Sewing scissors and manufacturing method thereof

A tailoring and rounding technology, applied in metal processing and other directions, can solve complicated problems, achieve beautiful appearance, beautiful appearance, and reduce the loss of grinding wheels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Next, a kind of tailor scissors and its manufacturing method of the present invention will be described in detail below with reference to the accompanying drawings.

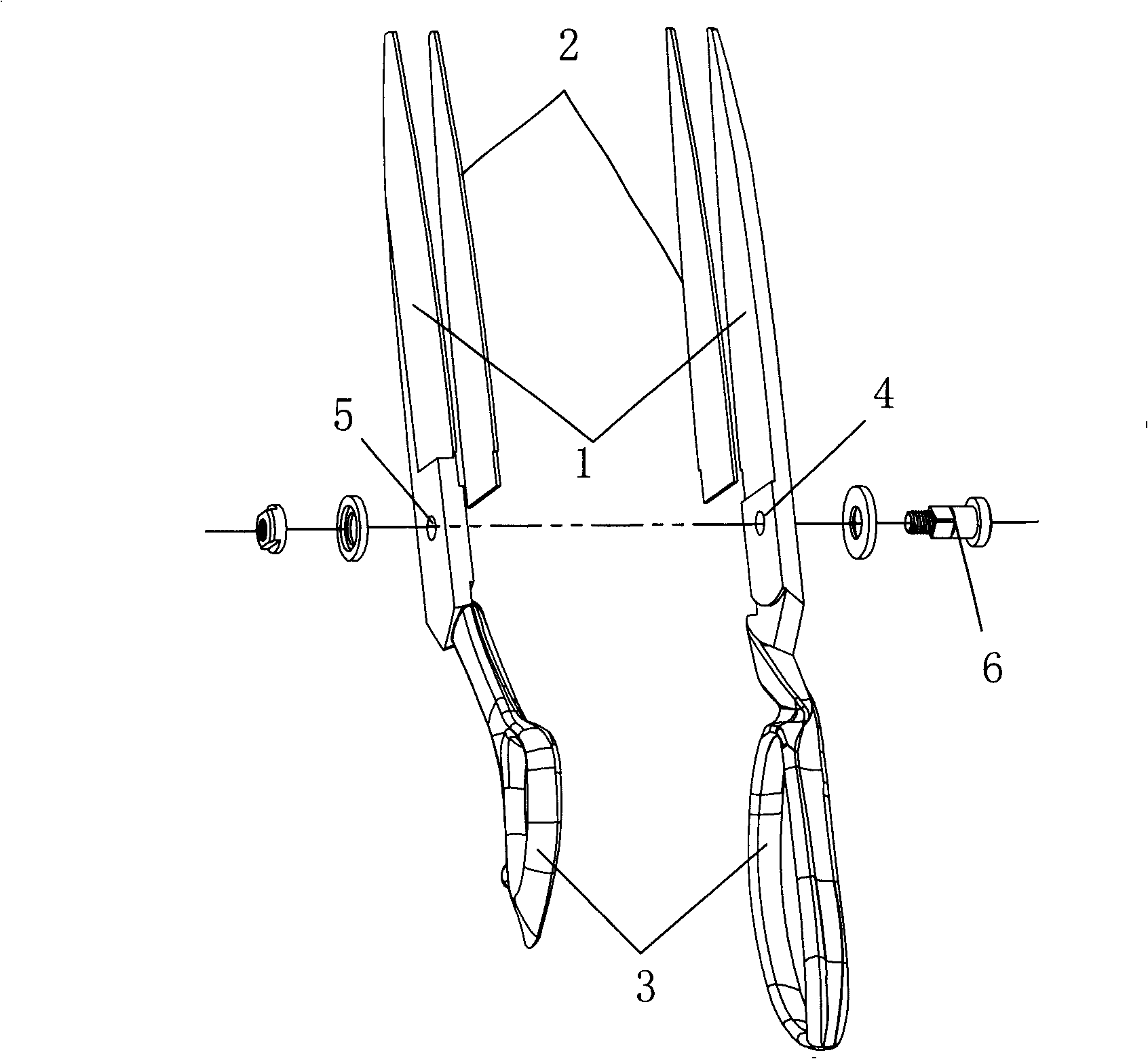

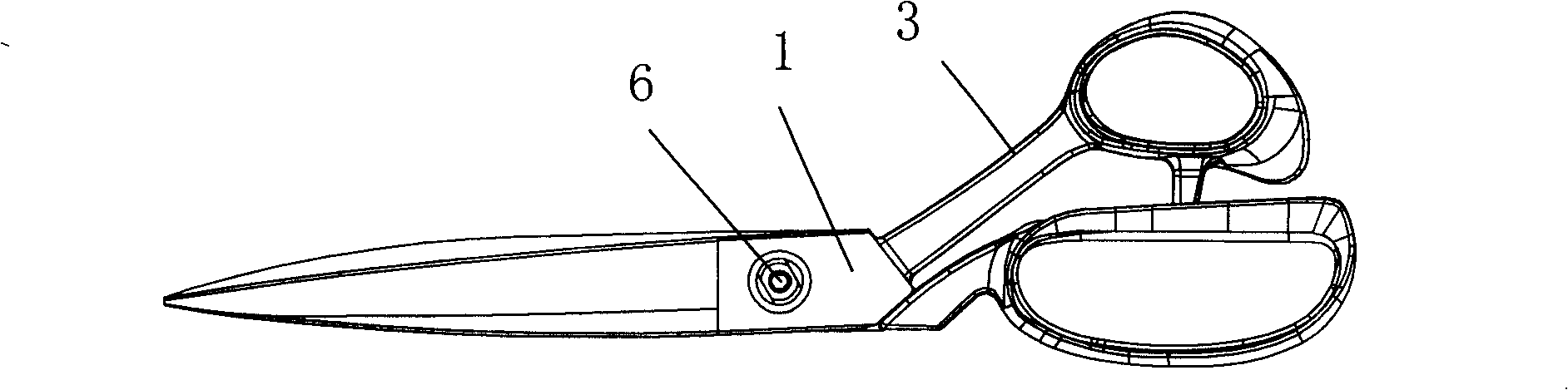

[0018] A kind of tailor scissors of the present invention, its structure is to be assembled by two precision casting knife bodies 1 corresponding to each other through the screw hole opened in the middle part and cooperate with the screw assembly, is installed on the cutting edge part of precision casting knife body 1 blade piece 2.

[0019] The screw holes provided in the middle of the precision casting cutter body 1 and the screw assemblies that cooperate with each other are stopper connecting parts, and a round square hole 5 is set on one of the precision casting cutter bodies, that is, half of the thickness of the cross section is the other half of the thickness of the round hole. For the screw hole of the square hole, it is enough to set the round hole 4 on the other precision casting cutter body, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com