PE pipe cutting device convenient for waste collection

A cutting device and waste collection technology, applied in separation methods, filtration separation, mechanical equipment, etc., can solve the problems of troublesome cleaning, shortening, and reducing the cutting speed of PE pipes, and achieve the effect of easy cleaning and convenient positioning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

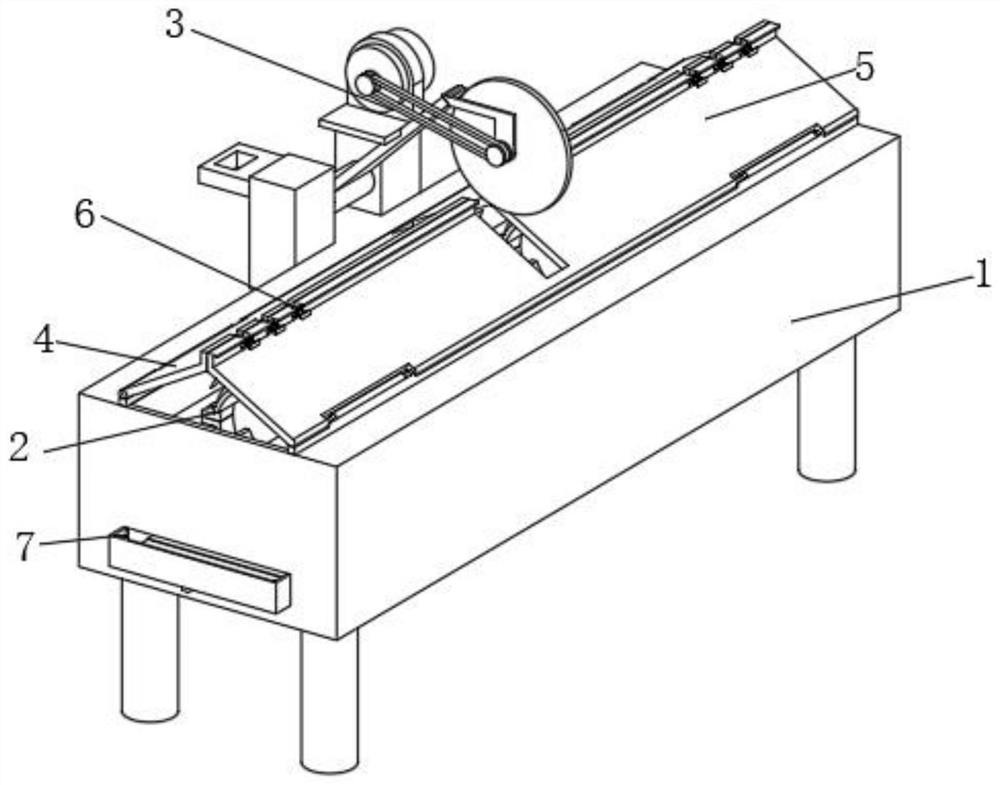

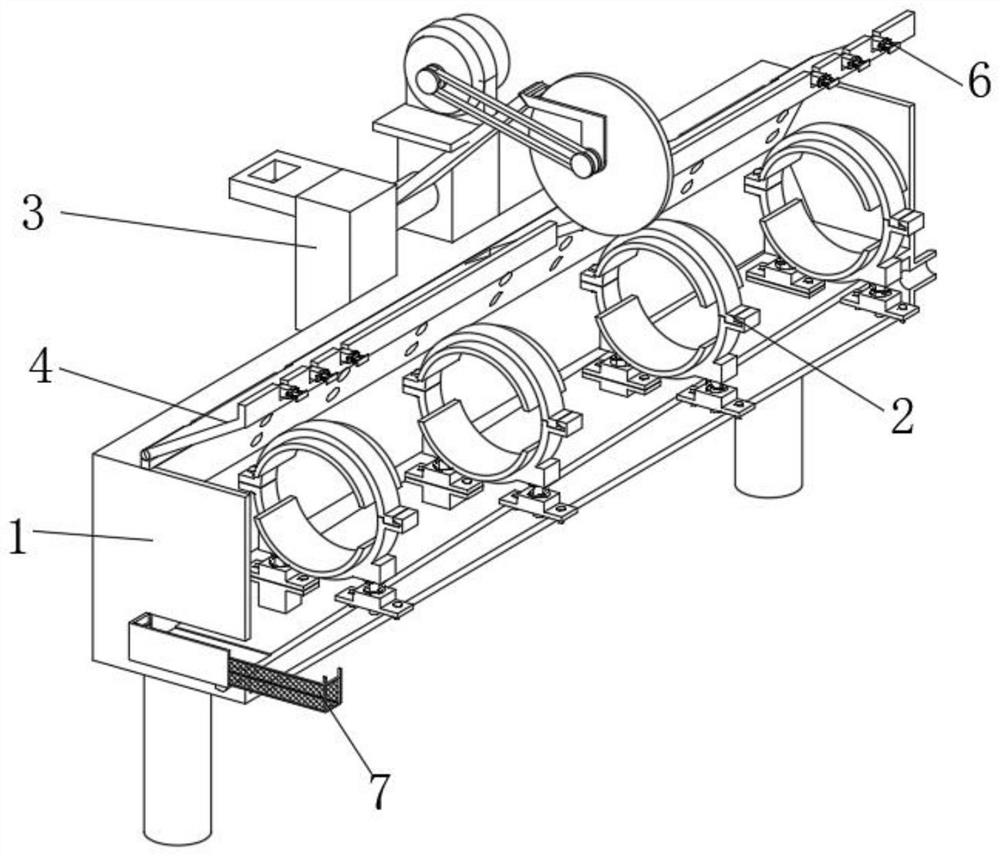

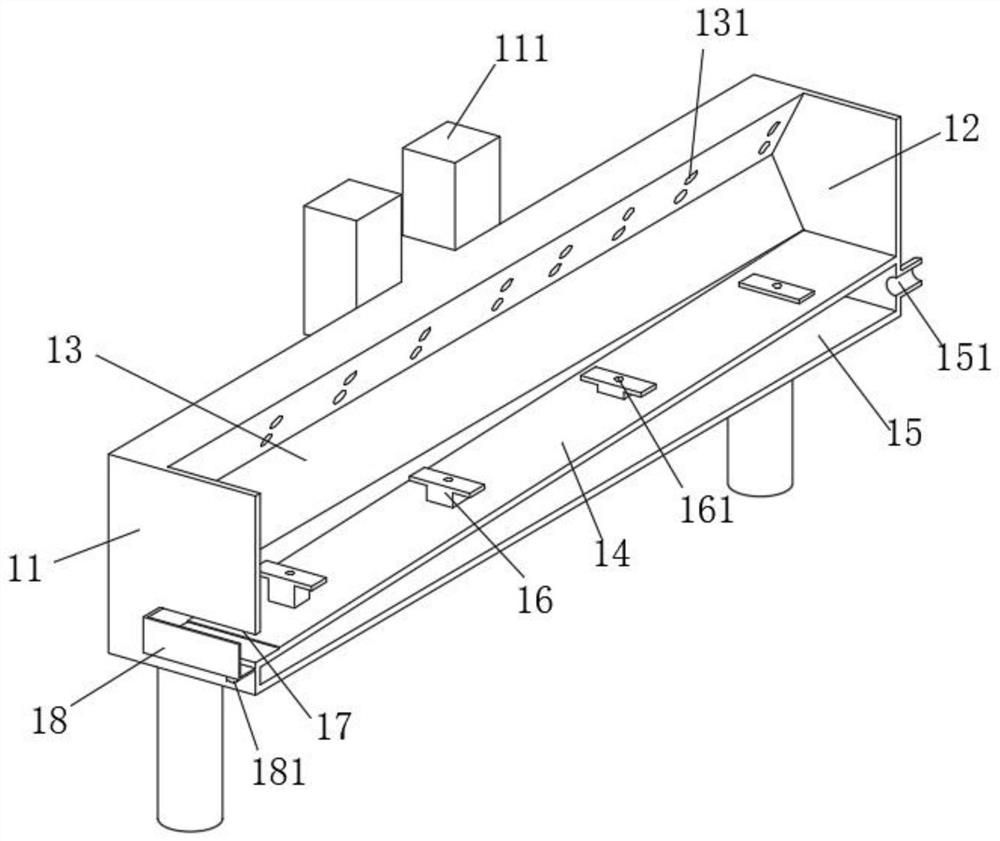

[0048] see Figure 1-Figure 10 As shown, a PE pipe cutting device that is convenient for waste collection is provided, including a mounting base 1, and the interior of the mounting base 1 is symmetrically provided with several fixing devices 2 along the length direction of the mounting base 1. The upper surface of the mounting base 1 A cutting device 3 is provided on one side, and a left baffle 4 and a right baffle 5 are symmetrically provided on the upper surface of the mounting base 1 near the middle, and several connecting devices 6 are arranged on the left baffle 4, and one side of the mounting base 1 A filter device 7 is provided near the bottom;

[0049] The mounting seat 1 includes a mounting shell 11, and the interior of the mounting shell 11 is symmetrically provided with a cutting groove 12. The top of the cutting groove 12 runs through the upper surface of the mounting shell 11, and the bottom of the cutting groove 12 is obliquely connected with a square sloping pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com