Novel technique for purification recovery of tiny silica flour

A technology of micro-silica powder and process, applied in the direction of silicon compounds, inorganic chemistry, non-metallic elements, etc., to achieve the requirements of reducing the quality of cloth bags, improving the effect of dust removal, and reducing the effect of filter wind resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

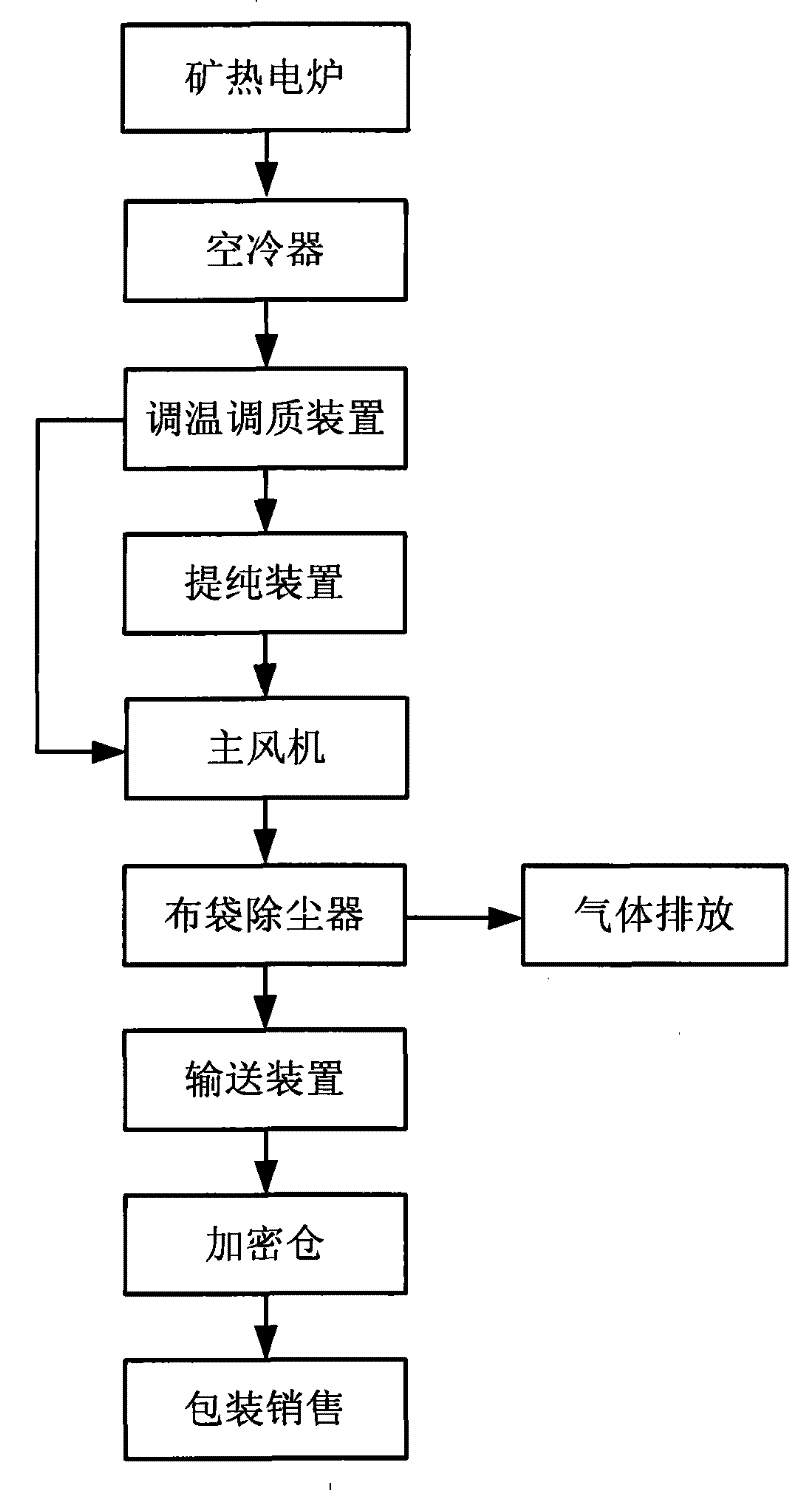

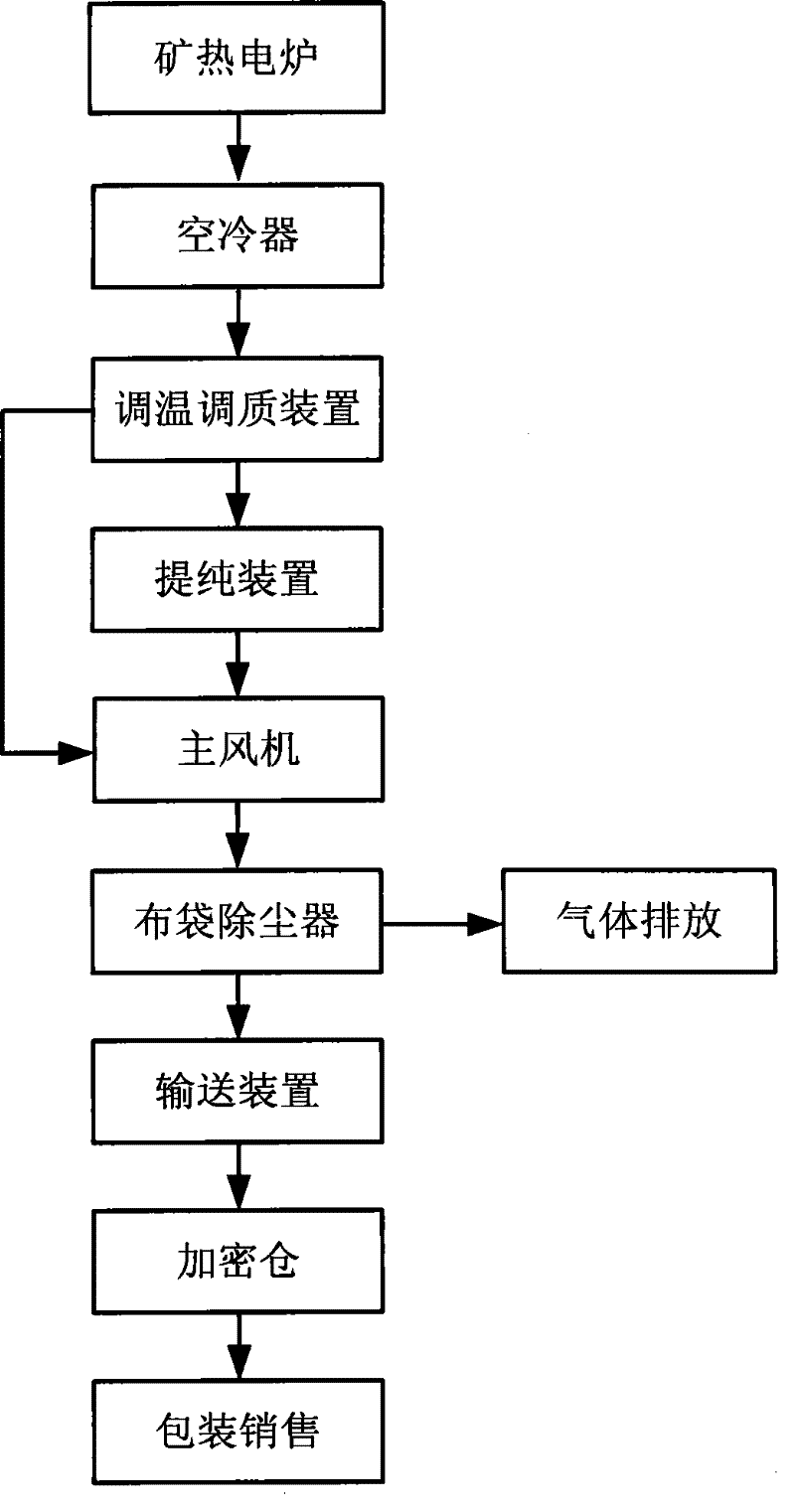

Method used

Image

Examples

Embodiment Construction

[0022] After the flue gas is cooled by the air cooler, it enters the temperature and tempering device through the pipeline. The device is equipped with a monitor and a controller inside, and the controller is also connected to the external main fan. The monitor is mainly used to monitor the temperature and concentration of flue gas. If the temperature of the flue gas is higher than the standard temperature range, the device will activate its adjacent valve to allow cold air to enter the system through the valve, and the cold air will mix with the flue gas to keep the temperature of the flue gas in a normal constant range Inside. In addition, when the soot concentration in the pipeline is too high, the controller will activate the valve connected to it to let the outside air enter the valve and mix with the flue gas with a higher concentration to reduce the concentration of the flue gas; if the soot concentration in the pipeline If the temperature is too low, the controller wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com