Dustproof ore conveying device for mining

A conveying device and dust-proof technology, applied in the direction of conveyor control devices, conveyors, conveyor objects, etc., can solve problems such as smashing, pulling force shifting to the other side, and easy shifting to the other side

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

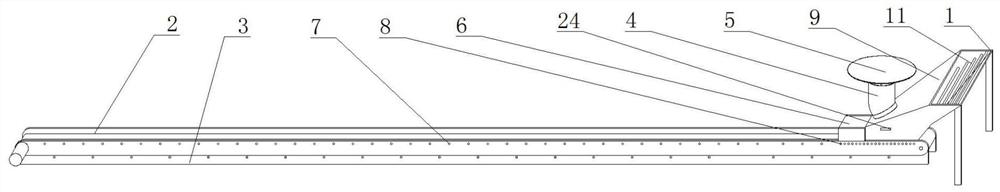

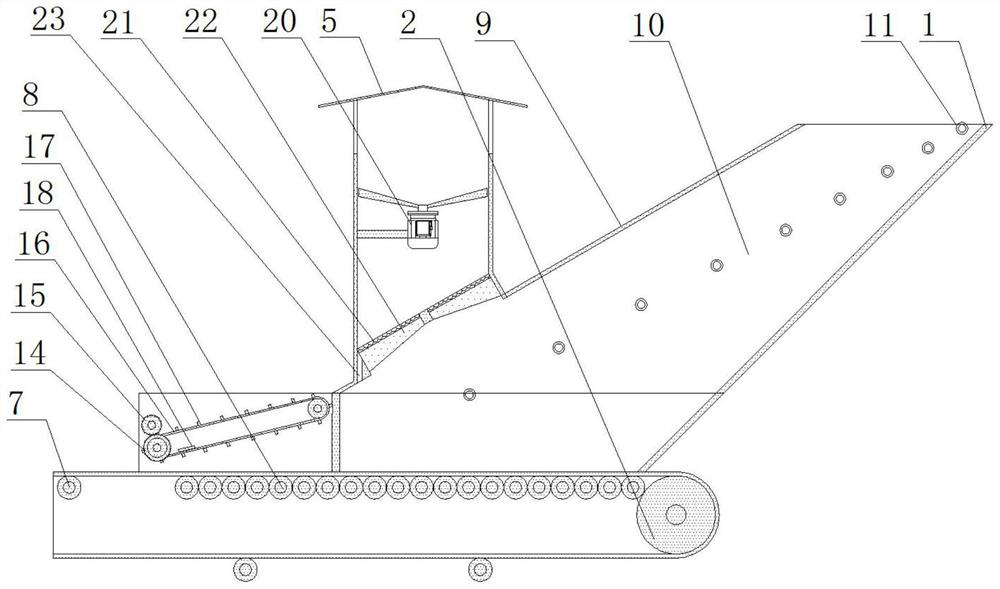

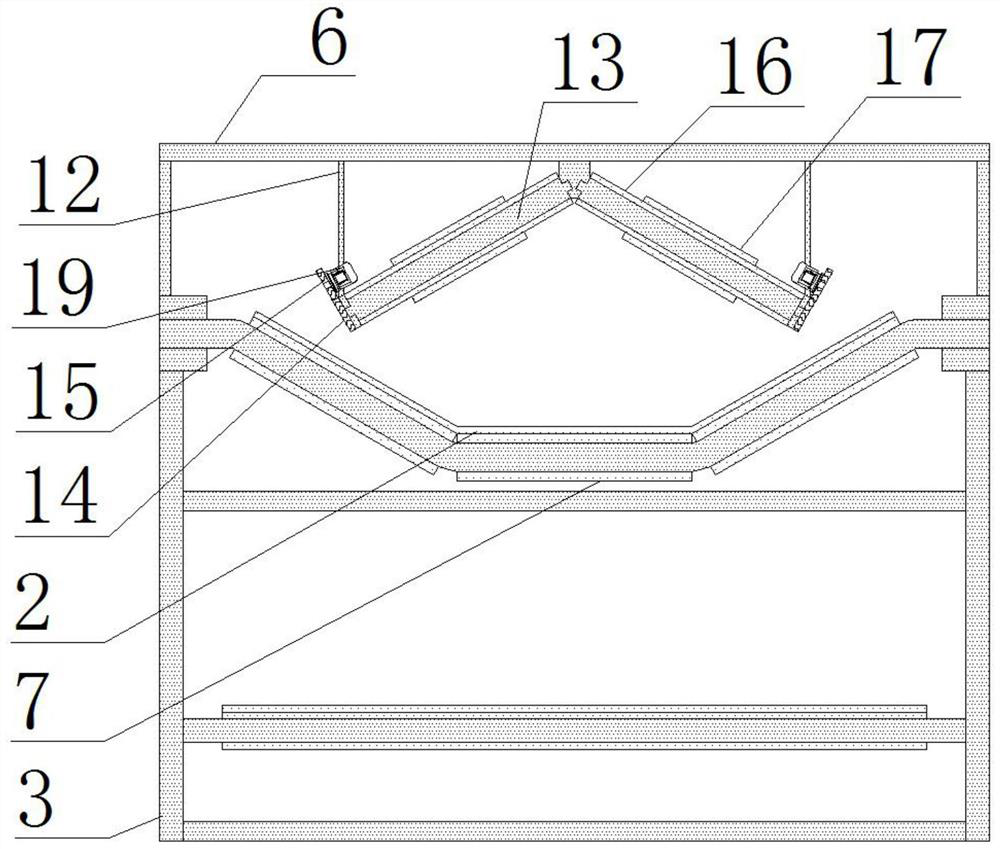

[0026] As a preferred embodiment of the present invention, the conveyor 2 includes a conveyor belt, five rollers and two motors, the five rollers are installed on both ends of the bracket through a rotating shaft, and the bolts on one side of the five rollers are installed on the two motors. On the output shaft of the conveyor belt, the conveyor belt is sleeved on the outer sides of the two drums 5, and the conveyor 2 can be opened by the switch 24, so that the top of the conveyor belt moves from right to left, and then the ore falling on the conveyor belt through the hopper is moved to the left Transportation, convenient for long-distance transportation of ore.

[0027]As a preferred embodiment of the present invention, the first roller 7 and the second roller 8 are installed on the support 3 through a rotating shaft, the top of one end of the conveyor belt is stuck on the top of the second roller 8, the bottom of the conveyor belt and the other The top of one side is stuck o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com