Scattering-preventing tool special for lead wire cutting

A special tool and wire technology, applied in the direction of line/collector parts, electrical components, circuits, etc., can solve the problems of difficulty in inserting terminals, difficulty in connecting terminals, and prolonging operation time, so as to prolong the service life of equipment and ensure safety. The effect of stable operation and avoiding wire breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

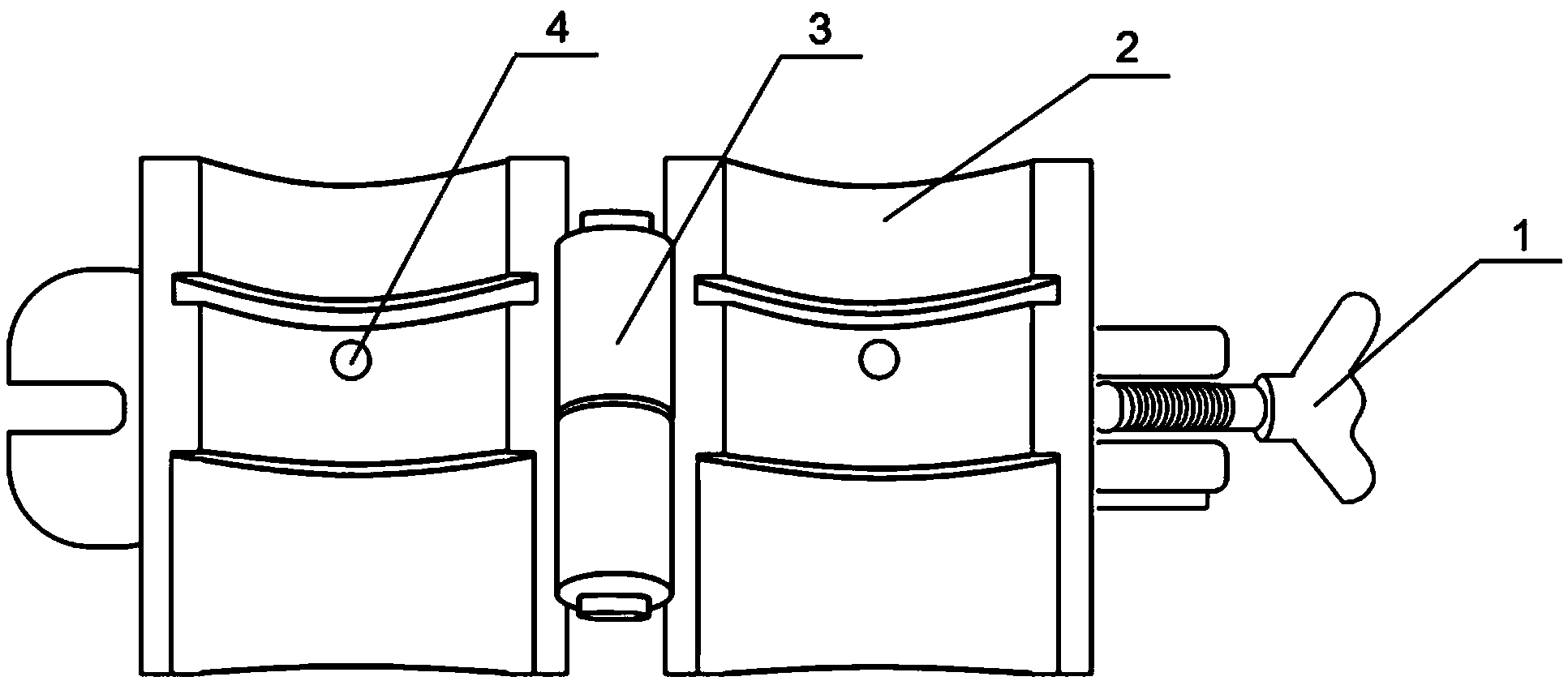

[0020] The wire cutting and anti-scattering special tool as shown in the figure is characterized in that it includes a butterfly bolt 1, an external clamp 2, a rotating shaft 3, an upper part of the mold 5, and a lower part 7 of the mold. The external clamp 2 is movably connected by the rotating shaft 3. A butterfly bolt 1 is installed on the side of the outer clamp 2; the upper part 5 and the lower part 7 of the mold are wrapped inside the outer clamp 2.

