Rapid cutting device for copper bar

A fast cutting, copper bar technology, applied in shearing devices, accessories of shearing machines, maintenance and safety accessories, etc., can solve the problems of waste of resources, reduce the quality of copper bars, uneven cutting surface, etc., to reduce waste , Improve the effect of cutting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

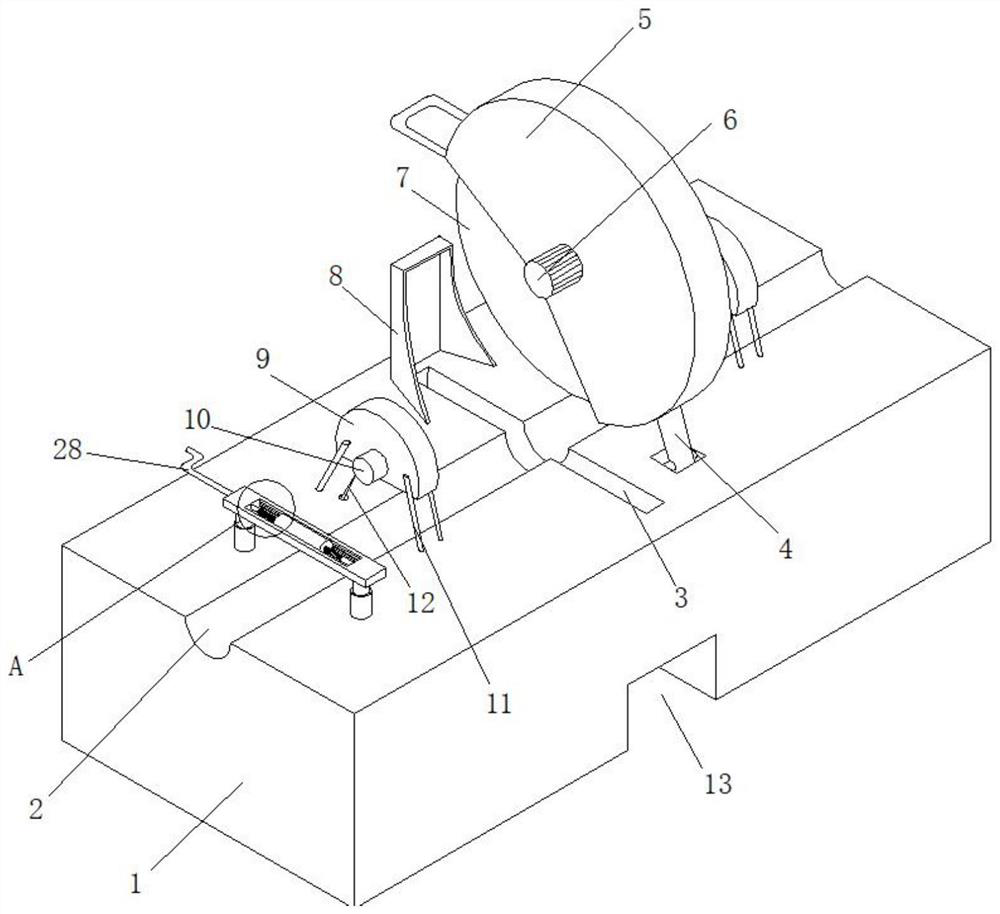

[0030] A rapid cutting device for copper and copper rods, comprising a main body 1, the top of the main body 1 is connected with a connecting column 4 through a spring 16, and a protective frame 5 is fixed on one side of the connecting column 4, and the middle position of one side of the protective frame 5 is A rotating motor 6 is installed at the position, and the output end of the rotating motor 6 is connected with a cutting knife 7, and a feeding groove 2 is arranged at the middle position of the top of the main body 1, and a cutting groove 3 is arranged at the middle position of the feeding groove 2.

[0031] The connecting column 4 cooperates with the spring 16 to facilitate the reset of the protective frame 5, thereby facilitating the operation of the operator and preventing the cutting knife 7 from falling due to gravity. 3. It is convenient for the cutting knife 7 to enter, so as to complete the purpose of cutting.

