Alumite cutting machine

A cutting machine, anodized aluminum technology, applied in the direction of static electricity, electrical components, metal processing, etc., can solve the problem of uneven cut surface of anodized aluminum film rolls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Such as Figure 1 to Figure 5 Shown:

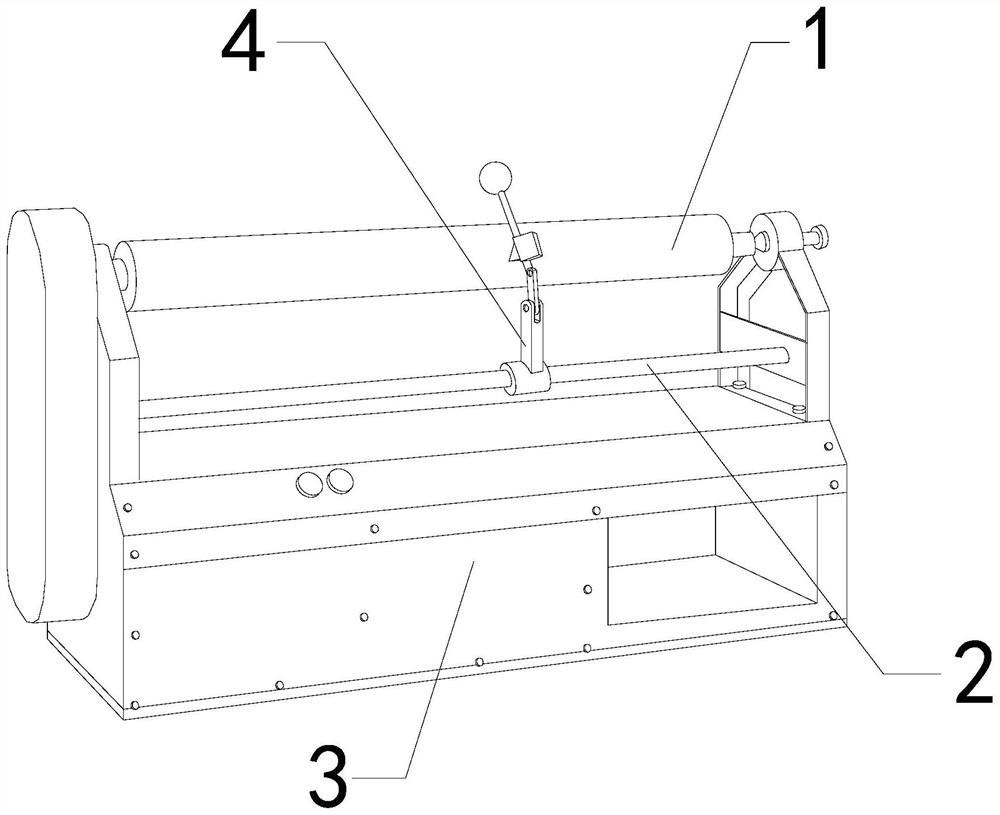

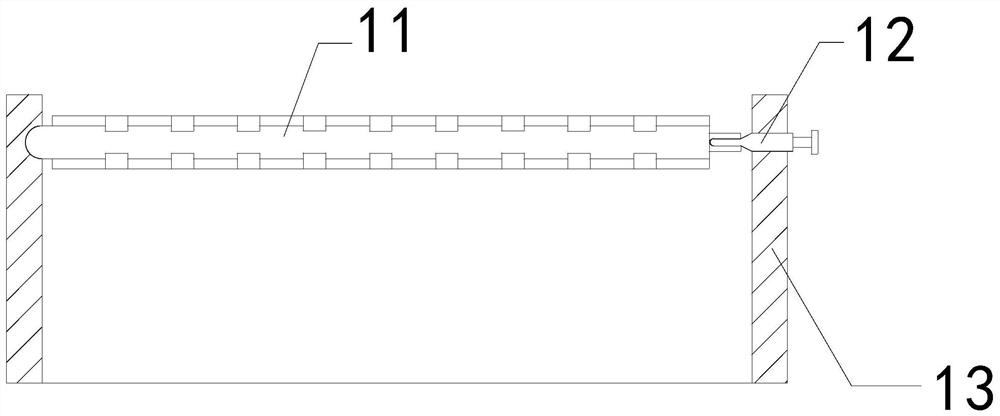

[0028] The present invention provides an anodized aluminum cutting machine, the structure of which includes a solid material mechanism 1, a guide rail 2, a base 3, and a cutting tool 4. The guide rail 2 is embedded in the inner side of the solid material mechanism 1. The outer surface of 2 is slidingly fitted, and the bottom of the solid material mechanism 1 is in contact with the upper surface of the base 3; the solid material mechanism 1 includes a rotating roller 11, fixing bolts 12, side plates 13, and the fixing bolts 12 Through the inner position of the side plate 13 , the rotating roller 11 is installed between the left inner wall of the side plate 13 and the fixing bolt 12 .

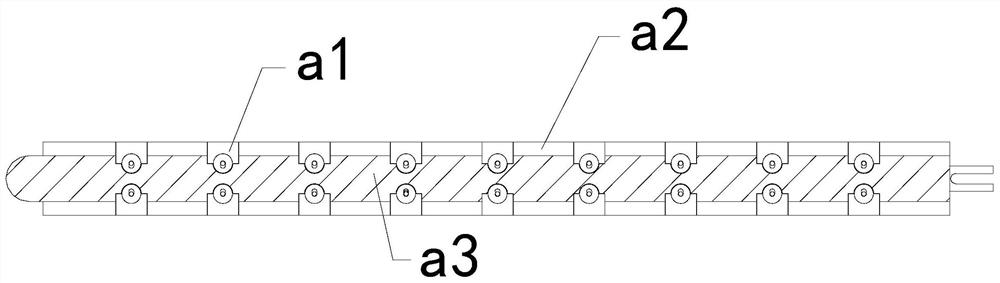

[0029] Wherein, the rotating roller 11 includes an extended block a1, an outer contact surface a2, and a middle fixed roller a3. The outer surfaces of the fixed roller a3 are attached to each other, and there are eighteen outstretched blocks a1, and...

Embodiment 2

[0035] Such as Figure 6-Figure 9 Shown:

[0036]Wherein, the cutting tool 4 includes a cutting head c1, a linkage rod c2, a movable rod c3, and a handle c4. The cutting head c1 is embedded in the inner position of the handle c4. The top hinge is connected, and the handle c4 is movably engaged with the upper end of the linkage rod c2. By swinging the handle c4 up and down, the distance between the cutting head c1 and the surface of the anodized aluminum film roll can be adjusted, so that the cutting head c1 can be rotated in pairs. Anodized aluminum film rolls are cut around.

[0037] Wherein, the handle c4 includes a guide strip c11, a frame c12, and a blade c13. The guide strip c11 is embedded and fixed on the right side of the frame c12, and the blade c13 is slidably matched with the inside of the frame c12. The reverse thrust generated by the blade c13 can make the blade c13 slide inward along the frame c12 for a certain distance, so that the static electricity on the bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com