[0021] The external clamping member 2 is provided with a clamping member screw hole 4.

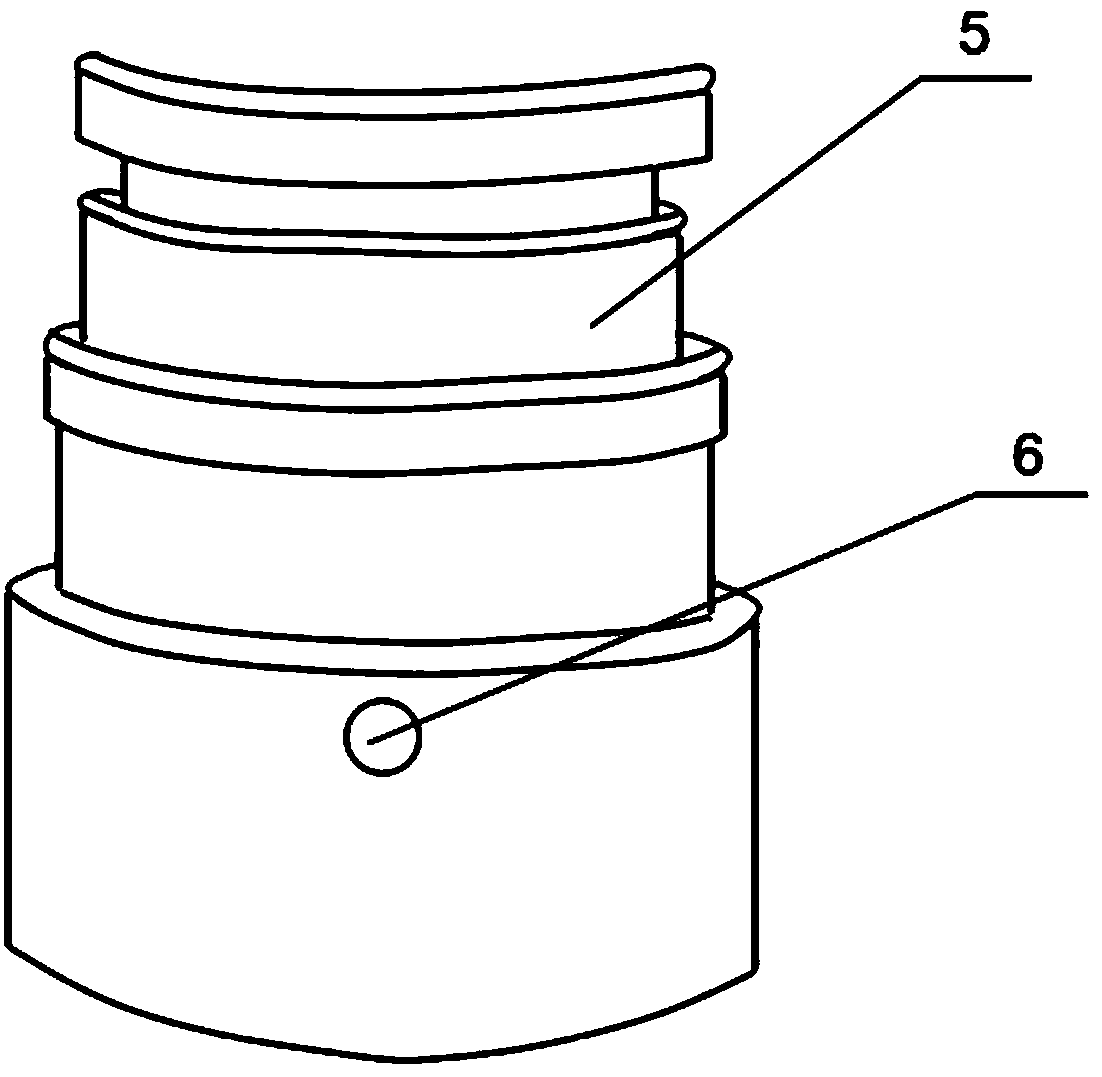

[0022] The upper part 5 of the mold is provided with a mold screw hole 6.

