Patents

Literature

64results about How to "Realize separate processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for improving saline-alkali soil by flat laying deep ploughing application of desulfurized gypsum

InactiveCN106171104AImprove processing effectEasy to handleOther chemical processesOrganic fertilisersGypsumAlkali soil

The invention discloses a method for improving saline-alkali soil by flat laying deep ploughing application of desulfurized gypsum. The method for improving saline-alkali soil by flat laying deep ploughing application of the desulfurized gypsum comprises a step S1 of performing matching of an improved material; a step S2 of treating saline-alkali soil surface layer soil; a step S3 of flatly laying the improved material on the saline-alkali soil where surface layer soil is removed; a step S4 of performing deep ploughing treatment; a step S5 of mixing the surface layer soil and the improved material; and a step S6 of performing irrigation. According to the method, different treatment modes are adopted for soils of different depths, the deep layer soil with a relatively low salinization degree is treated through a small amount of improved material, the surface layer soil with a high salinization degree is treated through a large amount of improved material, treatment of separating the different soils is achieved, and the saline-alkali soil treatment effect is improved.

Owner:SHANDONG SUNWAY LANDSCAPE TECH

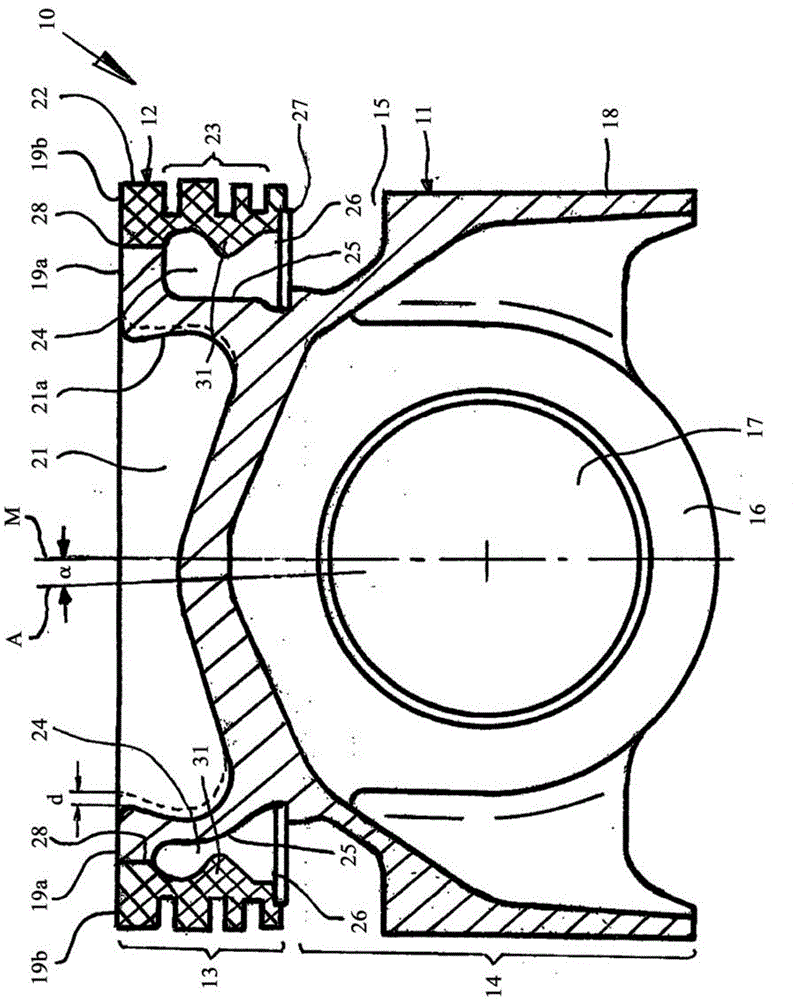

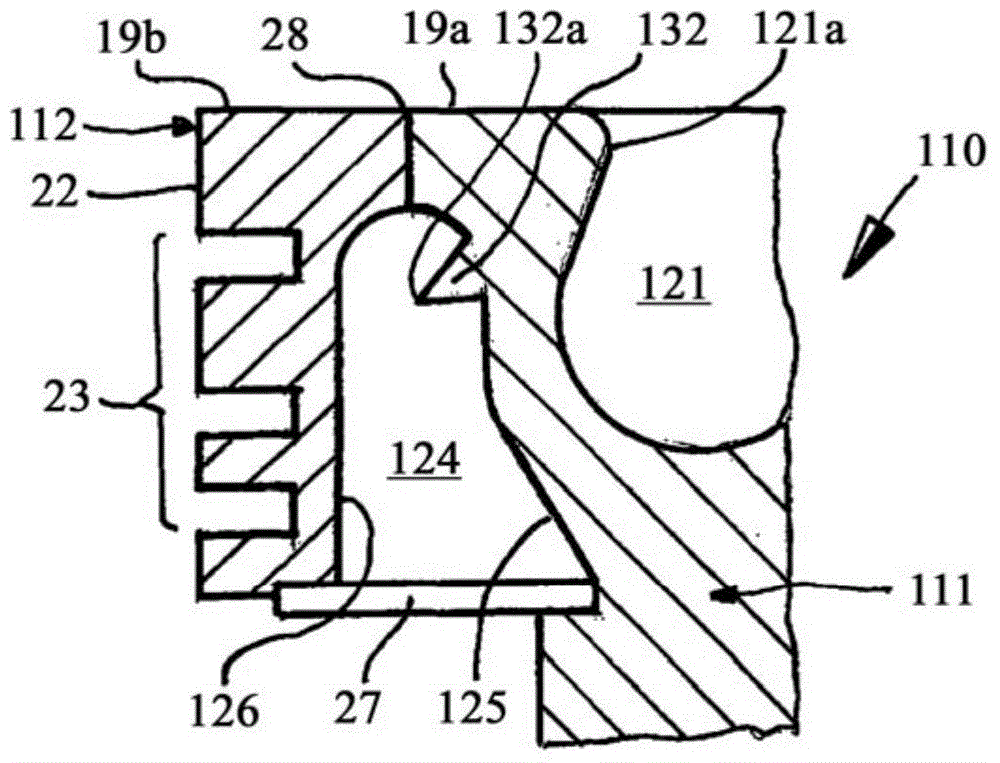

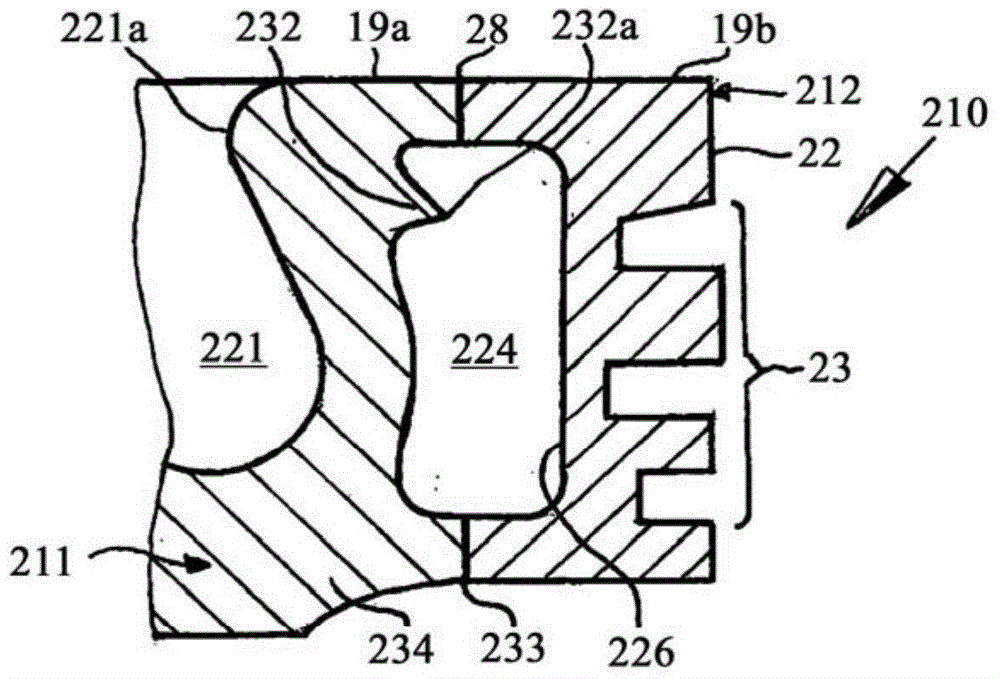

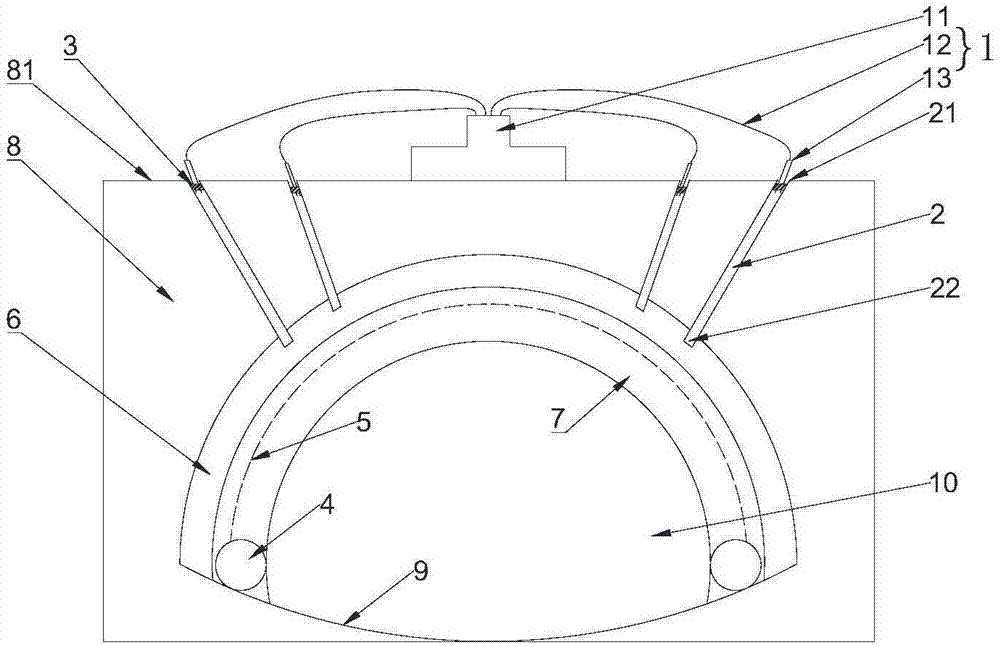

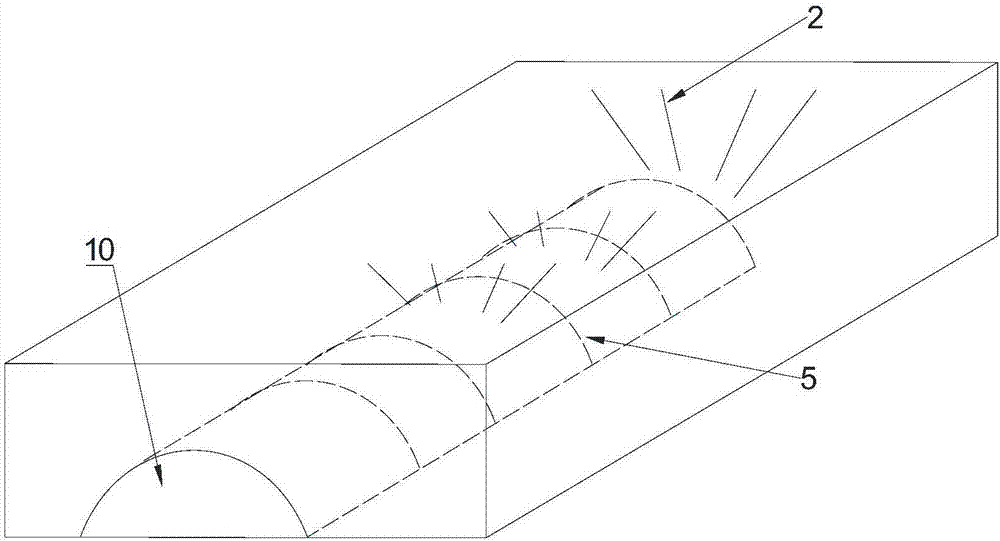

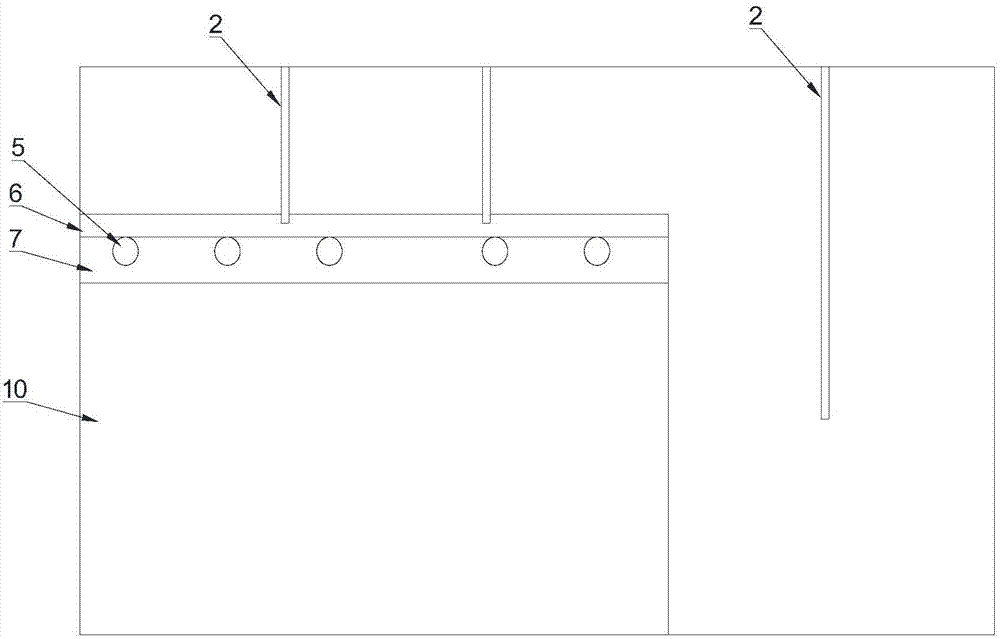

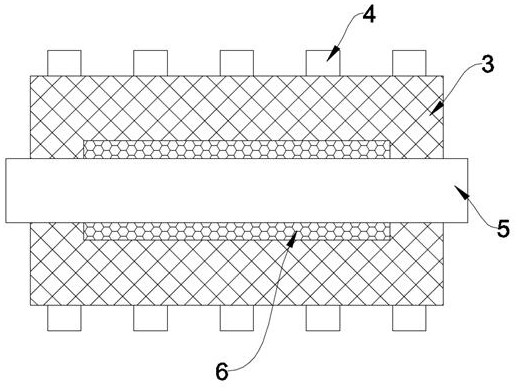

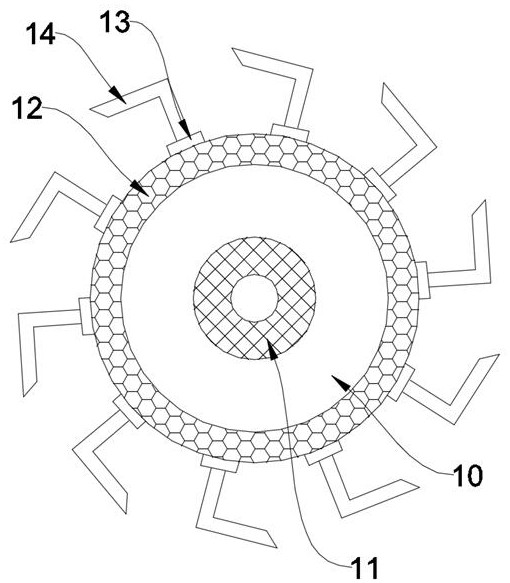

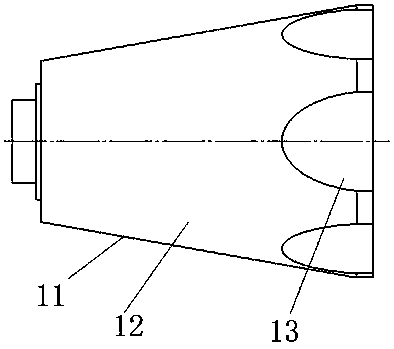

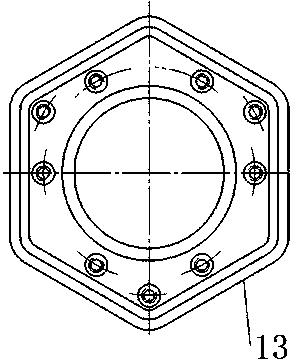

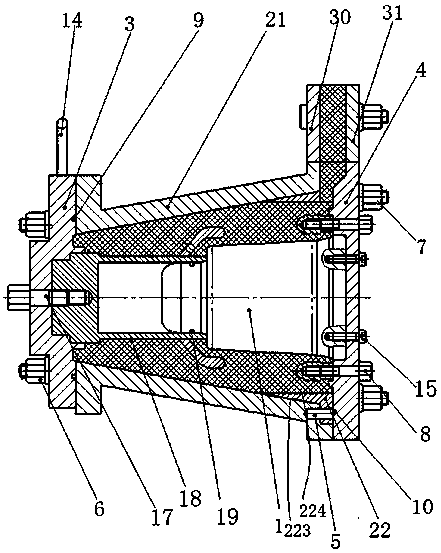

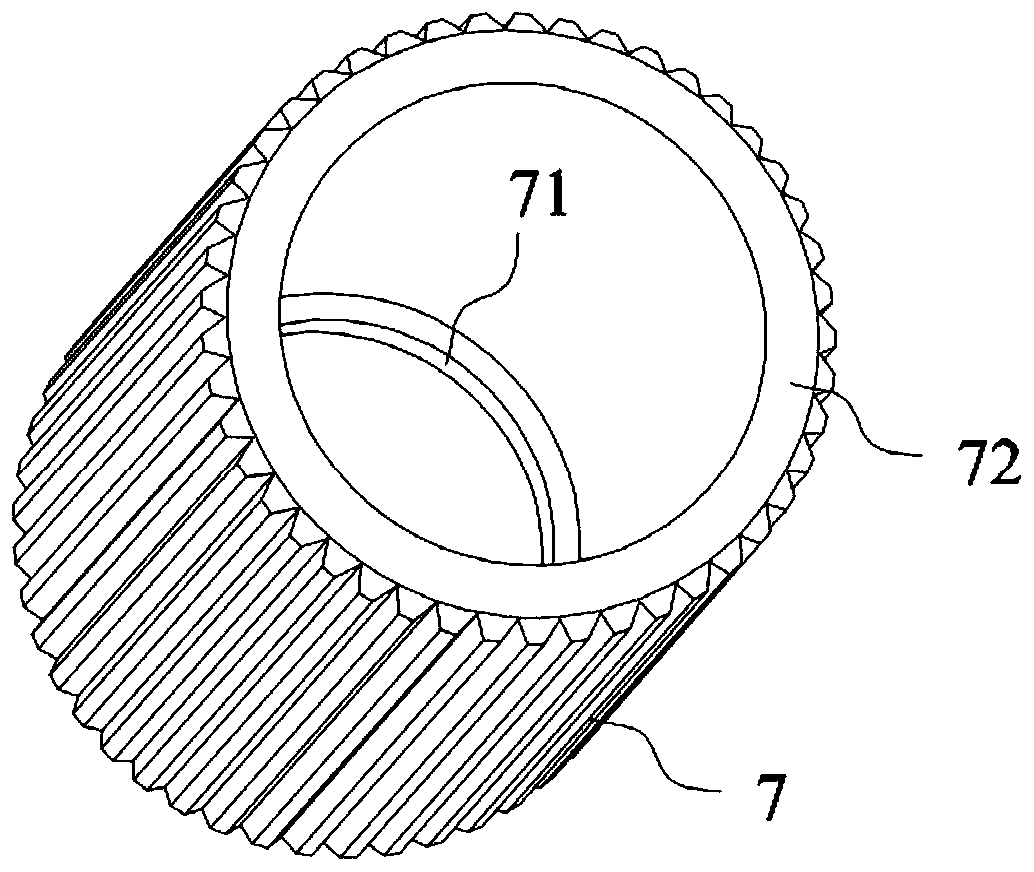

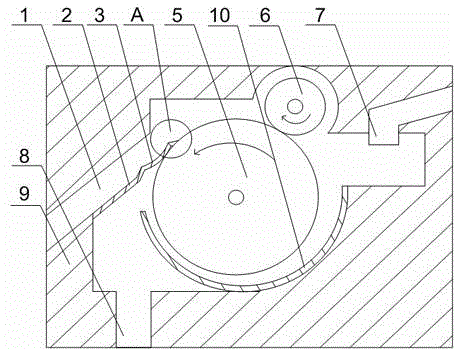

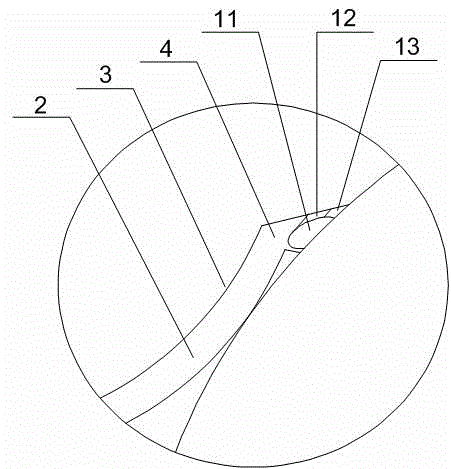

Piston for an internal combustion engine

InactiveCN104541044ARealize separate processingMeet different requirementsInternal combustion piston enginesPistonsCombustionPiston ring

The present invention relates to a piston (10, 110, 210, 310) for an internal combustion engine having a piston head (13) and a piston skirt (14), the piston (10, 110, 210, 310) comprising a piston base (11, 111, 211, 311) and a piston ring element (12, 112, 212, 312), the piston head (13) having a combustion recess (21, 121, 221). The invention is characterized in that the piston ring element (12, 112, 212, 312) has a portion (19b) of a piston crown, a circumferential fire land (22) and a circumferential ring section (23) with ring grooves, in that the piston base (11, 111, 211, 311) and the piston ring element (12, 112, 212, 312) form a circumferential cooling channel (24, 124, 224, 324) that extends between an inner lateral surface (25, 125, 225) in the region of the combustion recess (21, 121, 221) and an outer lateral surface (26, 126, 226, 326) in the region of the ring section (23), in that in the cooling channel (24, 124, 224, 324) on the outer lateral surface (26, 226) at least one flow guide element (31, 331) and / or on the inner lateral surface (125, 225) at least one heat conducting element (132, 232) is provided; and in that the piston base (11, 111, 211, 311) and the piston ring element (12, 112, 212, 312) have a circumferential seam (28) in the region of the piston crown (19a, 19b), via which they are non-detachably connected to one another.

