Method and device for reducing metal dissolution in domestic waste incinerator slag

A domestic waste incineration and slag technology, which is applied in the field of environmental protection technology and solid waste resource recovery, can solve problems such as surrounding environmental pollution, achieve low investment and operating costs, reduce metal dissolution, and enhance reactivity and volatility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

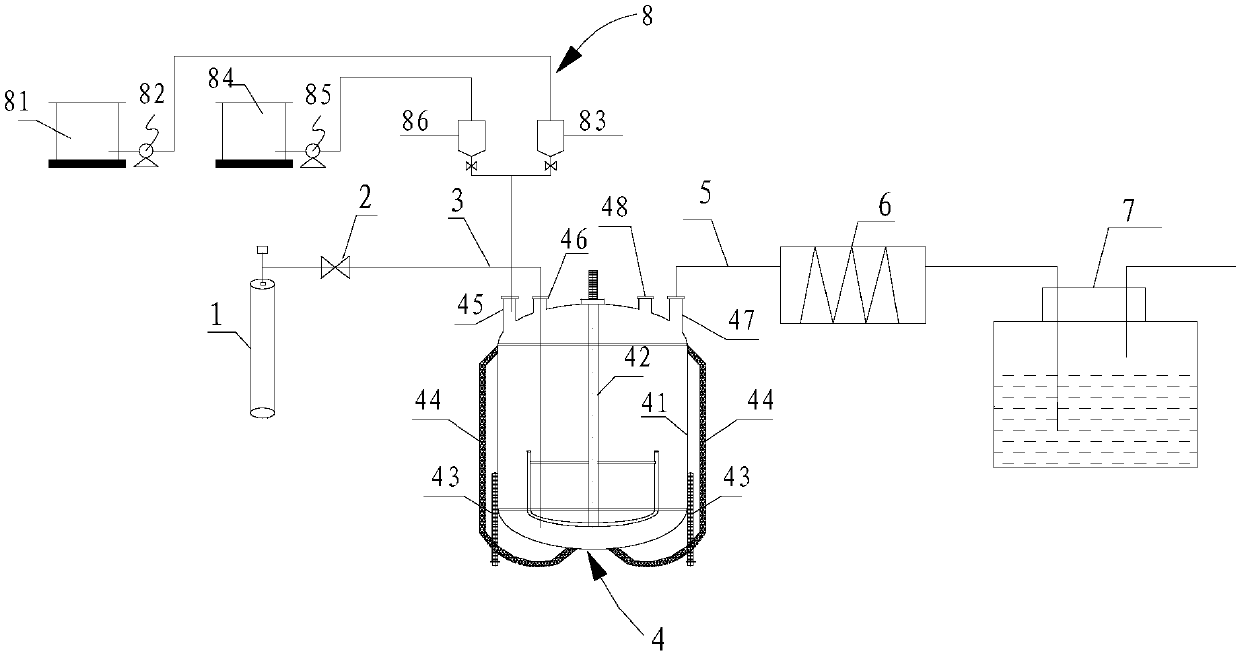

Image

Examples

Embodiment 1

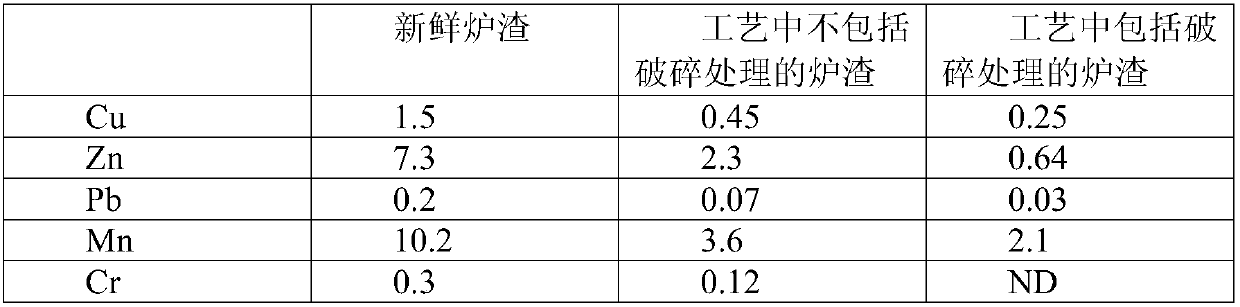

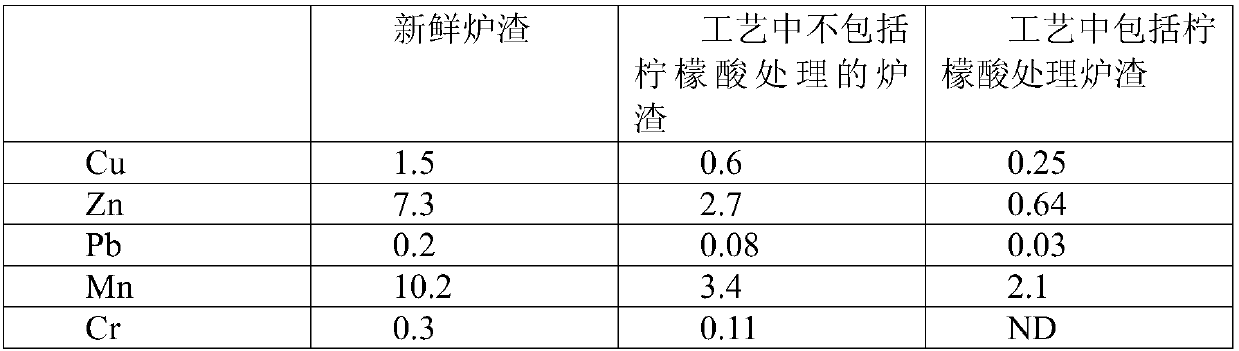

[0060] Crush domestic waste incinerator slag to a particle size of less than 5mm. Take domestic waste incinerator slag in a reaction kettle (2 / 3 height), pour 30% citric acid from the feed port until completely submerged in domestic waste incinerator slag, and soak for 12 hours. Thereafter, according to the domestic waste incineration slag and MgCl 2 Add MgCl at a mass ratio of 15:1 2 , turn on the mixer, stir well, make MgCl 2 Mix thoroughly with domestic waste incinerator slag. Turn on the thermocouple, raise the temperature to 700°C, and turn on the carrier gas (N 2 ) valve, domestic waste incineration slag reacted at high temperature in the reactor for 2 hours. The outlet gas during the reaction is connected to the condenser. In the condenser, the metal chlorides are condensed and collected for recycling. The outlet gas of the condenser passes through the tail gas purification device, and the tail gas purification device is equipped with lye for the absorption of aci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com