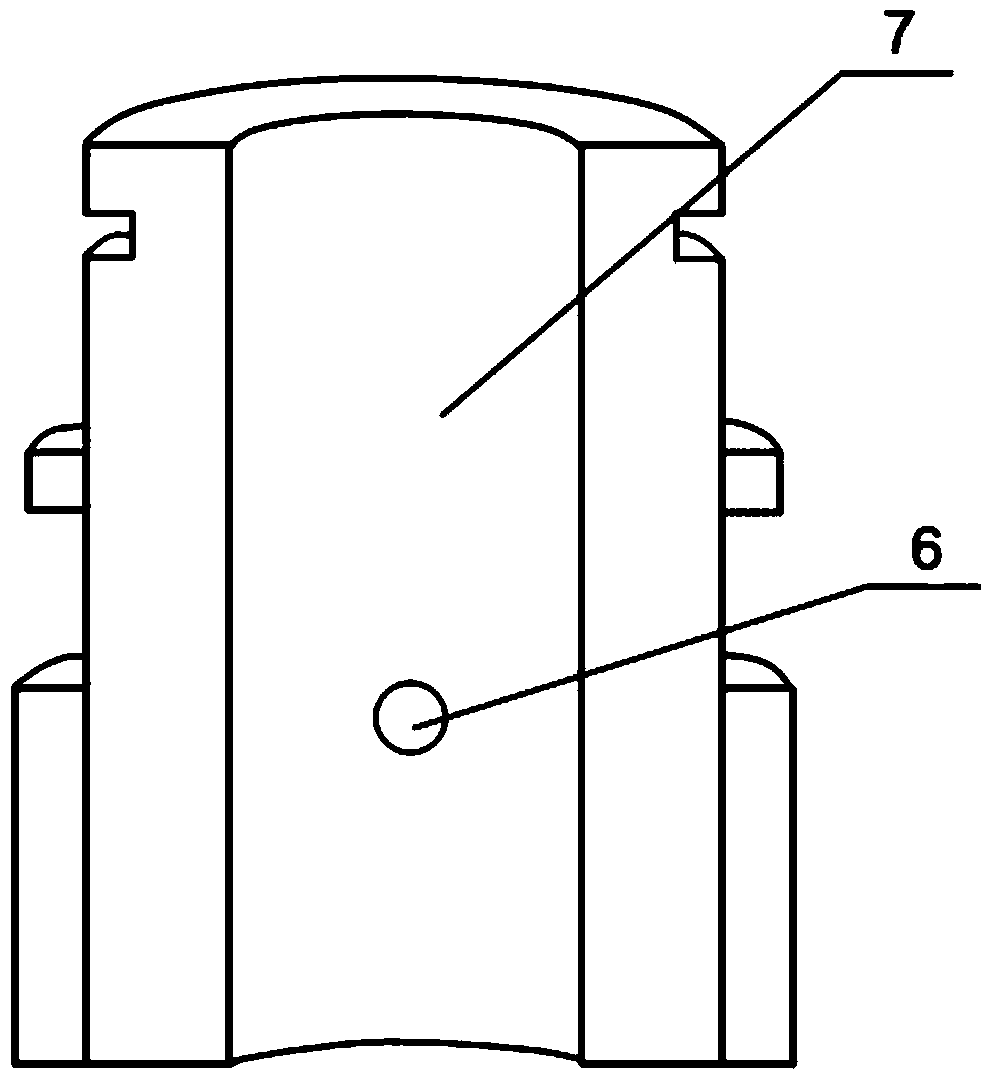

[0023] The lower part 7 of the mold is provided with a mold screw hole 6.

[0024] The upper part 5 of the mold, the lower part 7 of the mold and the external clamp 2 are fixedly connected by screws, and the screws pass through the clamp screw holes 4 and the mold screw holes 6.

[0025] When using this special tool for wire cutting and anti-scattering, first unscrew the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com