Owner:MAHLE INT GMBH

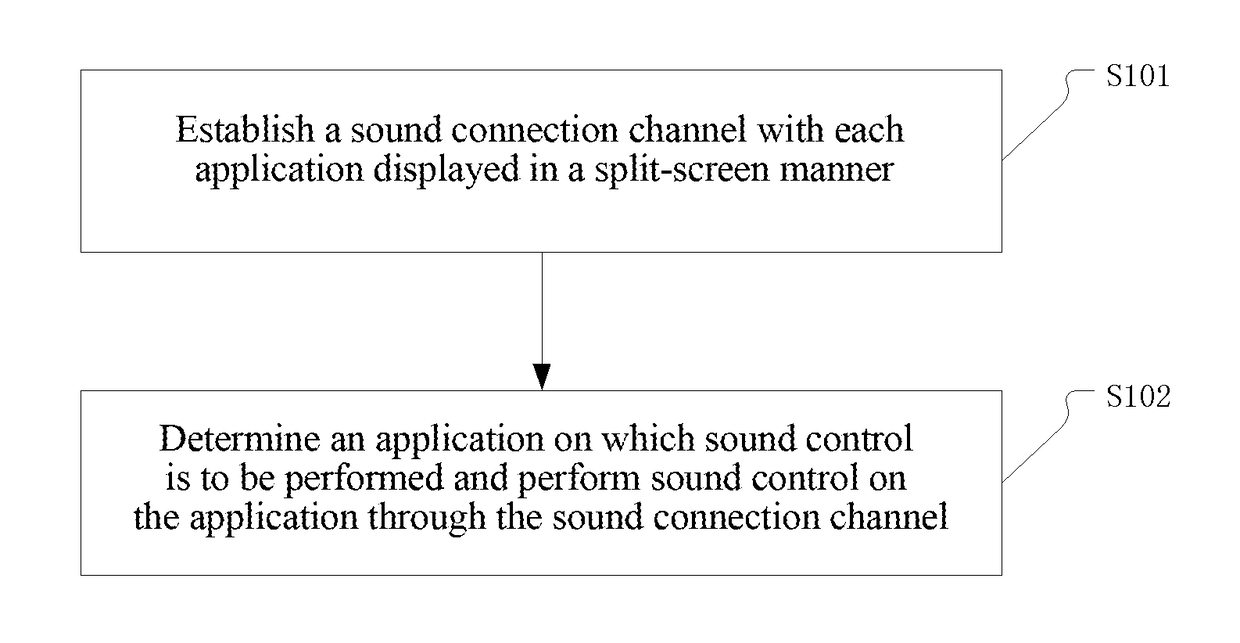

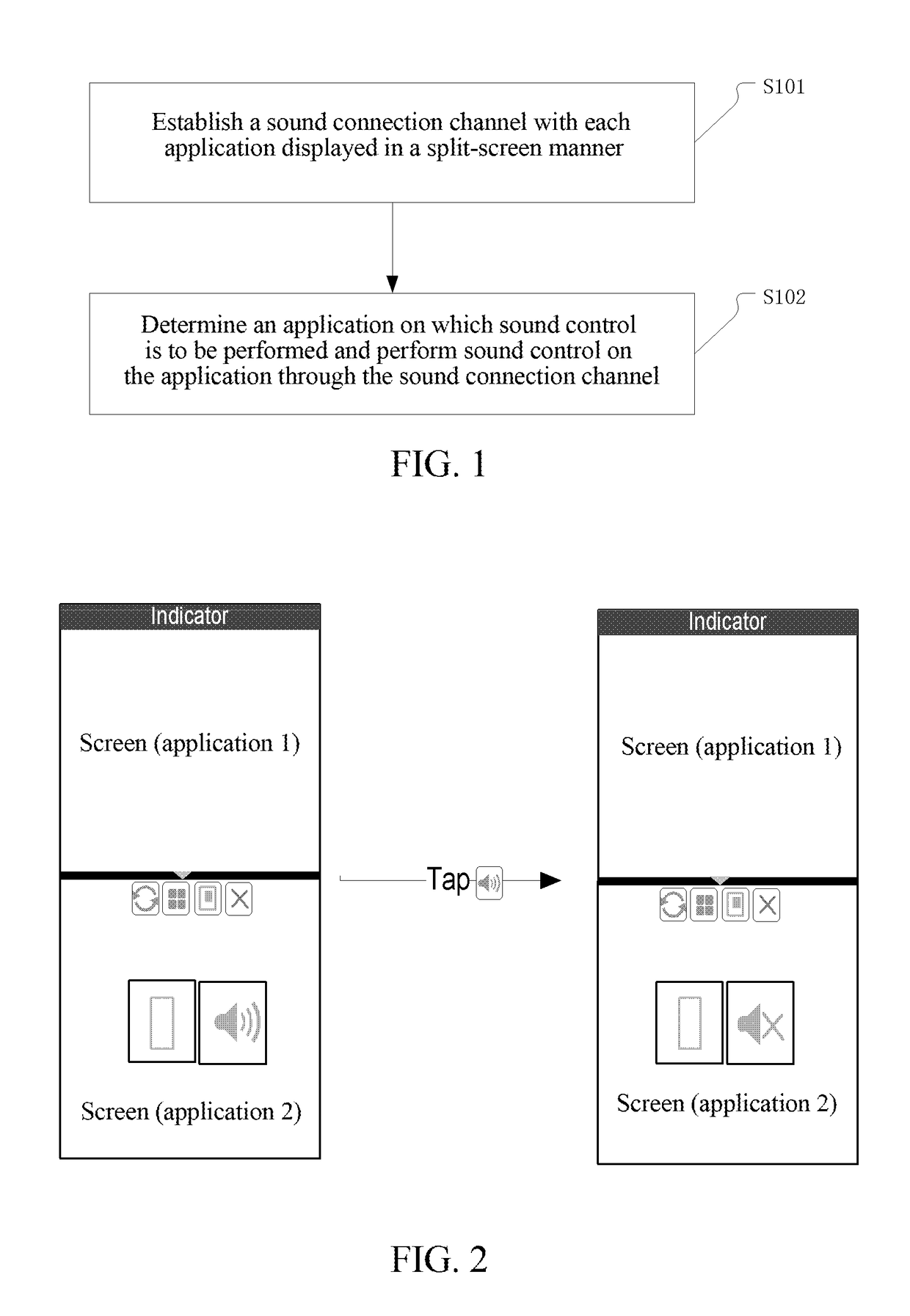

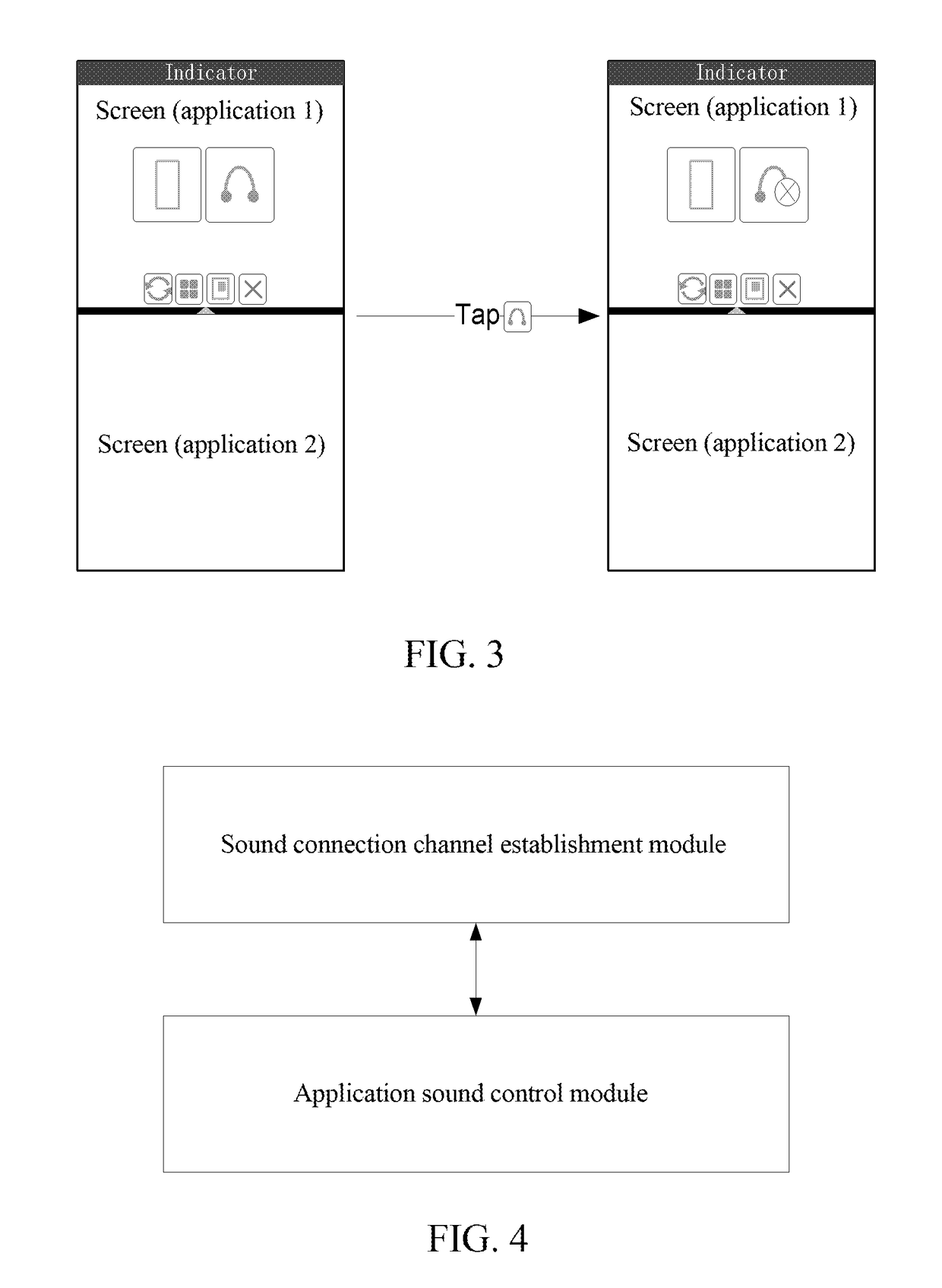

Method, System, and Computer Storage Medium for Voice Control of a Split-Screen Terminal

ActiveUS20170192741A1Realize separate processingSpeech recognitionSound input/outputSpeech soundComputer engineering

The embodiments of the present document provide a method and system for performing sound control on a split-screen terminal, and a computer storage medium. The method includes: establishing a sound connection channel for each application displayed in a split-screen manner; and determining an application on which sound control is to be performed and performing sound control on the application through the sound connection channel.

Owner:ZTE CORP

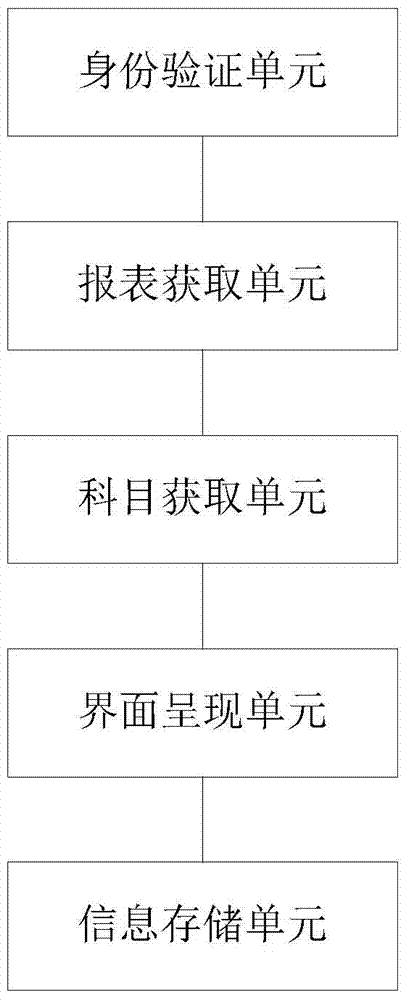

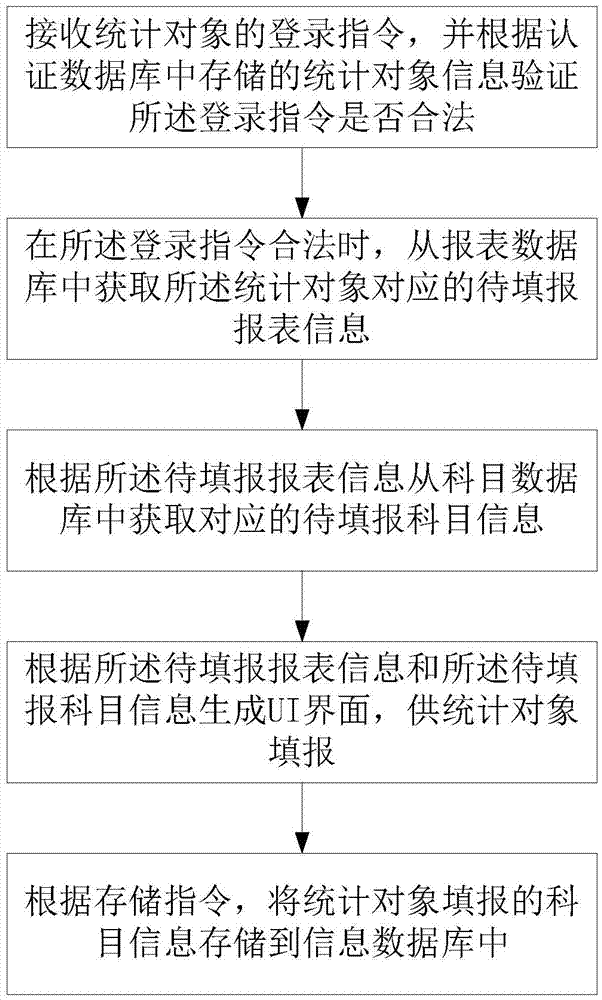

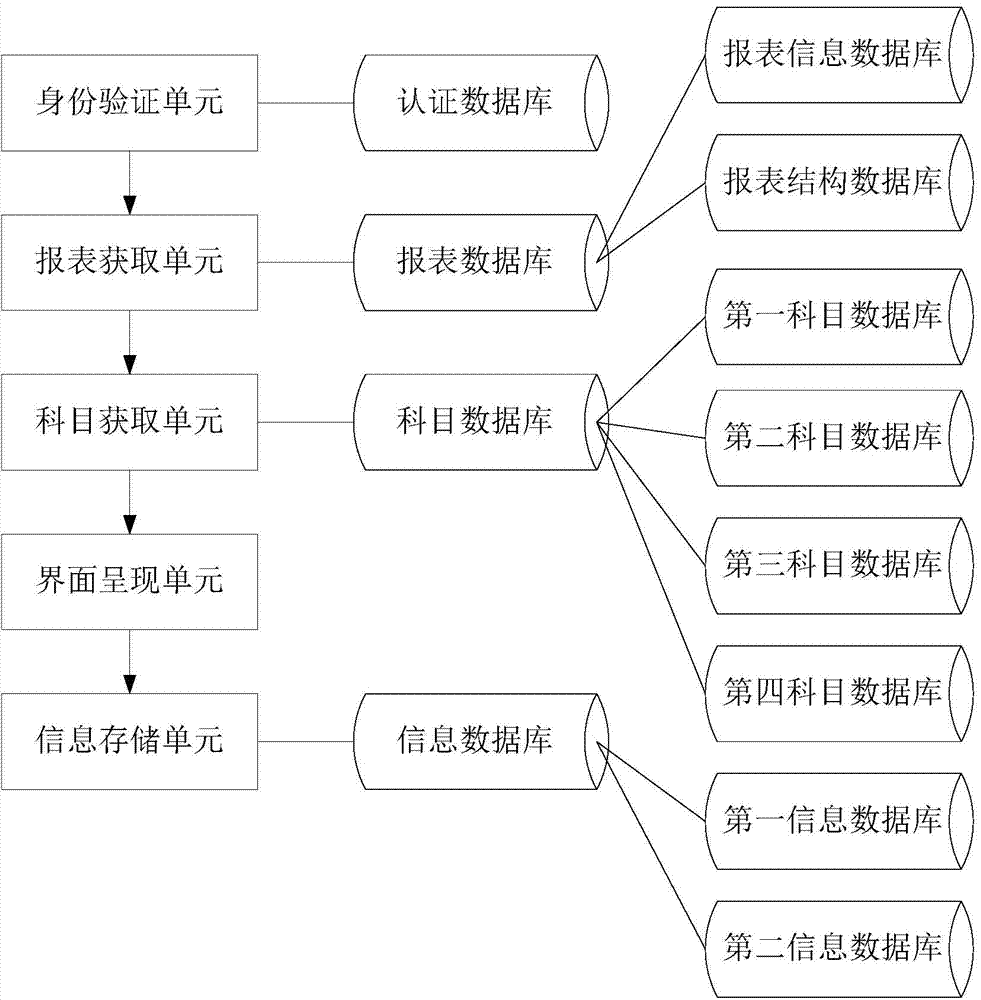

Information statistics management system

InactiveCN103679382ARealize separate processingImprove process efficiencyResourcesExtensibilityObject store

The invention provides an information statistics management system which comprises an identification unit, a report obtaining unit, a subject obtaining unit, an interface presenting unit and an information storage unit, wherein the identification unit is used for receiving login instructions of statistical objects and verifying whether the login instructions are legal according to the information of the statistical objects stored in an authentication database; the report obtaining unit is used for obtaining the corresponding subject information to be filled of the statistical objects from the report database; the subject obtaining unit is used for obtaining the corresponding subject information to be filled from the subject database according to the corresponding subject information to be filled; the interface presenting unit is used for generating UI interfaces according to the information of the report to the filled and the subject information to be filled, so that the statistical objects can fill the report; the information storage unit is used for storing the subject information filled by the statistical objects in the information database according to the stored instructions. The information statistics management system realizes the aims of separately processing the statistical object and the statistical content by allocating different databases and increasing the process processing efficiency of the statistical object, and has higher freedom and strong extensibility.

Owner:冷晔

Gas drainage system for tunnel and tunnel structure

PendingCN106979031AAvoid agglomerationAvoid safety hazards and even accidentsDrainageGas removalEngineering

The invention discloses a gas drainage system for a tunnel. The gas drainage system comprises a gas drainage hole passage achieving communicating of the front position of a tunnel advancing end point and the outside world, an gas evacuating device arranged outside the tunnel and connected with the gas drainage hole passage, and a sealing device, wherein the sealing device achieves sealing the gas drainage hole passage and the gas evacuating device in the connection position. By communicating of the front position of the tunnel advancing end point and the outside world, gas is extracted out and discharged before the tunnel is advanced to a gas gathering area, and security accidents due to gas gathering can be effectively prevented.

