Recycling device for waste liquid of numerical control cutting machine

A waste liquid recovery and cutting machine technology, applied in metal processing machinery parts, maintenance and safety accessories, cleaning methods and utensils, etc., can solve problems such as environmental pollution and loss, reduce production costs, improve service life, and prevent blockages Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

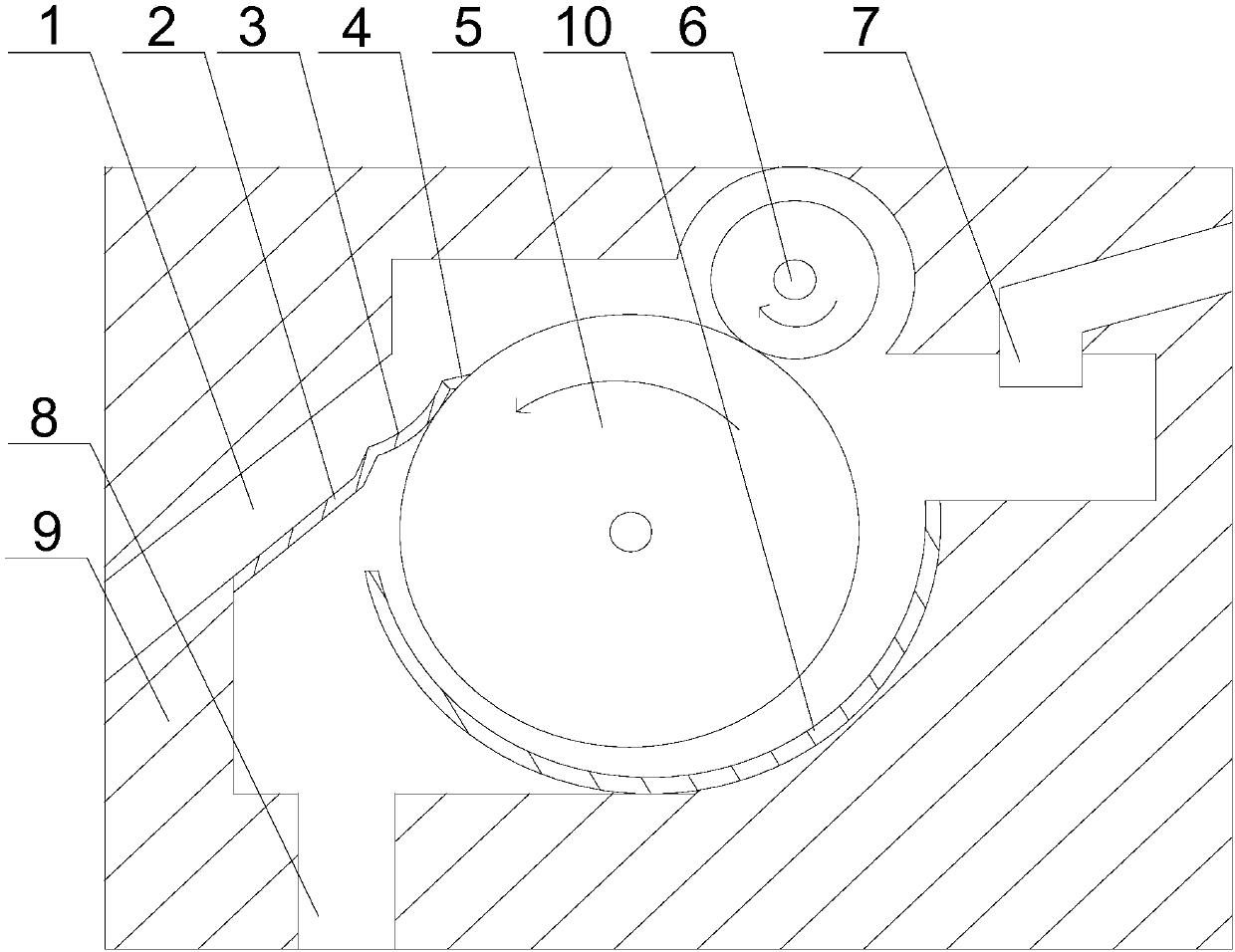

[0019] Such as figure 1 As shown, this embodiment includes a box body 9 with a cavity inside and a magnetic roller 5 rotatably arranged in the cavity, and a recovery hole 1, a liquid inlet 7 and a liquid outlet 8 are opened on the box 9 , and a baffle plate 10 with a semicircular section is installed on the bottom of the magnetic roller 5, a gap is left between the magnetic roller 5 and the baffle plate 10, and the liquid inlet 7, the liquid outlet 8 and the gap are connected to each other to form a drainage channel A downstream plate 2 is installed at the end of the recovery hole 1, the movable end of the downstream plate 2 is in contact with the outer wall of the magnetic roller 5, and the downstream plate 2, the recovery hole 1 and the inner wall of the cavity form a Discharge channel; also includes a rubber roller 6 which is rotatably arranged in the cavity, the rubber roller 6 is tangent to the magnetic roller 5; a scraping head 4 is installed at the end of the movable en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com