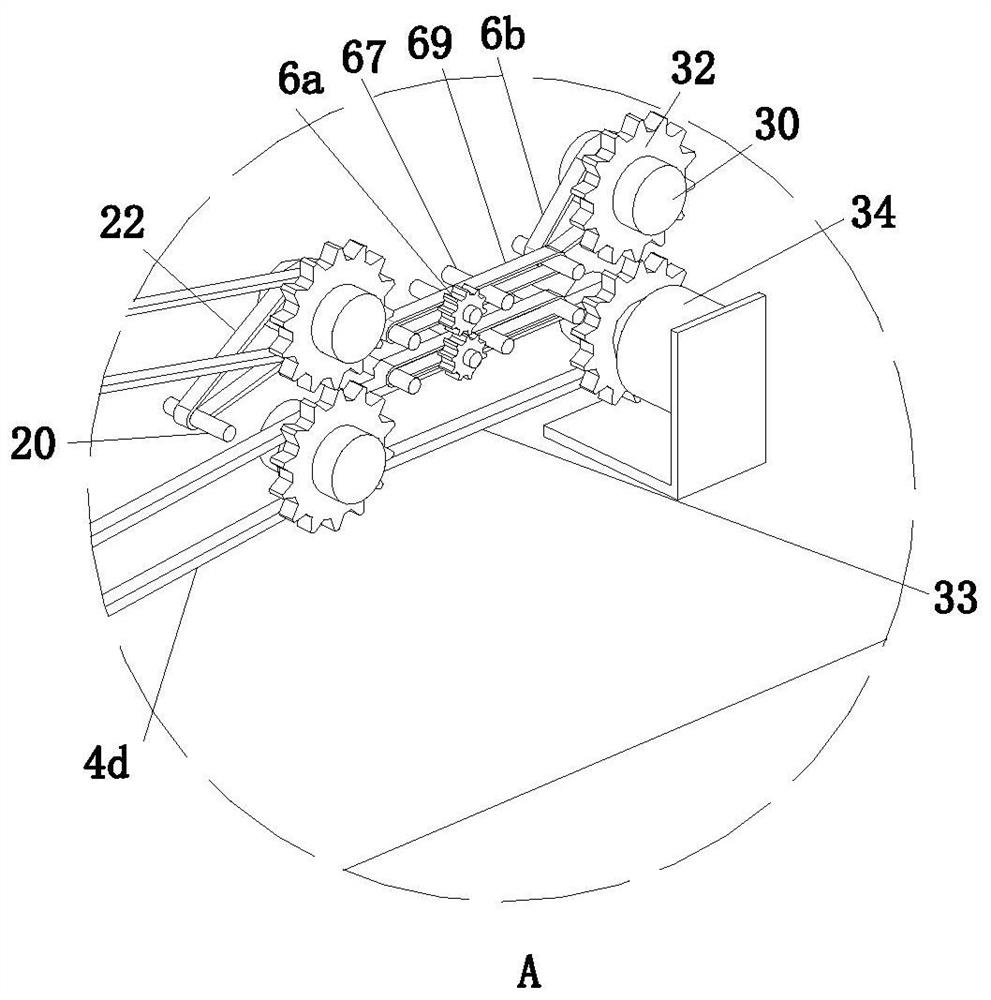

[0034] The transmission mechanism 3 includes a transmission shaft 30, a transmission roller 31, a No. 1 gear 32, a No. 1 belt 33 and a No. 1 motor 34....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com