Owner:ROAD & BRIDGE SOUTH CHINA EINGINEERING CO LTD +1

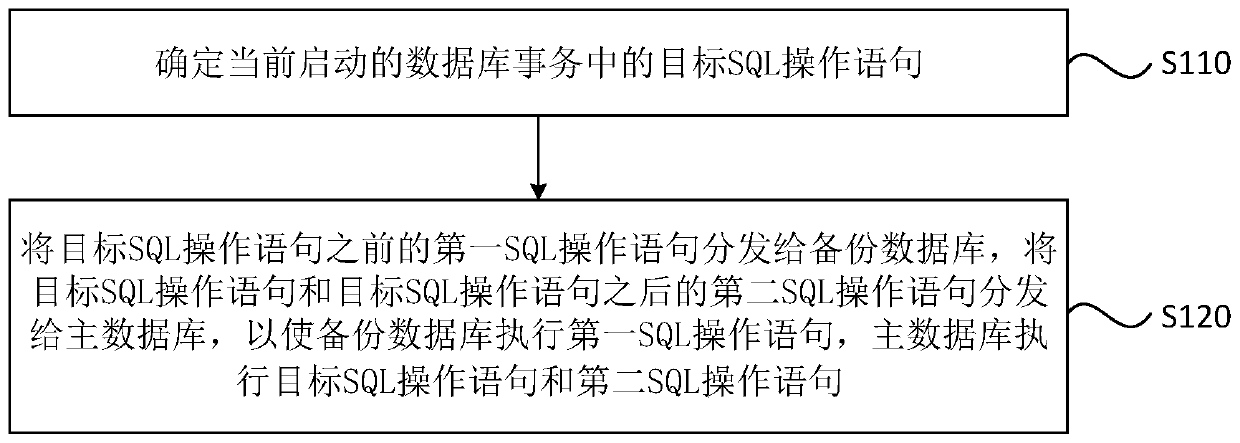

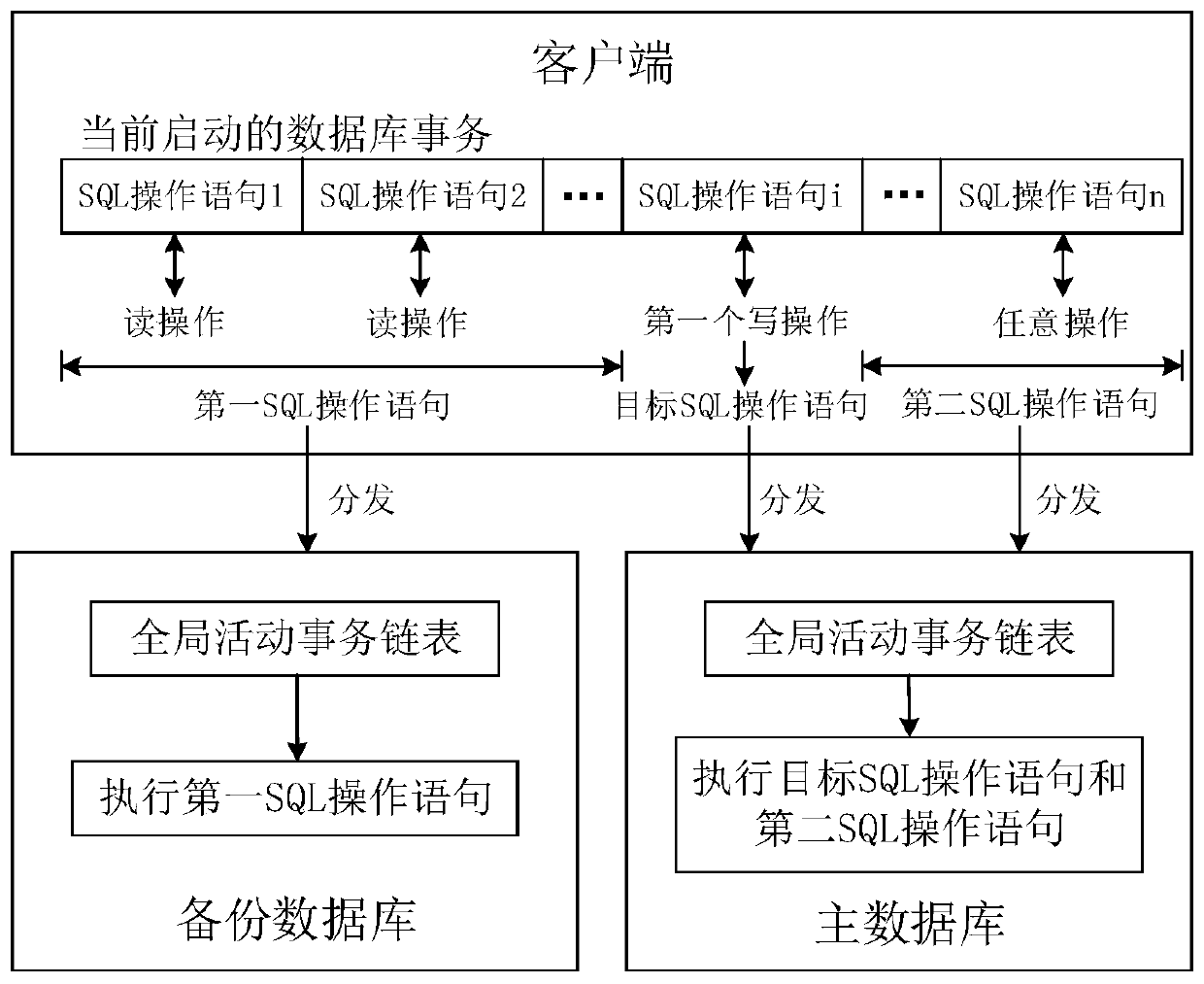

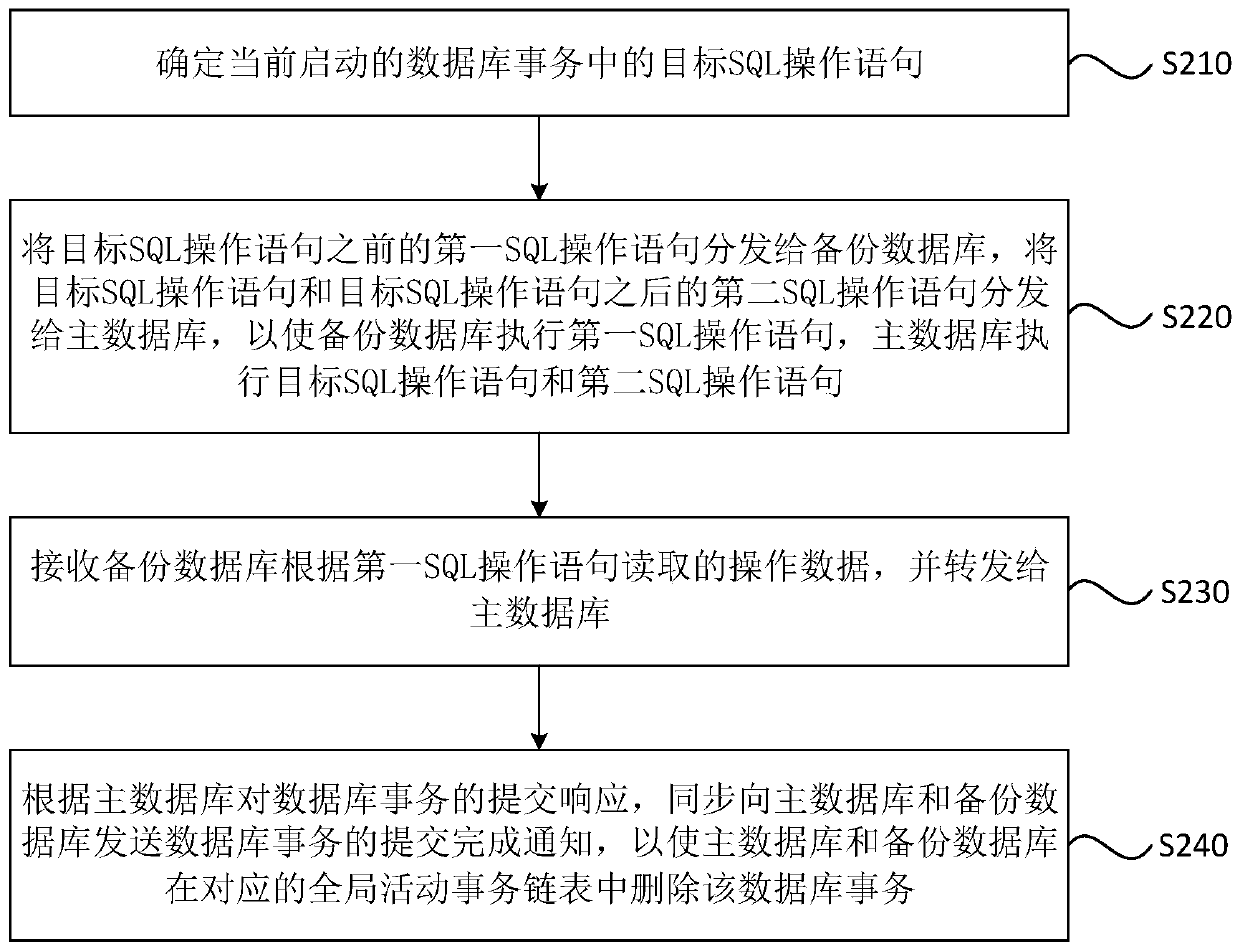

Data operation optimization method, device and system, equipment and storage medium

ActiveCN110188114AImprove accuracyRealize separate processingDigital data information retrievalSpecial data processing applicationsData operationsData library

The embodiment of the invention discloses a data operation optimization method, device and system, equipment and a storage medium. The data operation optimization method comprises the steps: determining a target SQL operation statement in a currently started database transaction, wherein the target SQL operation statement is an SQL operation statement corresponding to a first write operation in the database transaction; and distributing the first SQL operation statement before the target SQL operation statement to a backup database, and distributing the target SQL operation statement and the second SQL operation statement after the target SQL operation statement to a main database. According to the technical scheme provided by the embodiment of the invention, the first SQL operation statement is executed by the backup database, and the database transaction does not change any data, so that the data accessed to the backup database by the client is consistent with the data accessed to the main database, and the main database executes the target SQL operation statement and the second SQL operation statement, so that the separation processing of the read-write operation in the databasetransaction is realized, and the data reading accuracy is improved.

Owner:SHANGHAI DAMENG DATABASE

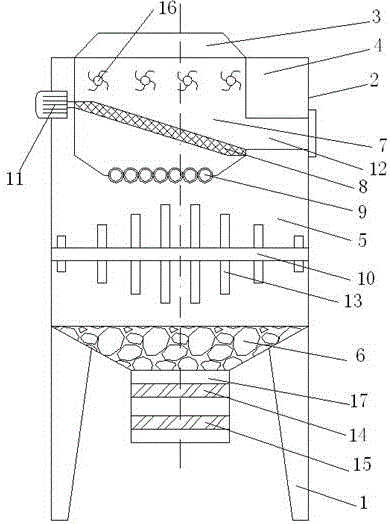

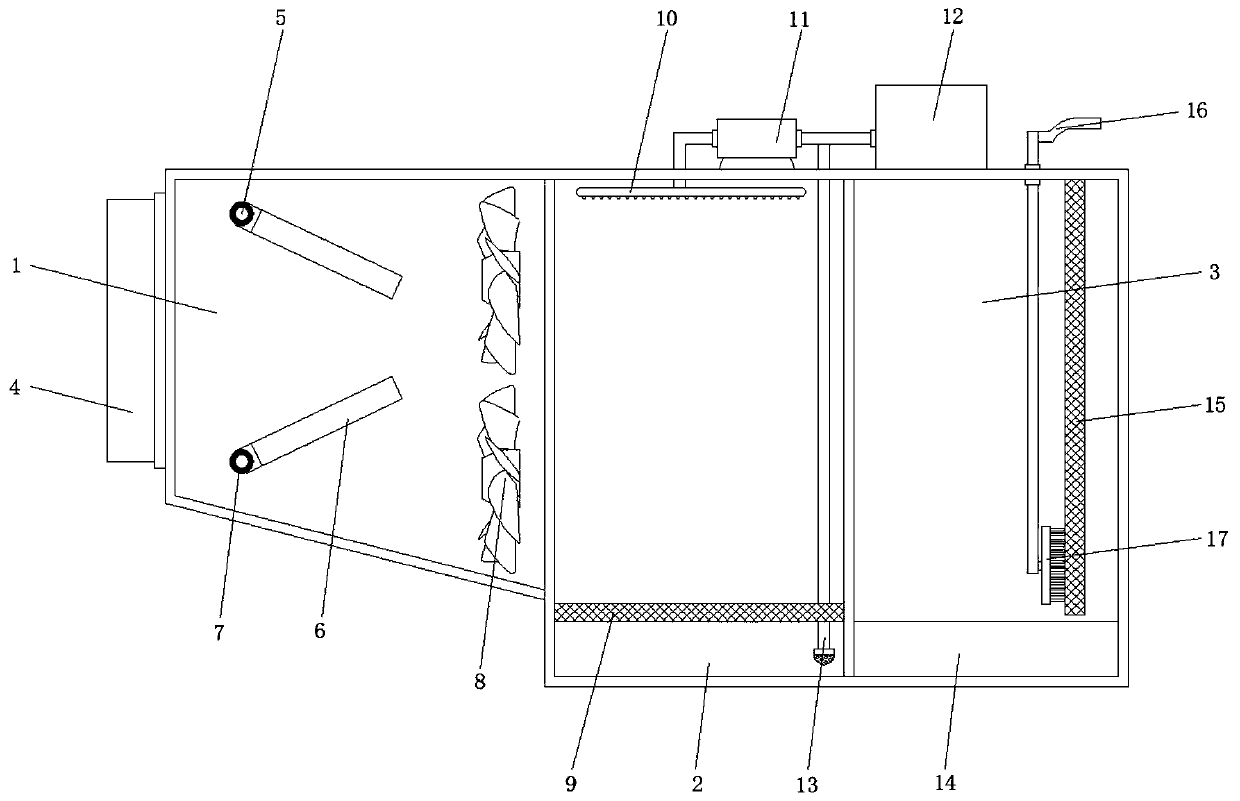

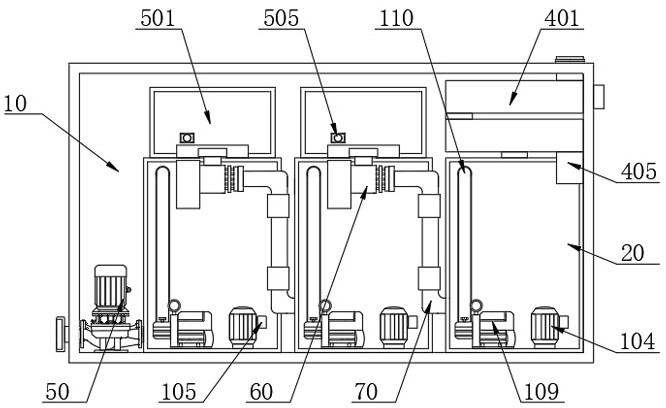

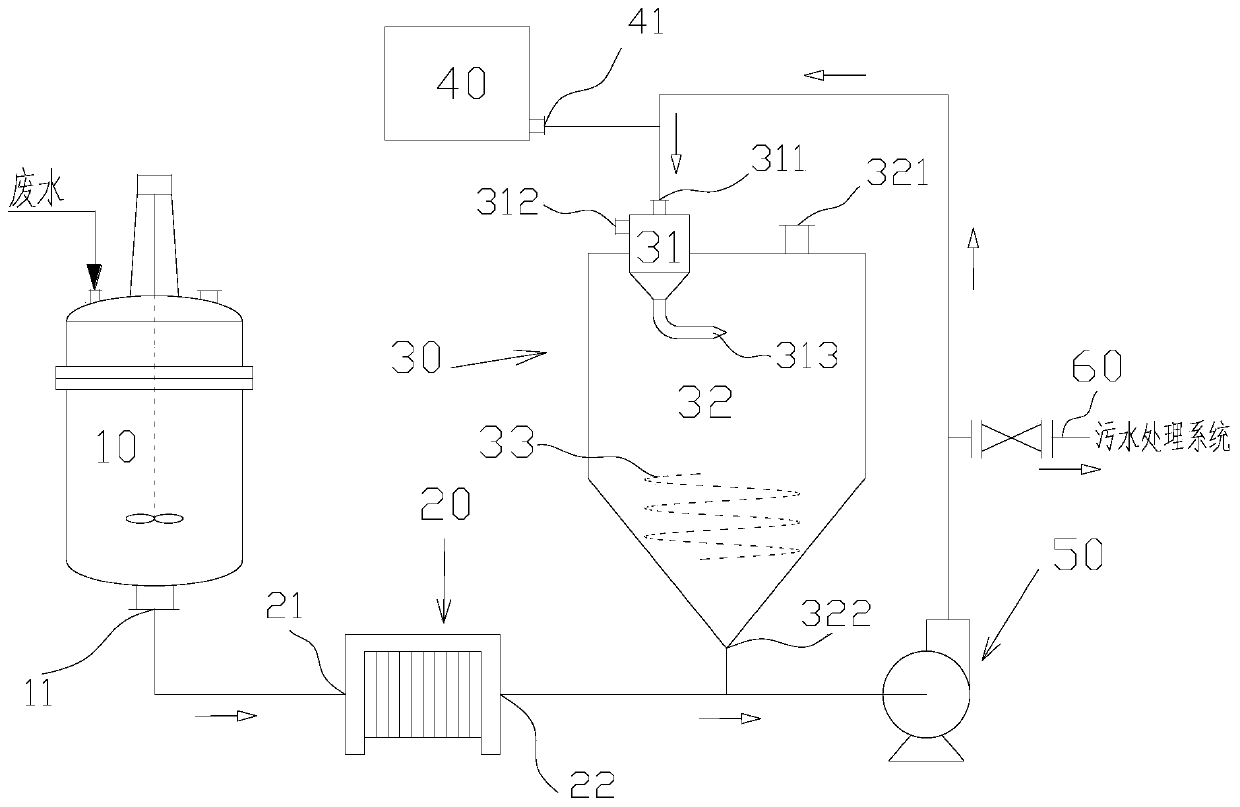

Waste water treatment equipment

InactiveCN105923807ARealize separate processingSimple structureFatty/oily/floating substances removal devicesTreatment involving filtrationWastewaterSewage

The invention relates to waste water treatment equipment. The waste water treatment equipment comprises a support and a barrel body, wherein the barrel body is arranged on the support, a feeding hole is formed in the upper end of the barrel body, a discharge hole is formed in the lower end of the barrel body, a separating cavity, a stirring cavity and a sediment cavity are arranged inside the barrel body in sequence from the top to the bottom, the separating cavity comprises a separating barrel body and a separating net connected to the interior of the separating barrel body, a pulverizing wheel is connected onto the lower end of the separating net, a stirring shaft is arranged inside the stirring cavity, the separating net is connected with a vibrating motor, the separating net is obliquely placed inside the separating barrel body, a taphole is formed in one side of the separating barrel body, the inlet of the taphole is formed in the oblique upper surface of the separating net, and the outlet end of the taphole is communicated with the barrel body. The waste water treatment equipment provided by the invention has the advantages that separation treatment on waste water is achieved, and the equipment has an integrally simple structure, is convenient to operate, can be used repeatedly, and is economic and environmental.

Owner:赵正芳

Medical waste treatment device with disinfection function

InactiveCN108325681AEasy to follow upPrevent leakageMedical waste disposalGrain treatmentsLiquid wasteDisinfectant

The invention discloses a medical waste treatment device with a disinfection function. The device comprises a casing, a feed hopper, a liquid box, crushing rollers, a sieve plate, a support plate anda collecting cavity, wherein the feed hopper is arranged in the middle of the upper end of the casing, and the support plate is fixedly mounted at the lower end of the inner side of the casing; a cavity is formed in the inner side of the support plate, a first baffle is glidingly connected in the cavity, a second spring is connected with the left end of the first baffle, a slider is fixedly connected with the right end of the first baffle, and a second baffle is glidingly connected with the right end of a discharging hole. The device is novel in design, when the sieve plate rotates upwards, waste on the sieve plate falls out under the action of gravity, a waste liquid and a disinfectant for disinfection fall out of the sieve plate, solid-liquid separation treatment is realized, meanwhile,the disinfectant at the upper end of the support plate is mixed with solid waste when through holes in the first baffle and the support plate are staggered, the treatment time of the disinfectant is prolonged, and the disinfection effect is improved.

Owner:合肥龙之韵医药技术有限公司

Recycling device for waste liquid of numerical control cutting machine

InactiveCN107837960ARealize separate processingAchieve re-useCleaning using toolsMagnetic separationNumerical controlLiquid waste

The invention discloses a recycling device for waste liquid of a numerical control cutting machine. The recycling device comprises a box body and a magnetic roller, the box body is provided with a recycling hole, a liquid inlet and a liquid outlet, the bottom of the magnetic roller is provided with a baffle with a semicircular section, a gap is reserved between the magnetic roller and the baffle,the liquid inlet, the liquid outlet and the gap are communicated with each other to form a drainage channel, a direct flow plate is mounted on the end part of the recycling hole, a movable end of thedirect flow plate makes contact with the outer wall of the magnetic roller, and a discharging channel is formed among the direct flow plate, the recycling hole and the inner wall of a cavity; the recycling device further comprises a rubber roller rotatably arranged in the cavity, and the rubber roller is tangential with the magnetic roller. Metal cutting liquid is separated by the drainage channeland the discharging channel, such that the separation between metal chippings in the metal cutting liquid and cooling liquid is further realized, the operation is simple, when in use, only a rotary speed of the rubber roller and an injection rate of the metal cutting liquid need to be adjusted, then the reuse of the metal chippings can be realized, and the production cost of the enterprise is reduced.

Owner:代洪波

A multi-stage treatment device for medical wastewater

The invention discloses a multi-stage treatment device for medical waste water, which relates to the field of medical equipment and includes a treatment box, a discharge inclined pipe is located in the treatment box, and the top of the treatment box is fixedly connected to two arc-shaped separation plates. The top is fixedly connected, the arc-shaped separation plate is embedded with a separation filter, the two sides of the treatment box are fixedly connected to the separation side box, and the separation side box is equipped with a garbage discharge mechanism. The net can separate the sewage from the solid waste, and the solid waste can be discharged out of the treatment box by setting the garbage discharge mechanism, and the water flow can be buffered by setting the buffer ball, which is convenient for the stable precipitation of large specific gravity impurities in the follow-up sewage. The device can separate and discharge the large-specific-gravity sediment while sedimenting the sewage, realize the further separation and treatment of the sewage, and have a multi-level effect on the treatment of the sewage, and the treatment effect is good.

Owner:诸城市人民医院 +1

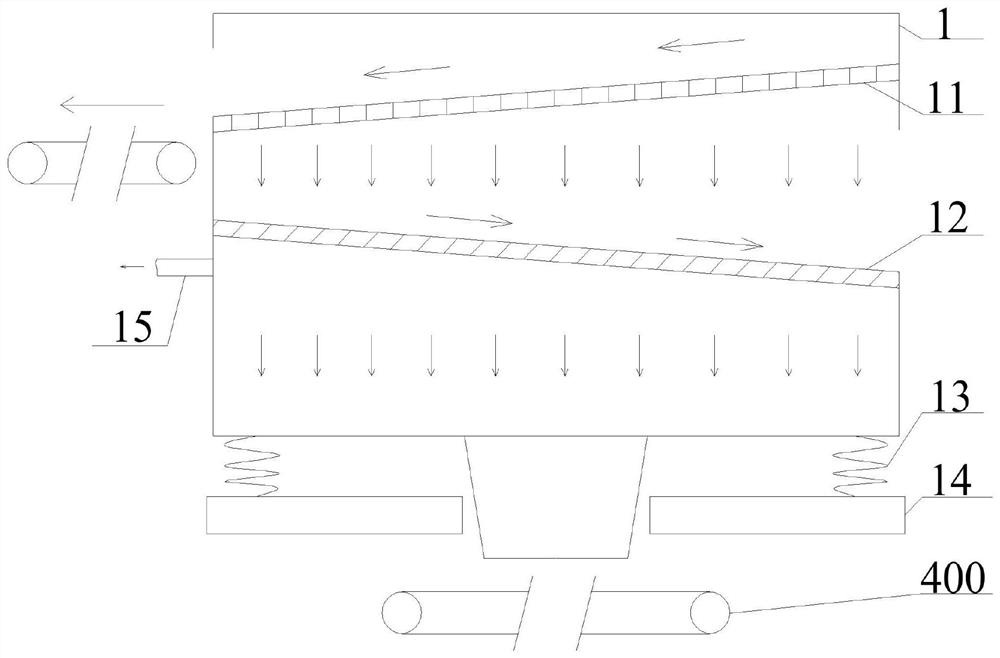

Building equipment casting sand-iron separating device

InactiveCN113019899AEfficient separationRealize separate processingSievingScreeningStructural engineeringSieve

The invention relates to the technical field of sand-iron separation, and provides a building equipment casting sand-iron separating device which comprises a vibration separation box, a middle conveying belt and a magnetic separation mechanism which are arranged in sequence. A primary sieve and a secondary sieve are arranged in the vibration separation box from top to bottom; each of the primary sieve and the secondary sieve has a preset inclination angle, and the tail ends of the primary sieve and the secondary sieve are correspondingly provided with a waste conveying belt and a middle conveying belt; the magnetic separation mechanism comprises a magnetic column; the magnetic column movably penetrates through a fixed plate and a steel shot barrel in sequence in a connected manner; and a backing material barrel is arranged below the magnetic column. In this way, through two-stage screening in the vibration separation box, a mixture of sand grains and steel shots after shot blasting is separated and discharged; then a mixed material is thrown onto the magnetic column of the magnetic separation mechanism; and the steel shots are adsorbed by the magnetic column, so that effective separation of the sand grains and the steel shots is realized. The building equipment casting sand-iron separating device is simple in structure and high in operation efficiency, and the sand-iron mixed material can be quickly separated.

