Preparation method and preparation system of fresh peel chews

A preparation system and fresh skin technology, which is applied in the fields of meat cutting equipment, feed, animal husbandry, etc., can solve the problems of excessive chemical residues, achieve the effect of rich nutrition, strong palatability, and avoid uneven cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

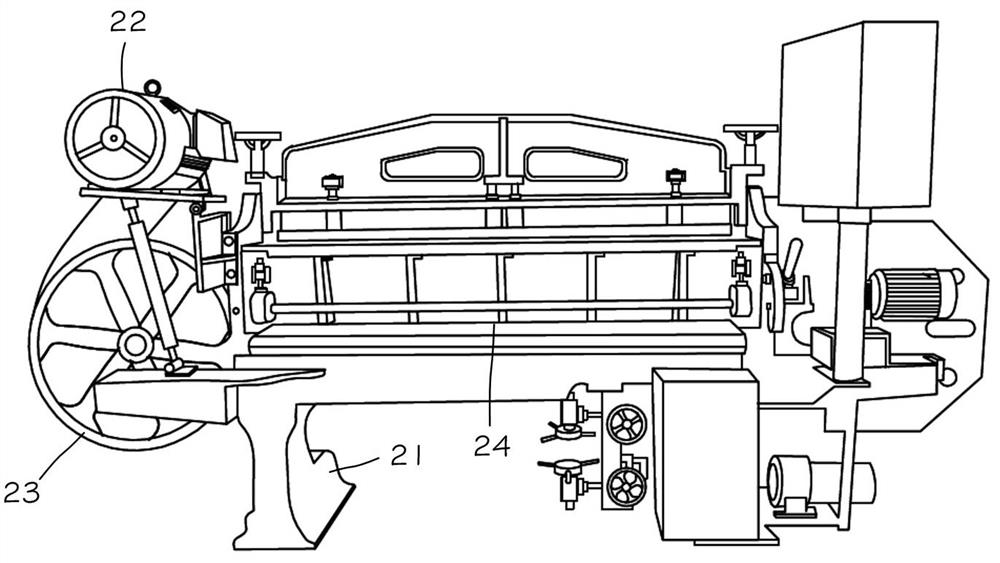

[0048] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention.

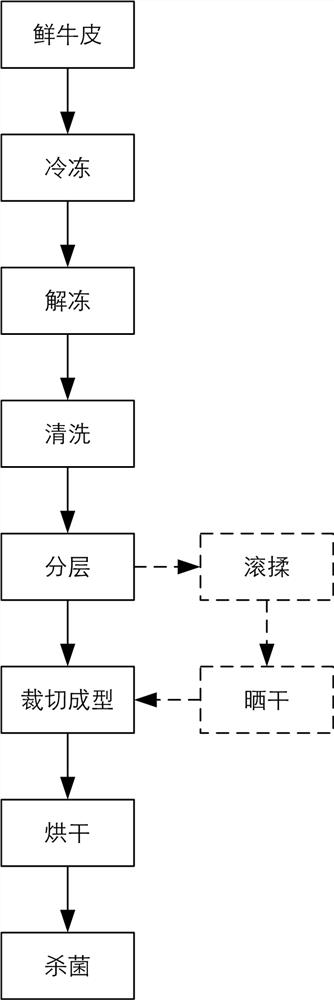

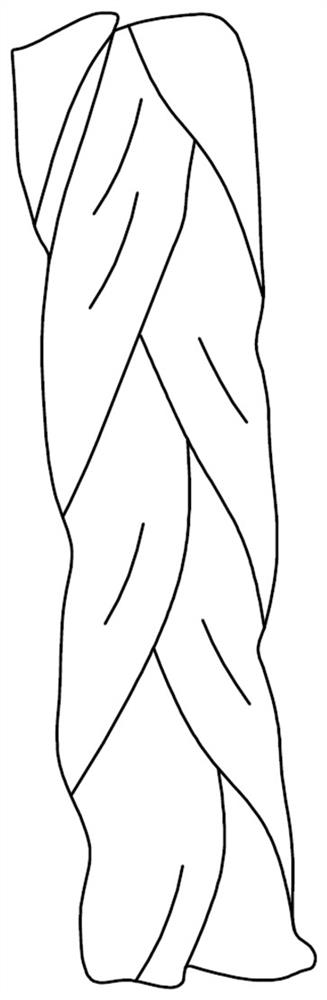

[0049] like Figures 1 to 6 The shown preparation method of the fresh skin chewing gum of the present invention adopts fresh cowhide as the main raw material, and adopts a physical-mechanical depilation process to avoid chemical residues caused by chemical depilation.

[0050] Step 1, freezing: the fresh skins are sent to a freezer for cryopreservation, and the temperature of the freezing step is -20°C to -15°C. The present invention uses fresh cowhide directly obtained from slaughtered animals, ensuring that the material is not subjected to any chemical treatment. The cowhide has high nutritional value, and this polymer collagen is easily absorbed by the human body after being processed.

[0051] Step 2, thawing: take the frozen fresh skin to thaw, and the thawing te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com