Embodiment 2

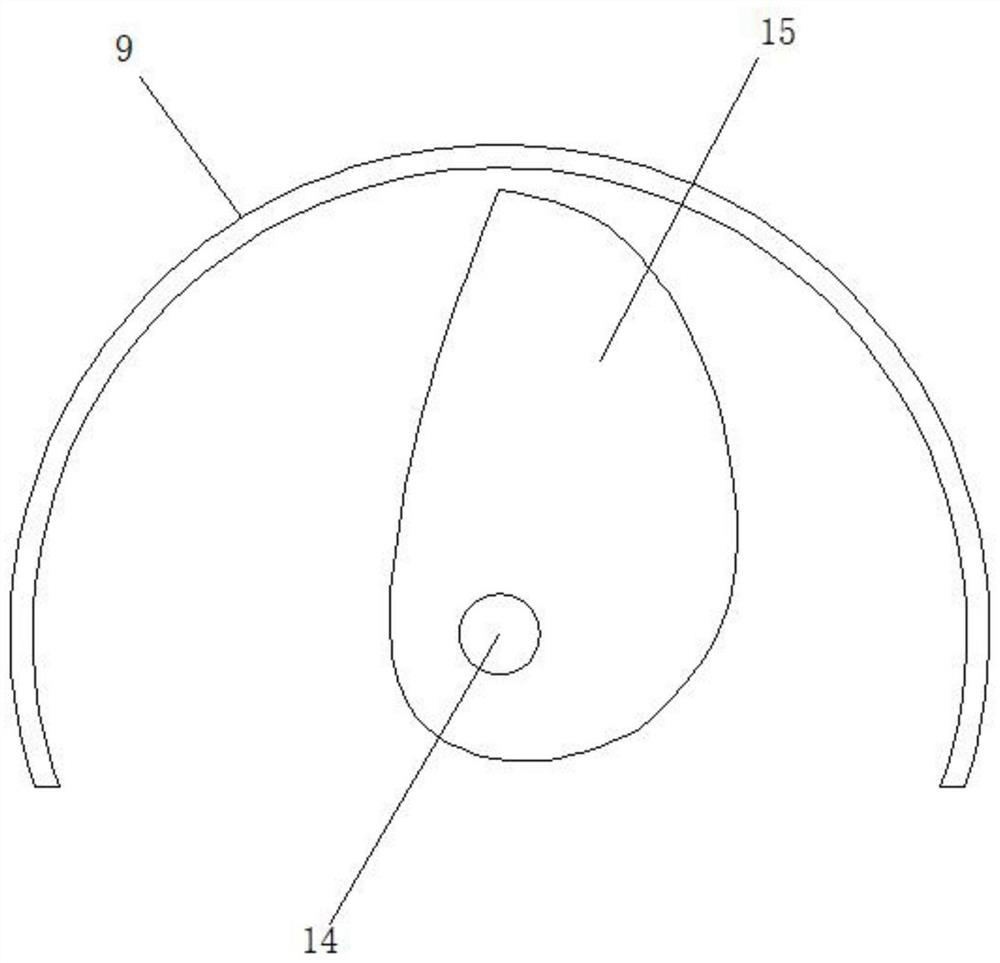

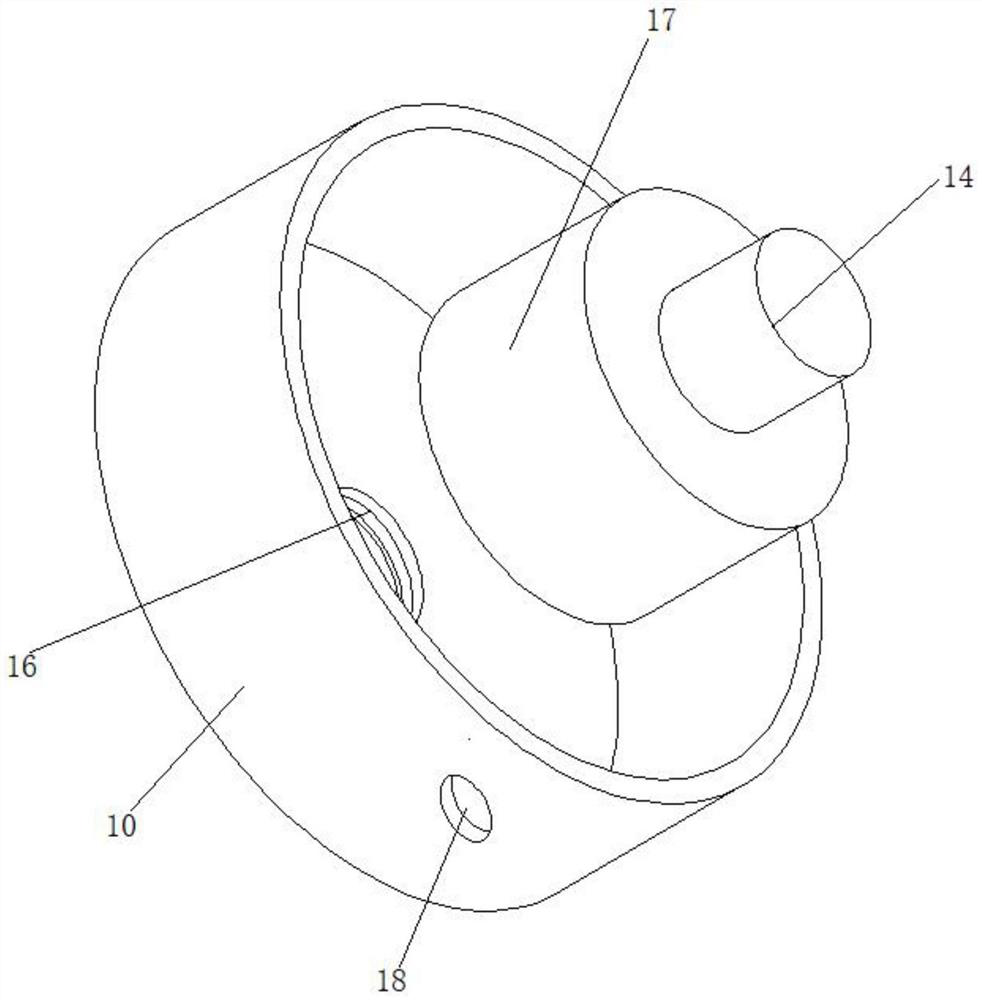

[0033] Both ends of the top of the main body 1 are equipped with a limit mechanism through the mounting bracket 11, and the top of the main body 1 is provided with an auxiliary plate 8 at one end of the cutting groove 3, and slots 20 are provided on both sides of the rear surface of the main body 1, and the slots 20 Both ends of the interior are provided with a first chute 21, one side of the first chute 21 is provided with a second chute 22, the inside of the slot 20 is slidably connected with a pull column 19, and both ends of the pull column 19 are A slide block 23 cooperating with the first chute 21 and the second chute 22 is provided, the limit mechanism includes a limit frame 9, and one side of the limit frame 9 is fixed with a tightening frame 10, and the limit frame 9 The inner rotation is connected with a rotating shaft 14 that penetrates to the inside of the tightening frame 10. The outer side of the rotating shaft 14 is positioned at the inside of the limiting frame ...

Embodiment 3

[0036] One side of the pull column 19 is provided with a handle, and the middle position on the other side of the pull column 19 is connected with the end of the rope 12, the rope 12 penetrates to the inside of the main body 1, and the inner top of the slot 20 is provided with a handle connected with the rope 12. Matching wheel.

[0037] The handle provided is convenient for the pulling of pull column 19, and pull column 19 is connected with rope 12, is convenient to the transmission of rope 12, and the running wheel of setting, avoids the wear and tear of rope 12 inside main body 1, increases the service life of rope 12.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com