Owner:徐家旺

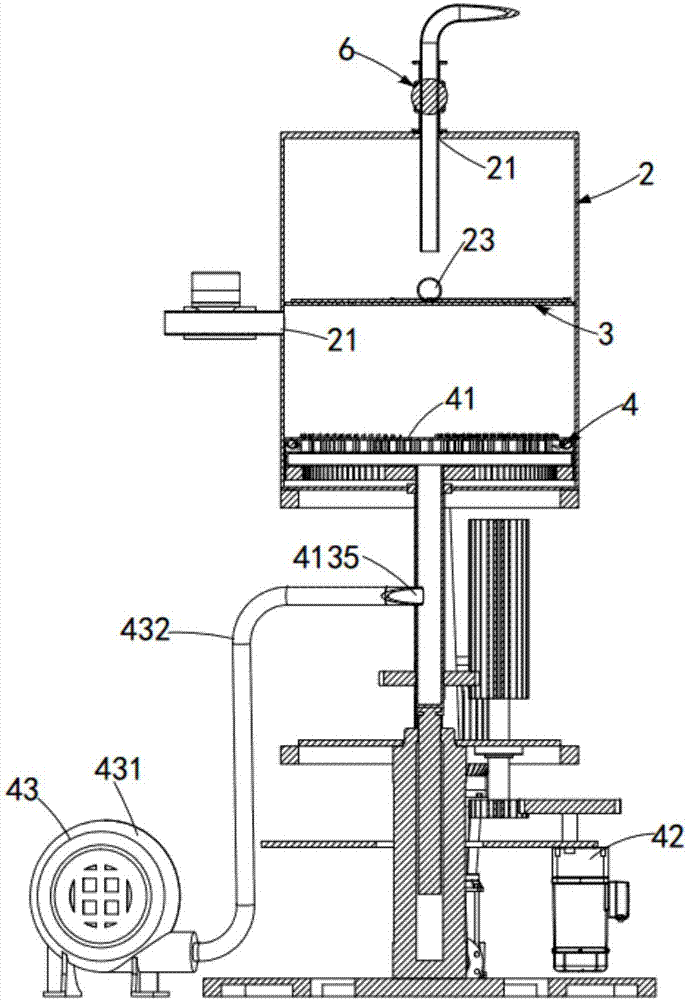

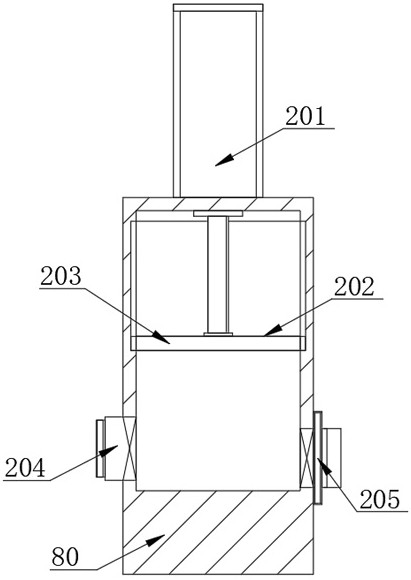

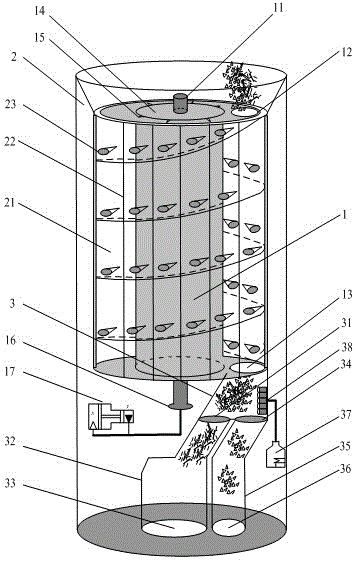

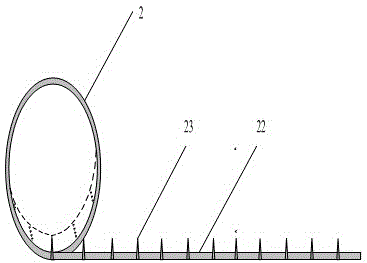

Efficient-recycling chemical-fiber textile wastewater treatment system

InactiveCN107352590AEnable recyclingRealize separate processingTreatment involving filtrationWaste water treatment from textile industryFiberSludge

The invention discloses an efficient recycling chemical fiber textile wastewater treatment system, aiming at solving the separation of short fibers and sludge in textile wastewater, and realizing the recovery and reuse of short fibers, which includes a compression barrel, a filter mechanism and a compressor The mechanism, which inputs the textile sewage into the compression barrel, uses the push piston mechanism to squeeze the sewage from bottom to top, combined with the interception function of the filter mechanism, makes the waste water, sludge and short fibers in the compression barrel from top to bottom. Automatic layered recovery solves the separation and treatment of short fiber pollutants and sludge in waste water, and realizes the recycling and reuse of short fibers.

Owner:HUZHOU CHENGXIN TEXTILE PRINTING & DYEING

Construction waste recovery device with classification function

PendingCN112536119ASolve the problem of sorting and recyclingRealize separate processingGas current separationMagnetic separationStructural engineeringWaste recovery

The invention discloses a construction waste recovery device with a classification function, and relates to the related field of construction waste. The device aims to solve the problem that the construction waste cannot be classified and recovered in the prior art. A rotating roller is arranged in a treatment box, a stepping motor is arranged at the rear end of the rotating roller, the stepping motor is connected with the rotating roller through a coupler, a screening plate is arranged at the lower end of the rotating roller, the screening plate is in a circular plate shape, and a material conveying pipe is arranged on one side of the upper end of the screening plate. The material conveying pipe is connected with the treatment box through argon arc welding, a secondary classification boxis arranged at the lower end of the material conveying pipe, the secondary classification box is connected with the material conveying pipe through argon arc welding, a crushing box is arranged at theupper end of the treatment box, the crushing box is connected with the treatment box through argon arc welding, and a feeding pipe is arranged on the crushing box. The feeding pipe is arranged to bein a circular pipe shape, and the feeding pipe is connected with the crushing box through argon arc welding.

Owner:刘亚萍

Recovery treating method for treating wastewater before coating sheet metal part

InactiveCN103112966ARealize separate processingReduce volumeMultistage water/sewage treatmentAluminium chlorohydrateWastewater

The invention discloses a recovery treating method for treating wastewater before coating a sheet metal part. The recovery treating method comprises the following steps: adding 1 to 15 parts by mass of aluminium polychlorid to 100 to 3000 parts by mass of wastewater treated before coating at the normal temperature; uniformly stirring; standing for 24 hours, thus obtaining recycle water and precipitate; separating the recycle water from the precipitate; and pressing the precipitate into a solid waste through a filter press. According to the recovery treating method, a certain amount of aluminium polychlorid is correspondingly added to the wastewater produced during treating before coating the sheet metal part and is uniformly stirred to realize the reaction between the added aluminium polychlorid and the impurities in the wastewater to obtain the precipitate, thus realizing the separation treatment of the wastewater, the separated recycle water can be recycled, and the precipitate is pressed into the solid waste by the filter press. Compared with the prior art, the recovery treating method has the advantages that the recycle of the wastewater treated before coating is realized, and the solid waste small in size and convenient to transport is produced, so that the cost of treating the wastewater before coating is greatly reduced as well as reducing the manufacture cost of an enterprise.

Owner:张卫东

Machining method for external molded part of outer mold of insulator pouring mold

The invention relates to a machining method for an external molded part of an outer mold of an insulator pouring mold. The machining method for the external molded part comprises the following steps that step1, the lathe machining is performed on blank, a circular cone segment with the axis extending in the left and right direction and the external diameter gradually largening from left to right is machined, and the taper of the circular cone segment is matched with that of an inner hole of a cone-shaped hole segment of a corresponding cone molded part; step2, a circular cone segment center hole which runs through in the axial direction of the circular cone segment is cut out in the middle of the circular cone segment through wire-electrode cutting to make the circular cone segment form one or at least two molded pieces with the thickness gradually thickening from left to right, wherein the one or at least two molded pieces are distributed in the periphery direction, the inner surfaceof each molded piece is of a plane structure which is used for forming an insulator plane in pouring, the machining of the external molded part is simple, and the machining efficiency is high. According to the machining method for the external molded part of the outer mold of the insulator pouring mold, the external molded part is machine by means of the above steps, the realization of separated machining of the external molded part and the cone molded part is facilitated, the machining difficulty of the outer mold is lowered, and the machining efficiency is improved.

Owner:HENAN PINGGAO ELECTRIC +2

Chemical waste gas treatment device and method

PendingCN110681236AEliminate odorReach classified multiple purificationCombination devicesGas treatmentCombustion chamberVapor–liquid separator

The invention discloses a chemical waste gas treatment method. The chemical waste gas treatment method comprises the following steps: introducing chemical waste gas into a settling chamber, and settling and decelerating the waste gas; introducing the settled chemical waste gas into a centrifugal gas-liquid separator to realize recovery of tar liquid in the waste gas; introducing the centrifuged waste gas into a cross-flow bed adsorption tower to realize separation treatment of organic matters; introducing the waste gas having undergone organic matter separation into clear water, and neutralizing and absorbing acid gas in the waste gas; introducing the waste gas having undergone acid neutralization into a combustion chamber, and introducing sufficient oxygen into the combustion chamber to fully oxidize part of gas in the waste gas; introducing the combusted and oxidized gas into an acetic acid solution to absorb residual organic amine in the waste gas; and finally, introducing the wastegas into an ozone oxidizer to eliminate the peculiar smell of the waste gas. The chemical waste gas treatment device and the method thereof in the invention belong to the technical field of waste gastreatment and achieve the purposes of classified and multi-stage purification of waste gas, refined treatment of the waste gas and improvement of waste gas treatment quality.

