Uniform-thickness slicing device for kiwi fruit processing

A technology of uniform thickness and kiwifruit, applied in metal processing and other directions, can solve the problems of kiwifruit accumulation, affecting cutting uniformity, inconvenient feeding of kiwifruit, etc., to ensure uniformity and reduce the effect of falling speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

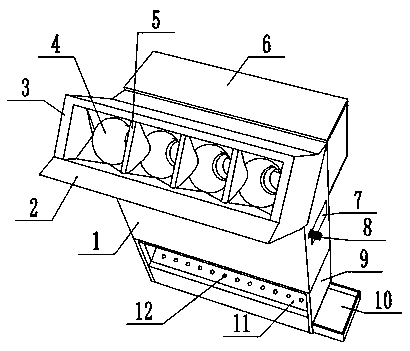

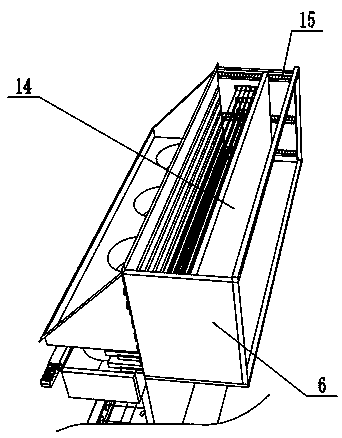

[0037] A slitting device with uniform thickness for kiwi fruit processing, such as Figure 1-7 As shown, it includes a shell 1 and a feed hopper 3; the top of the shell 1 is welded with an auxiliary frame 21, the feed hopper 3 is welded on the top of the auxiliary frame 21, the bottom of the shell 1 is welded with a blanking frame 9, and the auxiliary frame 21 A side box 6 is welded on the outer wall of one side, and a cross-cutting mechanism is arranged in the side box 6. Several spacers 5 are bonded to the inner wall of the feed hopper 3, and an elastic sleeve 4 is bonded to the side wall of the spacer bar 5. In the embodiment, preferably, the top of the spacer bar 5 is an arc-shaped structure, the elastic sleeve 4 is an elliptical sleeve structure, and one side of the bottom end of the feed hopper 3 is welded with a material guide plate 2, which can play a certain role in receiving , to prevent the kiwi fruit from falling out of the hopper 3, the design of the elastic sleev...

Embodiment 2

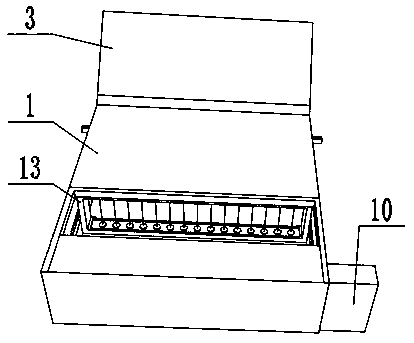

[0048] A slitting device with uniform thickness for kiwi fruit processing, such as figure 1 and figure 2 As shown, in order to solve the problem that the kiwifruit juice is not easy to clean up after being cut into strips; this embodiment makes the following improvements on the basis of Embodiment 1: one side outer wall of the blanking frame 9 has a blanking opening, and the inner wall of the blanking opening is welded There is a blanking plate 11 arranged inclinedly, and the outer wall of the blanking plate 11 is provided with several drain holes 12, and the side of the blanking frame 9 is slidingly connected with a waste liquid drawer 10; Guide material is taken out, and the juice that its surface produces because of cutting can flow in waste liquid drawer 10 and collect and use through drain hole 11.

[0049] When the present embodiment is in use, the cut kiwi fruit drops onto the blanking plate 11, and the juice on its surface enters the waste liquid drawer 10 through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com