Owner:SUZHOU JINGTIAN AIREN ENVIRONMENTAL TECH CO LTD

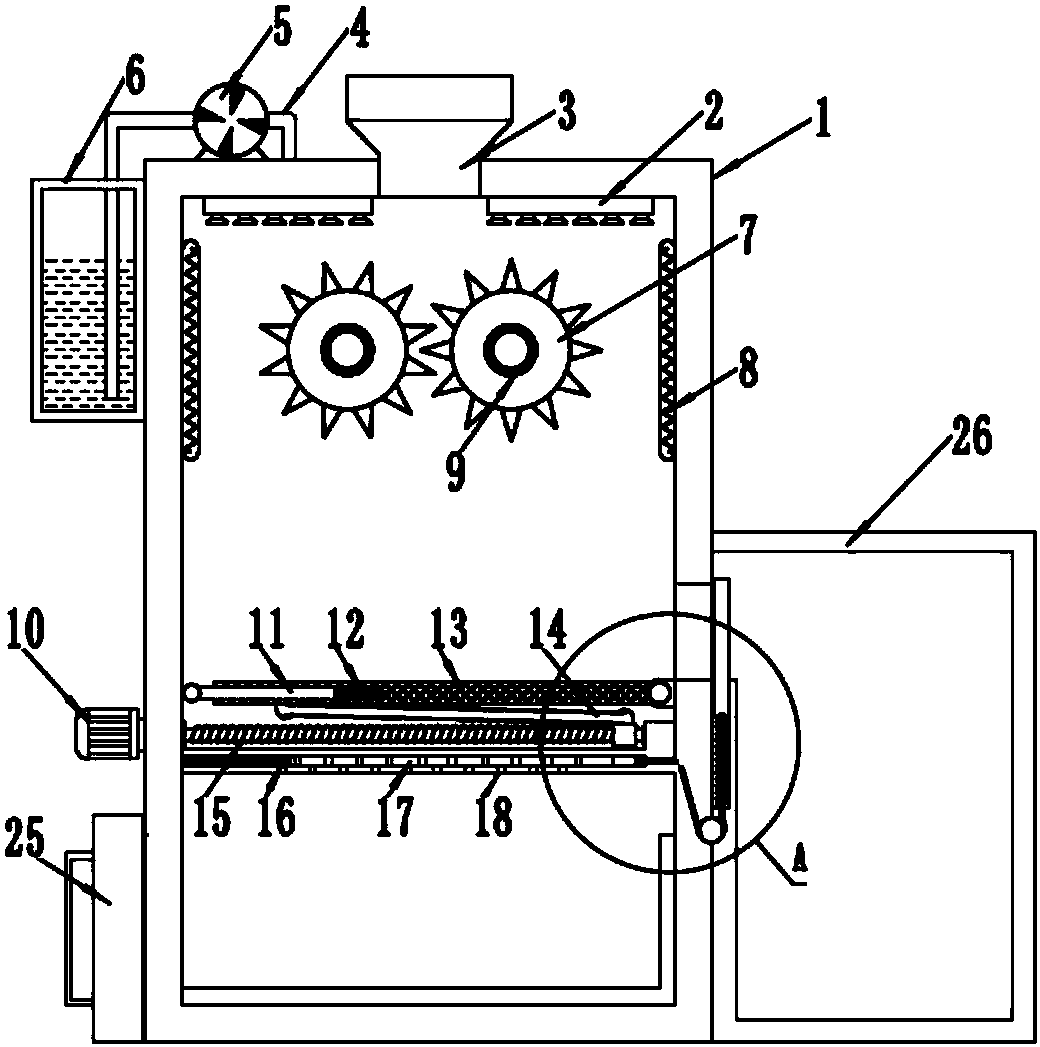

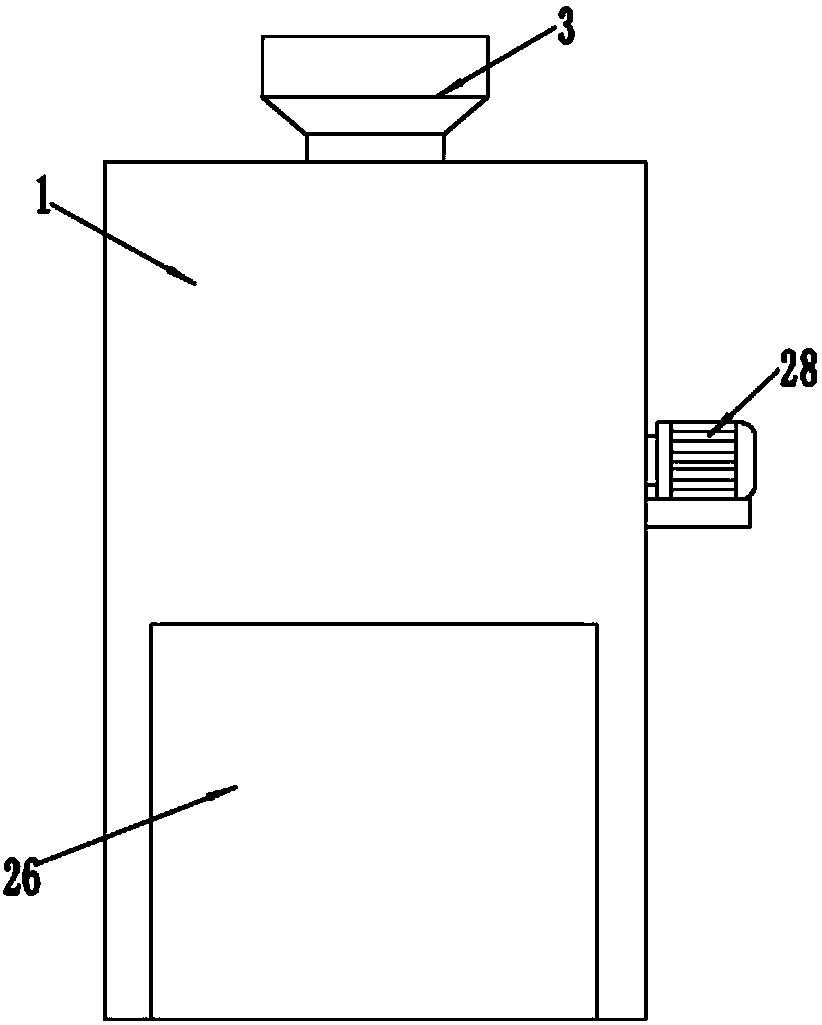

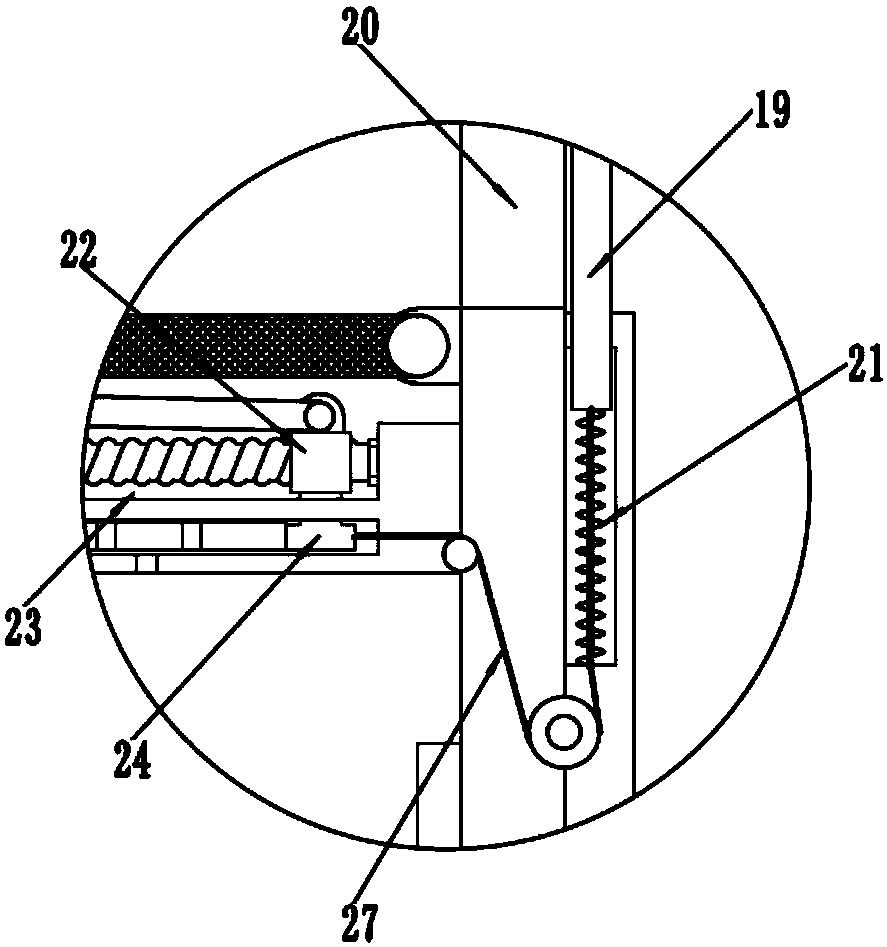

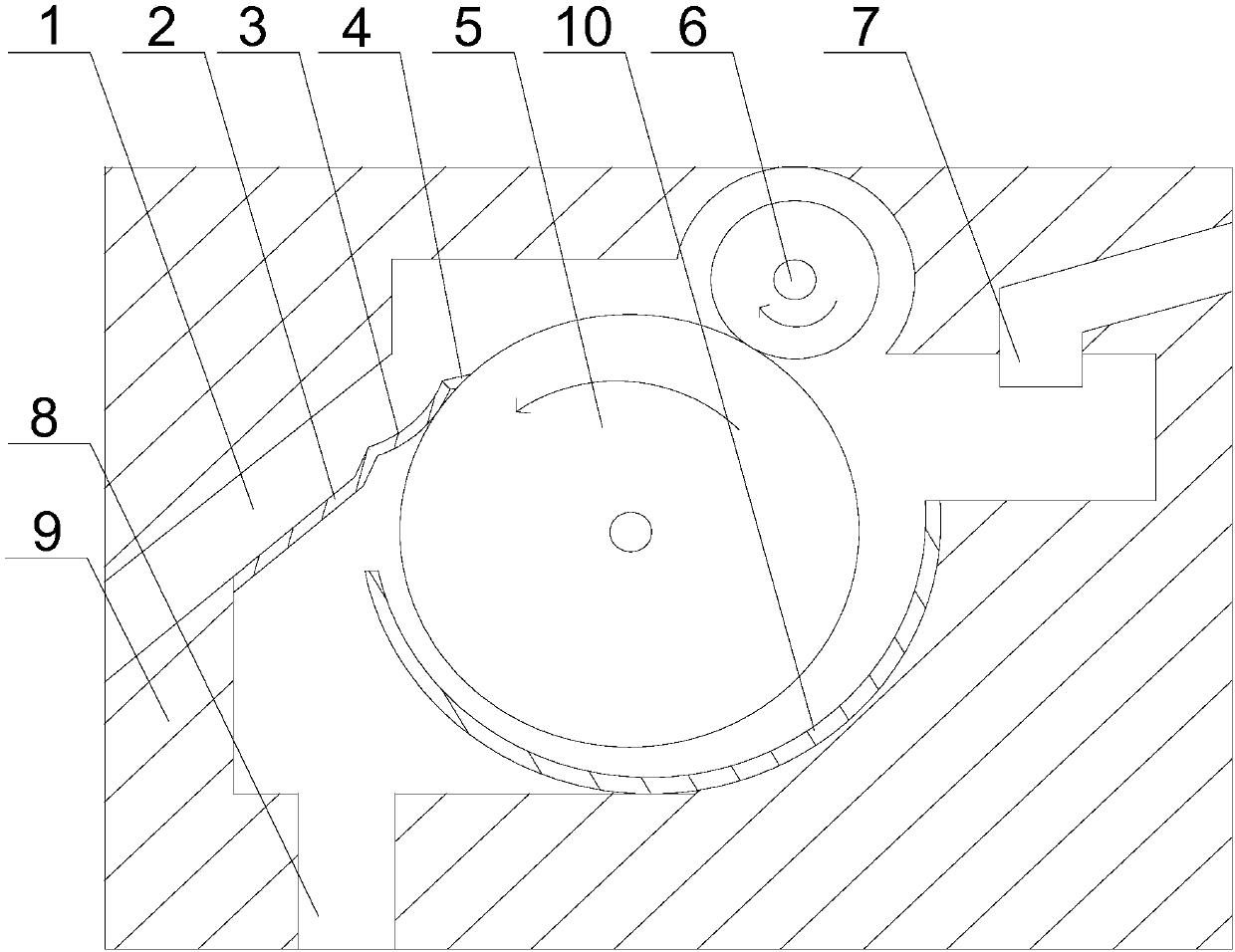

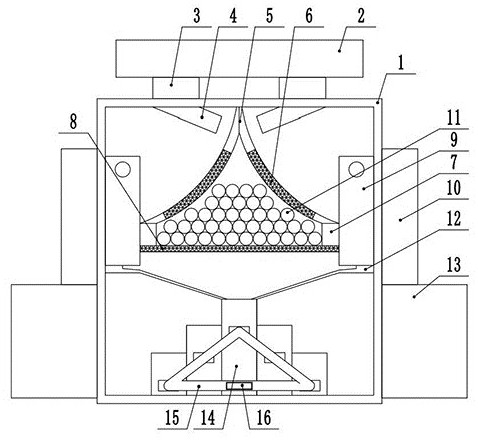

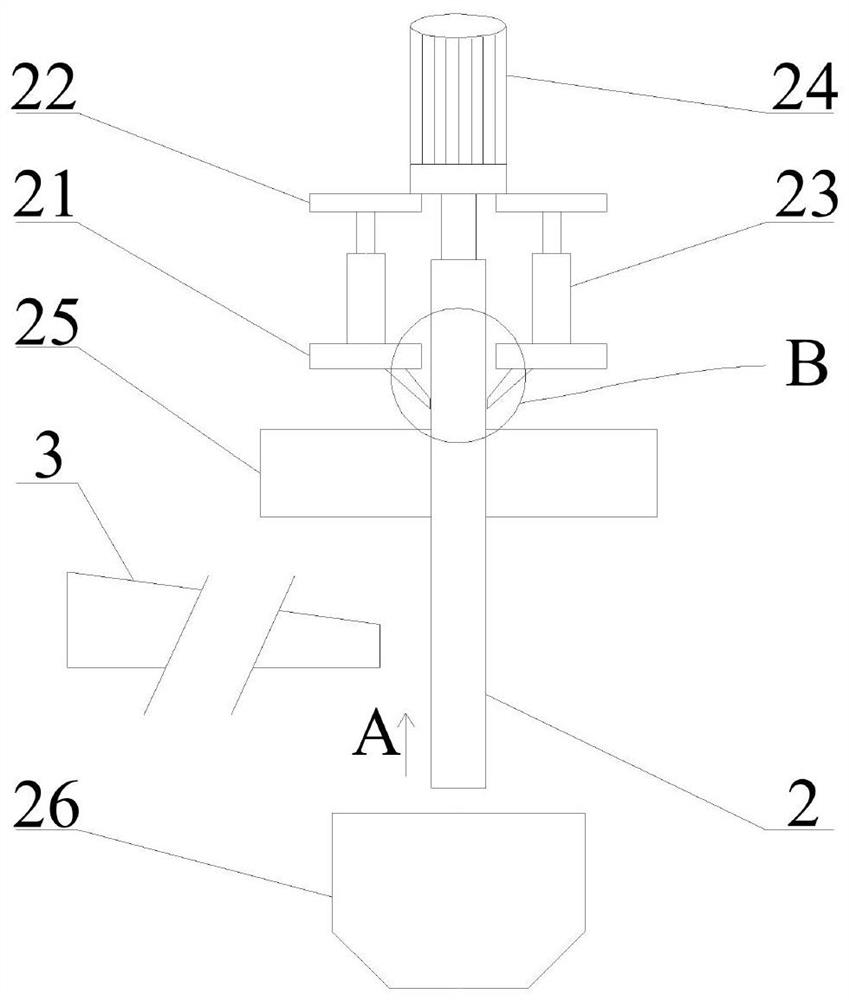

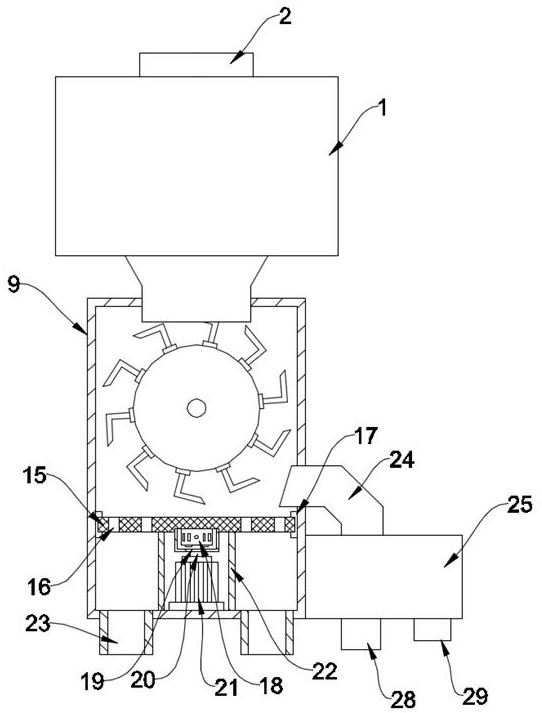

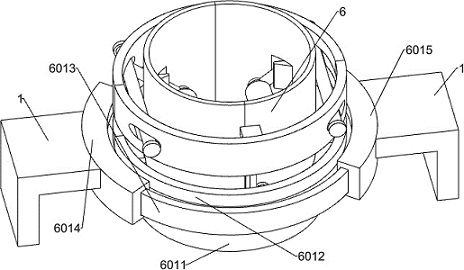

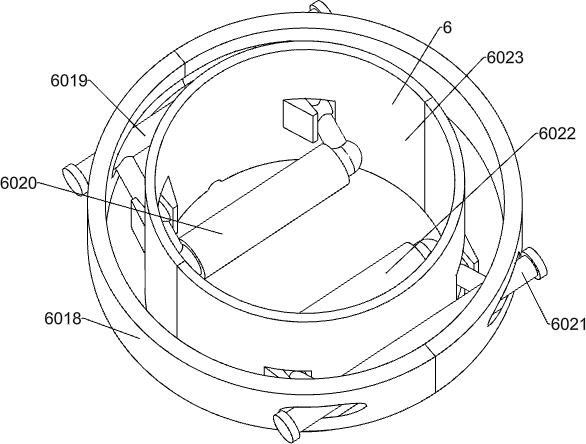

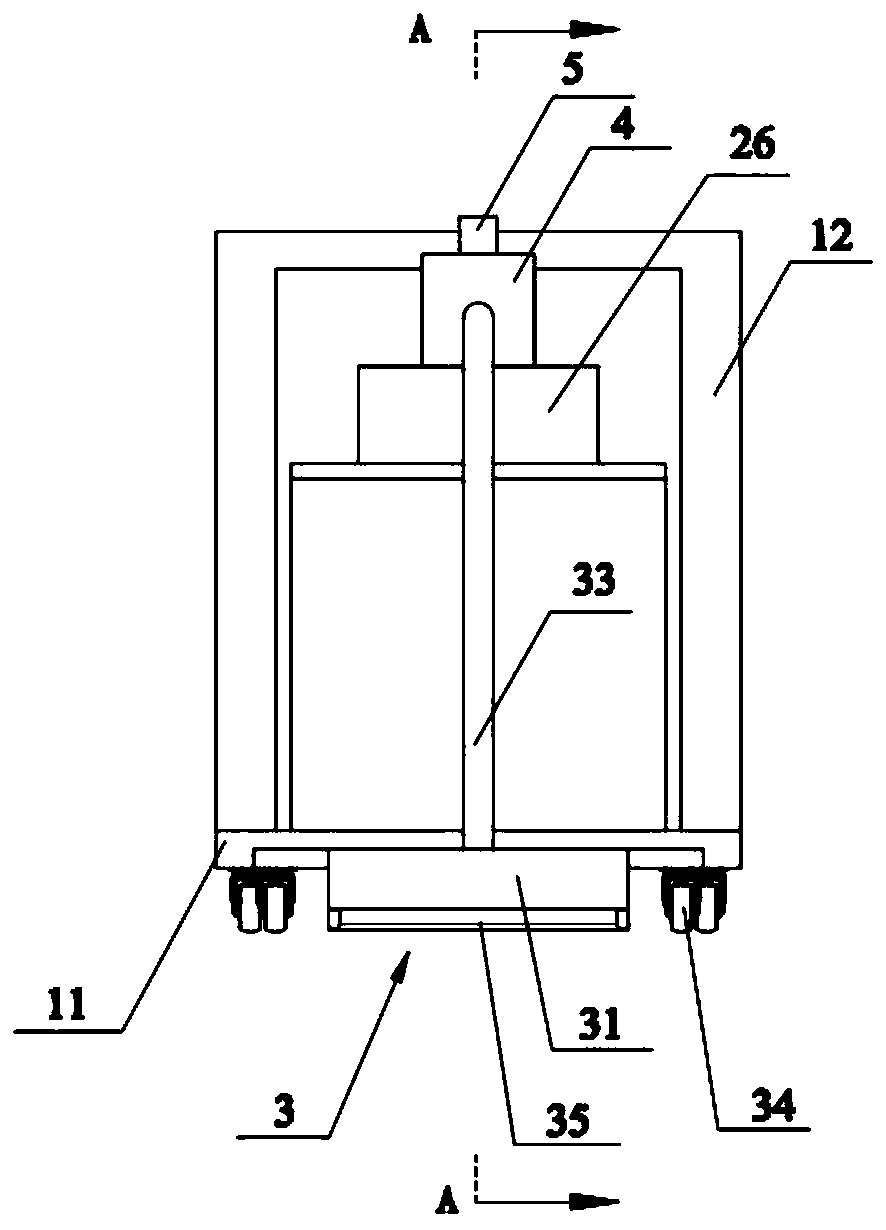

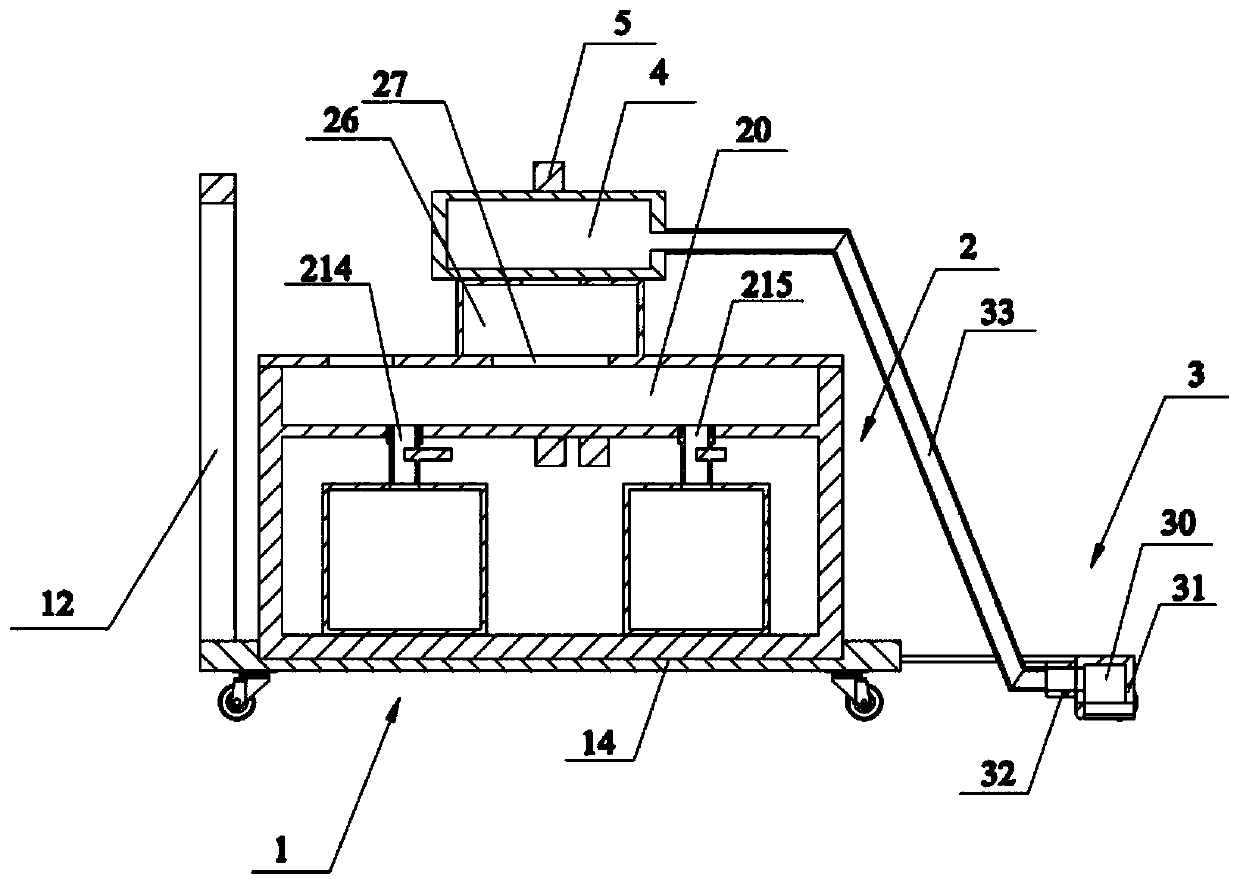

Bag breaking type kitchen garbage soup-water separation device

InactiveCN112999751ARealize separate processingAchieve separationFiltration circuitsProcess engineeringPlastic bag

The invention relates to the field of kitchen garbage, in particular to a bag breaking type kitchen garbage soup-water separation device. The technical problem of the invention is to provide the bag breaking type kitchen garbage soup-water separation device. The bag breaking type kitchen garbage soup-water separation device comprises a working machine bottom plate, a mounting main frame, an operation control screen, a multiple draining system and the like. The lower part of the mounting main frame is welded with a working machine bottom plate; the operation control screen is connected with the mounting main frame; the multiple draining system is connected with the mounting main frame; the lower portion of the collecting system is connected with the working machine bottom plate. According to the kitchen garbage soup-water separation device, the effects that soup-water separation treatment of kitchen garbage is achieved, plastic bags contained in the kitchen garbage are torn to discharge the soup-water in the kitchen garbage, the soup-water is drained out, and finally the soup-water separation effect in the kitchen garbage is achieved through rotating centrifugation are achieved.

Owner:张传德

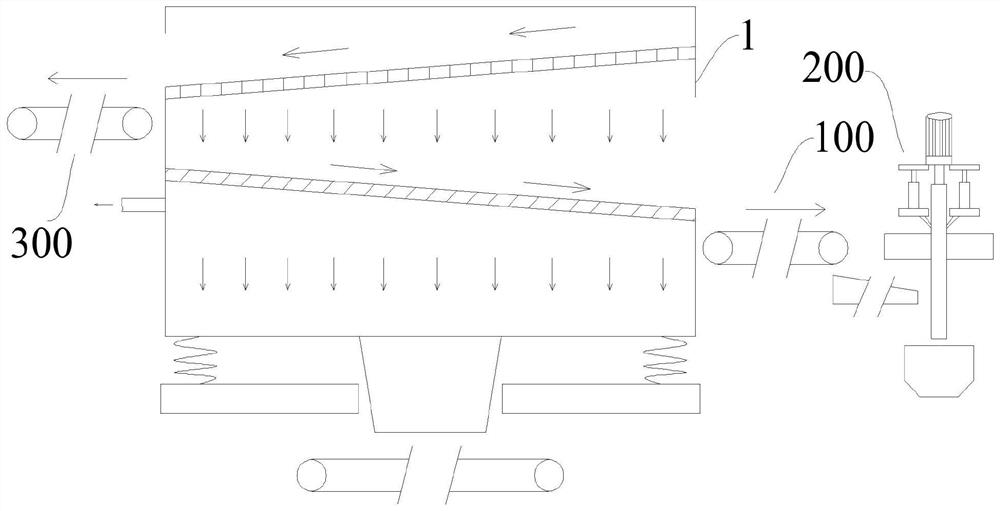

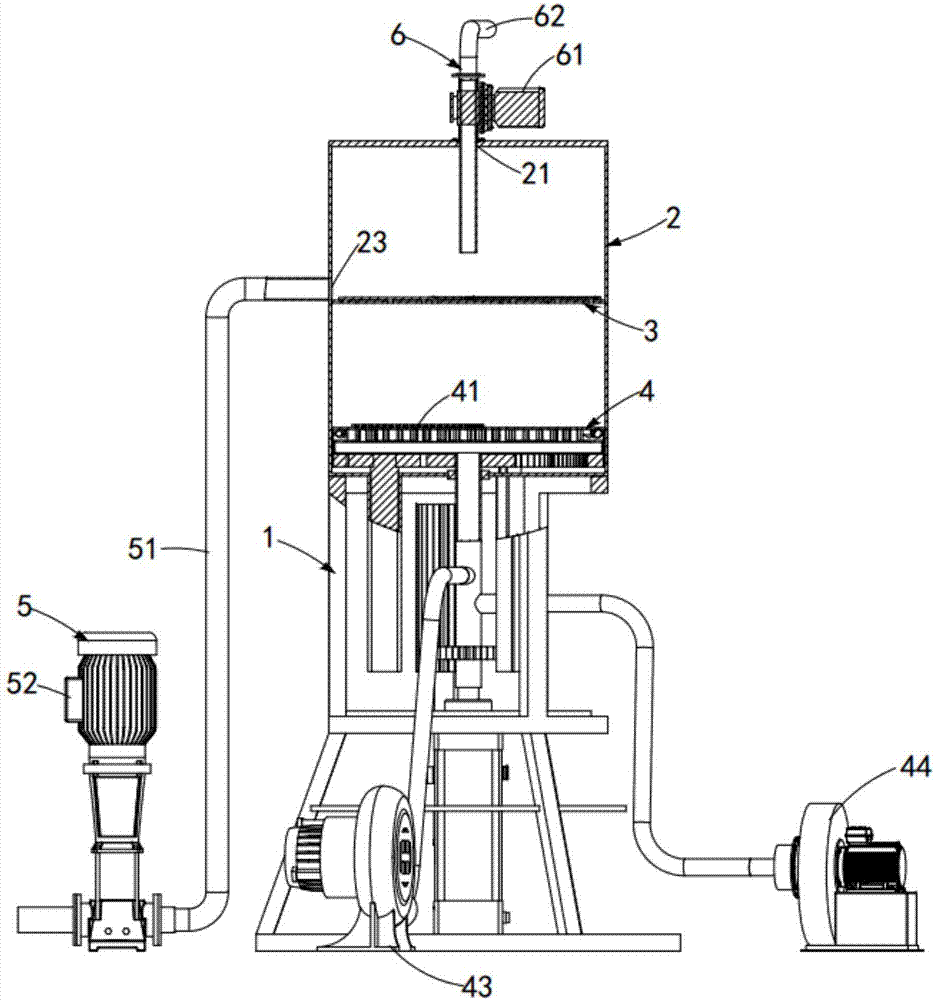

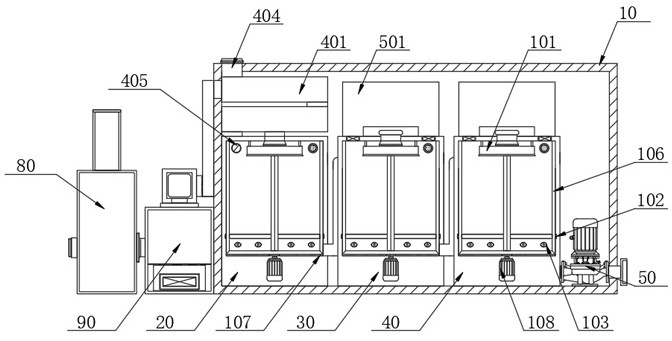

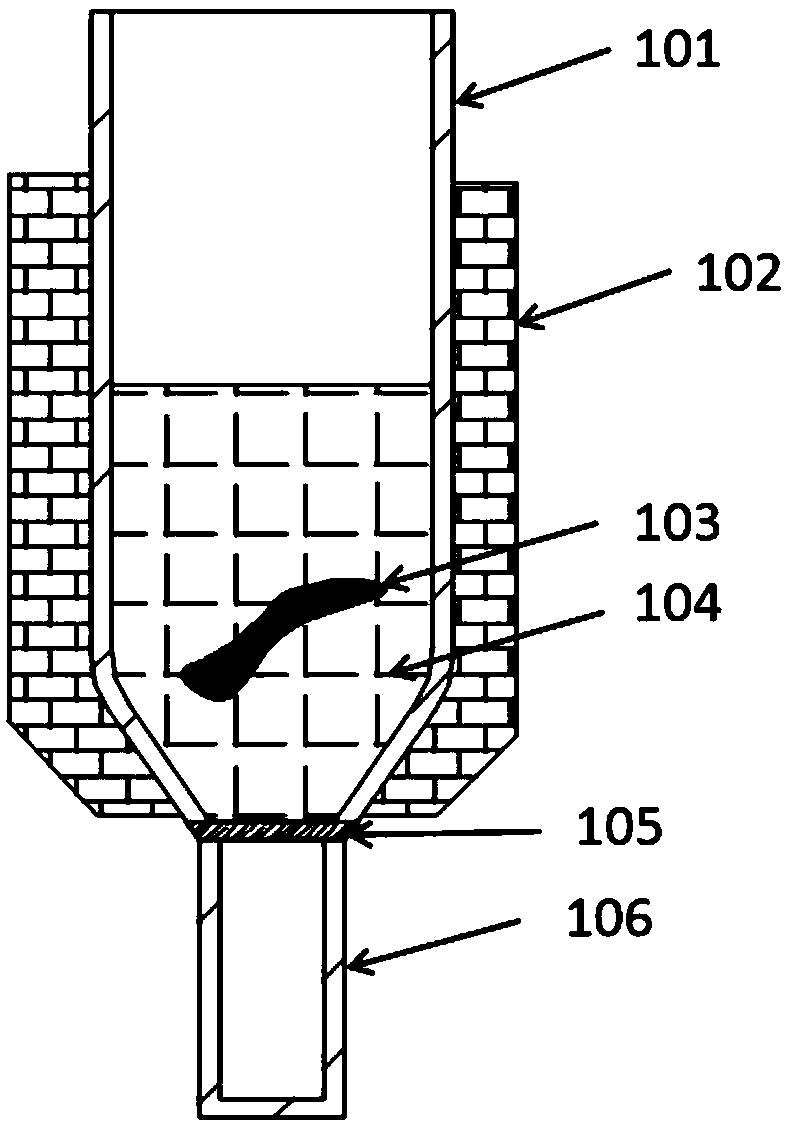

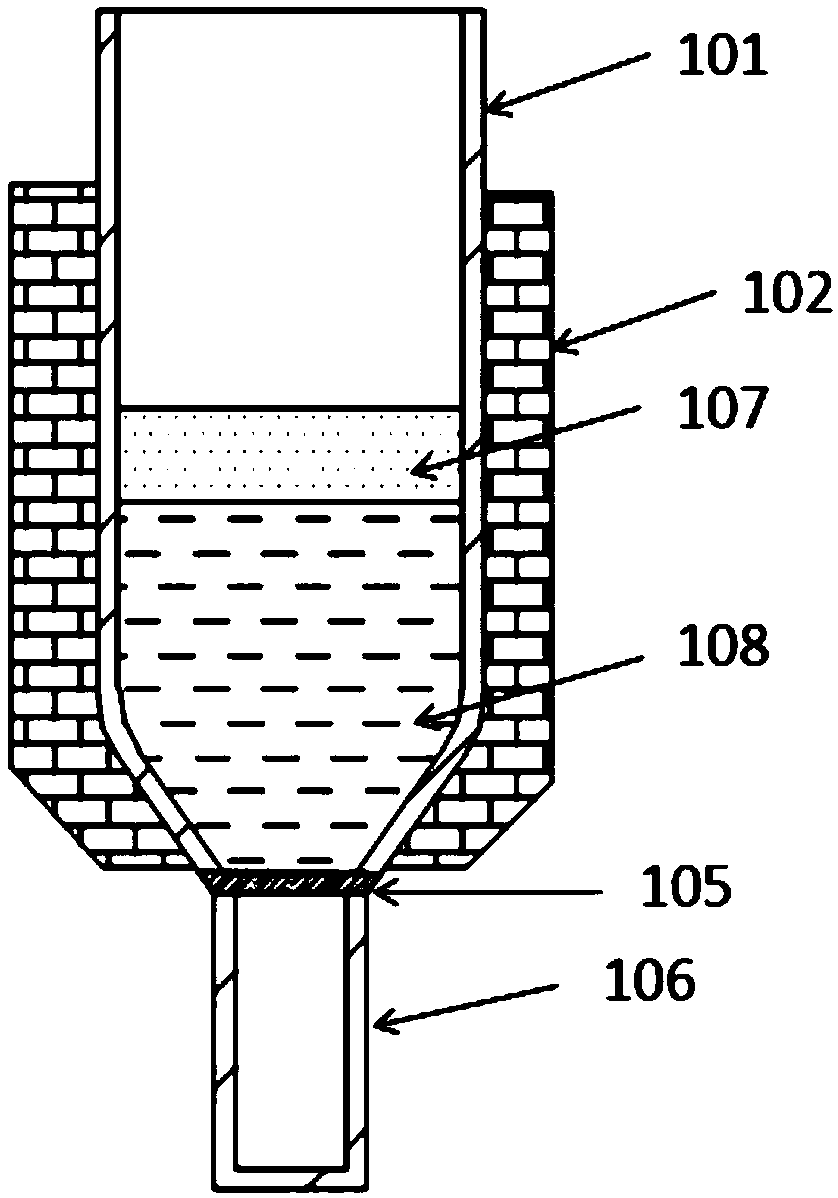

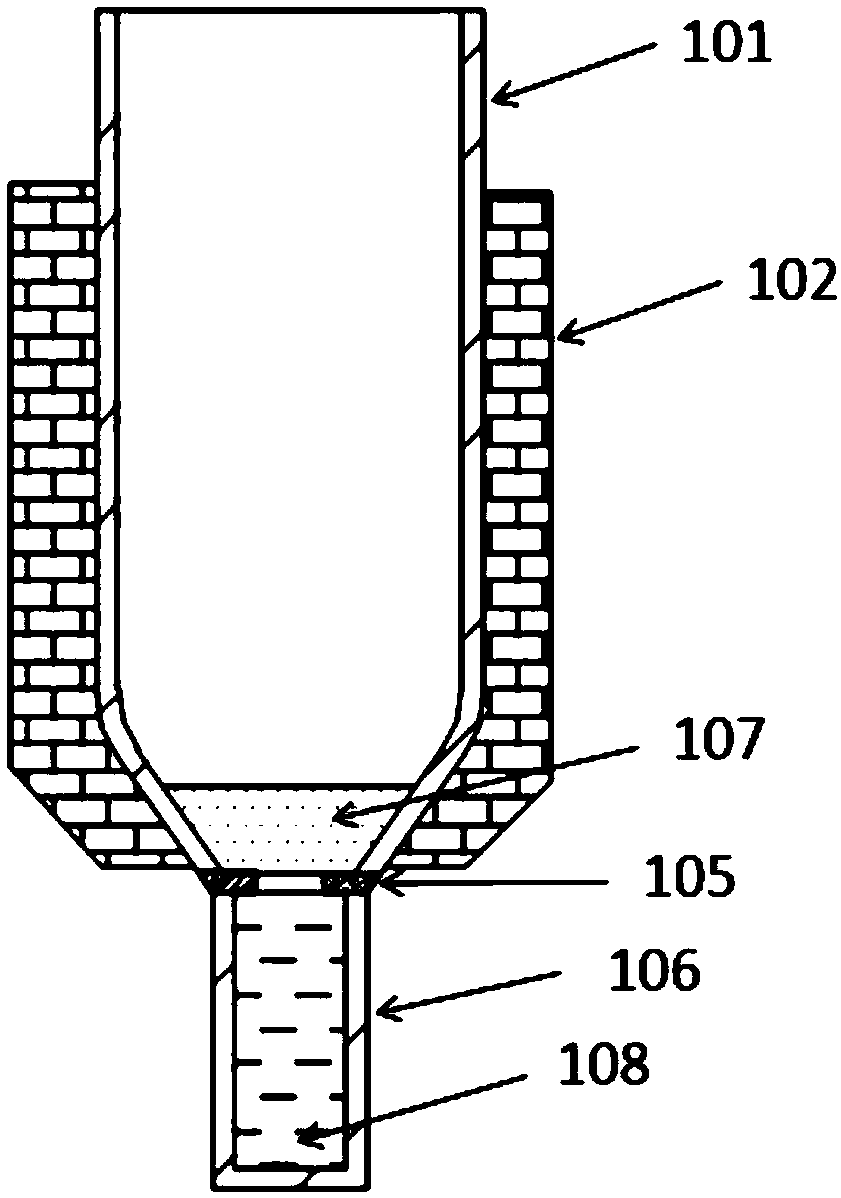

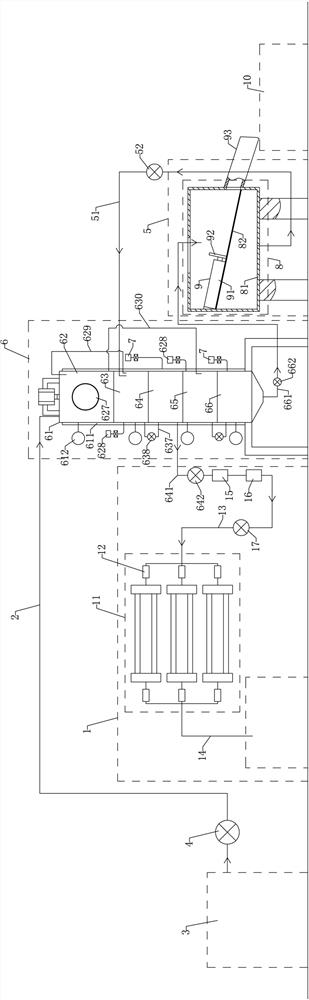

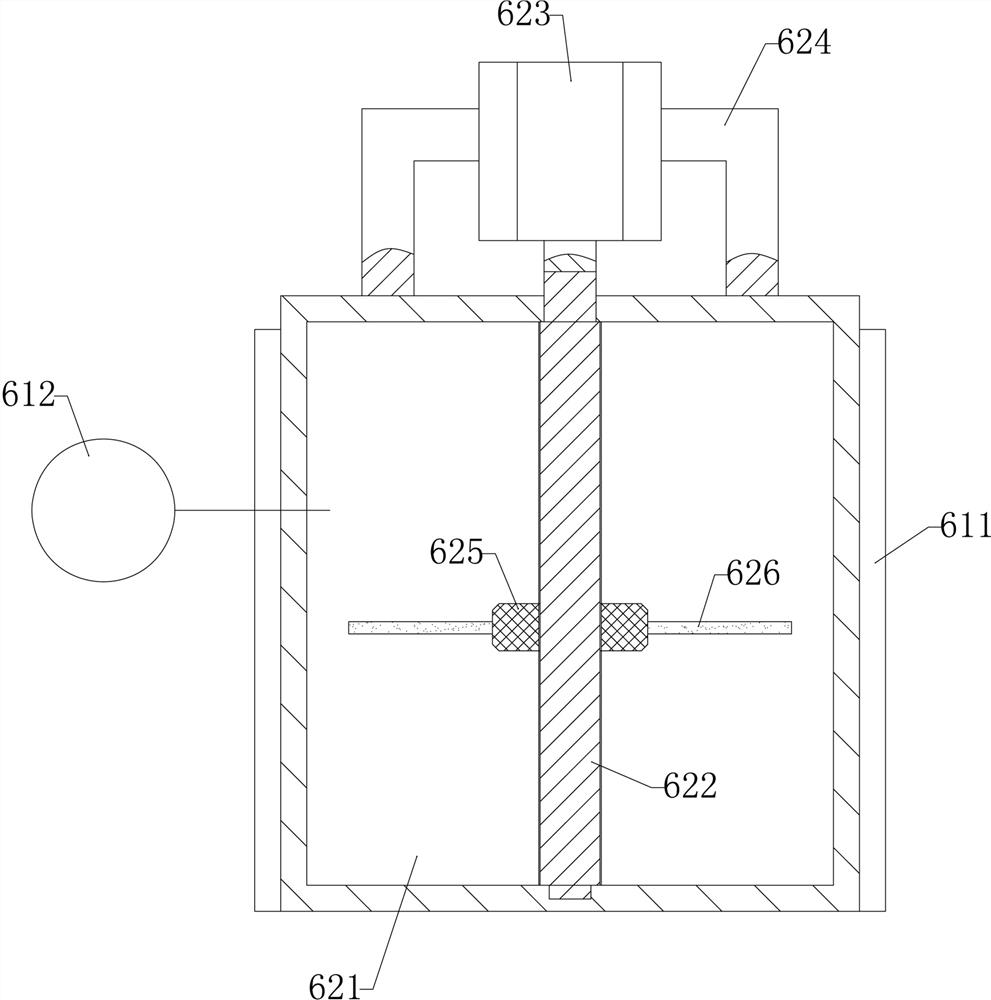

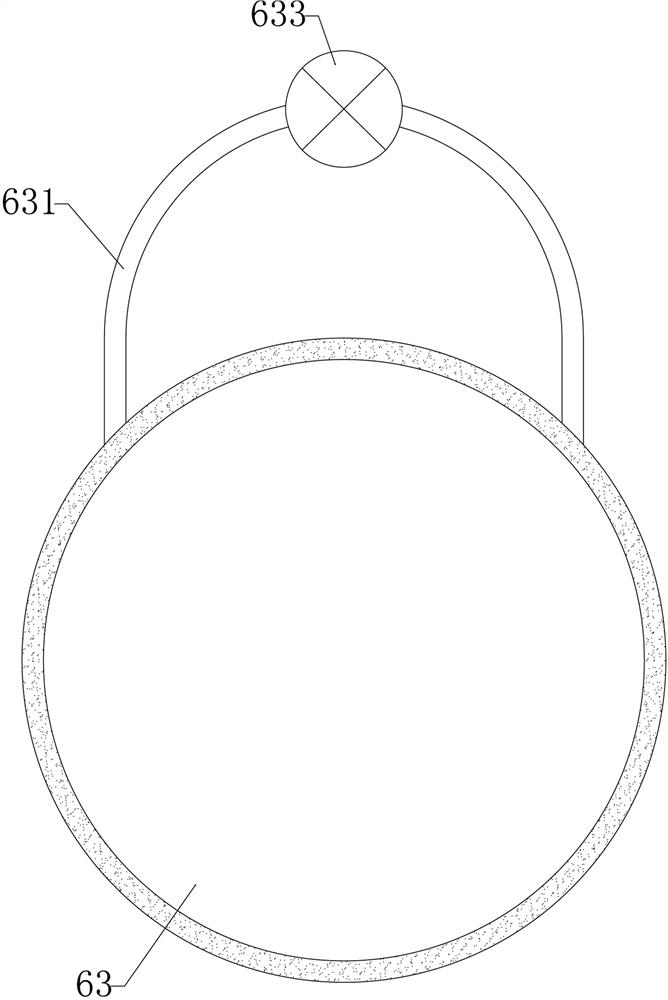

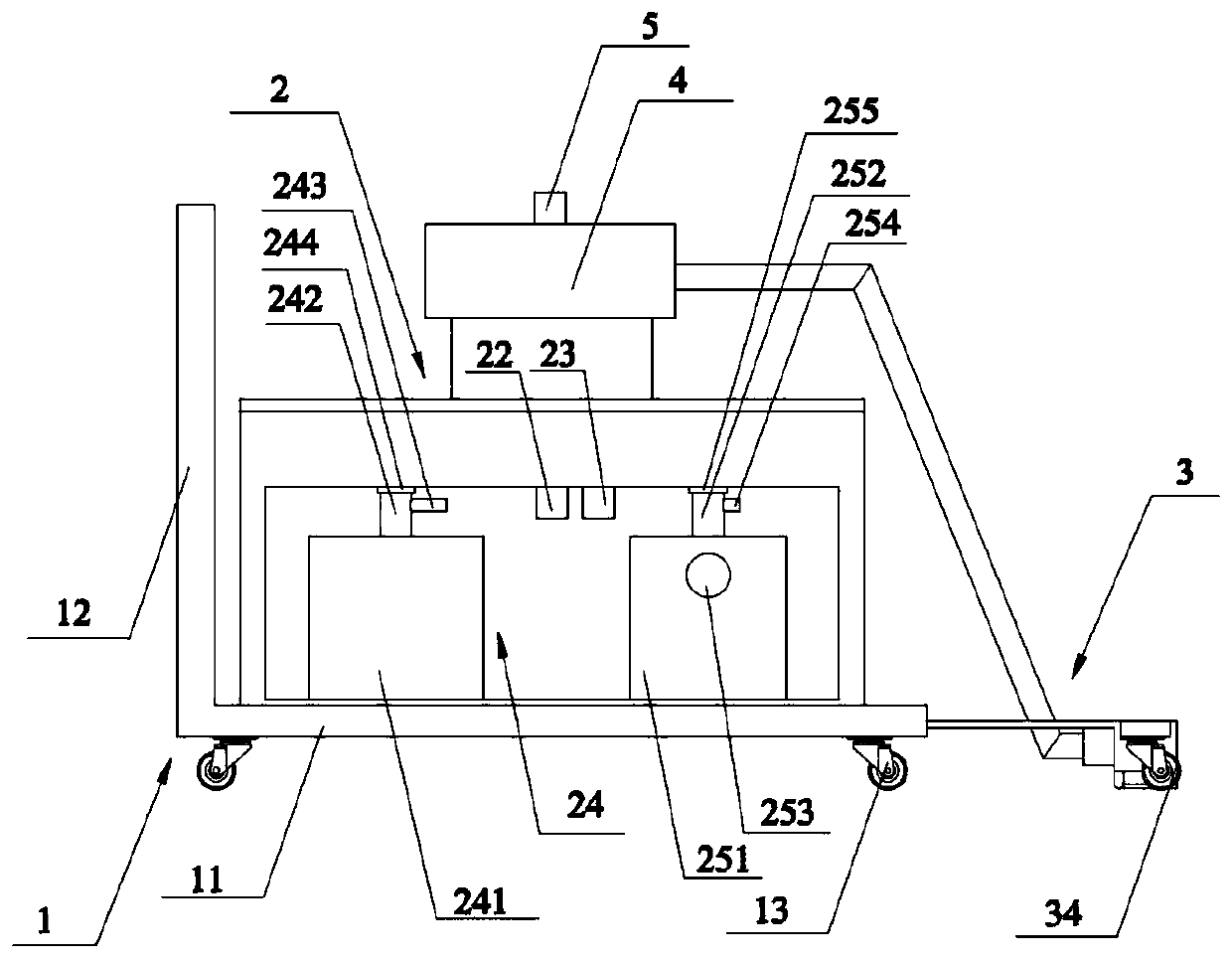

Pretreatment distillation device and method for continuous regeneration of waste lubricating oil

ActiveCN114768282AAffect the treatment effectImprove distillate effectVacuum distillation separationFatty substance recoveryOil canThermodynamics

The invention relates to the technical field of waste lubricating oil pretreatment, in particular to a pretreatment distillation device and method for continuous regeneration of waste lubricating oil, the pretreatment distillation device comprises a case, and a first-stage distillation retort, a second-stage distillation retort and a third-stage distillation retort are arranged in the case side by side; meanwhile, distillation mechanisms are arranged in the multiple stages of distillation retorts, vacuum distillation treatment is conducted on the waste lubricating oil in the first-stage distillation retort, the second-stage distillation retort and the third-stage distillation retort in sequence, gas is blown into the waste lubricating oil in the vacuum distillation process of the waste lubricating oil, bubbles are continuously blown out of the interior of the waste lubricating oil, and the waste lubricating oil is continuously discharged. According to the waste lubricating oil distillation device, on one hand, the distillation efficiency of waste lubricating oil can be improved, on the other hand, an oil film is prevented from being formed in the distillation process, meanwhile, coke on the inner wall of the distillation retort is cleaned through the scraping frame and the scraping plate in the distillation treatment process, and the continuous operation efficiency of the distillation device is improved while the fraction effect of the waste lubricating oil is guaranteed.

Owner:东营国安化工有限公司

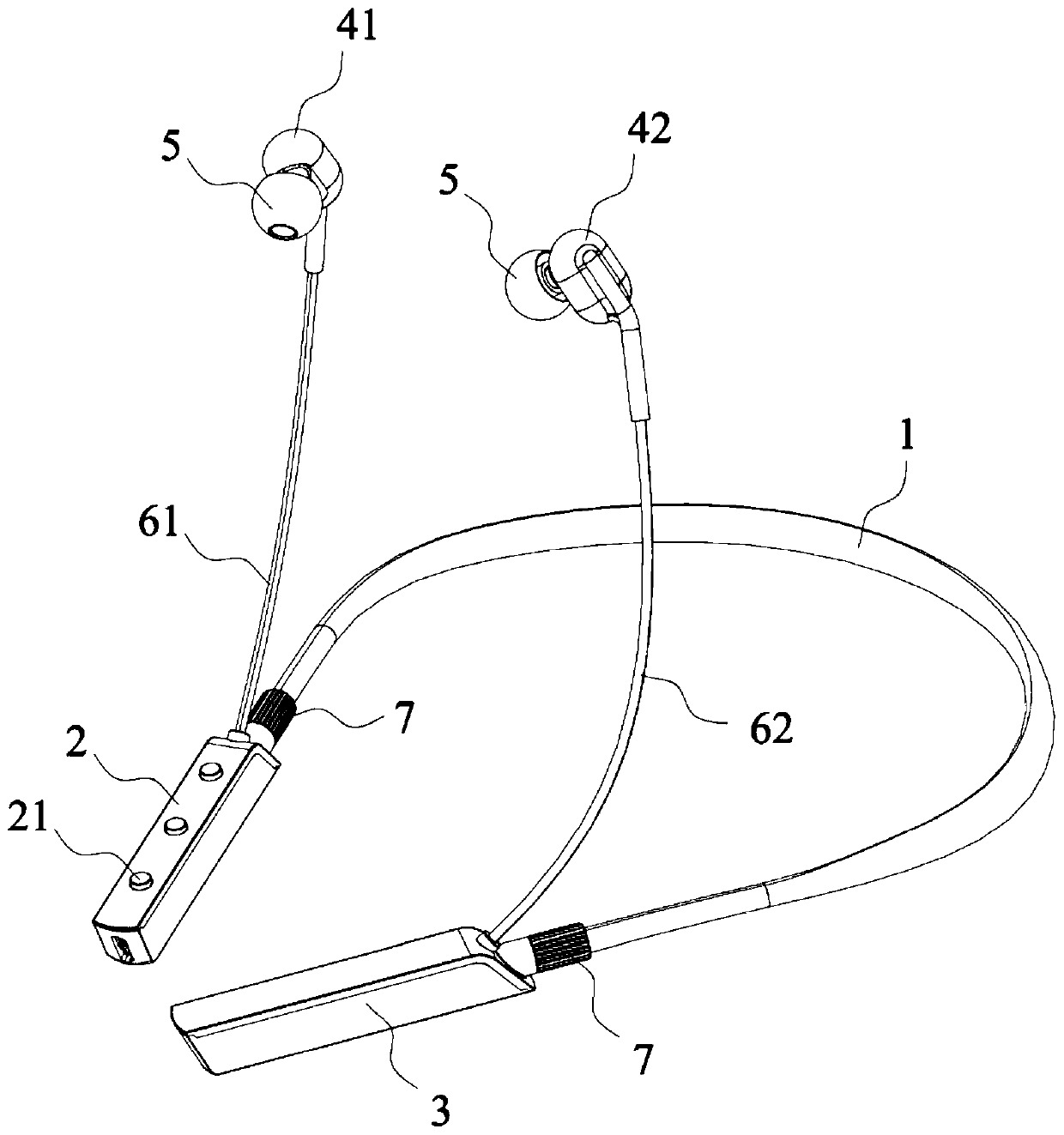

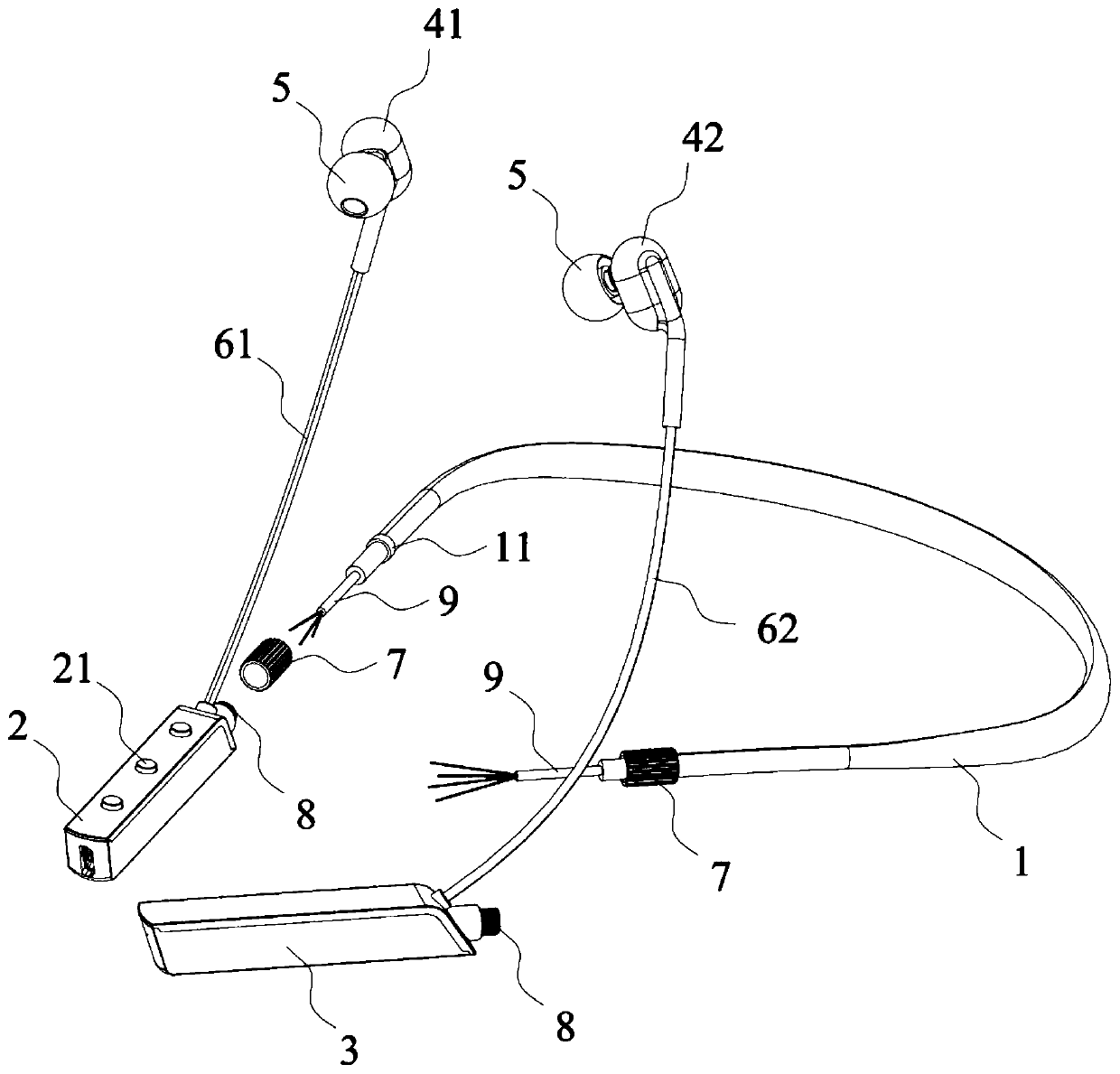

A connecting structure of a neckband Bluetooth earphone and the neckband Bluetooth earphone

InactiveCN109698987AGuaranteed connection strengthAvoid separationMicrophonesLoudspeakersHeadphonesBluetooth

The invention belongs to the technical field of earphones, and particularly discloses a connecting structure of a neckband Bluetooth headset and the neckband Bluetooth headset. The connecting structure is used for connecting a neck strap line, a first box body and a second box body of the neck strap Bluetooth earphone, and comprises a first connecting piece and a second connecting piece, the neckstrap line is sleeved with two first connecting pieces, and the first connecting pieces can rotate relative to the neck strap line; Second connecting pieces are arranged on the first box body and thesecond box body; One of the first connecting piece and the second connecting piece is provided with an external thread, the other one of the first connecting piece and the second connecting piece is provided with an internal thread, the two first connecting pieces and the two second connecting pieces are in threaded connection in a one-to-one correspondence mode to be used for connecting the neckstrap line with the two box bodies, and therefore the two box bodies and the neck strap line can be machined in a split mode, machining difficulty is reduced, and machining yield is guaranteed. Meanwhile, the connection strength of the two box bodies and the neck strap line can be ensured, and the two box bodies are prevented from being separated by accidental stress. The Bluetooth headset with the neck band comprises a connecting structure of the Bluetooth headset with the neck band.

Owner:美律电子(惠州)有限公司

Cutting fluid primary filter

InactiveCN104608003ARealize separate processingAchieve re-useMaintainance and safety accessoriesEngineeringFluid need

The invention discloses a cutting fluid primary filter which comprises a box and a magnetic roller. A recycling hole, a fluid inlet and a fluid outlet are formed in the box, a baffle is mounted on the bottom of the magnetic roller, a clearance is reserved between the magnetic roller and the baffle, the fluid inlet and the fluid outlet are communicated with the clearance to form a fluid drainage channel, a flow smoothing plate is mounted at the end of the recycling hole, the movable end of the flow smoothing plate makes contact with the outer wall of the magnetic roller, a material discharging channel is formed among the flow smoothing plate, the recycling hole and the inner wall of a cavity, a scraping head is mounted at the tail end of the movable end of the flow smoothing plate, an arc groove is formed in the middle of the scraping head, and the tail end of the scraping head is connected with a scraping blade through an elastic piece. According to the cutting fluid primary filter, metal cutting fluid is separated through the fluid drainage channel and the material discharging channel, separation treatment of metal fragments and cooling fluid in the metal cutting fluid is further achieved, when the cutting fluid primary filter is used, only the rotating speed of a rubber roller and the injection speed of the metal cutting fluid need to be adjusted, recycling of metal fragments can be achieved, and the production cost of enterprises is lowered.

Owner:CHENGDU KELIFU SCI & TECH

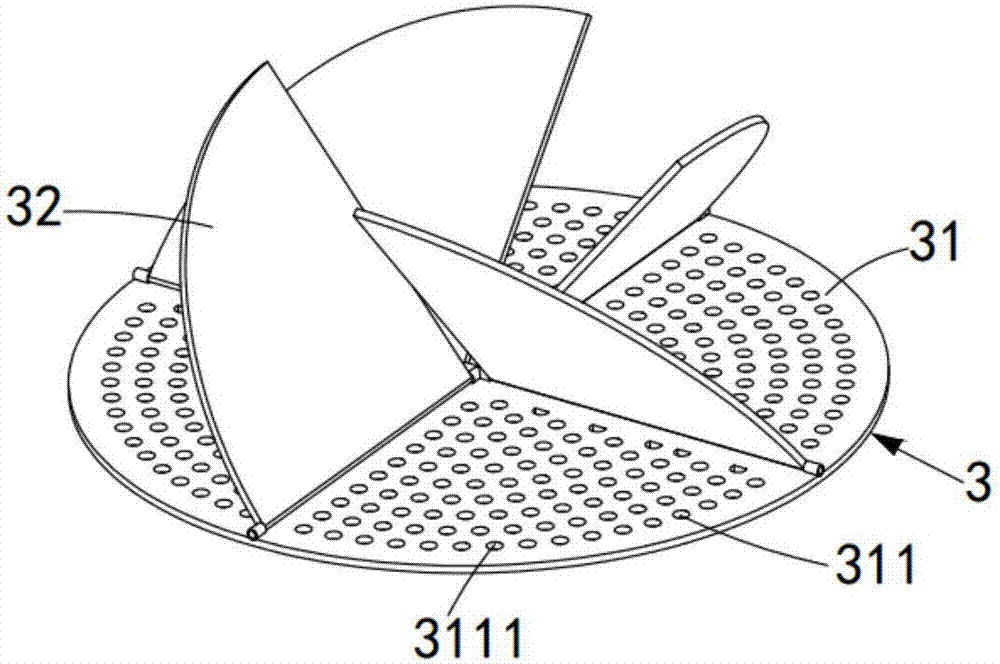

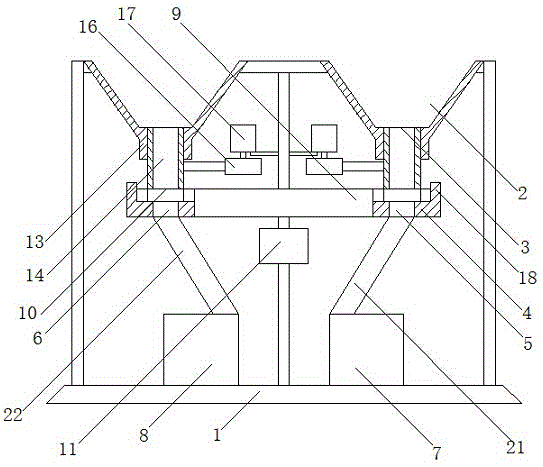

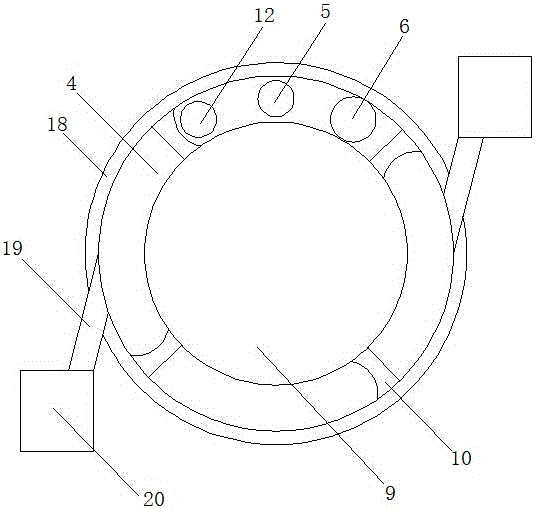

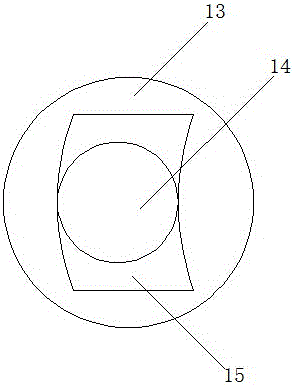

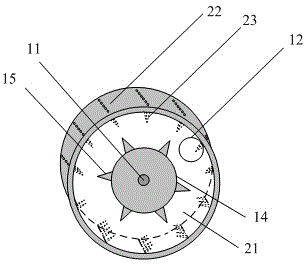

Annular-separation-based coin separation device

ActiveCN106251460ARealize separate processingEffective control of floor spaceCoin/paper handlersCircular discEngineering

The invention discloses an annular-separation-based coin separation device comprising a rack. A discharging funnel is arranged on the rack; and a coin separation plate is arranged at the lower end of the discharging funnel. A first separation slot body and a second separation slot body are arranged in the coin separation plate, wherein the diameter of the first separation slot body is smaller than that of the second separation slot body; the first separation slot body and the second separation slot body are communicated to a first collection groove and a second collection groove, wherein the two collection grooves are arranged at the lower end of the coin separation plate. A circular pushing plate is arranged inside the coin separation plate; and a plurality of pushing end bodies are arranged above the side end portion of the circular pushing plate. A color sensor is arranged above the coin separation plate. According to the device, during the coin separation process, the separation efficiency and the separation precision of the device are higher than those of the traditional screening way obviously.

Owner:江苏方济消防科技有限公司

Smashing and separating device for bagged industrial refuse

InactiveCN105128186ANot easy to tangleEasy to update and replacePlastic recyclingMechanical material recoveryWind forceLitter

The invention discloses a smashing and separating device for bagged industrial refuse. The smashing and separating device comprises a rotating rotor assembly, a rivet cylinder and a separating assembly. The rotating rotor assembly is composed of a rotating shaft, a conveying channel inlet, a conveying channel outlet, a rotary drum, blades and a transmission device. The rivet cylinder is composed of rivet hanging pieces and rivets. The separating assembly is composed of a light refuse subpackage cylinder, a common refuse subpackage cylinder, an air blower and the like. In the working process, refuse enters a refuse conveying channel from the conveying channel inlet of the rotating rotor assembly, when the rotary drum of the rotating rotor assembly rotates at a high speed, the refuse passes through the conveying channel and a bag is broken by the rivets, and the refuse is discharged out of the conveying channel outlet. In the falling process of the refuse from the rotor assembly, light refuse materials are blown into the light refuse subpackage cylinder through the wind force of the air blower, heavy common refuse falls into the common refuse subpackage cylinder, and separation of the refuse is achieved. According to the device, the rivets are used for breaking the bag of the refuse, the rivets and the rivet cylinder are not integrally installed, and disassembly and assembly can be conveniently carried out.

Owner:李海兰

Treatment system and technology for copper-containing and high ammonia-nitrogen wastewater

PendingCN110255774AAchieve recyclingRealize separate processingWater contaminantsTreatment involving filtrationAir compressionProduct gas

Belonging to the field of metallurgical wastewater treatment, the invention specifically relates to a treatment system for copper-containing and high ammonia-nitrogen wastewater. The system comprises a copper reactor, a filter unit and an ammonia-nitrogen separation device. The ammonia-nitrogen separation device comprises a gas-liquid mixing unit and a gas-liquid separation cavity. A liquid outlet of the copper reactor is connected to a liquid inlet of the filter unit, a filtrate outlet of the filter unit is connected to a liquid inlet of the gas-liquid mixing unit, the gas-liquid mixing unit is also equipped with an air inlet and a liquid outlet, the liquid outlet is communicated with the chamber of the gas-liquid separation cavity, the upper part and lower part of the gas-liquid separation cavity are respectively equipped with an air outlet and a liquid outlet. According to the technical scheme, copper-containing and high ammonia-nitrogen wastewater firstly undergoes copper recovery, then ammonia-nitrogen separation is carried out, and the pH value regulation and air compression in the ammonia-nitrogen separation process are both completed in the gas-liquid mixing unit, thus simplifying the treatment steps; the obtained gas and liquid mixture is directly injected into the separation chamber, the gas moves upward and the liquid gathers downward, thereby realizing the separation of ammonia-nitrogen gas.

Owner:JINLONG COPPER +1

Rapid dewaxing device for FFPE sample and using method of FFPE rapid dewaxing device

InactiveCN109142012AImprove acquisition purityAvoid influencePreparing sample for investigationPhysics

Owner:SHANGHAI MAG GENE NANOTECH CO LTD

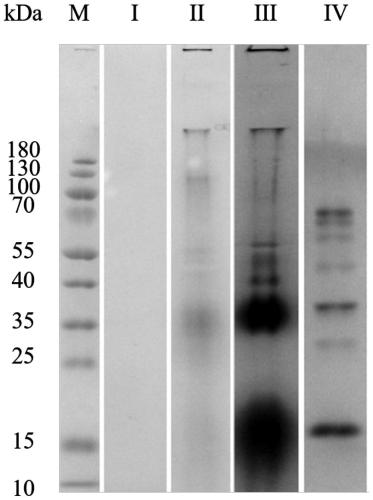

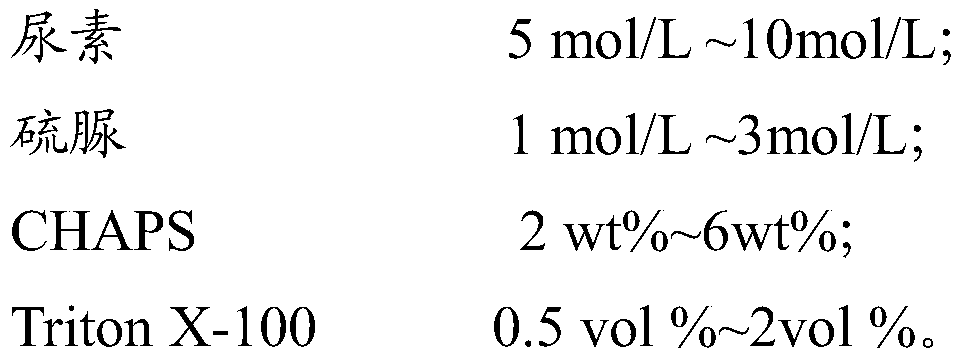

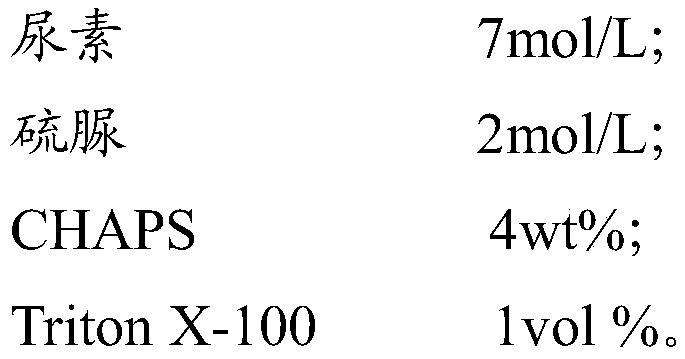

Composition and use thereof in protein extraction and/or dissolution

ActiveCN109879929ASimple ingredientsEasy to operatePeptide preparation methodsCrystallographySolubility

The invention relates to the technical field of protein extraction, and in particular to a composition and use thereof in protein extraction and / or dissolution. The composition is composed of urea thiourea Triton X-100 and CHAPS. While the composition contains a plurality of denaturants which can perform affinity with a surface hydrophobic subunit of a strongly hydrophobic protein in an ampholyte,a tertiary structure of a protein peptide chain is opened, the deactivation of catalytic subunits is avoided, and the protein agglomeration is also avoided. Therefore, the separation treatment of thestrongly hydrophobic protein is achieved, and the solubility of the protein is improved. The composition has simple composition, is convenient to operate and has a remarkable effect.

Owner:UNIV OF SCI & TECH OF CHINA

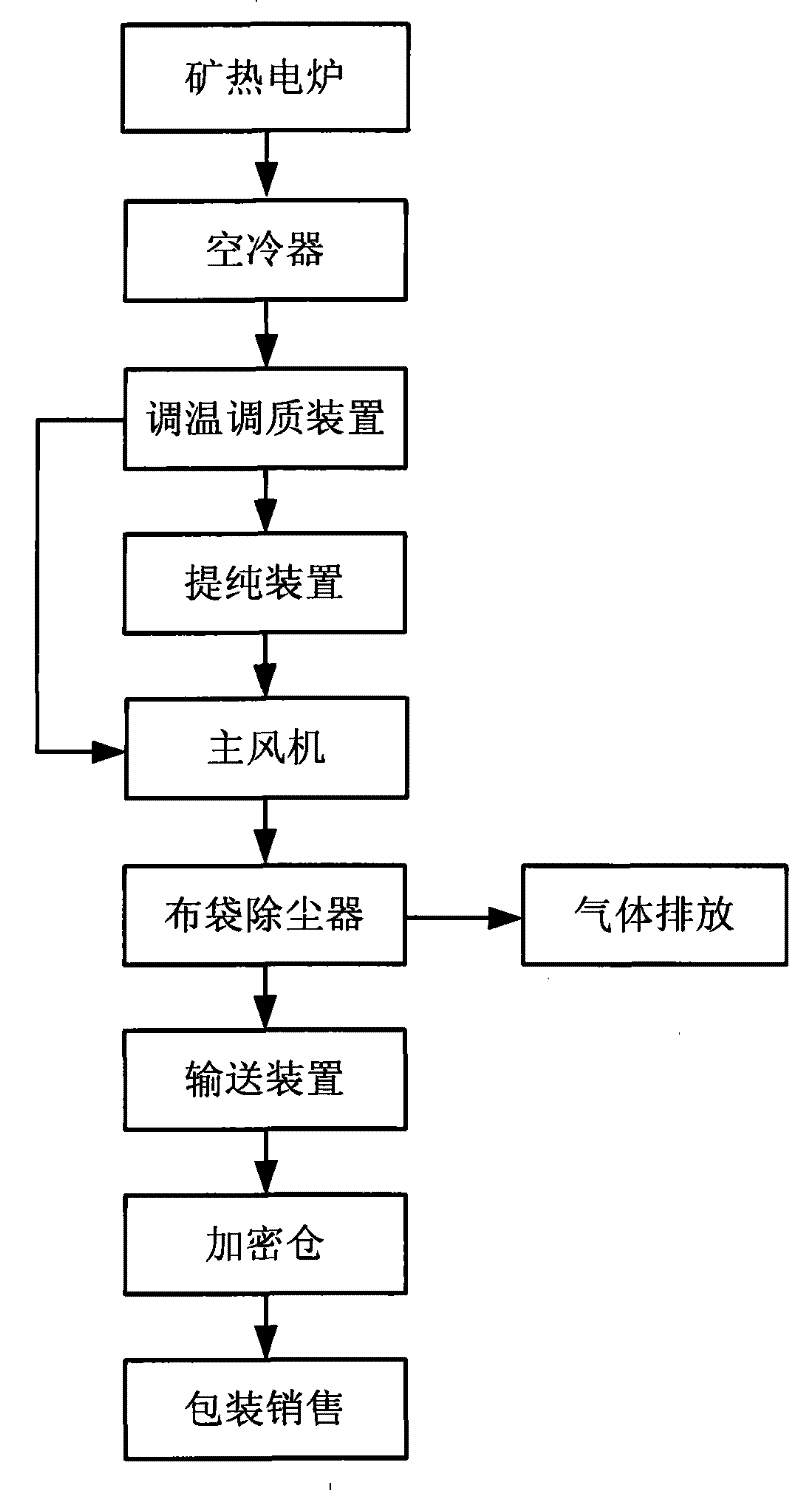

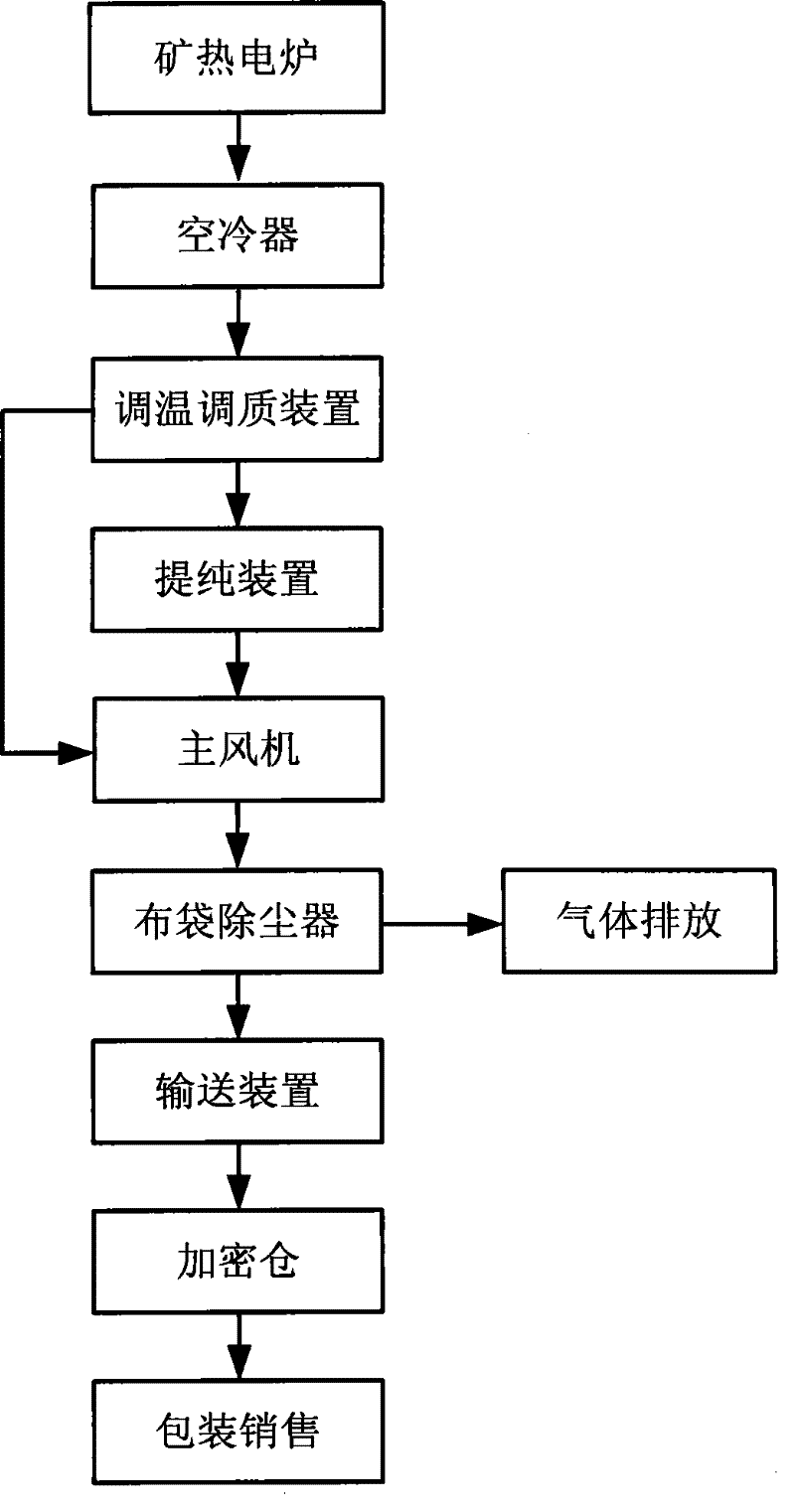

Novel technique for purification recovery of tiny silica flour

InactiveCN101269813BIncrease contentRealize separate processingSilicon compoundsFiltrationEngineering

The invention relates to a technology of micro silicon power purification, which mainly includes working procedures of monitoring and controlling, purification, recovery, etc. The new technology not only can effectively monitor and adjust the temperature and the thickness of high temperature dust and gas and avoid much fluctuation from being generated for gas volume and gas components because of the difference of raw materials and furnace conditions and the different stages of a smelting technology in the smelting process to influence the subsequent treatment technology and the product quality, but can realize the separation treatment of coarse particles and the dust of a plurality of metal oxides in dust and smoke through the ways of centrifugal separation, gravitational separation and electric separation and improve the content of SiO2 in the micro silicon power. The new technology causes a bag-type dust remover to collect aerosol micro silicon power of 0.01 micrometers through the way of coagulation of charged electric and static of the dust, and the micro silicon power is easy to realize shallow filtration when passing the bag to be filtered.

Owner:北京民海艳科技有限公司

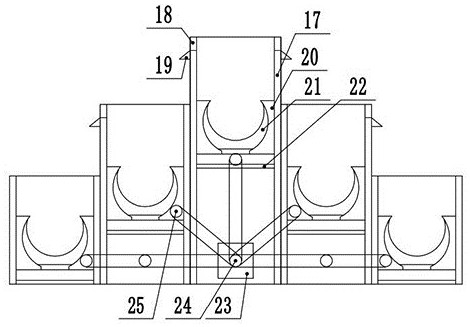

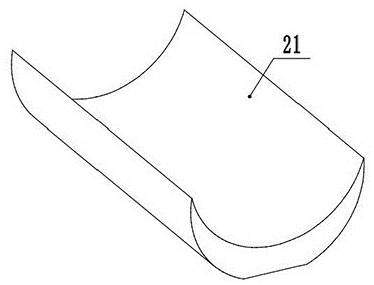

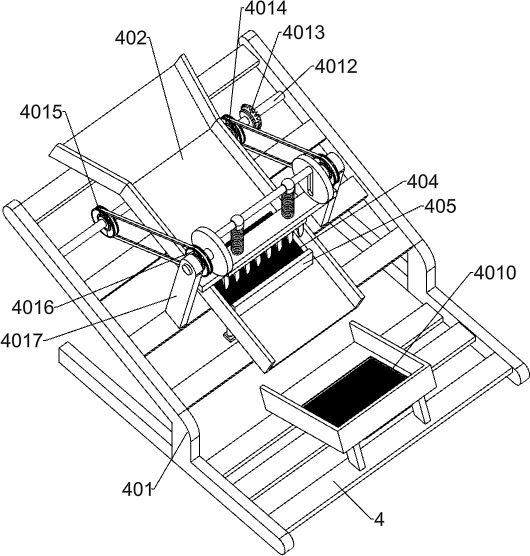

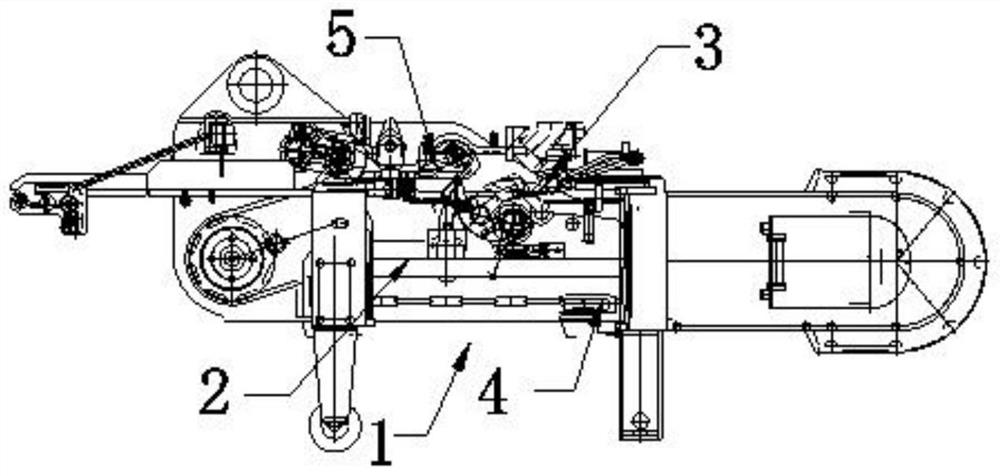

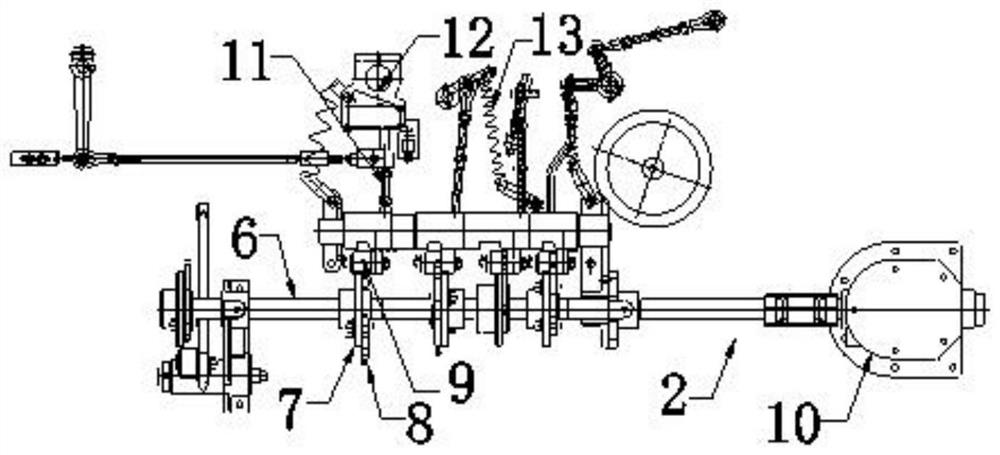

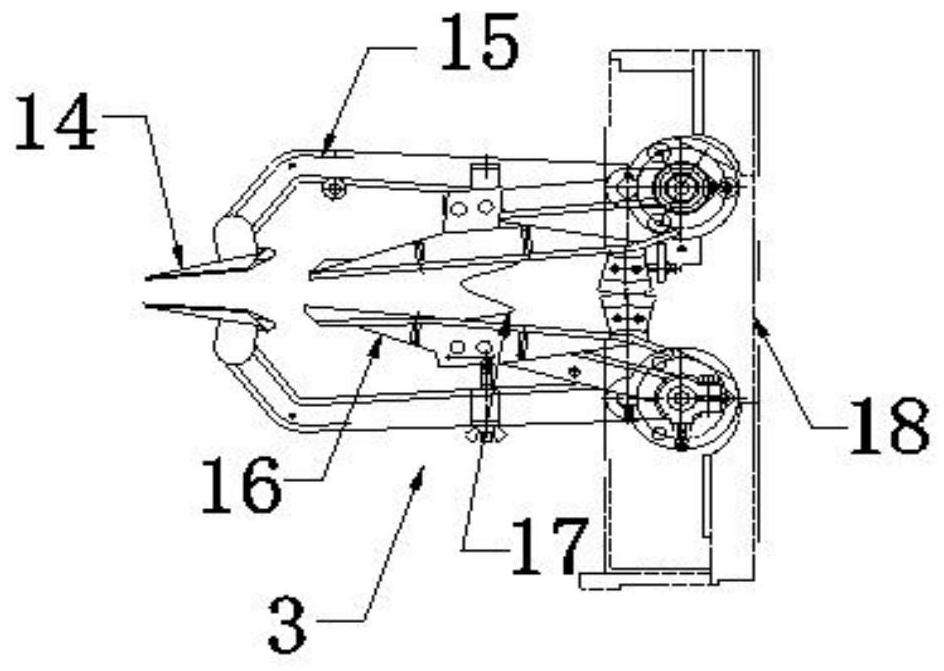

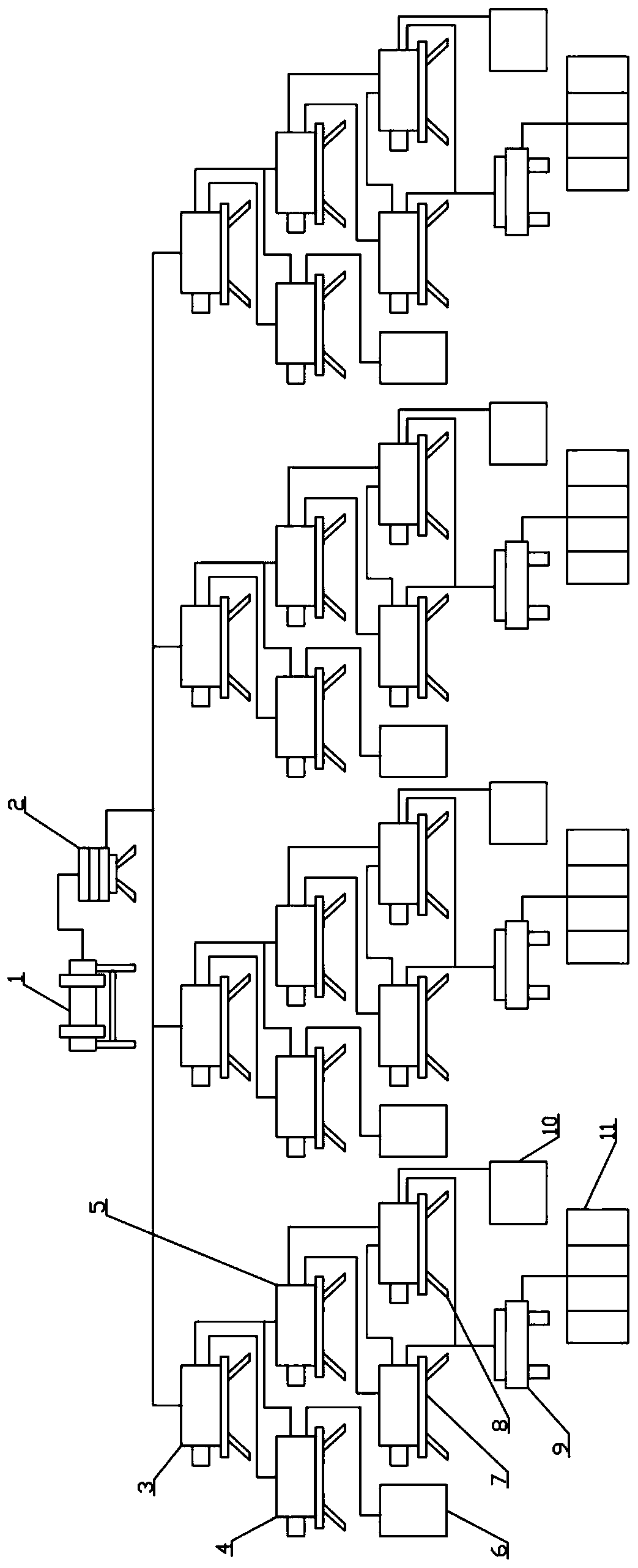

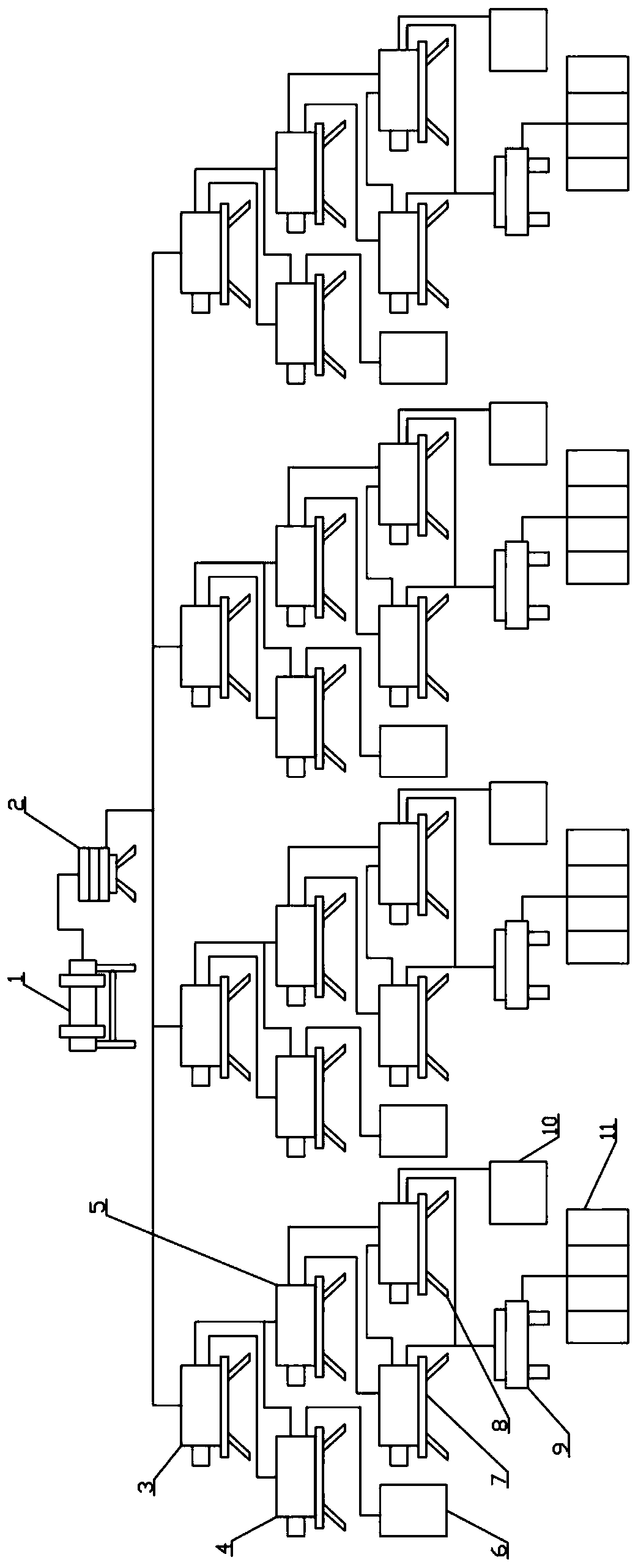

Automatic fishbone removing machine

The invention discloses an automatic fishbone removing machine. A main body comprises a fishbone removing machine body, a cam motion mechanism, a fish body straightening mechanism, a fish hanging andconveying mechanism and a fish belly bone removing mechanism, wherein the cam motion mechanism is arranged in the fishbone removing machine body; the fish body straightening mechanism is arranged on the top of the cam motion mechanism; the fish hanging and conveying mechanism is arranged on a side surface of one end of the fish body straightening mechanism; and the fish belly bone removing mechanism is arranged at the other end of the fish body straightening mechanism. Compared with manual operation, the automatic fishbone removing machine disclosed by the invention has the advantages that theworking efficiency is greatly improved, the labor cost is saved, and the working space of a conventional station is saved, so that the process of removing fish bones is more hygienic, and the possibility of fish meat pollution possibly caused by conventional manual operation is avoided.

Owner:NANTONG HAOYOU FOOD ADDITIVES

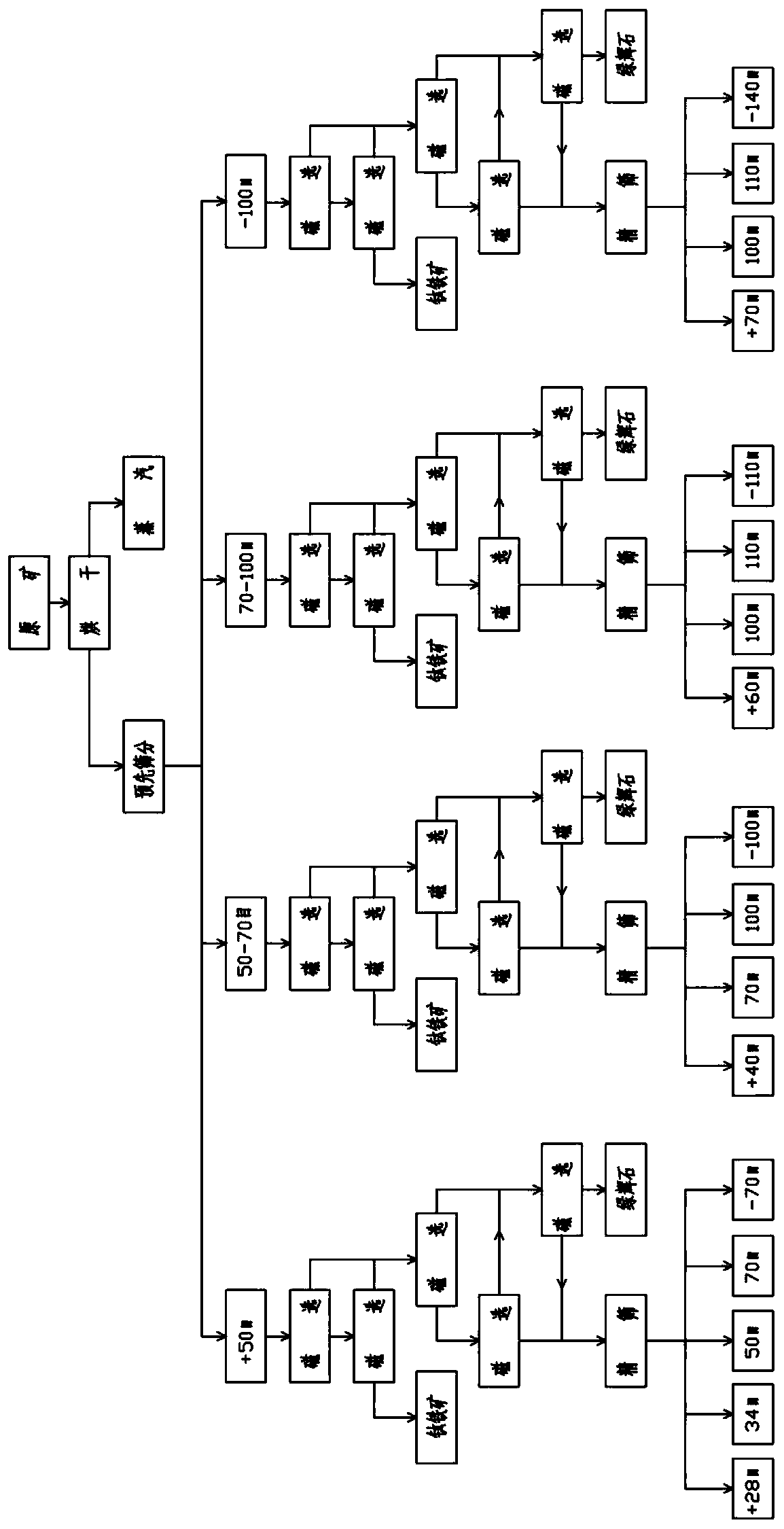

Efficient garnet combining and magnetic separation screening device and technology

PendingCN109909159AHigh purityRealize separate processingGas current separationMagnetic separationTitaniumEngineering

An efficient garnet combining and magnetic separation screening device comprises an assembly line for treating garnet containing crude sand. The assembly line is provided with a drying machine, a first screening machine, a second screening machine and a plurality of magnetic separation units. During magnetic separation screening, the garnet containing crude sand is dried, water in the crude sand is discharged, then, the dried crude sand is screened, the crude sand is screened into several parts according to the mesh number of the crude sand, then each part of crude sand is subjected to magnetic separation operation, iserite, rutile and omphacite in the crude sand are sorted out, finally, the left garnet sand is screened again, the crude sand is screened into several parts according to themesh number of the crude sand, and pure garnet sand different in mesh number is obtained. The device conducts operation of screening, magnetic separation and re-screening on the crude sand, separatedtreatment is conducted on the crude sand, the equipment treatment pressure is lowered, the treatment efficiency is improved, and the garnet higher in purity and more uniform in mesh number is obtained.

Owner:江苏金红新材料股份有限公司

Full-sealed quick sewage discharging system of excrement treatment equipment

InactiveCN112299678ARealize separate processingEfficient use ofSludge treatment by de-watering/drying/thickeningWaste water treatment from animal husbandryControl treatmentPre treatment

The invention relates to the technical field of fecal sewage treatment, in particular to a full-sealed quick sewage discharging system of excrement treatment equipment. The system comprises an excrement comprehensive treatment device, the upstream of the excrement comprehensive treatment device is inserted into an excrement pool through a material suction pipeline, a sewage suction pump is arranged on the material suction pipeline, an excrement concentration treatment device and an excrement purification treatment device are respectively arranged at the downstream of the excrement comprehensive treatment device, the excrement comprehensive treatment device is used for realizing pretreatment of excrement and realizing solid-liquid separation; the excrement concentration treatment device isused for receiving solid excrement separated by the excrement comprehensive treatment device and carrying out secondary treatment, and the excrement purification treatment device is used for receivingliquid excrement separated by the excrement comprehensive treatment device and carrying out secondary treatment. According to the system, a full-sealed control treatment mode is adopted in the earlier-stage treatment process of excrement, and solid and liquid separation treatment of the excrement can be effectively achieved according to needs.

Owner:SHANXIAN SHUNTIAN SPECIAL VEHICLE MFG CO LTD

Water-absorbing and oil-absorbing machine for oil pressing plant

InactiveCN110894086ARealize separate processingImprove cleaning efficiencyFatty/oily/floating substances removal devicesTreatment involving filtrationWater storageWater storage tank

The invention discloses a water-absorbing and oil-absorbing machine for an oil pressing plant. The water-absorbing and oil-absorbing machine comprises a movable vehicle body, an oil-water separation tank arranged at the top of the vehicle body and a suction head assembly arranged at the bottom of the vehicle body in the moving direction of the vehicle body, and a driving assembly communicated withthe oil-water separation tank and the suction head assembly, wherein the oil-water separation tank comprises a tank body with closed oil-water storage cavity formed in the top of the tank body, a refrigerator and a heater both installed at the bottom of the oil-water storage cavity, and a water storage tank and an oil storage tank both arranged in the tank body and communicated with the oil-waterstorage cavity; the water storage tank and the oil storage tank are each provided with a switch for opening and closing; the suction head assembly makes contact with the ground and can horizontally move along the ground; the driving assembly is used for forming negative pressure so as to allow sewage and dirty oil in an area covered by the suction head assembly to enter the oil-water storage cavity; and the vehicle body can move in a large range in a production workshop of the oil pressing plant, so a cleaning range is wide. Sewage and dirty oil are sucked into the oil-water storage cavity through negative pressure generated after the driving assembly is started, and only one person is needed in the whole operation, so cleaning efficiency is greatly improved.

Owner:怀化盛源油脂有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com